Cloudmirth

Basic Member-

Posts

33 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Cloudmirth

-

Panel Light Dimmer PN 800275 core wanted

Cloudmirth posted a topic in Vintage Mooneys (pre-J models)

Recently had the panel light controller on my '69 M20C fail. Don Maxwell repaired it and all is well and good. However considering that my previous Mooney (also a '69) had the dimmer crap out twice I'm expecting no better service on my current Mooney. So, what I'd like to do is find a rebuildable core dimmer so that I can have a spare on hand. Doing so will, of course, guarantee that I never have another failure and that's just fine. So, does anyone have a beat up worn out generally unserviceable dimmer that is taking up space in their shop? If so, let me know. Again, condition is unimportant as it will likely be rebuilt. -

'69 M20C Panel Light Controller/Dimmer

Cloudmirth replied to Cloudmirth's topic in Vintage Mooneys (pre-J models)

For those who may have been following this topic, a solution. My thanks to Minnesota Mooney Guy for his suggestion of Don Maxwell Aviation in Texas. They were, indeed, capable of, and willing to, repair my dimmer module and repairs were completed in just over a week. Excellent service and good people. So, if you have a '69 or '70 C, E or F with a dimmer module problem Don Maxwell is where to go. -

'69 M20C Panel Light Controller/Dimmer

Cloudmirth replied to Cloudmirth's topic in Vintage Mooneys (pre-J models)

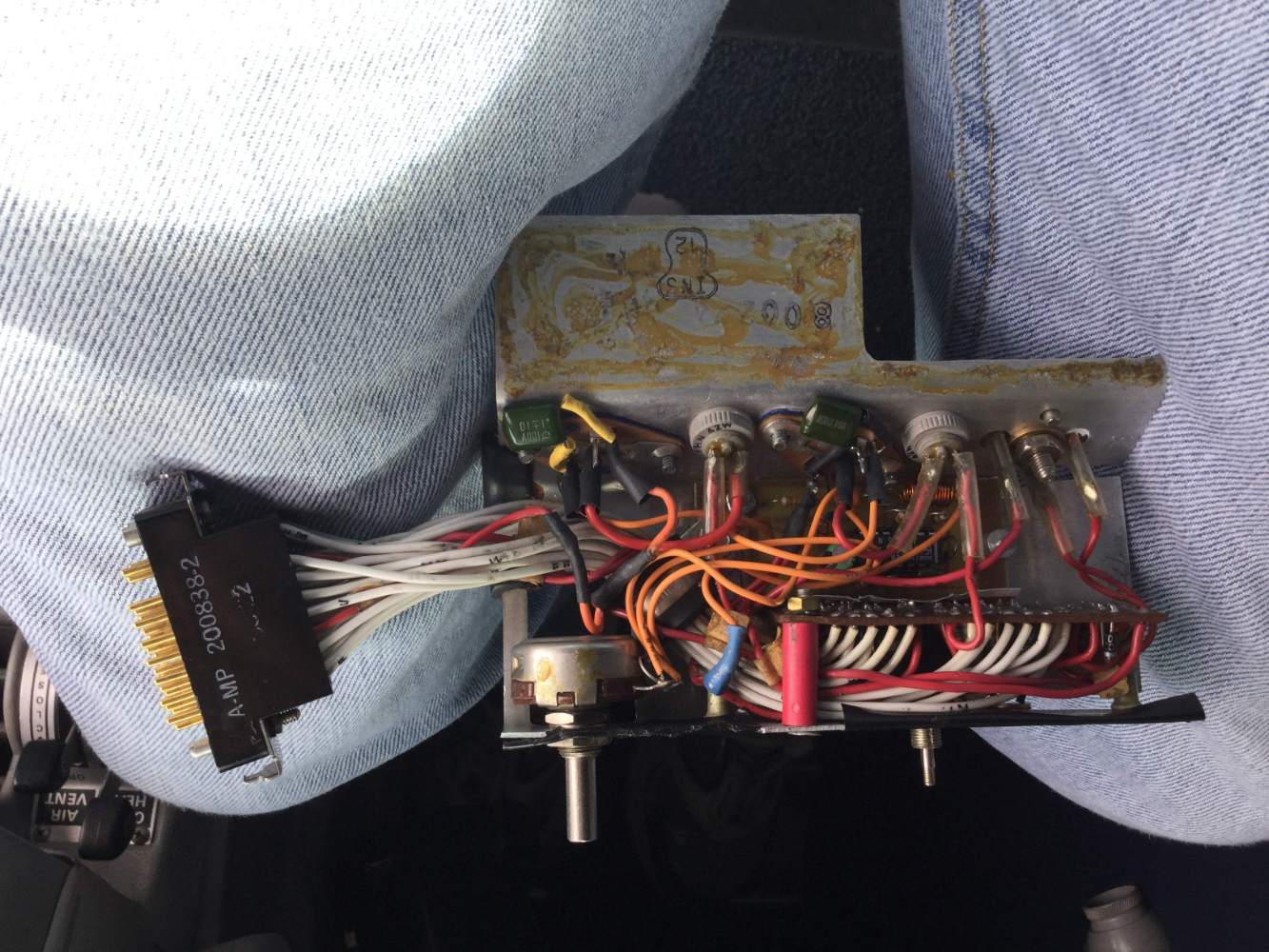

See photo attached. Note there is also a version of this dimmer with only two transistor but the unit is interchangeable with the 3 transistor version. -

'69 M20C Panel Light Controller/Dimmer

Cloudmirth replied to Cloudmirth's topic in Vintage Mooneys (pre-J models)

Has anyone done business with an outfit called Private Accessories? They claim to have a dimmer available but I've never heard of them. -

'69 M20C Panel Light Controller/Dimmer

Cloudmirth replied to Cloudmirth's topic in Vintage Mooneys (pre-J models)

If I cannot source a replacement (and yes, this is a request to anyone who has or knows where a replacement might be obtained) repairing my existing unit is a possibility. However, I now have two different schematics for the dimmer and neither one matches the unit in my plane. Why on earth did Mooney need to have multiple iterations of basically a simple item. In any event, my dimmer has only two transistors, one is a 2n442 and the second is a 2n2016 and there is only one fuse. Anybody got a schematic fit this one. -

'69 M20C Panel Light Controller/Dimmer

Cloudmirth replied to Cloudmirth's topic in Vintage Mooneys (pre-J models)

A detailed inspection revealed that it was most certainly a coronary so a transplant (or at the very least major surgery) is required. Now is I could just find a surgeon.... -

I'm sending out a Mayday. The panel light controller in my '69 M20C has suffered heart failure. Does anyone know anyone who can repair these modules or where I might find a replacement. Controllers from '69 and '70 C's and E's are the same I believe so any leads would be appreciated.

-

The suggestion regarding bad ground is a good one and I will look into that. As regards the "iris type dimmers" 1969 models did not use lamps with iris dimmers, rather there is a central "press to test" button that should illuminate all of the indicator lamps and in my case does so with the exception of the gear up lamp. Anyhow, keep those cards and letters coming in!

-

For those of you who may have followed this thread (or not) an update. After a considerable amount of head scratching and investigation my friendly local IA had something of a brainstorm. He asked me if the fuel caps (Shaw Aero) were vented. I replied that I really did not know but I suspected they were not. He then suggested that if the caps were not vented and the tank vent was plugged (I have O&N bladders) then perhaps as fuel was consumed the bladder was compressing forcing fuel out somewhere. While there did seem to be a certain logic to his suggestion I was dubious. Nonetheless, we checked the tank vent and indeed, a mud dauber or some such insect had set up housekeeping in the vent. After clearing vent of debris, the problem has not reappeared through a number of tank fills. So there we are, take it for what it's worth.

-

O.K. folks I need the benefit of your wisdom. The electric landing gear on my '69 C works perfectly but the gear up light does not illuminate. It also does not illuminate when the push to test switch is pushed (all other indicator lamps do light). I've changed the bulb but no dice. The service manual suggests that the gear up limit switch may have a problem but it would seem that even if it does, the PTT switch should illuminate the indicator lamp. Any thoughts you might care to share? The alleged wiring diagrams for the 69 models is a hopeless mess so tracing the problem is turning out to be harder than it should.

-

What's the street price for a used KX 155?

Cloudmirth replied to corn_flake's topic in Vintage Mooneys (pre-J models)

I had my kx155 overhauled by kx155.com last year. Cost was around $1,000. The radio came back looking and working like new. Ed only works on kx155’s and really knows his stuff. He even sends videos of the radio as he works on it to give you a better sense of what he’s doing and how the radio is performing. I would use his services again without reservation and, when he’s finished you have a radio you can trust -

All of the comments to this question are interesting and perhaps even plausible. The question that remains in my mind, however, is that to the best of my knowledge when the bladders were installed none of the old tank sealant was removed. Therefore, any fuel which may have leaked from the bladders should probably remain in the confines of the old tank space or leak out of the bottom thus leaving stains on the bottom of the wing. However, what we are seeing are fuel streaks well aft of the fuel tank area far removed from the original containment space. I would agree that if fuel had somehow migrated from the original tank space to wing bays at the aft edge of the wing then negative pressure in that area could pull fuel up through the seams. Seems (no pun intended) a little unlikely to me. I like the idea of fuel possibly leaking from between the bladder and the wing skin at the filler cap but it also would seem that if fuel was leaking from that source there would be streaks on the wing surface leading from the filler cap area back to the aft portion of the wing. In this case there are no such streaks. The evidence of fuel we have seen is at the very aft edge of the wing just before the flap and extending perhaps 3 feet in length from about a foot out from the fuselage. So while all of the comments so far have merit and are much appreciated, I believe I will apply the principle of occams razor and start with the simplest proposal first, i.e. look closely at the filler cap area. Nonetheless, keeps those cards and letters coming in folks as I am always open to new suggestions!

-

So here is where I call on your collective wisdom to solve a mystery. My '69 C has O&N bladders. Several times over the past year after returning from a flight I have found streaks of blue fuel on the top of the right wing directly behind the tank location, about 3 inches forward of the flap and stretching spanwise across a distance of a couple of feet. There has never been any evidence of fuel leakage on the underside of the aircraft nor is there any indication of fuel leakage in the cabin. A conversation with Mike at Griggs left him at a loss to explain this situation. As he stated, "fuel does not leak up". So, the question is how is the fuel getting there? Obviously where the stains are being found is well aft of the actual bladder location and lacking any evidence of tank leakage, the question is simply how is it getting there. Is Bernoulli's principle somehow involved. Note also that we have never seen any apparent fuel package past the fuel caps. OK, I'm at a loss so over to you!

-

In response to James M, the game plan is to determine, if in fact, the servos are leaking and if so, replace them to get the PC system back in operation. However, given the onerous nature of the task the juice may not be worth the squeeze. Next plan is to break the hose connections at the wing juncture and run a vacuum test from there. If it holds vacuum at leak I'll know that the wing servos are tight (but after 50 years you know what the odds of that are).

-

After reading the responses so far I have come to a few conclusions. First, the person who designed the layout for the wing servo installation obviously gave no thought to servicing same. Second, said person may actually have been a sadist. Third, after said person presented the plans for the servo installation to his boss, he should have been taken aside, given a polite but firm lecture on design criteria with later servicing in mind and then taken out and shot! Seriously, if you are going to go the the effort to put an access hole behind the aileron would it not make sense to have it line up with the servo retaining bolt? It also occurs to me that if you are lucky enough to actually get the servo out, how in Gods green earth would you ever get the retaining nut and washer back on? I truly appreciate the input so far and agree with Joe M that nailing down whether or not the wing servos are actually leaking before trying to pull them out is absolutely mandatory. Maybe I should just ditch flying and just take up needlework!

-

I am in need of your collective wisdom on the above captioned subject. I am working with my trusted IA to restore the PC system in my '69 C to working order. We have conducted the requisite tests and it appears that the problem is a leaking port wing servo. After removing the wing access panel we are at a loss as to how to get the servo out. While there is an access hold behind the aileron it does not line up with the servo mounting bolt so how to access the bolt is problematic. Also, the connector for the vacuum line is located behind the servo mounting bracket where it seem impossible to get access. So, while we are certain there is a way to remove the servo, we are perplexed as to how. Would anyone care to share the secret? Many thanks.

-

OK folks, here's a poser for you. Yesterday I was flying my '69 C and when I went to lower the gear just after it locked down the 70 amp alternator breaker tripped off and the entire electrical system went dead. I reset the breaker and all was well again. Upon leaving the airfield I raised the gear and flew home without issue but upon lowering the gear once again the Alt. breaker tripped and the electrical system went dead. Reset the breaker and again, all is well. Note, the gear breaker never tripped and there was never any odor of overheated wires or other obvious electrical system issues. It seems to me that if the gear motor was pulling too many amps, (as an aside the gear motor and transmission were overhauled by Lasar about 2 months ago) the gear breaker should trip, not the alternator breaker and, if the alternator breaker were to trip I don't believe that should take out the entire electrical system. So, I've got some thinking to do here and I'm open to thoughts on this subject.

-

I've run into an interesting problem with respect to the fuel level senders in my M20C. The senders are original and have never been reliable so had them overhauled by Air Parts of Lock Haven. Replaced the right sender and discovered that while it worked perfectly when tested outside of the tank (fuel gauge responded properly empty to full and everywhere in between) , once installed as the tank was filled the gauge indicated correctly until the tank was half full and then stopped and stayed at a half full indication even as the tank was topped off. It would seem likely that the fuel sender arm was somehow blocked as it rose in the tank. Has anyone else seen this problem with O&N bladders and if so, what is the correction required. Pulling the senders is easy, it's draining the tanks that's a pain so I would prefer to only need to do so once. Any thoughts.

-

O&N bladders (stupid question #53)

Cloudmirth replied to Cloudmirth's topic in Vintage Mooneys (pre-J models)

Just replaced the fuel level sender in the right tank (O&N bladders). Tested sender before installing and it moved the gauge perfectly empty to full. Once installed, as the tank was filled gauge moved from empty to half and then stopped. Has anyone had an issue with a sender hanging up in the bladder and, if so, what can be done about it. -

Well. after getting the plane up on jacks and doing a little investigation it became clear that the gear motor was on its way out. So, the motor and the gearbox are on the way to LASAR for rebuild. Interestingly I have heard that motor failure at around 3500 hours is not unusual and my M20C has almost exactly 3500 hours on it. Guess the motor knows exactly when to quit!

-

O&N bladders (stupid question #53)

Cloudmirth replied to Cloudmirth's topic in Vintage Mooneys (pre-J models)

Thanks for the very lucid explanations. Obviously I misinterpreted the use of the term interconnect that I had seen somewhere in reference to the bladders. The fact that each tank feeds only the fuel selector makes perfect sense. -

My current M20C is my first Mooney with bladders. I understand there is tube which connects the left and right tanks. Now for the stupid question. Because of the tank interconnection is my assumption that both tanks are feeding the engine regardless of the fuel selector position correct?

-

Recently had a situation where the gear retracted fine and fast (as usual) but was very slow extending and would not go all the way down. Cranked the gear down and landed at my favorite FBO where they are evaluating the issue. I suspect the motor is giving or has given up the ghost. I understand there is someone in CA who can rebuild the Dukes motors (if that turns out to actually be the problem). Does anyone know who that is and how to contact them?

-

O.K. folks here's a poser for you. My '69 M20C has decided to start discharging the battery even with the master off. I've put a meter between the battery and the contactor and can discern no drain (not even a few ma) with the switch off. The battery (Gill) is only 6 months old but it has done this twice over the past month. Everything else works just fine. With a freshly charged battery it starts right up, the alternator keeps the battery charged but let the plane sit for 10 days in the New England cold and battery voltage drops to about 9.8 volts and that's not enough to turn over the starter. So, the possibilities are: 1. a bad battery despite it being relatively new 2. some parasitic load on the system but with a low enough drain to not register on my meter or, 3. evil spirits? Anyone have some thoughts?

-

Interesting comments but not necessarily helpful. In this case we have a situation where the shunt is sound, the wiring to the meter is sound and regardless of what load is placed on the electrical system with the engine not running you can't get more than about a half needle negative deflection and upon startup when you should show a significant charge on the ammeter, again you maybe get half a needle positive deflection. Now admittedly it would appear that the meter is the most likely problem but again I have seen the exact same situation in two '69 Mooneys. Were the meters they used really that bad? Ammeters are about the most simple meters going so it's hard to see how they could be that inaccurate in two planes of the same vintage. Yes, going to a digital meter may turn out to be the way to go but really, there must be a more obvious solution. I suppose the next step is to take the meter out and test it but again, similar situations with two separate aircraft makes me wonder. Interesting how Stewart Warner can turn out inexpensive auto gauges that are accurate and inexpensive but we in the aircraft world live with hideously expensive gauges that fail with deadly regularity. Glad I have a voltmeter in the plane that at least tells me the alternator is putting out 14 volts.