-

Posts

38 -

Joined

-

Last visited

Contact Methods

-

Website URL

www.xevision.com

Profile Information

-

Gender

Male

-

Location

Ogden, Utah

-

Interests

Experimental Aircraft - Glasairs

-

Reg #

N789DB

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

FastGlasair's Achievements

-

XeVision® XeTREME™ LED LANDING LIGHT (par-36/46)

FastGlasair replied to 201Steve's topic in General Mooney Talk

Well up till now, that's not been the feedback we've gotten, regarding just the strobing mode appearance. Most have been relieved, that a cross-feeding sync wire, often difficult to implement (wing access and labor) was not required or needed at all. In fact everyone prior to this, has stated they "loved" the uniqueness and effectiveness of the dual light strobing pattern. Additionally, they all were in fact mostly concerned for collision avoidance benefits in high density traffic areas, low visibility (pollution or haze) and equally for the evident bird strike prevention. All of this on top of the superior output 1/3 mile+ effectiveness for landing, in the normal steady mode. Thanks, Dan -

XeVision® XeTREME™ LED LANDING LIGHT (par-36/46)

FastGlasair replied to 201Steve's topic in General Mooney Talk

Niko, We did quite a bit of research regarding maximum effectiveness, wig-wag, steady, strobing, irregular strobing. The most effective attention getter (the ultimate goal for wig-wag etc.) is a "wild" pattern. See the light pattern video below for a pair of our LED landing lights in strobing mode out at the wing tips. Note this pattern is especially effective for avoiding bird strikes too. (garnered from data) USDA Research - National Wildlife Research Center - Effectiveness of Aircraft Mounted Lighting to Reduce Bird Strikes. Our net conclusion, syncing the lights had no performance benefit for this strobing pattern we offer, in fact the opposite is true. https://www.xevision.com/led_aircraft.html Note if the 2 lights are quite close together, such as the cowling, we recommend only strobing one of them at a time, the other being off. Thanks for asking, Dan Blumel www.XeVision.com 801-622-7000 -

XeVision® XeTREME™ LED LANDING LIGHT (par-36/46)

FastGlasair replied to 201Steve's topic in General Mooney Talk

1. Already told you we monitor fan rotation, ie tach. We also have thermistors for such. Don't need to dramatically reduce output performance to prevent thermal runaway as yours must. Only a backup for us. 2. Extruded aluminum can't be made into a similar optimized shaped heatsink. 99% pure is required for cold forged parts. The length of the pins was optimized by testing, including infrared cameras. A large ∆T in fact is desired for efficient thermal extraction performance. 3. The 180+ F number was found to approximate the temps found from 3 other competitors units with less wattage than yours within 10 minutes of on time in a 70 F ambient environment. What kind of beneficial airflow (none) is found in an engine cowling without a blast tube "focused" on the heatsink of the unit ?? 4. A well and suitably compressed o-ring is making a great seal and no, there is no passage of anything in spite of your insistence. We use the same o-ring technology on our HID waterproof handheld searchlights that are certified for scuba diving to 50 meters. Those have been in use for about 20 years now, without a single water pressured or otherwise water intrusion issue. High dollar Rifle scopes and Spotting scopes use the same to keep argon or nitrogen contained within for many 10's of years as previously stated. We also have a vacuum chamber for testing altitude internal pressure variable effects. 5. Yes time will tell, we offer a 5 year warranty, even with a lens breakage failure we can easily repair the unit for a relatively very low cost. I often fly through rain and our customers are in many humid and rainy places around the world, not a single warranty claim of any kind so far in 3 years. Once the salts, mentioned earlier, turn light blue or even pink, the only way to change them back to dark blue is high temps in an oven (225-300F for 2 hours plus for the moisture to cook out and escape not remain), not the relatively low temps. occurring in the optical section. Thus they do show evidence of historic humidity or lack there of. 6. Well at least we assemble in USA and no, not every part is made in USA. 7. Yes better efficiency and one hell of a lot more as I have and our website indicates. Obviously you love "your" product that's great. Equally lots love ours too. Obviously not everyone does or will want to pay a premium for what we offer in distance illumination and other capabilities, those that do will. 8. We will shortly have STC approvals making installation simple and friendly for everyone. Until you can provide additional metrics of performance ie, Candela (Candle Power) or Lux output values and a graph similar to what WAT shows for output degradation over time as the unit heats up, there is no apples to Apples comparison at any level. Good day sir, I rest my case. The sparing session has been challenging yet "fun". We've been in the aviation lighting industry since 2002, no neophytes here. You aren't the first and won't be the last for a joust. We here are all experienced pilots, experimental aircraft builders ( 4 aircraft between 2 of us, 2 Glasair RG's, 1 Lancair 4P & 1 Nemesis NXT Reno Racer) as well we're seasoned engineers, Optical, Mechanical, Aeronautical and Electronics. One of 4 now retired being a PE in 3 states, NJ, NY and Utah. We occasionally try to use lay terms to help the understandings for others. -

XeVision® XeTREME™ LED LANDING LIGHT (par-36/46)

FastGlasair replied to 201Steve's topic in General Mooney Talk

Your manufacturer even indicates they MUST throttle back, the power, only one reason to do that, the dissipation of heat is inadequate to prevent LED thermal damage and eventual thermal runaway. Here is their website quote "SmarTemp - Temperature Dependedent Intensity Decrement" they cant even spell Dependent, also complex word games regarding thermally motivated & controlled power reduction. Irrespective, the heatsink surface area is too small and too shallow to efficiently move heat out of the unit (thermal wick effect) and transfer it away from the LED's. We use a deep "Pinfin" type "sand" blasted cold forged 99% pure Aluminum anodized heatsink to efficiently create the large ∆T needed to do so effectively and the fan to carry the heat away. Note our fan shroud is not black to reduce infrared absorbsion from exhausts and engines potentially behind it for cowling installs. Both AeroLEDS and WAT brand LEDs of lesser powers generate temps on their heatsinks of 180F + degrees within 10 minutes, even though they also throttle back to prevent or minimize unit electronics thermal damage. Our unit case due to the efficiency of our heatsinking and active cooling never goes beyond "warm in the hand" not by any definition hot. Only the front glass lens eventually gets hot enough to melt snow and ice, as is often needed and desired. Mounted In a location of a hot engine compartment with lots of infrared energy, a black colored absorbing heatsink becomes a negative not a positive. In that location without a blast tube feeding it cooler air, places it in an "oven", potentially hot before it's even turned on. I/we never claimed "hermetic" just an air tight seal and yes tested afterwards in my aircraft after a couple years of use. (Color changing special salts pouch still dark blue after 2+ years) proof of no moisture intrusion, an effective verification. Salts turn light blue to pink depending on amount of moisture contamination absorbed. Our product even passed the newest RTCA DO160 testing (lab certified and expensive) the strictest test levels for Both EMI and RFI. BTW without Candela ( or Lux numbers at some fixed distance ) it's impossible to verify or approximate any of your/their Lumens claims. Unless they used an Integrating sphere to measure the Lumens output of a finished unit, at a specific time (initial on etc). It's more likely they are multiplying the number of LED's X the LED manufacturers Lumens number, this doesn't take into account any optical efficiencies and losses. Likely about 10% the front plastic lens and hard to guess on the TIR optics. I suspect this unit is assembled in China, they only mention it is " designed / developed / distributed in USA not mentioning at all where it is made. Definitely not in Georgia, since they indicate no brick and mortar facility of any kind there. It appears they are using Four ( 4 ) Watt Cree LEDs X 27 = 108 Watts to the LEDs with 125 watts in that only 87% efficiency compare to ours at 92% including a fan that draws ~1.75 watts, without the fan draw, we are about 93.75% control circuitry efficient. -

XeVision® XeTREME™ LED LANDING LIGHT (par-36/46)

FastGlasair replied to 201Steve's topic in General Mooney Talk

-

XeVision® XeTREME™ LED LANDING LIGHT (par-36/46)

FastGlasair replied to 201Steve's topic in General Mooney Talk

-

XeVision® XeTREME™ LED LANDING LIGHT (par-36/46)

FastGlasair replied to 201Steve's topic in General Mooney Talk

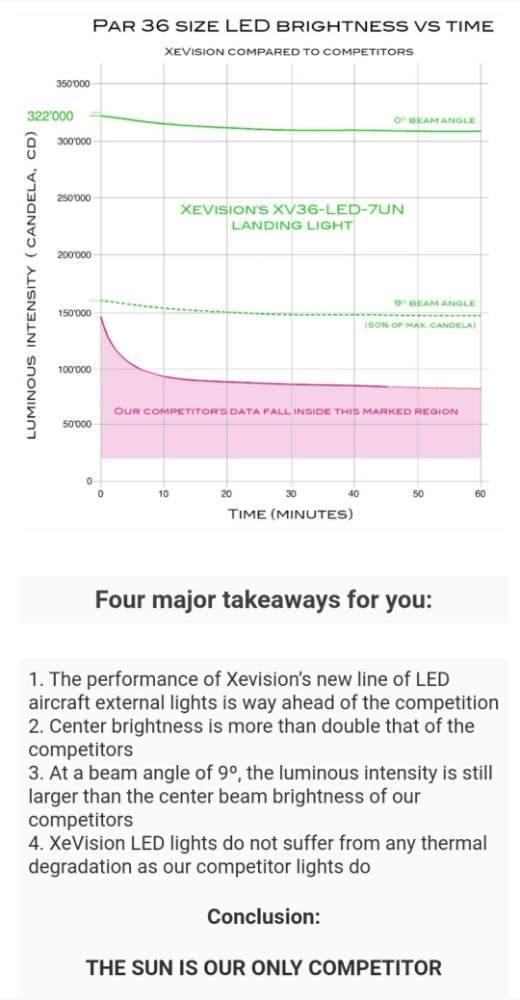

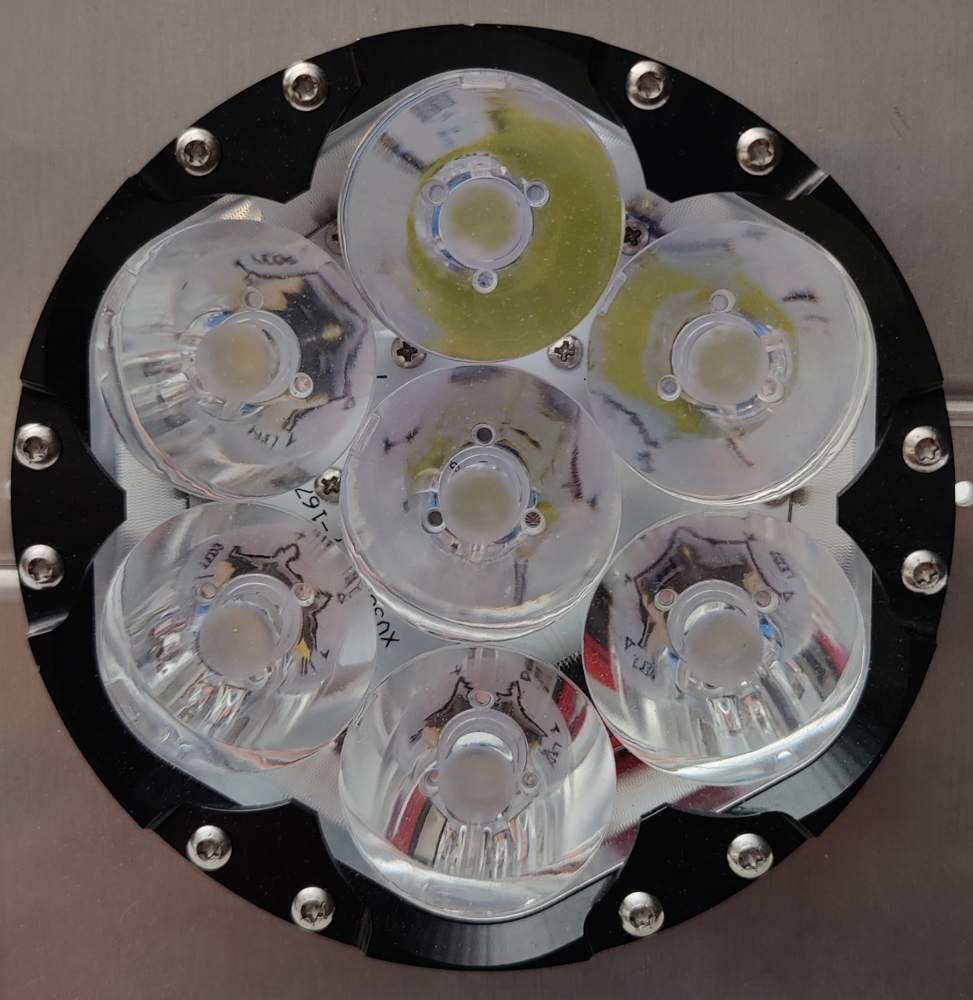

Thanks for asking. Its not really fair to call this a bulb, only the old Incandescents are a bulb and HID's also have a bulb within the reflector. For the quality and durability, $250 I would agree, That costs maybe $50 to actually make, not counting tooling and engineering costs spread over many thousands of units sold. Our LED is on quite another level, costing about 7X that just to make, not counting tooling or engineering costs. https://www.xevision.com/led_aircraft.html all the details are here. Our LED provides very useful illumination out past 1/3 mile and includes a strobing mode for collision avoidance. 320,000 Candela (Candle Power) sustained output, the others dim to about 1/2 output (about 1/3 of ours) within 5 to 10 minutes of being on. Most start at less than 1/2 our output when initially powered. 10,870 Lumens certified lab measured, coming out the front (not theoretical) The old incandescents Par36 (4.5" diam.) or Par 46 (5.75" diam.) provide a relatively small percentage of that output, making mostly heat energy not mostly light energy. Our units are sealed Nitrogen flooded, actively cooled, repairable (not throw away), upgradeable, and modular. Warranty 5 years or 2000 hours whichever occurs first. Dan Blumel - XeVision 801-622-7000 -

XeVision® XeTREME™ LED LANDING LIGHT (par-36/46)

FastGlasair replied to 201Steve's topic in General Mooney Talk

Thanks for that feedback, it's quite useful. Yes it can easily be installed in these Par 46 sized opening "tubes", as shown in the photos a few posts above. -

It seems, with a new mayoral administration at Ogden, Utah KOGD, we the hangar owners are about to "win" our legal case (without the courts) with a new Mayoral adminstration, come January 2nd 2024. Our leases said we had "first right of refusal to renew this lease" the only prescribed legal contract increases are CPI rate adjustments. www.xevision.com LED and HID landing & taxi lighting technology. Our ONLY competitor is the SUN.

-

Landing Lights: Whelen LED vs Aeroled or others

FastGlasair replied to Greg Ellis's topic in Vintage Mooneys (pre-J models)

Hope people will watch this YouTube video. Candela (CP), Lux & Lumens "OH MY" !! - The established standards by which Landing lighting performance is measured. https://youtube.com/watch?v=3NL6wjAoTEg&feature=share8 6 The technical part about landing and taxi lighting ( Lumens, Lux Candela ) starts 25 seconds in, after a high quality video-graphic flying introduction. Hope you all find it interesting and informational. Dan www.xevision.com -

XeVision® XeTREME™ LED LANDING LIGHT (par-36/46)

FastGlasair replied to 201Steve's topic in General Mooney Talk

Hope people will watch this YouTube video -

If you are familiar with Mike Patey (of some aviation fame), his project of elite hangars at Spanish Fork, Utah airport that receives FAA grant assurance money. They are offering an initial 50 year lease term with the cities option for additional renewal(s) or alternatively purchase the hangars back at fair market value at the end of the first 50 years, or possibly even at a much later time.

-

No, this is about general situations happening all across the country, often Airports management blaming the FAA for "making/requiring" airports to add reversionary language (or even require enforcement if they have it) of this language to leases, both new leases and renewals. The ONLY FAA requirements are leases should not normally exceed 50 years per issuance or for any additional renewal(s). The airports can't blame the FAA for airport breaches of previous leases or renewals, only contract laws would apply. If building a new hangar and reversionary language is included, nothing illegal about that if you agreed too it. You have no recourse at that point. You accepted the terms of the contract.