Dialed In

Supporter-

Posts

86 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Dialed In

-

1) I put a new PCU on last year and had the same symptoms. Prop was new in 2006 and has 1500hrs on it. I got ahold of the manufacturer APS and they told me to send it back to them. They polished a spool and sent it back to me. It now works as expected. If you need contact info let me know. 2) Check and make sure your oil cooler lines are routed to the correct ports on your filter head. I also rebuilt my engine this year with oversight. OAT 60 degrees @ 6500ft yesterday 68%power 100 degrees ROP and 206 degree oil temp. 35 hours on engine so far. Oil cooler should be warm if your oil temp is over 190 at shut down.

-

Make sure you blow out all of the contact cleaner before your final assembly or it will eat the weather pack.

-

Hidden Damage, Looking for Repair Options

Dialed In replied to AerostarDriver's topic in Vintage Mooneys (pre-J models)

@AerostarDriver what did you decide to do on this repair and how did it turn out? -

Engine gurus, Oil usage problem M20K 231

Dialed In replied to Steve Dawson's topic in General Mooney Talk

@Steve Dawson any headway yet? -

1964 m20e s/n#311 nose gear door rod end picture

Dialed In replied to Hradec's topic in Vintage Mooneys (pre-J models)

-

Engine gurus, Oil usage problem M20K 231

Dialed In replied to Steve Dawson's topic in General Mooney Talk

I'm just trying to get a more complete picture. An inflight mag check would tell you that both ignition systems are firing under load. A runup mag check might be good but when the pressures and temperatures are higher in flight a maginal plug may be not firing. I'm pretty green on aircraft piston engines but I do know that when running on one plug the EGT's for that cylinder go way high. The engine will run like this in cruise but I have heard under full power it can be detrimental. Also if the plug is not firing it will accumulate carbon and foul. I would perform a compression check on the cylinder to see if there is air leaking anywhere it should not be. Don't assume the cylinder is good just because it was just gone through. Turbo's don't produce positive pressure all of the time, just when the drive pressure from the exhaust is greater than the suction from the intake. It is common to have a vacuum in the intake system at idle. How much is your oil usage in quarts/hr? Is everything else satisfactory? Good power? If the only complaint is fouling a plug it could be a bad plug, bad wire, or something wrong with the mag. -

Engine gurus, Oil usage problem M20K 231

Dialed In replied to Steve Dawson's topic in General Mooney Talk

Have you done a bore scope inspection and compression test on the number one cylinder since overhaul? What do you have for engine monitoring? How hot is the number one cylinder vs others? Have you performed an inflight mag check? When do you find the fouled plug? At the next run up or after the flight it runs rough? -

Looking for a governor (H-1, PCU5000)

Dialed In replied to lithium366's topic in Vintage Mooneys (pre-J models)

I had a terrible experience with west coast governor last year when I purchased my new pcu-5000. I will never do business with them again. The guys that manufacture the pcu, APS, however are top notch and have fantastic service. Find someone other then west coast to buy it from though. -

https://www.flywildblue.com/airplane-for-sale/1967-piper-arrow/n3962t @N2391Y I have a 1965 m20E and love it. I have not read all the responses however my hanger neighbor is selling this arrow, it is well sorted and he takes very good care of it. If I were in the market this one would be towards the top of my list.

-

Surefly Electronic Ignition Fitted to a M20K

Dialed In replied to Robert Bridges's topic in General Mooney Talk

It would have likely been cheaper to just move the tach pickup to the other mag instead of using the signal converter. I suspect when you kill the surefly mag the signal also dies so you get no tach reading. I just went through this install and elected to move my tach pickup to the right mag instead of using a signal converter. -

M20E Winter Operations

Dialed In replied to MooneyMunnerlyn's topic in Vintage Mooneys (pre-J models)

I’ve never heated the tail section of my E and have yet to have had an issue, I even have a 5 year old wet gill battery. I typically plug the oil pan heater in over night and then heat the cabin for 1/2-1 hour before the flight. It’s not uncommon for us to have 2-3 weeks of highs in the -20 Fahrenheit during winter and I fly a couple hours every week. I did have the gyro serviced three years ago, it was the first time the oil had been changed in it since 1965. -

So I have my engine assembled and hung on the plane, I have done all my ground runs and everything seems normal. During the ground runs we were about 60 degrees outside and after the ground run we went through an annual. Now the weather has changed and we are 20-30 degrees Fahrenheit for a high and around 10 for a low. I plan on following lycoming’s recommendations on breaking in an engine. My IA is fine with doing the break in when it’s chilly like this since the DA will be lower and the cooling will be better. I should mention he worked on aircraft in Alaska for a few years so he is familiar with the cold and breaking in engines. I’m not worried about the cold starts as the engine and oil will be at 70 degrees. I’m just curious what others opinions are on breaking in an engine when it’s cold outside. I’m well aware of ring flutter and cylinder cooling in the decent. Thanks, -Chase

-

What were the hours and how long ago (calander) was the overhaul preformed?

-

You can see the weep hole on my manifold pressure line at the top by a small dab of silicone if you zoom in. I think most are further down by the intake.

-

Do you have a mechanical gauge or digital?

-

Another question who here removes the piston from the head when they come back from overhaul to inspect, clean, measure? And who installs them never taking the pistons out of the barrel with the theory it’s one less operation to risk breaking rings?

-

And I have seen several people with crank stands that prefer to assemble the case 1/2’s on a bench then place it on the stand. Do those of you here that have crank stands build up the entire engine on the stand or is there a good reason to put the 1/2’s together first on a bench? My IA has a stand.

-

I have a pressure pot I use for pre-oiling in my day job but in my day job I know where to hook it up to send the oil through the filter. Is there a port on these engines that anyone knows about that would direct the new oil through the filter before going through the bearings? I have not looked or searched just though I would ask here first.

-

I have watched a fair amount of videos in assembling these engines. Some use an assembly lube on the cam that the cam grinder recommended after coating the surfaces with the oil/stp concoction. Do any of you use assembly lube on top of the lycoming recommended lube? Lycon reconditioned the cylinders, the new angle valve cylinders were still a long ways out. I had them balanced and polished while they were there.

-

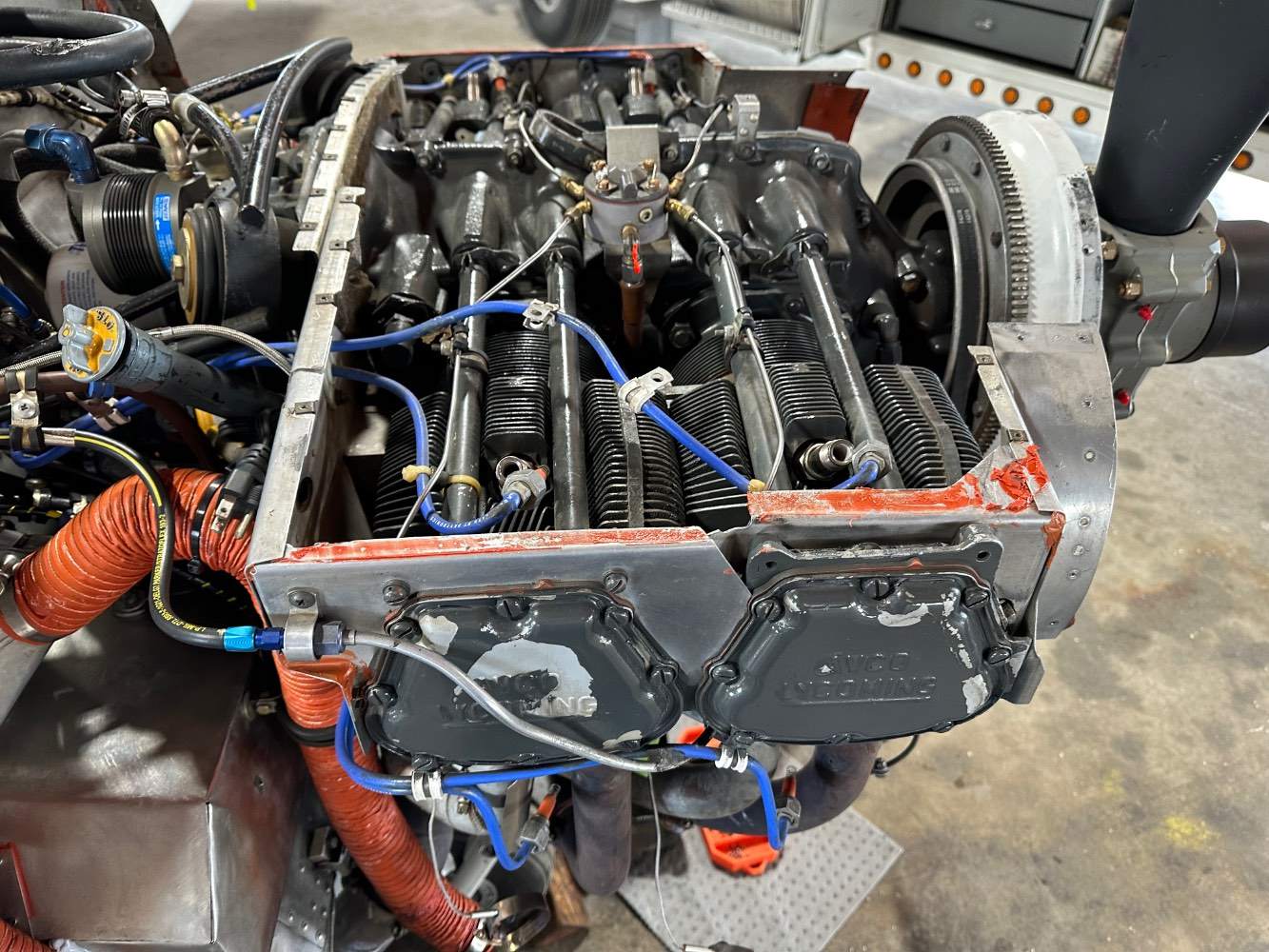

Well I pulled my IO 360 A1A off the front of my E in the beginning of July and tore it down. I sent everything off for machining and everything has gone smoothly so far. I have everything back but the hardware I sent out to get cad plated. My IA and I are going to assemble it here in a little over a week so I thought I would ask the brain trust for any tips or tricks they have. I know many of you do this type of thing for a living and obviously have gone through many engines, what are some things you do to make assembly go easier for you? I’m not asking for anything against the manual but just some of your tips and tricks you might be willing to let go of. There are a couple people I’d like to thank right off the bat. @N201MKTurbo Rich thanks for recommending nickson’s for the case, Rudy is hilarious and their work is phenomenal. @jetdriven thanks for the posts on 15B26588 lifters, they seem to be readily available now. Clarence you have helped in more ways than I can write down, literally every time I look something up you had the answer or a good tip losing you on this forum is huge. There have been many others that have contributed in the past (Cliffy) so thank you for bringing your experience and expertise to this forum.

-

I would also check your turbo. I have had seals fail on both the turbine and compressor side, more often the compressor side. All you have to do is check your induction tubing for oil residue, if it’s bad it will be dry from the filter to the turbo then from the turbo to the servo will be wet. You can also check the exhaust manifold before the turbo is there residue there or just after the turbo? They can pump a lot of oil out in short order if they completely fail. I would agree that it sounds like an oil ring on #2 but the turbo is probably worth a quick check.

-

Oddly enough I’m in the exact same situation. @M20Doc what would you do to fix this situation? I had a plane power alternator installed three years ago on a 65 m20E and they used the original generator belt. There was no travel left in the adjusting slot it was all the way in indicating the belt could be longer. The plane power kit did not supply a belt and did not recommend a size. So do I just order the belt indicated in the Lycoming parts manual and hope it fits even though I have the large generator pulley still?

-

It really depends on the depth of the issue. I guess what I normally do is take pictures and contact the shop that did the work. A lot of times the Forman or owner do not know about these issues, it could just be a bad mechanic and they have not caught onto them yet. You could go on to tell them how poor the quality is and if they are work a damn they will stand behind the work. If it’s bad enough you could report them to the FSDO but be prepared if the FSDO wants to inspect the plane. Most of the time I just end up eating it after talking to the shop. You should at least give them the option to make it right though.

-

I am glad your flight was successful and I also feel your pain. This last annual every single item the shop touched there was something wrong with. The list is too long to type out here and I won’t bore everyone with those problems but that’s the main reason I have been doing everything I can under supervision. I’m a mechanic by trade and this issue is certainly not limited to aviation. I typically remove the cowls from the plane and look over everything that was touched after maintenance for this reason. Stay safe I don’t see this issue getting any better.

-

I appreciate your response however I guess I didn’t see an answer. Can we time a lycoming to 25 degree BTDC when the data plate states 20 legally? If not is there an option to change the data plate to 25 degrees? I’m not trying to debate the performance gains, I know I want 25 degrees BTDC. Can it be just up to the IA to determine if he wants to time it to 25 degrees?