Nippernaper

Basic Member-

Posts

152 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Nippernaper

-

Ah, I understand where you're coming from now. Agreed that what I'm looking at is a normal, "lazy" take-off without any attempt at max performance. Also, I see your point that 2500' is not necessarily the same as runway length (shorter may be OK, since lift off will be much sooner). I was just interested to see what kind of performance I'm actually getting, and set my expectations, and operating procedures, accordingly. I'll still be practicing short and soft fields to keep my skills up, but I try and avoid the need to use them.

-

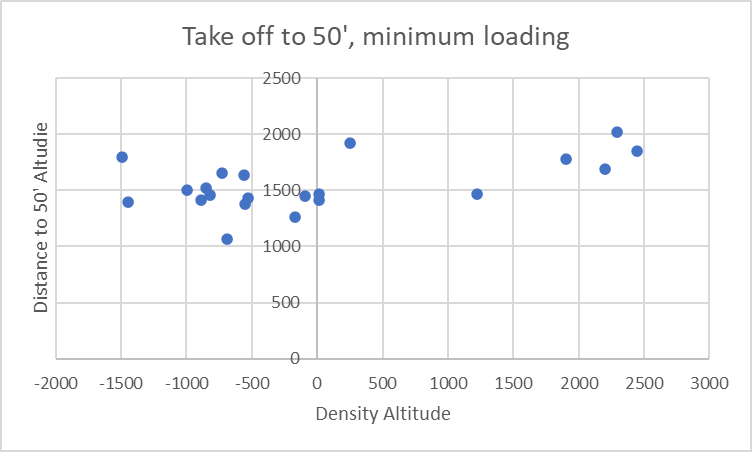

I will do my best. For all of the flights in the past year where I had all 4 seats loaded and some baggage, and with tanks at 50 gallons (this was not a small number of flights, maybe 50 or so), from the recorded data I extracted the distance from start of take off roll to 50'. For my home airport I calculated the mean and standard deviation of the distances. Taking the mean and adding 2.5 standard deviations results in a distance in terms of take off over a 50' obstacle that should be exceeded only about 6 times every 1000 takeoffs. This yields the 2500' number. So, based on the weather conditions typical at my home field, the field elevation, the weights I usually fly the aircraft, and how I fly the aircraft, 2500' would seem to be a relatively conservative number for the distance to a 50' obstacle. I of course also check the POH for the take off performance numbers, but they are always less than that. I found it very interesting to see how I was actually performing in terms of take offs, versus what the POH was predicting for a given DA. We're often advised to allow a healthy margin over the numbers in the POH since we're not trained test pilots flying brand new aircraft, and now I have a basis for determining what a safe margin is, based on how I fly my airplane.

-

What I've been trying to do with the data is not use it to adjust my flying technique (although it could definitely use some improvement), but rather to better understand what performance I'm getting, and make sure I stay well within that performance envelope. For example, regardless of what the POH says, when I'm fully loaded at a reasonable density altitude, based on the data I shouldn't be using a runway any shorter than 2500 feet. I'll continue to work on my skills and technique with my instructor, but I want to make sure I'm not pushing the envelope.

-

Identified time when altitude reached 50 feet above that during the takeoff run, calculated distance based on latitude/longitude values from the GPS data.

-

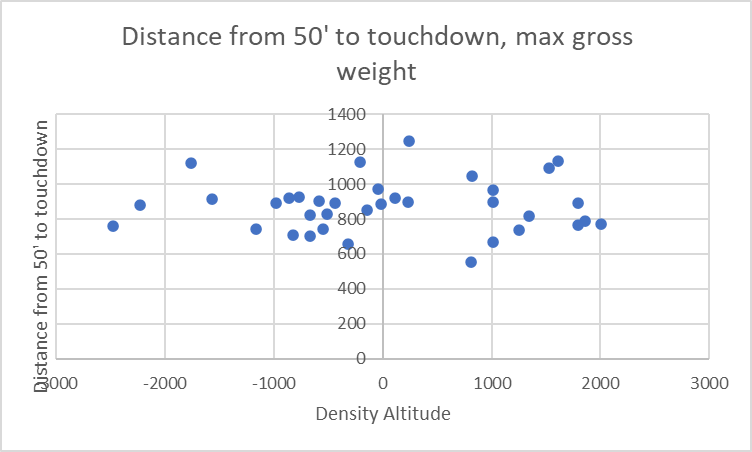

Good point. I figured wind based on GPS speed versus TAS at 50' altitude for the landing data. See graph below. I did not do that for take off (unfortunately). If I get around to reprocessing, I'll add that variable to the calculations. It general, landing distance decreases, but there is still significant scatter.

-

Altitude is indicated, not GPS (from the air data computer). Mean of take off distance was 2075', standard deviation was 224' at max gross.

-

I have a G3X touch in my J, and I've been wondering for a while if there might be more to learn from the data recorded than what Savvy analyzes. Savvy is great, but they tend to focus on engine related parameters, and a lot of the new PFD and MFD equipment record a whole lot more than EGT and CHT. With altitude, lat and long, GPS speed, etc., I figured there might be a way to review typical take off and landing performance, as opposed to the POH numbers. Take off data was more straightforward to extract. Landing data not so much, as the ground roll tends to be related to where the turn-offs are. Hopefully I figure out how to attach a few graphs below. The most meaningful I found was distance to a 50' altitude over field altitude versus Density Altitude on take off, and distance from 50' altitude to touch down on landing, for two weight conditions: just me with typical baggage, and fully loaded (within 50 lbs of gross weight). Taking mean and standard deviations, I then set a minimum field length based on the mean plus 2.5 times the standard deviation. This results in a conservative estimate of performance, based on how I fly my plane, at the loadings I typically have.

-

I know of someone who installed a dimmable LED, and had this exact result (no dimming) Sent from my iPhone using Tapatalk

-

Tow bar is still working great. As I said in the earlier posts, it's a bit on the heavy side. If I were to make another one, I'd use lighter gauge square tubing (and maybe a little smaller as well). I'll get some overall dimensions this afternoon and post.

-

The OP symptoms sound exactly like the trouble I had after acquiring my '78J. After having the master cylinders rebuilt system flushed, etc., it turned out the left master cylinder on the pilots side would physically conflict with another component when fully depressed, and become hung-up, unable to release. This was not a hydraulic issue, but a physical conflict between components which would prevent the cylinder from retracting. When you apply the parking brake, you have a tendency to push harder on the brakes then just about any other time, and this led to the issue only showing up when using the parking brake. You might want to have the owner check this.

-

Best Place for a Mooney Annual in the Northeast

Nippernaper replied to joegoersch's topic in Modern Mooney Discussion

Just picked up my J from Weber yesterday from the annual. They do good work. Not a bargain basement price, but well worth it in my book. They know their Mooneys, and are easy to work with in my experience. Sent from my iPhone using Tapatalk -

Looking through the NTSB database, where a structural failure has occurred prior to impact, failures of both wings do not appear to be especially rare. See below for an example from 2019 in a PA28: The left aileron, outboard sections of the left and right wings, and the left and right horizontal stabilizers were located about 1,500, 1,000, and 900 ft from the main wreckage, respectively. Fractured areas of the left and right wings and the horizontal stabilizers were consistent with overload separation before ground impact.

-

Good point. I guess I'm not too surprised that both wings can fail more-or-less simultaneously in a high g maneuver, as failure of one wing may not immediately result in an unloading of the other wing, especially if the rate of increase in the g loading is high. In that case, even if the failure loads of the two wings differ, they probably are close enough that one failure will follow the other, if the loading is still increasing.

-

It may seem counterintuitive, but it does seem like that's how wings typically fail. See video link below of a cropduster pulling it's wings off.

-

I thought it might be good to wrap up some of the structural strength discussion that occurred in this thread, now that the final report is out. NTSB estimates the wings failed during a pull-up (or tightening of the spiral dive) at more than 8 Gs. Three passengers, and the plane's gross weight is listed at 3564 lbs. Assuming partial fuel and standard passenger weights, weight at the time of the accident would be somewhere around 3340 lbs (based on an assumed useful load of around 990 lbs). So, failure load is somewhere around 26,700 lbs for the wings under positive (upward) loading. For those of us flying mid-bodies or short bodies, with essentially the same wing structure, that means the wing failure load is somewhere north of 9.5 Gs. Probably more, since the decrease in weight from the long bodies to the mid and short bodies is mostly in the fuselage and engine, which will decrease the bending moments in the wings more than a straight ratio of weights. Summarizing, although the Mooney wing is not infinitely strong, and you can break them by going fast enough and pulling back hard enough, they are incredibly robust, and likely one of the strongest airframes in the GA fleet.

-

Exactly. My J matches your speeds and fuel flows just about right on. Sent from my iPhone using Tapatalk

-

Under the wing works well. I have seen some in the NACA inlet on the copilots side of the fuselage (J models). When I upgraded the panel on my J, avionics shop installed the OAT probe on the belly near the tail. It's hard to believe, but the exhaust raised the temperature of the probe by tens of degrees f. Had them relocate it to the factory position in the wing. Sent from my iPhone using Tapatalk

-

I just pour from the camguard bottle, and use the clear strip and oz markings to estimate the correct amount. A little more or less isnt going to hurt anything; we're not formulating medications here! No muss no fuss. Sent from my iPhone using Tapatalk

-

Mooney 201 lands on high power lines in MD

Nippernaper replied to ArtVandelay's topic in Mooney Safety & Accident Discussion

I was flying the same day, a bit north of this airport, and earlier in the day and had to miss an approach when the ceiling ended up being substantially lower than the ATIS ( and the minimums). It was a little bumpy, but not too bad. Winds were very strong out of the south west, and there may have been some mountain wave action present even though the nearest ridge lines are pretty far west. HOWEVER, if you can’t fly an ILS to minimums in light turbulence without descending below glide slope so far that you hit obstructions, you shouldn’t be flying IFR. This is far from the first time a pilot has descended well below where they should be on an approach, and will not be the last. It is up to us to make sure we are proficient and current. The numbers on the charts are absolutes. This was flyable weather with no icing. Sent from my iPad using Tapatalk -

Mooney 201 lands on high power lines in MD

Nippernaper replied to ArtVandelay's topic in Mooney Safety & Accident Discussion

From several youtube videos playing the live atc audio feed from earlier in the flight, it seems this pilot was having serious trouble flying vectors and programming his gps. You could see this coming. Descending below glidepath is a distressingly common cause of ifr accidents. No equipment failures required. He probably struck the wires away from the tower, and they redirected him into the structure, at a reduced speed. Sent from my iPhone using Tapatalk -

I've spent $15,000 in the past 5 years dealing with valve issues that ultimately come from burning leaded avgas. By my calculations, that's about a $3.30 per gallon surcharge on the fuel I've used. I can't wait to get rid of 100LL. Sent from my iPhone using Tapatalk

-

This. I spent a lot of time working through baffle issues, oil cooler flushing, etc. and the ultimate solution was to adjust closed flap position in the summer months. Sent from my iPhone using Tapatalk

-

Also this outfit is very good, have used them twice. https://www.spinner-repairs.com/link.html Nippernaper Sent from my iPhone using Tapatalk

-

When I saw the accident listed below on Kathryn's report, I was hoping it wasn't you. Please do let us know how you are when appropriate. Nippernaper Kathryn's Report: Lancair IV-P, N994PT: Accident occurred December 25, 2021 at Ford Airport (KIMT), Iron Mountain, Michigan (kathrynsreport.com)

-

Just replaced mine last week after living with a stiff cable for three years. Went the lube route first, but that didn't really help much. New one is silky smooth, so much better! Sent from my iPhone using Tapatalk