Jonás

Basic Member-

Posts

28 -

Joined

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Jonás

-

M20M TLS spreadsheet of “the approach numbers.”

Jonás replied to Jonás's topic in Mooney Bravo Owners

Hello Donkaye, Thank you for sharing your checklist with me. It helped me a lot. -

M20M TLS spreadsheet of “the approach numbers.”

Jonás replied to Jonás's topic in Mooney Bravo Owners

-

M20M TLS spreadsheet of “the approach numbers.”

Jonás replied to Jonás's topic in Mooney Bravo Owners

Thank you for sharing your experience with me. I will add the columns. About the oil, my seems to stay stable at about 9 qts. -

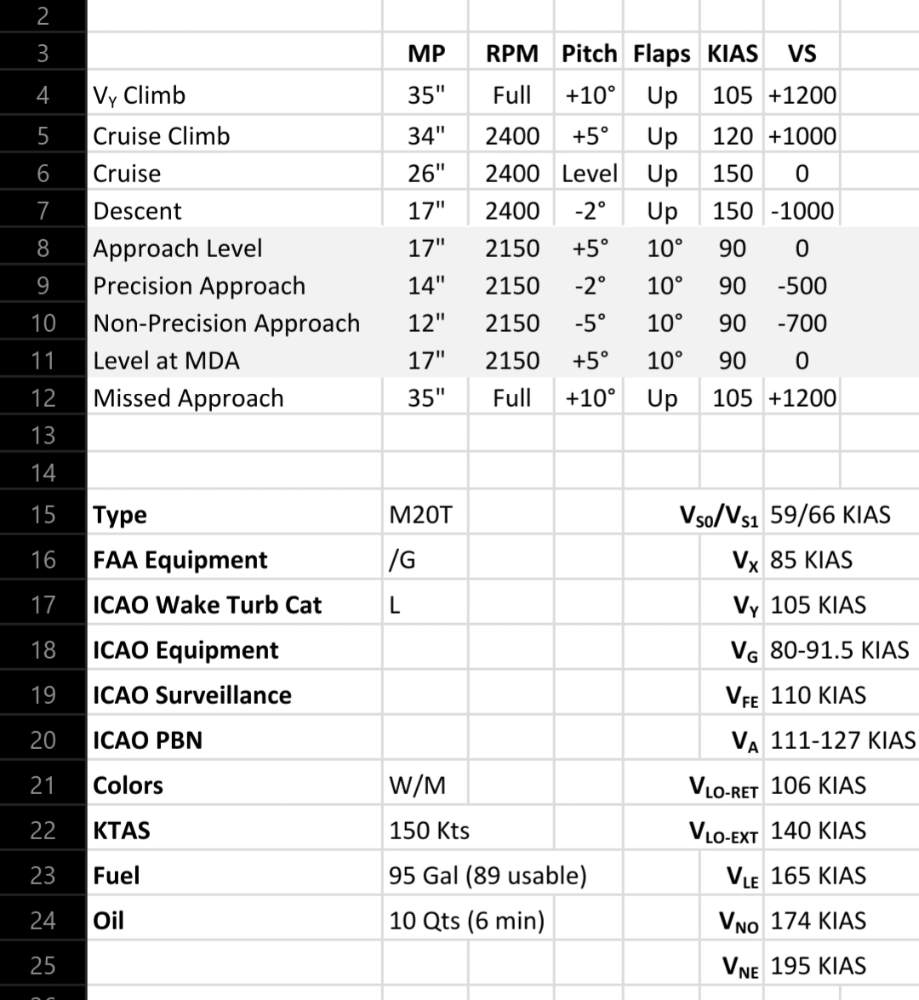

Can anyone help me do a bit more tweaking. I am sharing this sheet to see if you agree with these numbers. I am training for my IFR rating and I am trying to simplify to a minimum, the setting and speed configuration. Please let me know what you think. Thanks

-

Hi, Thanks. I have been using FlyQ. But if you can export as text file, I could manipulate it. Coco5652@gmail.com

-

Regarding the boost pump: What I do, which is not stated on the list, is the following: When I do the cabin part of the preflight and then the master on, I prime the engine for 5 seconds. Then off to compete the outside preflight check. This works really well for me. The engine starts right a way regardless of temperature.

-

Hi @Junkman Thanks for your comments. I have a 1993 model. I tried to cut and paste every item from my POH. I will take a look again and contrast. Remember that you can modify the list I created by adding other sections or modifying and import to your phone. Just follow the format. If you share your list with me, I would appreciated. Thanks

-

Hello to all, Just in case anyone is interested in having a checklist in the phone, I am sharing mine here. I tried to copy all the fields the best I could from my POH. Download this app and import the attached file. Check out "Aviation Checklists"https://play.google.com/store/apps/details?id=com.mb.avchecklists NOTE: I DO NOT GUARANTEE THE ACCURACY. USE IT AT OUR OWN RISK. MODIFY IT AS YOU WISH. ANY SUGGESTIONS WILL BE WELCOME. MOONEY M20M TLS CHECK LIST V1.txt

-

Ideal M20M TLS oil pressure during run up?

Jonás replied to Jonás's topic in Modern Mooney Discussion

Thanks for the response. My mechanic was a concern because he saw a 90PSI at run up. I am new to the Bravo and do not have a frame of reference. The range that I have seen this far during flight is between 75-85PSI. Update: My mechanic call Victor Aviation Service and They confirmed that at about 90 PSI during run up and between 72PSI to 85PSI "is what they like to see in flight". -

Hello to all, I am wondering about the upper limit for engine oil pressure and the damage to the pump and filter associated with it. I hope that I can benefit with the vast collective knowledge in this forum. What do you think is the ideal oil pressure, 2000 RPM during run up for a M20M TLS Bravo with TIO540-AF1B model and about 300 hours?

-

Indeed, Contrary to what they said, the vide captures the exact moment when the white car hits the plane. Luckily the passenger had not exit.

-

VID_20210228_172118_961.mp4

-

Only if you have been infected you may get the symptoms again. I had the first shot and got the symptoms for a day and a half. My friend had not symptoms. The reason is the antibodies still active. I am getting the second shot in a week.

-

Okay Steve, i agree with you. It is an old accident and that the buyer should be taken into account when making a decision. I personally don't have any problem buying a plane that has been properly repaired, provided that the price is fair. It is my understanding that A new accident would lower the value of the plane by as much as 20%. Although it is less, I do not know what is the depreciation percentage for a repair that has been Proven for over 20 years. Nonetheless, I would have prefer if the seller had made that disclosure when I was inquiring at this plane over a year ago.

-

Hello To All, When looking for Bravo Last year, this was one of the planes I reserch. The plane has an accident which may explains why it has not been able to sell at the asking price. Note that the following accident description: #NTSB2 Accident Occurred on: 1995-07-13 00:00:00 Narrative (ACCP): QcOn July 13, 1995, at 0727 hours Pacific daylight time, a Mooney M-20-M, N200CT, was substantially damaged during an aborted takeoff at Santa Monica, California. The pilot and passenger were not injured. Visual meteorological conditions prevailed for the departure, and an instrument flight plan was filed. The flight was originating as a personal cross-country flight destined for Abilene, Texas. The pilot stated that during the takeoff roll on runway 21, he realized that he had no airspeed indication. He chose to abort the takeoff at that point. At the west end of the runway, skid marks indicated that the airplane went sideways and the left landing gear collapsed. The left wing settled to the ground and fuel ignited from the wing fuel vent area. The brief fire burnt into the wing structure. The wing was also damaged from ground contact. The pilot had contracted for repairs to the vacuum/instrument system while at Santa Monica. According to a Federal Aviation Administration (FAA) inspector, examination of the airspeed plumbing revealed that the plastic pitot tube was not connected at the airspeed indicator. Further examination of the tube failed to reveal a crush imprint from the "B" nut cone. The cone was found on the cockpit floor. An airspeed repair date of January 23, 1995, was affixed to the airspeed instrument case. The pilot stated that the M20 brakes are not adequate to stop a TLS model, near gross weight, down hill with a slight tailwind. He stated that the brakes should have been enlarged with the gross weight increase. He further stated that he now has the double puck brakes and that they are much more effective. Narrative (ACCF): DURING THE TAKEOFF ROLL THE PILOT REALIZED THAT HE HAD NO AIRSPEED INDICATION AND CHOSE TO ABORT. THE AIRCRAFT SKIDDED OFF THE END OF THE RUNWAY COLLAPSING A MAIN LANDING GEAR RESULTING IN A FIRE AT THE MID-WING FUEL VENT AREA. THE PILOT HAD CONTRACTED FOR INSTRUMENT REPAIRS IN ANOTHER AREA OF THE INSTRUMENT PANEL JUST PRIOR TO DEPARTURE. POSTACCIDENT EXAMINATION REVEALED THAT THE PITOT LINE TO THE AIRSPEED INDICATOR HAD BEEN IMPROPERLY INSTALLED AND WAS SUBSEQUENTLY PULLED OUT OF THE INSTRUMENT WHILE OTHER WORK WAS BEING PREFORMED NEAR IT. Narrative (CAUSE): the pilot's improper remedial action during an aborted takeoff due to an improperly installed pitot line to the airspeed indicator.

-

Hello, This is a lawyer I would recommend. Mr. Lampert has been in the business for over 25yrs. Best of luck KATZMAN LAMPERT & STOLL, PLLC 9596 Metro Airport Avenue Broomfield, CO 80021 Direct: (303) 410-7716 Office: (303) 465-3663 Fax: (303) 867-1565

-

Maryland Mechanic, Massachusetts Prebuy Inspection

Jonás replied to anthem4arequiem's topic in General Mooney Talk

I agree with the earlier post. I highly recommend Lawrence Airmotive KLWM. I use to maintain my two aircraft with the prior owner of the place and now with Nik the current owner. Honest and diligent at a fair cost. However, if you want a comprehensive inspection, ask the seller to fly the plane to Air-Mods Service Center of Trenton-Robbinsville airport (N87) New Jersey. Not a far place to go to for a Mooney. At this place, you will pay more but will get an extensive list of major and minor issues including structure corrosion. This way you will not be surprise later. Also, if the seller refuse to fly the plane to a reasonable distance for a pre-buy with a reputable mechanic, that should raise a YELLOW flag. (Not a RED FLAG) Do yourself a favor and do not cut corners with the pre-buy inspection. -

Maryland Mechanic, Massachusetts Prebuy Inspection

Jonás replied to anthem4arequiem's topic in General Mooney Talk

I agree with the earlier post. I highly recommend Lawrence Airmotive KLWM. I use to maintain my two aircraft with the prior owner of the place and now with Nik the current owner. Honest and diligent at a fair cost. However, if you want a comprehensive inspection, ask the seller to fly the plane to Air-Mods Service Center of Trenton-Robbinsville airport (N87) New Jersey. Not a far place to go to for a Mooney. At this place, you will pay more but will get an extensive list of major and minor issues including structure corrosion. This way you will not be surprise later. Also, if the seller refuse to fly the plane to a reasonable distance for a pre-buy with a reputable mechanic, that should raise a YELLOW flag. (Not a RED FLAG) Do yourself a favor and do not cut corners with the pre-buy inspection. -

Thanks for sharing the link to the early postings regarding the accident. The incident attracted a lot of attention because of the AOPA and PBS report that was released just 5 days before the accident and because of the 5.2 M I got for my HS school to start an aviation program in the heart of NYC. Indee landing was challenging. Primarily because of the the low altitude we were flying at, under class B at only about 1500 to 1600 ft. However, all pilot are trained to deal with emergencies like this one. In my case, I was lucky enough to spot a golf course a few miles away. I feel that Luck is a deterning factor.

-

This happened after a 36K Overhaul. Analysis During cruise flight, the pilot noticed an increase in cylinder head temperature on two cylinders and unsuccessfully attempted to reduce the temperature. He reported that he soon heard "an explosion" and noted a hole in the engine cowling. He performed a forced landing to a golf course, during which the landing gear collapsed, which resulted in substantial damage to the right wing. Postaccident examination of the engine revealed that the Nos. 1 and 2 connecting rods exhibited thermal discoloration consistent with a loss of lubrication. Additionally, the breakaway torques measured at 8 of the 12 through-bolts showed that they were below the manufacturer's specifications. The No. 2 main bearing saddles exhibited impingement damage, and the No. 2 bearing was partially rotated clockwise, which blocked the oil passages leading to the connecting rod bearings. The mating surfaces of the main bearing saddles had remnants of silk thread around the through-bolt holes, which was contrary to manufacturer guidance that prohibited placing silk thread in these areas. Given this information, it is likely that maintenance personnel applied silk thread to a prohibited area during an engine overhaul that occurred about 255.8 flight hours before the accident. This resulted in a loss of torque on the crankcase through-bolts, which allowed the No. 2 main bearings to shift, resulting in restriction of lubrication to that area and subsequent engine failure. Probable Cause and Findings The National Transportation Safety Board determines the probable cause(s) of this accident to be: Maintenance personnel's improper assembly of the engine during overhaul, which resulted in lubrication restriction due to a bearing shift and the subsequent engine failure. http://www.kathrynsreport.com/2020/06/loss-of-engine-power-total-mooney-m20k.html?m=1