-

Posts

19 -

Joined

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by prestonvanloon

-

Rocker Switch Cover Replacements - 3D Print your own

prestonvanloon replied to freff's topic in Modern Mooney Discussion

Does anyone have stl files to share? I ordered the ETA type from shapeways last year, but saw it's no longer an option there. -

Garmin Database Concierge Updates

prestonvanloon replied to Marauder's topic in Avionics/Panel Discussion

I called garmin with this exact issue. There is a known bug in the software and the workaround is to install only one update at a time. I believe there is an update for the hardware but only a garmin retailer has access to those kind of updates. Sent from my iPad using Tapatalk- 27 replies

-

- garmin database concierge

- concierge

- (and 1 more)

-

Help Save Historic Whiteman Airport

prestonvanloon replied to drb930's topic in Miscellaneous Aviation Talk

I used to have a hangar at WHP, it is a very nice airport in the valley. It would be a true shame to close this. Los Angeles has great general aviation options, but with SMO closing and potentially WHP too… what’s next? EMT? -

Attitude Indicator gone bad

prestonvanloon replied to prestonvanloon's topic in Avionics/Panel Discussion

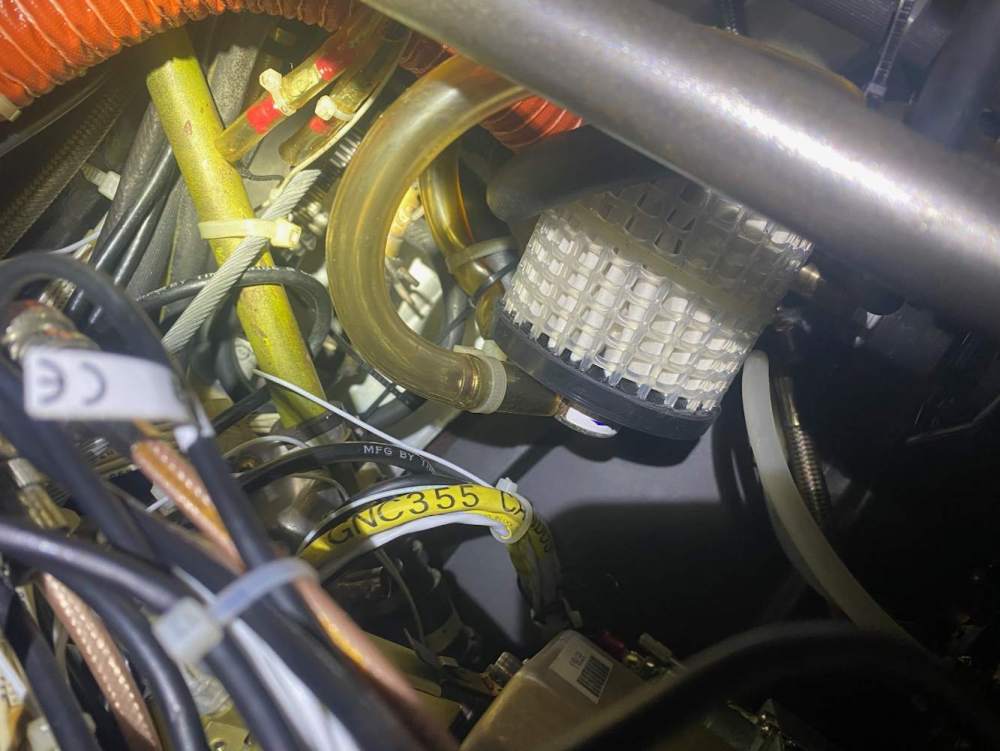

Yes, I think that Forge replaced the black vacuum line in the back and then zip tied the existing polyethylene tubing.They mentioned lines were dry rotting and debris falling off at the touch. I think the lines they replaced were to the PC wing leveler system. I'm not sure what they did there, but the wing leveler would not turn off and ultimately had to be disconnected. I think we'll replace the yellow tubing in next annual. -

Attitude Indicator gone bad

prestonvanloon replied to prestonvanloon's topic in Avionics/Panel Discussion

Problem solved! Spoiler: It wasn't the attitude indicator. I followed the advice of many here to go forward with an overhaul. I called AQI, ordered an exchange gyro, and told the mechanic to hold off on any troubleshooting until the new gyro arrived. The mechanic was under the panel for about 2 minutes before he said "you gotta see this" (see picture below). The avionics shop that replaced the vacuum lines zip tied the line so tight that it was crushed. We clipped 3 or 4 zip ties off and everything was back to operational. I'll return the instrument back to AQI for a refund since the AI is working properly again. The shop that completed the vacuum line replacement and zip ties was Forge Flightworks (previously known as Carpenter Avionics) at MQY. We're skeptical that the previous shop used the correct vacuum hose as well. These clear tubes don't look right. Any thoughts? -

Attitude Indicator gone bad

prestonvanloon replied to prestonvanloon's topic in Avionics/Panel Discussion

This could help determine that the AI is, in fact, the problem. If we can swap out the AI for a known working one and that behaves properly then we know it's the AI and not further in the vacuum system. Overhaul seems like the most viable option. Dual G5s would be nice though... -

Attitude Indicator gone bad

prestonvanloon replied to prestonvanloon's topic in Avionics/Panel Discussion

Update: the suction regulator has been adjusted to the correct suction and the attitude indicator is still misbehaving. A&P troubleshooting soon -

Attitude Indicator gone bad

prestonvanloon replied to prestonvanloon's topic in Avionics/Panel Discussion

I'm wondering if having too much suction could cause such an issue? The attitude indicator is rated for 4.5" +/- 0.5" and the suction at cruise is 5.5". -

Any ideas why the attitude indicator is showing 10 degrees pitch up and a slight right roll in straight and level flight and on the ground? Things I have noticed, but may or may not be relevant: - Attitude indicator takes a long time to "wake up" on the ground. - During recent avionics install, several dry rotting vacuum lines were replaced behind the panel. - The suction gauge is indicating around 5.5" of vacuum pressure at cruise. The green arc on this gauge is around 4.5" and 5". - Directional gyro works better than before the line replacement. - The attitude indicator responds correctly to pitch and roll movements. It's just not centered in straight and level flight. - The last AI overhaul was in 2004 - Sigmatek 5000B-20 Besides replacing the AI and DG entirely with electronic instruments, what are the probable causes and solutions to these issues? Any recommendations for AI overhaul facilities?

-

He's a rescue, but we guess that he's a Terrier / Shiba Inu mix. He's about 24lbs and fits in a backpack

-

I think they are a must have for a long trip. Our dog keeps them on, but shakes them off as soon as the engine is shut down.

-

Rough engine with take off power

prestonvanloon replied to prestonvanloon's topic in Modern Mooney Discussion

No data. Insight Avionics GEM 603 engine monitor. What is ALCOR? I did another mag check after the issue on the ground and couldn't reproduce it any issue. This might be because I had leaned aggressively in taxi and then did the run up. I'm also leaning towards fowled plug because they had a lot of deposits on the plugs when I cleaned them and the issues seem correlated to mixture being too rich. Perhaps I need to always lean appropriately in the pattern or find a better take off mixture? It wasn't a high altitude airport (field elevation 800 feet). -

Run up was OK. Mag check was about 75 RPM drop on either side. Prop cycled OK. I flew from KWHP to KVNY for some pattern work and do a ground VOR check. I land at KVNY, perform the VOR check, then take off for some pattern work. The first touch and go was fine. On the second one, I think I might have heard a few pops like backfiring but I am not sure. The engine was still producing full power at this point. On take off from the third touch and go, I noticed a much slower climb, rough running engine (possible infrequent backfiring and more than usual vibration), and very low CHT / EGT on cylinder 4. By very low I mean it wasn't registering above 200°F. The airplane was in the take off configuration, full throttle, mixture full rich, boost pump on, turbo normalizer off. Pulling the throttle back to about 50% to 70% reduced the engine vibration to normal and cylinder 4 CHT/EGT returned to normal range (300° to 400°F) with the other cylinders. In fact, cylinder 4 might have been briefly hotter than the other cylinders after reducing power. I continued in the pattern and observed the same marginal power, engine roughness, and lowered CHT/EGT on cylinder 4 in the fourth touch and go. Leaning in flight didn't seem to help, only reducing power would restore normal engine operation. I then returned to KWHP without issue at 50% to 70% throttle in a brief cruise. Some other information: - The engine had been running for at least 40 minutes prior to the 3rd touch and go, mostly in flight - Ground operations were leaned aggressively, but all pattern work was done with full rich mixture, cowl flaps open, boost pump on, turbo off - Just before flying, I topped off with 47gallons of 100LL. (It was definitely NOT Jet A. KWHP doesn't self-serve Jet A, and I sumped both tanks to check fuel after refuel). - The airplane experienced loud backfiring on take off about 5 flight hours prior to this flight (a few weeks ago). Immediately following the significant backfiring event, I removed, cleaned, and gapped all spark plugs except cylinder 2 & 4 bottom plugs as I was having a hard time removing them with limited tools. The airplane performed fine for approx 5 flight hours until today's flight. The CHT/EGT monitoring was not observed on the initial flight with backfiring. - Oil pressure and oil temperature were fine, observed 6 quarts of oil in pre-flight check. - 1977 M20J Lycoming IO-360 with turbo normalizer What do you think the problem is?

-

Where to get replacement door keys?

prestonvanloon replied to prestonvanloon's topic in Modern Mooney Discussion

I can confirm. It took me about 30 seconds to pick the lock with a rake pick lol I don’t park the plane outside often, but I’d like to at least deter a handle puller while on a short stop or overnight parking -

Where to get replacement door keys?

prestonvanloon replied to prestonvanloon's topic in Modern Mooney Discussion

I thought about re-pinning the door locks to match the ignition but I was having a hard time getting the lock off the cargo door and I didn’t try the main door yet. I suppose I can live with 3 different keys -

Where to get replacement door keys?

prestonvanloon replied to prestonvanloon's topic in Modern Mooney Discussion

I was able to impression the lock and make a new key for the cargo door. It looks like I also have 3 different keys... I ran out of time to make a key for the main door but I was disappointed to learn the cargo door key did not turn the main door lock. Great idea on the color codes! -

I'm looking to get a replacement door key for my M20J. The ignition key is different from the door lock and I do not have a copy of the original keys for the doors. The door lock has "LL328" written on it. I checked with a friend that also has a M20J with the same lock inscribed with "LL328" and their key did not turn the lock. I tried ordering a Herman Miller replacement key for LL328 since it uses the same IN8 key blank. This did not work either. (See attached photo with the Herman Miller key in the door) The lock does turn, I was able to pick the lock with basic lock picking tools. Without taking the lock out of the door(s) and disassembling the lock, is there another way to manufacture or order a replacement key?

-

Looking for a CFI at KWHP

prestonvanloon replied to prestonvanloon's topic in Miscellaneous Aviation Talk

Thanks Dan! I have Kevin's number, I'll shoot him a message. At a minimum, I need CFI for insurance checkout. Instrument rating is the next step after that. -

I'm looking for a CFI at KWHP with experience in a Mooney M20J for instrument rating. Does anyone have any leads or suggestions? Thanks!