-

Posts

95 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by pilot_jb

-

.thumb.jpg.55c318b31497f1c59a3912b07d503432.jpg)

**FOUND** - Inspection Cover Assembly 210113-1

pilot_jb replied to pilot_jb's topic in Avionics / Parts Classifieds

Bumping this up for added photos. Still looking... -

It's definitely closed now. All you get is a, "Sorry we're closed" sign that fills the screen. It's a real bummer. I've order a fair amount from them in the past.

-

.thumb.jpg.55c318b31497f1c59a3912b07d503432.jpg)

Oil control rings and lessons learned - with pics!

pilot_jb replied to canamex's topic in Vintage Mooneys (pre-J models)

I don't know your mechanic, but if he saw this and didn't realize what was going on then there is a major issue with his skill level...and there's no way he didn't see it. This sort of failure will usually also show up in the exhaust pipe and on the belly, as well as the plugs...even before a possible low compression reading. Borescope inspections are also your friend and should be conducted regularly. I look in my cylinders during each spark plug service, and at the back of the exhaust valves (more relevant here) while the exhaust is removed at annual. -

.thumb.jpg.55c318b31497f1c59a3912b07d503432.jpg)

Crazy or stupid? Oil leak revealed

pilot_jb replied to BDPetersen's topic in Vintage Mooneys (pre-J models)

Did no one else here notice that RTV was previously used when the sump gasket was installed? Probably doesn't matter at this point, but did you check the sump bolts for proper torque? With RTV under there, which it shouldn't be, the torque would have never been "correct" and will change over time. -

.thumb.jpg.55c318b31497f1c59a3912b07d503432.jpg)

**FOUND** - Inspection Cover Assembly 210113-1

pilot_jb replied to pilot_jb's topic in Avionics / Parts Classifieds

As stated, it’s the inboard and forward mist inspection plate. Under the wing behind the leading edge but in front of the tank. There’s two on the plane like this; one on each side. These two are two-piece construction and are the only inspection plates made this way. Someone way before my time fabricated one from a flat piece of aluminum and I want to make it right. -

.thumb.jpg.55c318b31497f1c59a3912b07d503432.jpg)

Whats the shortest strip you will land at?

pilot_jb replied to Niko182's topic in General Mooney Talk

45G is my home airport. We have at least three Mooneys on the field. Basically, we have a grass runway with a paved centerline. -

.thumb.jpg.55c318b31497f1c59a3912b07d503432.jpg)

Who locks their controls like this?

pilot_jb replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

Simply this to tie the yokes together. Simple, cheap, and very effective. https://www.amazon.com/gp/product/B07GN9MJRR/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 -

.thumb.jpg.55c318b31497f1c59a3912b07d503432.jpg)

Intermittently Failed Left Mag Check...Now It Won't Pass

pilot_jb replied to pilot_jb's topic in General Mooney Talk

We end up pulling the mags. The points and the rotor were shot. Fixed it right up. -

.thumb.jpg.55c318b31497f1c59a3912b07d503432.jpg)

Intermittently Failed Left Mag Check...Now It Won't Pass

pilot_jb replied to pilot_jb's topic in General Mooney Talk

A ground mag check produces a 200-300 RPM drop with what I consider to be a rough running engine. Plug timing was set approximately 20 tech hours ago. -

.thumb.jpg.55c318b31497f1c59a3912b07d503432.jpg)

Intermittently Failed Left Mag Check...Now It Won't Pass

pilot_jb replied to pilot_jb's topic in General Mooney Talk

Not a formal engine monitor, but a Mixture Mizer. This is an instrument that shows peak EGT for one cylinder at a time, but not actual EGT. It will display actual CGT. Also, it does not record data. Finally, I do have an EI EP-5L fuel computer, but, again, all of my readings and data recording are manual. -

About to start really digging in... Went through a period of time when I would Intermittently fail a left mag check. The issue started happening progressively more often, so as the first step in diagnosing the problem, we swapped plugs from the right to the left. The expected result was for the problem to move to the right if it was the plugs, and to stay on the left if it was the wires or magneto. Oddly enough, the issue corrected itself. Temporarily, and always on the ground, both mags passed with flying colors under warm and hot scenarios. I let the plane cool and then the problem returned. We then found the timing to be, at most, a couple degrees off. After this was corrected, I once again could not get it to fail a check on either side. I let the plane sit for a couple days, and now the issue is as bad as it's been...can't get it to pass on the left. We also rebuilt the P-leads, because we found the left side wiring to be old, brittle, and only connected by a few strands of wire. Both mags have 512 hours. IO360-A1A Bendix S4LN-200 shower of sparks Left dropping between 200-250 RPM with the last round of runup's showing a 300 RPM drop once. Bottom number 4 plug is slightly wet with oil, but is not totally uncommon and should not be enough to cause the drop My planned next step is to pull the mags, which is going to be a total PitA. Is there anything else I/we should look at prior to pulling them? If pulling them is the only option, who is the recommended mag shop for Bendix? Thanks!

-

I don't have access to the map, but am wondering if I'm listed. If not, I would like to be. Thanks!

-

Gentlemen, For reasons we won't discuss, it's come time for me to negotiate the value of my M20F (No...I'm not selling her). I need a recommendation for a fair, trustworthy, appraisal in the southeast Michigan area. Thanks!

-

-

I'll be at the hangar tonight. I'll gladly send you whatever you need.

-

Damn. Sometimes a second set of eyes is worth the world. Major, "Why didn't I think of that" moment. lol!

-

My homemade tow bar for vehicles came with the plane, but I think the previous owners got it right, except for not making the pin long enough to pin the other side and lock it in.

-

.thumb.jpg.55c318b31497f1c59a3912b07d503432.jpg)

WOW!! Very Bad interaction with Don Maxwell

pilot_jb replied to mooneybuilder's topic in General Mooney Talk

The original post in more than 5 years old. -

I have a second person left my wing

-

I’ve been moving the passenger seat full forward, and then wrapping the lap belt around and tightening to suit. My concern has been causing a crack, which is to be inspected each year. I’ll try bungees between both yokes.

-

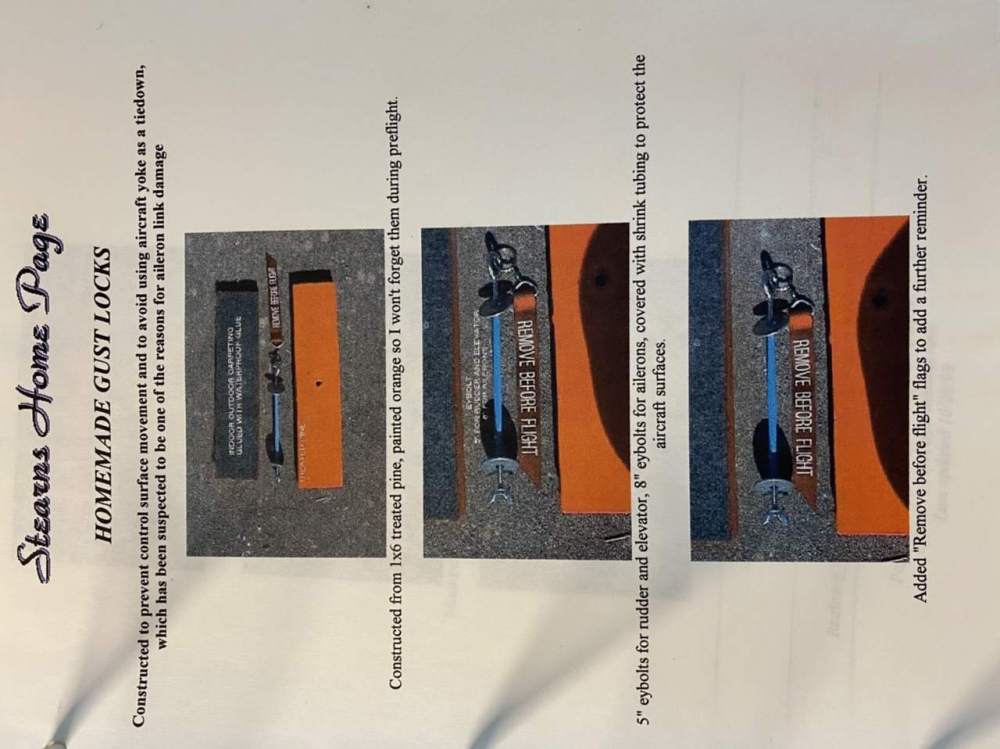

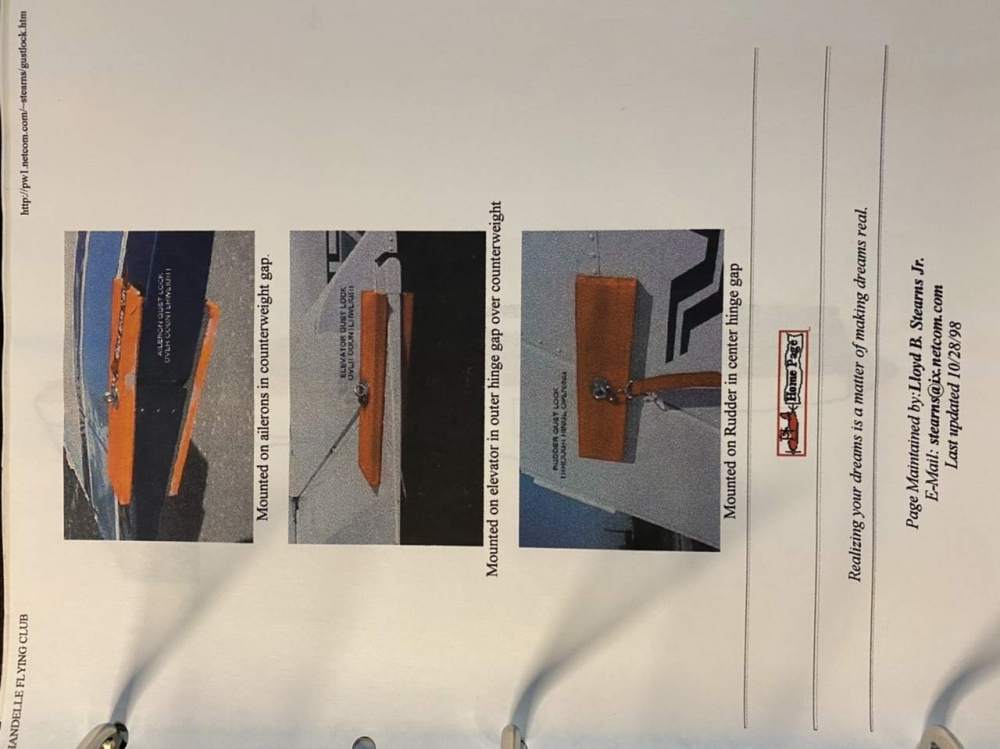

I’m starting to use my Mooney for something more than local trips for Breakfast and lunch at the many airport diners available around my area. Longer CCs where I’m forced to leave my plane outside at strange airports for days, or even weeks, is going to be more common for me. I found instructions for homemade gust locks in the paperwork I received from the previous owners (see attached). However, they do not appear to be adaptable to plane with gap seals, such as mine. Does anyone have any alternate ideas you’re willing to share? Thanks!

-

Guys, I need some help here. I’ve been chasing a leak in my right tank since last year and I’m a bit baffled, because it’s now moved in a major way. Last year, my IA and I sealed a leak which was showing along the bottom of the right spar in the gear well. We got it, but not completely. We’re in MI and it may or may not be important that it started after it got cold. After it got cold this year the same leak became worse, so we went back in. I found the internal leak location using Don’s soap and vacuum method and repeated this process each time (twice). Since the internal leak was at the top of the spar right behind the middle access panel on the top of the wing, I think we just missed it the first time. This area is really tight and we were much more liberal with the sealant last year, because we waited to reseal the access panel. This will make sense to those of you who have done it. After repairing the leak a few weeks ago, the wing was completely dry, and the plane sat through several cold/warm cycles of weather. Today, I flew the plane for the first time since the latest repair. On base, about .5 hours into the flight, I got a heavy fuel scent in the cabin. I pulled up to the pump, got under the wing, and now she’s leaking heavily into the leading edge. By heavy, I mean pooling. I didn’t look inside the leading edge before the flight, but I’m confident that it wasn’t leaking from the front until sometime during the flight, and the front of the right side was never a problem. My question is this...is it possible that the tank is being pressurized, likely though the vent tube, in flight? It doesn’t make sense that the back is no longer leaking, but the front is now has a running leak, and during the first flight after being dry on the ground for several weeks. It seems to me that something is pushing the fuel past the seams. Is there a one way valve in the fuel vent that may be stuck open? Thoughts? This is getting frustrating to the point that I’m thinking about selling my beloved F.

-

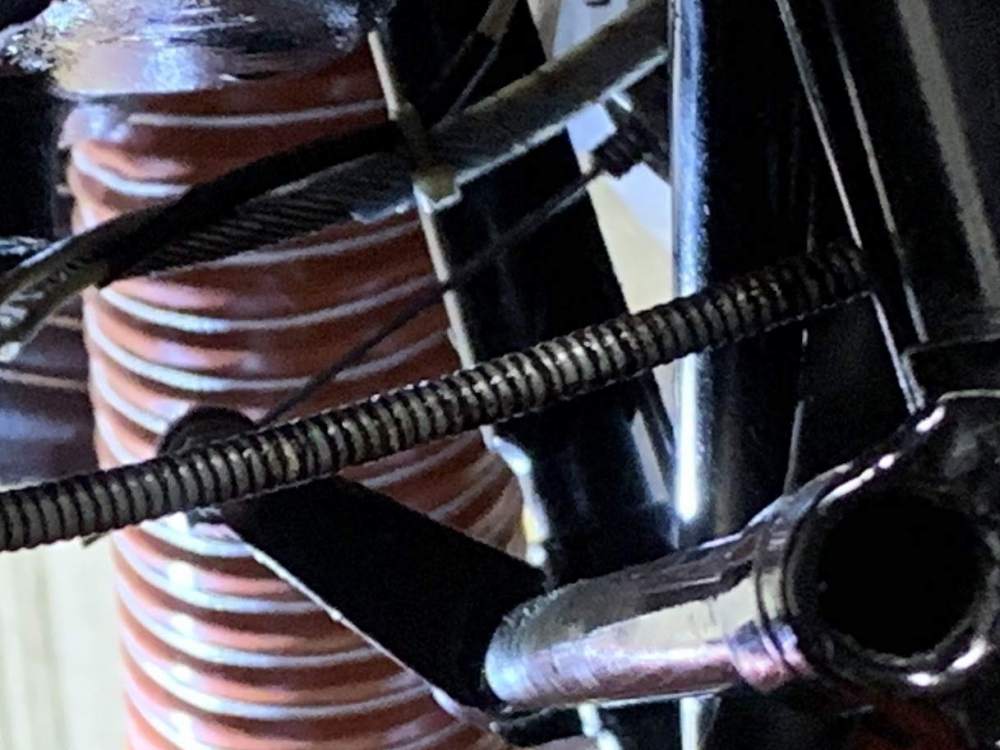

Thanks a bunch, Shadrach. Sure enough, the clamp is not there. In fact, the sheath has been trimmed back too far for a clamp. My guess is that the adjustment wire is bending under the load of the pressure inside the cowl. I'll be at the airport tonight. Who am I kidding? I there almost every night. I'll take a look under the panel to see if there's enough slack in the cable length to expose more in the engine compartment. My plane was stripped down and refurbished by the previous owners years ago. Overall, they did a really good job, but there are some small issues, as there always are. The cowl flap control cable was changed to this version. https://www.aircraftspruce.com/pages/ap/controls_thandle/a1870.php Cheap enough to replace leaving the sheath longer if necessary. I'll let the thread know how this goes. Thanks!

-

I really appreciate it.