-

Posts

24 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by mikejr718

-

M20C New engine monitor. ROP and LOP

mikejr718 replied to mikejr718's topic in Vintage Mooneys (pre-J models)

Is there a "How to post video" somewhere on the site? -

M20C New engine monitor. ROP and LOP

mikejr718 replied to mikejr718's topic in Vintage Mooneys (pre-J models)

Can someone confirm the videos posted? -

Trying out the new engine monitor on a recent cross country. Not sure about lean of peak operation, any leaner and it got pretty rough. Trying out the new engine monitor on a recent cross country. Not sure about lean of peak operation, any leaner and it got pretty rough. D799F313-07F1-452C-8260-114318C137DB.MOV826B302B-F16A-4595-A479-C2B7CF0D21F4.MOV

-

M20c panel upgrade in progress

mikejr718 replied to Capt Brad's topic in Vintage Mooneys (pre-J models)

I was advised to replace the entire panel in my C, was told old radio stack mounting would not support the weight and bulk of new stuff 1D9EFF32-0541-4D57-A4EB-3C33D1EC2BEA.MOV -

The 3bladed prop had a vibration that we never could balance out. Had it below .04ips and still shook in flight, worse at higher power settings. 2 bladed much smoother. Balanced to .03 ips its a night and day difference. Performance wise the take off roll is noticeably longer and climb rate noticeable less. The big gain is in cruise speed. Plane is a 75 M20C At 75 percent power at 5500 ft I am seeing 149kts true. A couple of weeks ago saw 152 kts true at 24in/2400rpm but have not been able to duplicate it since. With the 3 blade I would be lucky to see 140 kts. I can run higher power settings without the plane feeling like it’s shaking itself apart. It’s almost turbine smooth full throttle and prop all the way forward in climb. Also autopilot works much better with less vibration.

-

Just removed a 3 blade Hartzel top prop and replaced it with a 2 blade hartzel HC-C2YK-1BF and now when shutting down engine prop comes to a stop vertically, 12 and 6 oclock. After reading it appears i may need to remove the prop and move the bushing that orient it. I have read the 3 Blade install instructions and they dont mention moving bushings. Just seems odd that prop would end up vertical at shutdown. Prop functions fine and balances down to .03 ips . 1975 M20C O-360-A1D

-

jetdriven, If you have visors for sale I would be interested. check messages

-

Still available?

-

What are you looking for ?? Avionics

mikejr718 replied to Alan Fox's topic in Avionics / Parts Classifieds

Is the tkm mx11 in the bottom of one of the photos available? -

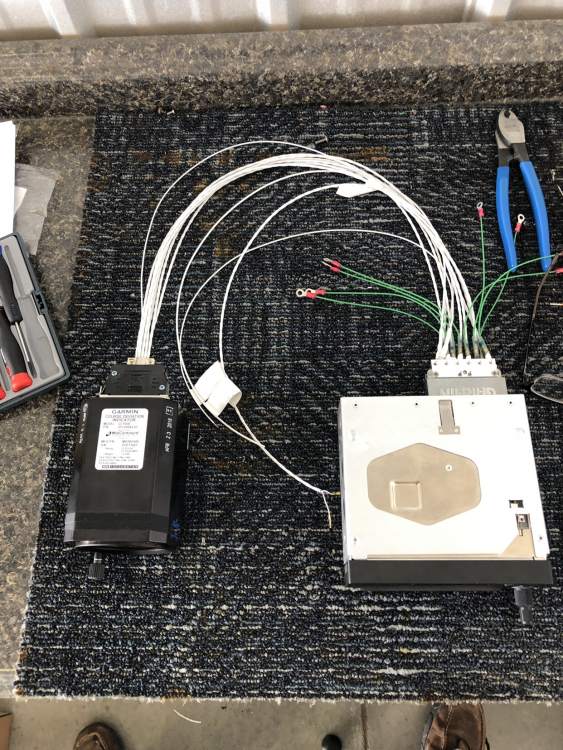

I think I probably have 6-8 hours in the harness and at least 25 in the plane including gps antenna install. This includes cleaning up old wiring. I sent the avionics rails out to be tig welded. Sent from my iPhone using Tapatalk

-

-

G5 Hsi install would have required a magnetometer be installed and would have also needed a gad29 module installation to be able to talk to the autopilot. Using the gi106b made a much simpler installation. If I want to move to dual g5's in the future i will probably remove the narco radio and replace it with a garmin nav/com and use the indicator with it.

-

I used a new gi106b. I could have used the old king indicator but decided to get the new garmin instead. The gps will work with many older indicators.

-

Recently installed a new Garmin gps175 in a 1975 Mooney M20C. I removed the ADF, Loran, Kns 80 and indicator. Before beginning After opening up panel Building the harness was pretty straightforward. Harness configured to connect to stec50 providing nav and approach functions, no gpss. Laying out new stack Had to have all the old holes in the radio rack rails tig welded closed to allow new holes to be drilled. Ready to go back together I have a short video of the finished product but not sure how to post it. Sent from my iPhone using Tapatalk

-

Have been trying to chase down a vibration in my 1975 m20c. Is fine on the ground but vibration starts after taking off and climbing. Goes away when power is pulled back to decend Have dynamically balanced prop(3 blade Hartzell) Noticed the engine baffles are starting to rub on the battery box. Thinking the engine mounts have allowed the engine to sag and rub. Mounts are old, 20 years if log book is correct. Planning on replacing mounts and shimming engine to match cowl. Can I expect envy improvement in vibration level?

-

Flew a friend from bta to ear to pick up a Cherokee. Cam back as a flight of two. Really had to pull back the power so he could keep up 3E7F2CFB-CFFB-40BD-BCD4-6E2DFC6CF903.MOV

-

-

Wanted to update this thread. Tracked down problem to an antenna access port installed between the radio and antenna. Removed it and things improved drastically. I looks somewhat home made and allowed some one to hook up a handheld radio and use the antenna associated with the mx11. It was mounted in the panel near the radio. After removing it had to open it up to see the insides

-

I leveled the plane this morning and checked it per m20-202 and it appears to be just inside the specs that make the shim not necessary. It seemed to take a lot of pressure from the compression tool I rented from lasar just to get it back together without the shim. It came apart with little pressure from the tool, I think the old disks had compressed and hardened a lot. I dread thinking about trying to compress things enough to get it together with the shim. Is it important to get it well inside the specs or will just inside be ok. I was hoping after a few landings and some use the new disks would compress some.

-

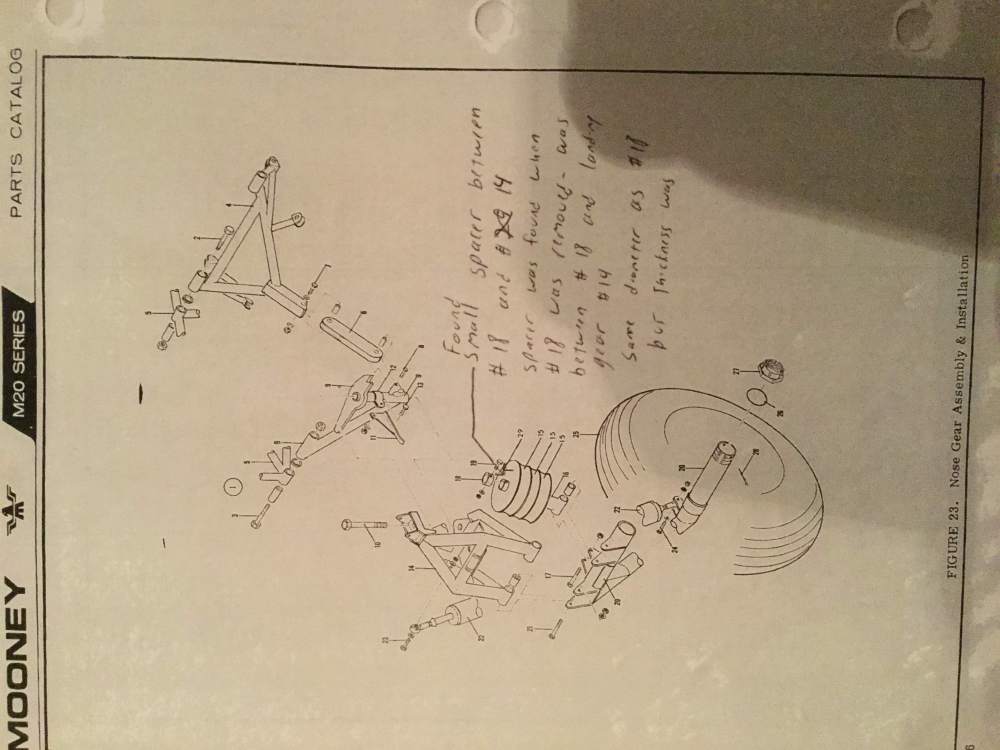

Found a spacer under the collar that holds the top of the sock disc stack. I didn’t see it in the parts catalog and thought I would be unable to compress discs with it in there. I left it out and was able to get things back together. It still took quite a bit of force using the special tool to compress the discs. Would like help as to why it was there and if it’s necessary. The old discs were like rocks and were quite a bit shorter than the new ones put in. See photos

-

Is there supposed to be continuity between the antenna wire and the metal parts of the antenna that the screws go into?

-

I have a tkm mx11 as the comm 2 in my 1975 Mooney m20c ranger. The radio seems to have limited range and usually fails to transmit sometimes after warmed up. Comm 1 is a narco mk12d+ that works surprisingly well for being a narco. Standing back looking at the plane a few days ago it looked like the finish on the rear antenna did not match the rest of the plane. I have the stock 7 antennas. The cork gasket at the base of the radio looked dried up and shriveled so I thought I would remove the antenna and see if it appeared corroded, damaged etc. It was attached with three painted screws and one ground type screw with two star washers on it. The gasket was keeping the entire base of the antenna from contacting the aircraft and underneath the antenna was completely painted. I also have continuity from the center pin of the antenna to the metal base of the antenna. I confirmed the rear antenna is connected to comm2. Can I assume that this installation of this antenna could be part of the problem and the antenna itself may be bad based on the continuity from the center antenna conductor and the antenna base?