Spuderman1

Basic Member-

Posts

29 -

Joined

-

Last visited

About Spuderman1

- Birthday 07/08/1988

Profile Information

-

Gender

Male

-

Location

Morden, Manitoba, Canada

-

Reg #

C-GOLE

-

Model

M20f

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Spuderman1's Achievements

-

High oil temp. Rpm loss. Rough ground run

Spuderman1 replied to Spuderman1's topic in Vintage Mooneys (pre-J models)

I have no objection to trying different oil but my issue is when the plane has run 20w50 as long as I have had it and it's always kept the oil below 200 and all of a sudden my temps get out of control. I don't want to make a band aid fix. -

High oil temp. Rpm loss. Rough ground run

Spuderman1 replied to Spuderman1's topic in Vintage Mooneys (pre-J models)

My oil p gets down to mid 60's when temps are that high. Worst part is on landing while I'm rolling out to slow down it drops down to around 20. Jeff -

High oil temp. Rpm loss. Rough ground run

Spuderman1 replied to Spuderman1's topic in Vintage Mooneys (pre-J models)

Cht 1 is a gasket probe on a original cht probe due to it being a jpi830. I'm a subscriber of savvy since the day I had my jpi installed. They are definetly an amazing tool! -

High oil temp. Rpm loss. Rough ground run

Spuderman1 replied to Spuderman1's topic in Vintage Mooneys (pre-J models)

Time to revive a old post... So it's been a long year of chasing a high oil temp issue. And we'll. The plane now has new baffle seals and just recently got a new aero classic oil cooler. But... temps are better but still too high like 217f in cruise to high. I've had the had the old vernatherm out numerous times and Installed a new one but same temp. I've now bought a new Donaldson oil filter housing thinking what if my old housing had been machined and now doesn't seal perfect. So now with the new housing and new vernatherm I figured I would test the seal. I installed the vernatherm in the housing (with the aluminium washer/seal) I heated up the water and noticed the vernatherm doesn't seal against the seat of the housing. Now i removed the aluminium washer/seal that goes between the vernatherm and housing to get the vernatherm ckoser to seat. And we'll it worked somewhat. It looked as tho it sealed so I dropped some red die into one of the cavities and it still transferred the color through the vernatherm. Question is how well does the vernatherm need to seal. And is there a thinner aluminium washer. Attached is the flight testing my cooler. https://apps.savvyaviation.com/flights/4095588/be71e73f-37f2-423a-a771-099cb0233fbc -

Thanks for the diagram!!! Definetly answers some questions!! I've been having high oil temp issues and was wondering how its possible for the cooler to get plugged up.

-

Just trying to understand my engine more and i cant seem to find a answer anywhere. I'm curious of the flow of oil through the engine. After going through the oil pickup screen in the sump I take it it goes through the oil pump then from there I'm a little lost. Does it go through the oil filter then oil cooler then into the engine. Or sump, pump, cooler, filter then into the engine. Thanks

-

High oil temp. Rpm loss. Rough ground run

Spuderman1 replied to Spuderman1's topic in Vintage Mooneys (pre-J models)

It's staying in the green. That's taking into account red line is 245 and it gets into the high 230's. I actually had the oil filter housing removed a few days ago to get the seat re machined. The old vernatherm had a wear mark all around the top so it must habe been seating. I'm thinking since I'm this far into it I may as well spend the couple extra dollars and put that rebuilt vernatherm in. I'm curious what on a vernatherm fails. Is it that they get weak or just not extend enough. -

High oil temp. Rpm loss. Rough ground run

Spuderman1 replied to Spuderman1's topic in Vintage Mooneys (pre-J models)

So as a little update. I've had my vernatherm pulled off and tested at which it would expand at the proper temp. We replaced my oil press ball and spring. And found the prop cable has some slop so it let's the prop wander a little. My oil pressure is back to normal but my oil temp has still continued to be a issue. I've noticed that the not power and the faster I fly the temp will slowly come down. The slower and dirtier I fly (landing config) my temp will wander up. Makes me wonder that even of the vernatherm does cycle properly is it really working properly. I was able to get my hands on a rebuilt vernatherm I tested them side by side and the old vernatherm opened approx twice as far as the rebuilt one. Does that mean the old one is possibly weak and under pressure It doesn't seal and force the oil through the cooler? I also had my cooler removed and flushed. A little bit of sludge came out. We swapped the oil lines which used to flow in on the top of the cooler to now flow into the bottom of the cooler and out on the top. -

High oil temp. Rpm loss. Rough ground run

Spuderman1 replied to Spuderman1's topic in Vintage Mooneys (pre-J models)

one thing i did notice now after going through my flight data. prior to doing my cylinders (which had extreme blow by, oil would be black within a hour, and burnt a quart every 2.5 hours) my oil pressure used to spike up to the 90's then settle around 75-80psi in cruise, after cylinders were done after about 10 hours into break in my oil pressures settled down to 65-68 in cruise... im i just being over paranoid now that i have a analyser and can see every little change in engine operation? my last visit to the mechanic we adjusted the governor to bring back my rpm and we also bumped my oil pressure back up to 75 psi in cruise. im just concerned these are band aids on a (hopefully not) larger problem. -

High oil temp. Rpm loss. Rough ground run

Spuderman1 replied to Spuderman1's topic in Vintage Mooneys (pre-J models)

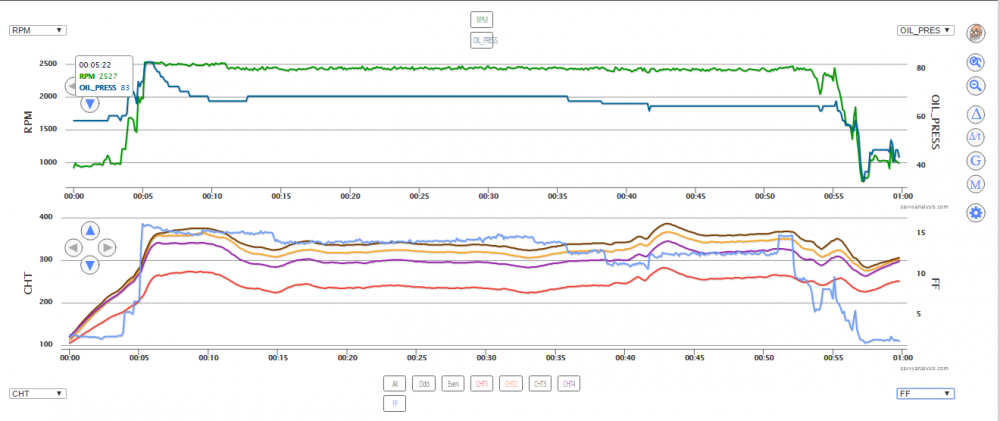

here is the screen shot of the take off when i first realised i had high oil temps. the next screen shot will have my issue with when i could only get 2500rpm. this was the flight i noticed i wasnt able to get full rpm as a matter of fact i kept the prop nob in all the way the whole trip. please let me know if there is another graph or parameter that would help show data better. -

High oil temp. Rpm loss. Rough ground run

Spuderman1 replied to Spuderman1's topic in Vintage Mooneys (pre-J models)

My prop cable I'm sure is original. From 1967. One thing i noticed is once I shut down and prop is at full fine I can reach in and wiggle the governor arm up and down about 1/8 inch. We had replaced the price that screws onto the prop cable and connects to the arm on the governor. I realize 1/8 inch may be alot but what could possibly have made my prop only get 2500rpm I had the prop cable screwed in all the way till it was tight. -

High oil temp. Rpm loss. Rough ground run

Spuderman1 replied to Spuderman1's topic in Vintage Mooneys (pre-J models)

Since the cylinders are so fresh and still in mineral oil would It be worth an oil anylysis? I'll get them compression tested. Oil is a nice golden brown color. Could timing cause high oil temp? After my last flight I had a p lead break free. So installed a new end onto the wire and that's the only work that had been done. Wondering if a mag could have shifted perhaps. -

High oil temp. Rpm loss. Rough ground run

Spuderman1 replied to Spuderman1's topic in Vintage Mooneys (pre-J models)

Engine has 1300smoh. Altho it just got tore down approx 120hrs ago due to crack on case and got a new case. Prop has 70 hours. Hub got rebuilt at that point. My oil p on start up if I remember correct is around 85. When at normal operating temp. Jpi indicating 190dC oil pressure is at 75psi. The last time I lost rpm down to 2500 we adjusted the governor and also bumped up the oil pressure 10psi (65 up to 75) My jpi oil temp probe is at the front passenger side by the prop. I tested it and it reads right. So how is it my back probe (original) indicates 190 between the oil cooler and oil filter. ( I have oil cooler relocate) but it jumps 40 dC by the time it makes it to the front probe. -

So almost 1 year ago had my stock governor loose rpm and was only able to produce 2500ish rpm at all stages of flight. I jumped to the conclusion the governor was tired so I installed a new pcu5000. Rpm was back and producing around 2660rpm. I had some oil burn issues that got resolved 2 months ago at last annual when we replaced all 4 cylinders. I've been break in mode flying the snot out of it. And so far I've never seen cht so nice (mid 300's). All of a sudden after about 8 hours i notice my rpm would only be able to produce 2500 once again. We adjusted the governor and rpm was back and plane has flown amazing for the next 6 hours. Now on my last flight my anyliser warned me of high oil temp. My old steam gauge showed 190 but my jpi was indicating 235. I landed to find the would have at full idle only 12psi oil pressure. And the plane would run really rough. Like loping really bad. Where do I start? Oil cooler just got pulled and flushed and vernatherm got pulled and it opens at the proper temp. Why would I loose rpm so randomly?

-

I'm liking the questions! I'm no mechanic but I love getting my hands dirt and this is definitely educating me on my new plane! In regards to the oil change we would add 7 quarts, the dip stick would read 7 quarts, I would fly the plane home. 30min and the next day when I would check it it would be at 6 (my guess is due to oil filter and cooler taking up some oil).. next day I would do a 2 hour breakfast run and the fallowing day or next time I go flying it would be between 5 and 5.5 quarts. The case is not leaking. I have no visible drips on the engine nore inside the cowling. Next step will have to be a compression test to see if the rings are any good. I know if I run anything over 6 it's definetly on the belly.