-

Posts

398 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by 211º

-

So today was finally a day where I was back in KC, it was dry on the tarmac, and it was above freezing (by quite a bit today too). I was able to view the rods after removing a panel and also able to see where the rods enter the wings. On the RIGHT side, the rod was being "held up" or "less able to move" because of some grime build up. After removing this grime from around the rod, the LEFT aileron then went to its stop. I didn't have the correct screw driver with me to open the near inboard access panel to look from the other side, but right now, I'm 90% confident of the problem and its fix. Tomorrow when I look from the other side, I'll be fully confident.

-

The next time it is above about 35ºF and free of most snow, I'm going to look up/down inside the control levers behind the panel, pull the panel under the Johnson bar and look up, and look at the wing root area. In a perfect world, it will be able to be fixed/addressed and also be able to find the cause of the issue (not just poke around until "hey, it is all ok again"). I'll update with photos when the solution is discovered.

-

Is this visible from the small access panel in the wing or from inside the plane under the front seat's floor board?

-

I thought about this and it still might be the case, but I think that the pest would have to have found its final resting location with the recent extreme cold.

-

I thought that this might have been it - a kinked chain from a gust of wind or jet blast... but I didn't find that.

-

Yes - great point - it is all connected... even on the other side.

-

I need to look up and under the panel - this might be the issue.

-

I did a "thought experiment" the other day while drifting off to sleep and I had the same thought - in my thought experiment, I even thought through that it might be the other side limiting travel. I was under the wing opening an inspection panel this evening hoping that I'd find a tangled chain, but no luck there.

-

PC was on on the ground during runup... but it was the usual tension (and no stupid questions).

-

Here is my current conundrum. I fly long cross countries about every week. About six weeks ago. I had to leave the Mooney outside in Kansas City for eight days. During this time, there wasn't any extreme weather, thunderstorms, or high winds of note (at least as far as I know). Then, six weeks ago when I began to head back to Tuscaloosa, I did my pre-flight and everything was normal up until, I did my free and correct. When I tested turning the control wheel to the right, everything was fine, but when I tested to the left, it felt like the control wheel did not go over as far as it normally does. Then I looked back-and-forth to the right and the left aileron and sure enough, the left aileron did not flex upward as much as the right was doing. I asked Tower if I could shut down and get out of the airplane to look at something while in the run-up area, and they agreed. When I got out of the plane and looked at and touched the left aileron, sure enough, it just felt like it wasn't flexing as far as it should. It also didn't feel like it was hitting a stop. It almost felt like it was pressing up against something kind mushy - but not mushy enough to press hard into it and make the aileron travel a little more. A mechanic has removed the control rods and connections to the aileron and without anything connected to the aileron, it will flex up and down without issue (it moves freely). So, it seems that the problem is somewhere in the control linkage between the control wheel and the rods that connect to the aileron. The mechanic also looked at the linkages below the cockpit and did not notice any issue (or see any debris that that might have fallen through the Johnson bar gap). Has anyone ever had anything similar happen? With everything being "hard connected" I can't get my brain around where there might be an issue.

-

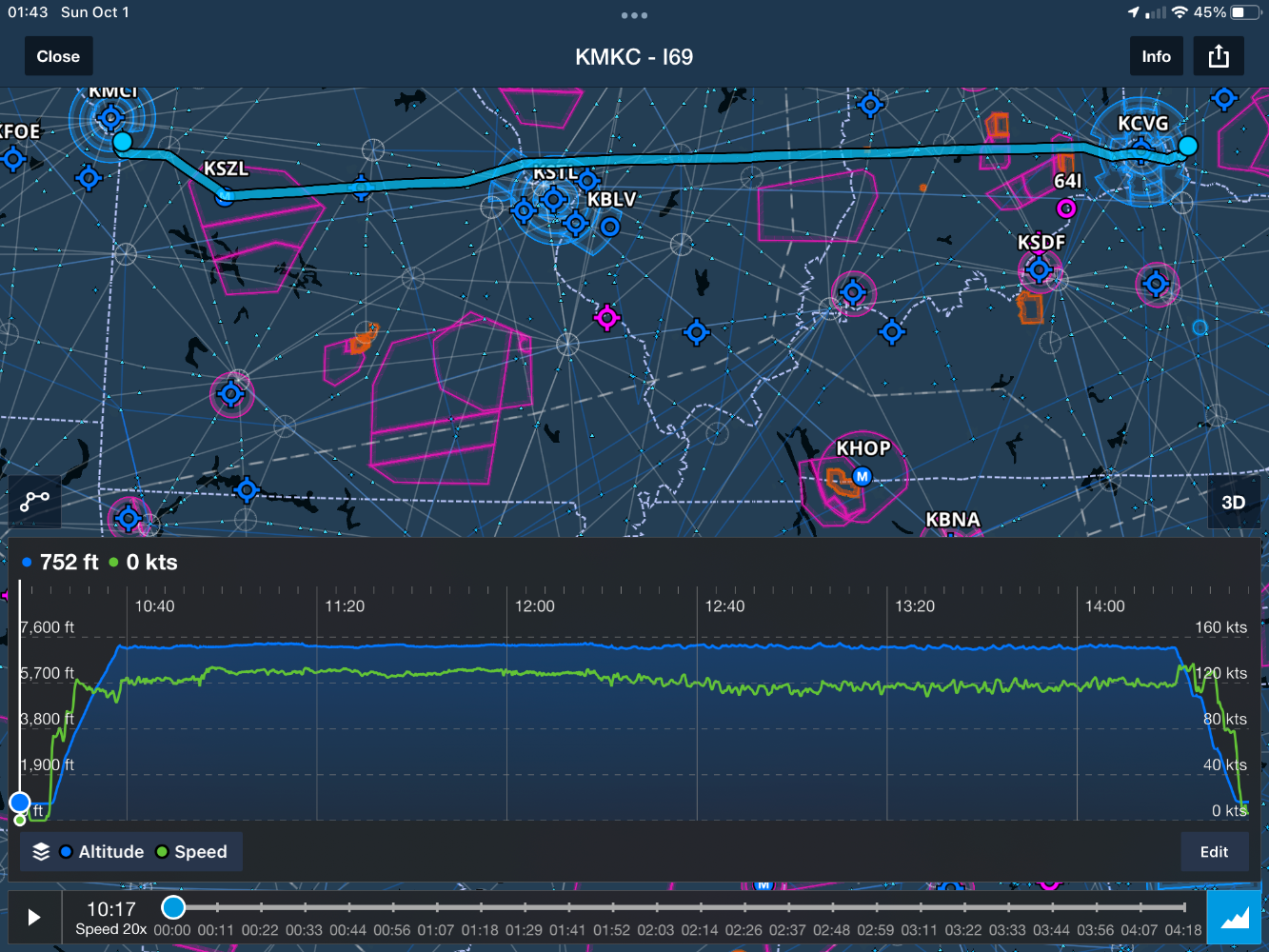

I thought of @0TreeLemur and his posts from a while back where he flew one leg by hand and one leg with a working-well autopilot. Yesterday, I did the same thing, but on a single flight - encouraged by a failed vacuum pump. It is good to see how much better a pilot I am with a working Brittain system.

-

I’m consistently and constantly pleased with the usefulness of IFR - before my ticket this flight would have been legal, but I would have been stressed the whole way about what was really waiting for me at the other end. I’m sure others have noted this… but I’m pretty sure that I smelled something similar to smoke from wood fires as I descended into the haze.

-

Following the transitioning moon westbound in an early morning flight to KC. Butter smooth, very quiet on the radio - no meows on 121.5, weird to get Chicago Center on initial call up instead of Grissom Approach. And nice to discern the ground for my just-in-case needs about 30 minutes before sunrise.

-

I alternate 10 from each tank twice for a total of 40 used. I have a hard rule that I will land - regardless of how much father - before switching “just one last time.” So my 5 hour flights are always LOP at 7.5 gph even though I could probably do it a little quicker ROP and use just a little over 40 gallon.

-

Building on this thread… While flying westbound with a good 15 kt or so headwind, I was flying LOP. So far so good. Then (because I was a little bored) I increased to ROP. I probably need to do the spreadsheet, but it seemed like the relative difference (or extrapolated) increase in IAS was not linear with the increase in GS. My GS increased about 15% greater than IAS. That made me wonder… could the Airspeed indicator be less precise at lower IAS. Sent from my iPad using Tapatalk Pro

-

Have you ever felt like an aerial-Moses? I was pretty darn sure that I was going to need to land short and wait for the storm line to pass over the airport. (Well. I did have to slow down and wait for the storm to pass over the airport (but without landing), but the parting path was nice.)

-

A little bit after I landed at Downtown KC Airport, this Mooney did a touch and go - I had my camera out as the storm behind the airport was pretty cool and lit well... So I grabbed the Mooney too.

-

I usually put the route in Weather Spork app and then (in profile view) use the slider to watch the weather progress through the 3 or 4 day view. My written down IFR minimums (includes icing forecast) are high enough that I can see if it a possibility or not fairly well. I also find that it is possible to fly around many lines of thunderstorms or to land and wait two hours for them to pass over (and grab a nap).

-

Saying hello, just moved near KLUK

211º replied to catchman86's topic in Vintage Mooneys (pre-J models)

Call Jason at Sporty’s (513) 735-9500 extension 2 - east of Cincinnati at Clermont Co. airport (I69) I heard that my old hangar at KLUK is still open. And it fits an E… kind of. DM me if you want details on the Lunken one. -

A little hard to see in this photo, but passing 6.5 years. Having trouble starting now. Going to get a new battery. But also going to test the old battery then put it on a just-also-probably-prematurely-ordered battery minder with declassification. I hope to (for science) do a test after it decalcifies.

-

December has been quite busy and I've not been here for a while. My guess is that anyone who initially posts their plane for sale (without purchasing another one) will have seller's remorse. In short, I'm keeping her - there really isn't a better model of plane out there. Some planes get the grade of A in many categories, but then D's in several others. The M20E is a solid "above average" B (at a minimum) in all categories. Sorry in advance for the quasi bait-and-pull-back.

-

Coming out of an annual... During the annual, I didn't fly for about a month. In the past when the plane was down for a month, I felt like the plane was in some type of lockdown and it was excruciatingly long. This time it was an owner-assisted and the meaty part of the annual was done efficiently and quickly. This time, it was I (and my travel schedule) who took a long time to get everything back in place. The difference between being able to be around the Mooney and to look at things in my own hangar versus her being put away in jail in the mechanic's hangar is so very different. Owner-assisted for the win.

-

And not for any real reason… except if you could define something like this, why not make it seemingly reasonable.”

-

Oh. I was not clear. The engineer in me was hoping and thinking that there would be something like 180 teeth in 360°. (Or at least 150, not 149). Of course, last night as I was falling asleep I was thinking… maybe if this was a straight line and the tops and troughs were averaged over the straight line, it’d be a simpler number. (Not a mechanical engineer)

-

Information that will probably push something useful out of your brain... 149 teeth in 360 deg (M20E IO-360-A1A) 360°/149 teeth or 2.42 deg per tooth I counted 10.5 teeth from TDC to 25º BTDC mark 10.5 x 2.42 = 25.4º