willerjim273

Supporter-

Posts

86 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by willerjim273

-

Greetings everyone, I just donated and would like to post to classifieds. Never been down this path. I go to: https://mooneyspace.com/forum/10-aircraft-classifieds/ Where a "start new topic". Is "start new topic" the way to post? Or am I looking for a "post" option? Use this forum to post your Mooney aircraft for sale. Other aircraft types will not be permitted here. Only supporters (those that have donated $10 or more in the past year) can create new topics in this forum. I am guessing it takes a while for the "post" option to appear? Thanks

-

1980 M20K, for the B&D gauge required equipment. No joy. I understand it is a K" type "thermistor" style. Max temp is 400. Can a CHT probe be used with resistors? Can an IA sign off on such a setup? Dan at Lasar he is out and does not have a source right now. It has a white plastic sheathing. I have the JPI with CDT working just fine. Looking for that ship probe. Anyone have a source on theses?. I am still looking, Seems everyone is out of stock. Tks Thanks CDT PROBE, AOO2-CDT, M111CDT

-

Does anyone have a source for the pin layout for this instrument. Skyman sold me the gauge. Good price. We will see if it works. I may be wrong, but it looks like I have to have this working even though I have an EDM 701 that works perfectly with the CDT and TIT options. Not much desire to "experiment" and destroy the "new one". I have seen it called a "413A" as well. Tks

-

JPI 701 no luck powering up on bench.

willerjim273 replied to willerjim273's topic in General Mooney Talk

I finally pulled my head out of my ass. There are #'s on the 25 PIN. Thanks.. Anybody know what happens if the reset button is pressed on back of unit? https://www.aircraftspruce.com/catalog/pdf/edm830manual.pdf. I am ready to light her up. If nothing happens and I am right pins, then reset on BACK of unit will...........? Erase all data or is data saved despite. Thanks Anyone going to Sun and Fun? -

JPI 701 no luck powering up on bench.

willerjim273 replied to willerjim273's topic in General Mooney Talk

Sorry if a double reply, but no marks on my unit. -

Hello all, I am trying to Bench Download Data from my 701. Unit works fine in plane. Unable to power up on bench. . Here is what manual says. BELOW IS MALE AND FEMALE UNIVERSAL MAP FIRST ONE IS “MALE” Pls see pics below. spent most of day on this today and am psssssssssd. If you look at pics attached, the unit has to be inverted to orient and find pin 13 for + and 25 for -. So now, unit is upside down but the 25 pins make sense. I have put power and grounds as the pics show WITHA 2 AMP INLINE FUSE as per JPI. I am blowing fuses, so that is good, not damage. Unit has over JPI min from battery, 12.2v. Did they invert these things? Also I have the basic 701. Time to upgrade for any reason? Everything works fine. Thanks guys......and gals!

-

Clarification on my post. about oil pressure problem on M20K Just read post Oil pressure relief valve, again: Low pressure high temps: Standoff again. To clarify, this needs to be added: I approved the shop owner to test fly the plane to confirm himself the problems and see the low pressures and high temps

-

Hello all. Happy New Year. My engine is a 1980 M20K GB C LB with Black Magic and intercooler. I fly mainly out of the Denver area over the rocks to Grand Junction. 15.5 to 17.5k is typical. I usually run her at 65% and have kept the JDM alarms very conservative. No problems until my last annual. The shop is a reputable one, I believe, and they do not seem to get any more honest then Greg the owner. I departed BJC for EIK (20 miles) with barley enough time to put the gear down by the time tower let me go. I SHOULD have conducted a thorough flight test. I landed and put her away. On the next flight, with an instructor friend, the EI-17 audio alert blared "check engine monitor". The oil temp alarm sounded exceeding the limit of 200. I know that is low, but let's not get into that right now. Point is that high oil temps has never been an issue. The oil pressure was down at the bottom of the green and we were at 8000 ft. Marginal at best but certainly not right. And for sure not going over the mtns. I just reviewed the past postings on TSIO 360's and this issue. The most appropriate is from March of 2015 when Don had the same problem. Will, Doc and Don figured it had to be a piece of crud in the relief valve (RV) port. I popped the cowl and located it. I read how Don, and his short mechanic, had to make a jig and decided that picture did not look great. I had also just had the plane annualed. If I messed with it and it went south, guess what? So I took her back about a week later with no more than an hour TT since they worked on it. We went on a 3 week vacation out of town. I approved the shop owner to fly the plane. He said he had mucho, mucho time in the 231, owned 50+ airplanes etc. etc., and was very familiar with the need to NOT over boost. I had just installed a vernier throttle for that reason. My 231 has always been EXTREMELY sensitive to over boost. And I have been pretty fanatical about that issue to the point that I had a digital manifold pressure Brand: Aerospace Logic M210 with fuel flow installed 2 yrs ago. I explained to him that the throttle was VERY sensitive and to just use the vernier for takeoff. Back to the point. While out of town we talked. He said he had to abort the takeoff because "things did not look right." He said he over boosted and had never experienced anything like that sensitivity before. So, 2 oil change later, no metal in the oil. We changed oil filter twice now and no metal. Bottom line is it has been 2 months in his shop and he does not seem to be motivated to figure it out. I have told him quote clearly that regardless of the cause, I am not placing blame anywhere and I am happy to pay to get it fixed. Just get it done. I am a paying customer and do not expect any favors. I am of the position that since he has been keeping her hangered at BJC at his expense, I prefer he do it and not take it away for obvious reasons. We may need a psyc to figure this one out. I have seen dozens of planes in and out in the meantime. It sounds like he does own a fleet of flight school planes and demand is stupid. So a Mexican......."south American" standoff. I stopped by today and the plane is still sitting there taking up valuable space. He first started talking about the sensitivity of the throttle saying that he needs to check the oil lines going to the turbo.. He has heard that if they are reversed, that can cause the sensitivity problem. Like I was there to talk about that? I have flown that plane for close to 5 years now and have always just been super careful. Never made any metal and have great compressions. How di that come up? I said fine, but what about the problems I brought the plane to get fixed in the first place? He had finally adjusted the pressure valve and thinks he can get the plane back to me tomorrow, 3 Jan. I said hold on! Have you tested to verify all is well? No. My engine is like Don's. There is no adjustment on that block. I told him that that RV does not have an adjustment. He said he put a "washer" in there. I have hired Mike Busch's outfit. About $600 by the way. But the shop does not want to "work with them" were the words of the rep of Mike's on this case. Mike's policy it appears is they cannot do much if the mechanic will not take guidance. What would you do? I obviously need to get a oil analysis or at least see the filter before I accept the AC. No desire right now to go in there guns blazing and have her pushed out of the hangar. Could he have really have screwed something serious up? Kind of doubt it, but what if? Can you mess up an engine with a quick 40 or higher MP? (I have seen 40MP before with plenty of throttle to go, but the pop off always gets your attention, if you have any feeling for the machine. Being an experienced airplane guy it is doubtful he would not immediately pull power. Is he afraid of something or just super busy? To describe the sensitivity I assume is inherent is thus: On takeoff, max brakes, at 30 inches release brakes, twist in about a # 2 pencil lead amount more and I am at 36-38. If a # 2 pencil total width is added, you are at 40. Sensitive. You other K guys. Is that about right? Thanks guys.

-

Anyone know of a good CFI in Denver Thanks

-

I am replacing the floor light for the gear down confirmation. The one that is bad is a "330".. Same thing? Looks same, but not sure. Thanks

-

Anyone tried these? https://www.mouser.com/ProductDetail/Dialight/586-1101-105F?qs=xy3UPL2NuFsrkb1vOUIzNA%3D%3D&mgh=1&gclid=CjwKCAjwp9qZBhBkEiwAsYFsbwwrQlHDLF5xPyCHWdmGF9wjPIsd9BfylSymkdNtpgUvVnP1_4xEKBoCn4wQAvD_BwE My ship is 14 volts so I figure the 586-1106-103F WHITE.

-

I am back to the experts here about my last post re: low and higher oil temps.(as a note here: according to forum etiquette Is it proper to just add on to the previous post? Or start a new one?) Going over the timeline here's what I have: I picked up the plane 3.6 hours ago after an annual. Good shop nice guy all that. Anybody who knows Greg at BJC knows what I'm talking about. I have a JPI. It’s an older one, 700 series, that does not monitor oil pressure. I have oil temp alarm set for 197 degrees oil temperature. First thing I noticed on the flight home was the oil alarm went off on the JPI. I've been flying this plane for 3 years and very, very seldom does the oil temperature alarm sound. I realize that 200 to 210 it's not anything to worry about but I rather just sideline that discussion for later. At the same time I looked down and the oil pressure was right on the line of yellow and green, 30 lbs. . Again my JPI does not monitor oil pressure. I was at 8000 ft. I have taken her no higher than 8000 ft on several flights since then. Same results. Prior To the annual at 16500 ft my oil temperature was just above minimum and oil pressure was about 46.-50. Now it is 30lbs at 8,000 ft. with higher than normal oil temps. Taking her up to 17k to get over the rocks out of Denver does not seem like a great idea. First thing that came up as the cause was the oil pressure relief valve system. I called Continental and they ran my engine serial number telling me that I do not have an adjustable system. I can see where it is coming off the block, but I'm not sure I'm comfortable being able to get it back in if I take it apart and clean it..The mechanic says if I bring it into the shop that's what he'll do, unless he see something else that's “obvious”. Of course he'll “T” in and check the gauge first. In the last week, I have: 1) changed the oil not knowing what he used. No difference. 2) Drained the oil again and, pulled the filter and took it to the mechanic. No metal. I have a father-in-law that just went into hospice and a wife in Reno. I'd rather not drive. Research- hours of it: Possible culprits seem to be that there is a speck of dirt or something blocking the seat on my fixed pressure relief valve. Again I have the non adjustable pressure relief valve set up. The cap-plug comes out of the block at an angle if anyone has that setup. So I am fixated on that oil pressure relief valve. I am set now to take it back to the mechanic on Monday. Right now I don't think he fully realizes that this occurred right after the annual (I went on a 3 week out of town trip in the meantime). Status right now is she has a new filter and 7 qts of oil and I am ready to take her back to the shop. Looking forward, if it is not the pressure relief system, what then? Any thoughts?

-

So I called Continental Aero. They looked up engine from data plate. There is no adjustment. So looking at the parts page, they are saying that there is nothing inside of the the cap. That means getting parts inside of # 16. I have not cracked it yet. I will let shop do that and test the gauge. Thanks

-

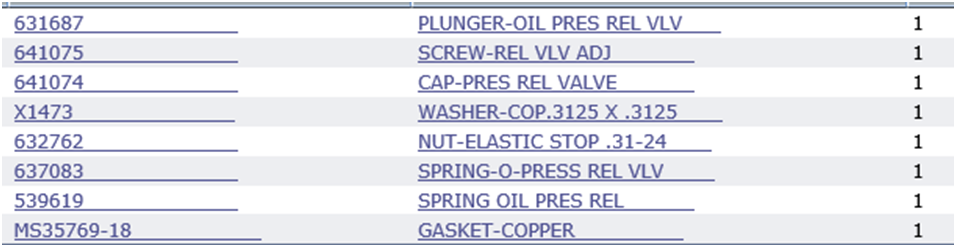

Exactly. But not that simple. He is stumped as well. Just talked to Continental Aero. My engine had no pressure adjustment. Yes, no adjustment. What I need is called an EQ6516, which is going to be a bear to find. the parts in that kit are listed below. It is a long story, but with that kit, I can have adjustable oil pressure. Tks For perspective in case anyone has or will come up in the future, we are talking the accessory case here. My engine is TSI0360GB1B - Accessory Case Part Listing GO HERE: http://continental.aero/support/illustrated-parts-catalog.aspx, AND SELECT ABOVE ENGINE #. Thanks if anyone has any experience on this.

-

I have read all that I can on this subject. 1980 M20K, She is a GB/LB meaning it was converted. I have read about "lapping" and also about a jamb nut with a screw adjustment. There is nothing wrong with engine. I am figuring that the 2 above procedures are one or the other, not both. Before annual, she has always run right on the line of yellow/green. Thanks

-

? Possible to get nose gear doors too tight?

willerjim273 replied to willerjim273's topic in Modern Mooney Discussion

OK, So the chaffing is from overlap, not really interference. Thanks. Exactly what I was looking for.