-

Posts

118 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Posts posted by TNIndy

-

-

We added the two lines and saw a noticeable increase in MP. Unfortunately not as much as the STC shows. at 10,500 ft I'm seeing 24.5". One odd thing is that when I engage the turbo I see an immediate decrease in fuel pressure then it recovers over the next couple minutes. I would expect a drop but not a 60% drop. If I turn the boost pump on it recovers immediately and maintains even if I turn the boost back off quickly.

Thanks for everyone's help. I will continue to look for airflow leaks in an effort to see more boost.

-

Sorry for the confusion. The air bleed line is connected to the fuel pump. The two fittings at the air box don't have anything connected.

-

35 minutes ago, N201MKTurbo said:

The engine won't just run poorly, it will quit above ~4000 feet.

I was on a flight to Santa Barbara at 15000 feet and the engine started running very rough. I was over Apple Valley CA and spiraled down and landed. The engine started running OK when I got down to pattern altitude. I looked the engine over and didn't find anything, so I took off and continued on my trip. The runup was fine and the takeoff was fine, so I turned on course and started to climb. Climbing through about 4000 the engine started getting rough again, so I returned to the airport again. I looked the engine over a little closer and fount one of the hoses to the injector bleeds had come apart. It seems I forgot to tighten the hose clamp. This affected two cylinders. after tightening the clamp the engine worked fine. It was basically running on two cylinders with the air bleeds disconnected.

So why do you think it runs well now? Those fittings have been disconnected for years, I don't get much boost with the turbo engaged but I do get about 3 to 4 psi.

-

I've got the correct routing from Rajay. I need to dig through the logs and other STC's to see if I can find any mention of why they were rerouted. The sad thing is that three different shops worked on the MP issue. Turbo has been off twice for testing and inspecting. No one noticed two open fittings coming out of the air box. Thanks to everyone for the help. Once I get this all worked out, I will post what we find.

-

2

2

-

-

40 minutes ago, M20F said:

That pipe right in the front of the cowling what is that hooked to down below. If you look at my pictures same set up but that line is hooked to the unhooked lines you showed.

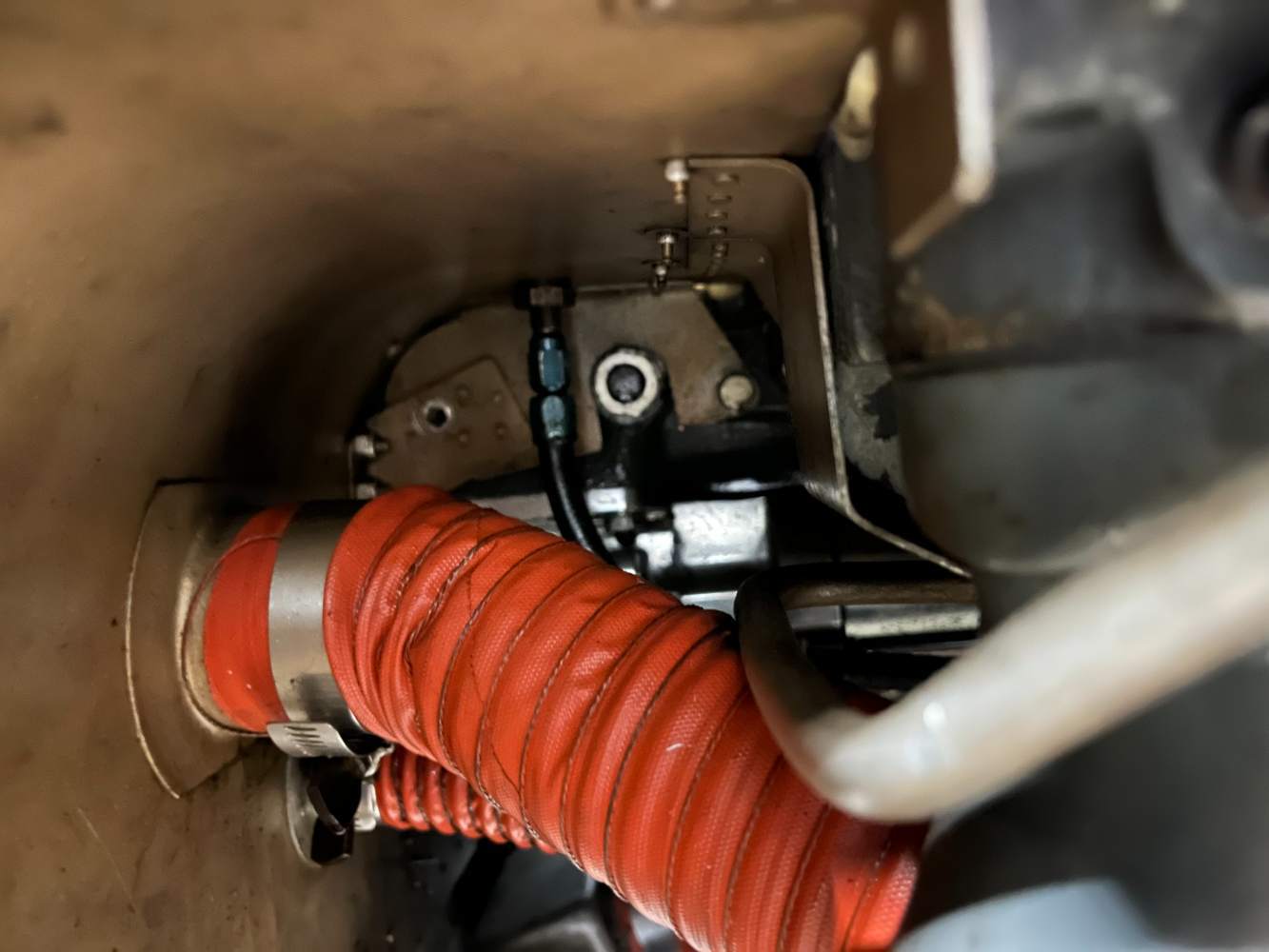

It's going to the fuel pump. The last picture shows it terminating at the fuel pump.

-

-

The line is rerouted and connected behind the engine under the mags. All I had was my cell phone light so I couldn't see much. I will look again tonight and see if I can trace it down.

-

15 minutes ago, LOCOLJ said:

I am not sure about MP bleed off, but in my system the air inlet box will capture boosted air from the turbo by closing a flapper and thoes two fittings capture the higher pressure air in the box and distribute it the the injectors and fuel pump. In your picture, the lower fitting that is aft should have a line going to the fuel pump and the other fitting has a line going vertically to a bulkhead fitting through the baffling and then to the rest of the lines for the upper deck pressure to the injectors. If the waste gate is fully closing then you are likely loosing boost pressure between the turbo and the fuel servo. If those fittings are open they might be your source. Also look at the condition of the hose from the turbo to the air inlet box, the inlet box for holes I found a few there, and make sure the flapper is fully closing with its gasket is in good shape. Not much left to investigate...

Thanks, this helps. Sounds like we should cap them off to see if MP increases and start reviewing all the STC’s to see if we can find a reason both lines were rerouted.

-

Thanks for the help. My MP tops out just under 22 at 11,500 ft. Am I incorrect in the assumption that those two fittings being open allow MP to bleed off?

My injector bleed runs to the rear of the engine under the mag but I can’t see where it ends. -

We've been working on getting rated boost from our Rajay turbo system. Sent the turbo to Maine Turbo for bench testing, had then waste gate adjusted then verified it's closing fully with an endoscope. Now we are looking at airflow and ducting again. We noticed two fittings that no longer have anything connected. Can anyone tell me what these are? The pic is of the pilot side of the aluminum box that the turbo boost air enters. It seems these would be constantly leaking boost pressure.

-

One option may be to find a local Mooney pilot with several years of experience and ask them to go up for an hour or so. Together you may see something and short cut lots of troubleshooting on your own. I'm fortunate to have two semi local CFI's with Mooney's and I learn something every time they fly with me.

-

I used the product Jaeger suggests. I attached a picture. It's not cheap but is durable. For holes with cracks I used fiberglass resin and woven fiberglass mesh. When everything was repaired I sent the pieces to Hector at AeroComfort and had them covered in ultraleather. For me, it was a much bigger project than I anticipated. But then, all of my projects are bigger than I anticipate. Some of us never learn.

-

1

1

-

-

1 hour ago, Shadrach said:

Ouch that is a 40% increase over what they asked in 2019 when I had mine done. Are they still asking the customer to send a check and return shipping label with the core?

It runs infinitely stronger than the original Dukes design and I expect it wall last quite a while longer.

Yes, you have to pay upfront but there aren't many other options. The shop got a second quote for $1378 so that made the $685 seem a little better

-

I had mine rebuilt at Aeromotors earlier this year. $685 plus.......

-

1

1

-

-

On 7/16/2023 at 9:16 PM, M20F said:

RayJays don’t have intercoolers so you are pushing really hot air into the cylinders. You need to run really rich (I am almost 12GPH at 190). I don’t believe the electro air is approved for turbos and if it is variable timing you will have a bad day if you lose your manifold sensor. That being said with unpressurized mags weird things can happen at altitude.

What altitude are you noticing the roughness at? Mine is pretty solid to FL190 and starts to get progressively wonky after that.My mechanic suggested that I swap out my remaining 4 massive electrode plugs with Tempest fine wire. All roughness is gone! Now I need to determine the correct mixture with the turbo engaged without CHT’s creeping up.

-

2

2

-

-

Everything worked well as far as registering. Appreciate all the effort that goes into these events. Enjoyed last year

-

1

1

-

-

On 7/16/2023 at 10:16 PM, M20F said:

RayJays don’t have intercoolers so you are pushing really hot air into the cylinders. You need to run really rich (I am almost 12GPH at 190). I don’t believe the electro air is approved for turbos and if it is variable timing you will have a bad day if you lose your manifold sensor. That being said with unpressurized mags weird things can happen at altitude.

What altitude are you noticing the roughness at? Mine is pretty solid to FL190 and starts to get progressively wonky after that.I haven’t tried it above 10,500. I’ll look back at my engine trends to see how rich I was running but I feel certain I wasn’t as high as 12 GPH. I appreciate your help

-

GAMI spread is usually right at 1 GPH. I will have to see if the spread is more with the turbo engaged. I am getting GAMI injectors installed in August so that will improve. Cylinders do peak in the same order whether the turbo is engaged or not. I hadn't thought of an intake leak but we can easily check that on the ground.

-

I have a 67 M20F with a Rajay Turbo. I've owned the plane for a couple of years but haven't been using the turbo because of an oil leak in the turbo system. Long story......in summary I had the turbo bench tested, it tested fine and we ended up replacing a check valve. Now that the oil leak is finally fixed, I have been trying to use the turbo. The engine runs rough with the turbo engaged. I get boost and increased speed but the roughness is noticeable. Previously I assumed I was fowling plugs because of oil making it to the cylinders via the turbo.

Also, I have an Electroaire system with Tempest fine wire plugs. The other four are massive electrode.

It doesn't seem to make a difference if I am running LOP or ROP

I appreciate any thoughts or suggestions

-

I think your costs look a little high in a couple places but once you add back GPS, Foreflight, other charts etc. It probably evens out. (I have separate charts for the Dynon and Avidyne)

The real question, as others have pointed out, is what do things cost during the first year. I think the shop that did my prebuy was pretty good and the shop that did my first annual. Things still failed shortly after both that added up quick. It feels like the more I fly, the less I spend in maintenance if that makes any since. Also, fix each item as it comes up, things add up if you wait.

-

1

1

-

-

On 2/5/2022 at 1:09 AM, y2kiah said:

Ok, I'll start with the good stuff:

- The EIS gives a strong spark as advertised. During engine run-up the RPM drop is a barely noticeable 20 RPM when the mag is turned off, while running on the mag alone drops the usual 100 RPM.

- The engine is happy over a very large mixture range including well lean of peak

- It's cool to have a switch panel and push-button start in place of the key

- I recently had an in-flight mag failure after 3 hrs of cruising with what turned out to be a slowly dying mag, which led to a loud pop, followed by a very rough engine that was still capable of making some power. Luckily, I did not need to use that power since I was over an airport at the time and simply glided down and landed as if it was an engine failure. I taxied in, did a mag check, and confirmed that the mag was dead. I wondered why running on the EIS was so rough, since under most circumstances you wouldn't notice any power reduction turning off the mag in flight. As is turned out, the 3hrs of cruise on a faulty mag had fouled up all of the spark plugs pretty bad, and the engine was really unhappy without all of the plugs firing. Cylinder #4 was especially impacted and looked like it was making no power during that event. I was thankful for the strong spark of the EIS. If I had been running on two mags, there is a chance the engine may have failed outright in that condition.

Now for some of the bad:

- Coming right back to the mag failure event, the pucker factor increases when you lose your mag because your engine is now totally dependent on the electrical system. Make sure your alternator and battery are in good condition if you are going to install the EIS. If you have the option to install backups for either, I would recommend it. Secondly, I wonder if the strong spark of the EIS led to the engine running smooth enough over 3 hours as the mag was dying, that it was hiding early warning signs of the impending failure. If I had been running on two mags, maybe I would have noticed a decrease in power or roughness earlier in the flight, and ended the flight before the total failure, and under safer conditions. Why did #4 lose almost all power, while the the others continued to operate? The bottom plugs on 2 and 4 run from the EIS. Those likely fouled up more than the top (EIS) plugs on 1 and 3.

- The lead wire connections were designed for automotive plugs and are too flimsy for aircraft engines. There is no mechanical clamping, they rely on friction alone to keep the wire in place compressing the spring. As the wire ages, the friction decreases and the connections have a tendency to slip, leading to loss of contact with the plug. I had to replace one of my lead wires because the connection kept slipping out in flight. All of that voltage has to go somewhere. It ended up shorting and burned a hole through the side of the wire insulation (within the plug). This has apparently been a common problem with the Electroair. It was not a cheap fix.

- The system is unfamiliar to a large number of mechanics out there. I had a mechanic (not at my home shop) tell me the gap on my plugs was too big, until I reminded him that the EIS uses different plugs with a larger gap. Make sure you are very familiar with the system and double check for correct plug installation after any maintenance.

- You have to cram another system and all of its wiring onto your firewall, where space is already tight. Changing the oil filter on my J with all of that extra stuff in the way is a real hassle. Not sure how that would impact a Bravo.

Overall I am happy with the system, it works very well if all of the components are healthy. My take is that you are not relieved from the burden of mag maintenance, or the risk of mag failure, so I would not factor that into the decision too heavily. If your remaining mag does fail, the failure mode of your engine changes as compared to running two mags. You'll probably also have some new maintenance items pop up from time to time.

I agree with pirep from y2kiah although I am not aware of the lead wire connections being designed for automotive plugs.

I have the Electroair system on my turbo normalized M20F. The system works well and the guys at Smooth Power are great to work with. I like the push button start rather than the key also.

-

I didn't reply to the state of TN quick enough because I was working out of town. Their assessment was less than I paid so I ended up paying less. This was in 2021

-

2

2

-

-

I hope it turns out well. It's great to see it being saved rather than used for parts. Keep in mind that although it's expensive to fix everything while it's apart, it's much more expensive to take things apart multiple times.

-

1

1

-

-

On 6/20/2023 at 7:43 PM, Yetti said:

Just replace the inner core with proper sized Bowden Cable. Or piano wire.

That's was the original plan. I couldn't get the front end pulled forward enough to take it loose. I pulled it out today after removing the rear clamp and hope to reinstall tomorrow with Teflon coated stainless spring wire.

Got my wings back from the paint shop

in General Mooney Talk

Posted

Looks Great!