-

Posts

86 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Derrickearly

-

Rough engine in flight

Derrickearly replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

Sounds like I should discuss this with my mechanic. -

Rough engine in flight

Derrickearly replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

Thank you! I didn’t think to look at the egt and cht readings. Now I know what to look for. -

Rough engine in flight

Derrickearly replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

Thank you! I didn’t think to look at the egt and cht readings. Now I know what to look for. -

Just finished leaning to peak at 7000 ft, and the engine started running rough. Similar to 3 of 4 cylinders firing. I reverted to full rich. Turned on the boost pump. Cycled left, right and back to both magnetos. No change. Just started to look for a place to make a precautionary landing, and the roughness cleared. I switched fuel tanks, and continued my flight without a recurrence. Any ideas? I was thinking maybe a bit of water in the fuel. I drained both sumps. The right had a few drops of water, and the left was clear. I was flying on the left when the engine was rough. I also drained the sump in the cockpit during preflight using 5 seconds on both sides. Scratching my head.

-

Great idea! You also confirmed my imbalance concern.

-

Snow was piled up on the left side of the plane including where a blade passes through the cone. I cleared the snow and ice on the outside of the cone with some falling back inside. I thought to inspect inside and found lots more snow. My first thought was to leave it there and let the motor spin it out. Then, I worried about a persistent imbalance. Sorry for the lack of photos. Low light and rushed to finish the job. Had lots of snow to move.

-

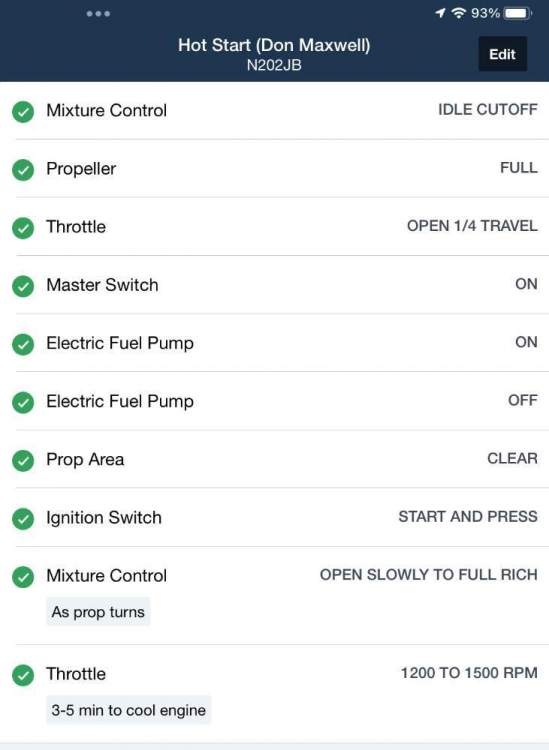

Hot start procedures for IO-360

Derrickearly replied to LeRoy Johnston's topic in Modern Mooney Discussion

-

Did some snow and ice clearing two evenings ago. Found my prop cone was full of snow. Thought to remove the cone to clear, but didn't like the thought of losing hardware. Then, I had the bright idea of pouring warm water into the cone to melt out the snow. Rotating the prop a bit drained all the melted snow and water.

-

Who locks their controls like this?

Derrickearly replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

Sitting in the right seat and securing the left seat belt on the yoke is pretty comfortable. -

I set the trim and flaps to takeoff. I'll pull the yoke all the way back, and apply full power. This is just like a soft field takeoff. I relax the back pressure as soon as the nose wheel lifts. I try to keep the nosewheel just an inch above the runway. Soon after the mains will lift off, I lower the nose a bit to accelerate to 70 or 80 KIAS. This method was taught to me by Chuck McGill out in San Diego when I was getting my 20J type training back in 2015.

-

Who locks their controls like this?

Derrickearly replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

-

Who locks their controls like this?

Derrickearly replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

I'll give these a try. Thank you for the photos and recommendation. -

Slowing down to lower gear

Derrickearly replied to M20 Ogler's topic in Vintage Mooneys (pre-J models)

I do the same. However, the bird I'm flying now has three blades, so when I pull power it slows down really fast. -

The emails from Lycoming technical support were received yesterday. It looks like they were recommending using the rich of peak (ROP) method for leaning to peak for the first cylinder.

-

I received clarification from Lycoming on the above question. "This means that you must be at least 150 degrees on the rich side of peak EGT. For example, you would not want to be at only 125 degrees on the rich side of peak, or you would be excessively lean under the spelled out conditions." I also asked what did they mean by peak EGT for economy. "The first cylinder to reach peak egt would be the correct one. If you were to lean the last one to peak egt then the others would be lean of peak which is not recommended by Lycoming." This goes against the lean of peak folks.

-

Which link please?

-

The manual says for peak power "never lean beyond 150 F". What does that mean? If I'm going for peak power, I would be tempted to use 100 F instead of 150 F ROP.

-

I really like your target egt temp approach! Makes sense.

-

Here is what the Lycoming IO-390-A manual says about leaning during climb. "On engines with manual mixture control, maintain mixture control in “Full Rich” position for rated take-off, climb and maximum cruise powers (above approximately 75%). However, during take-off from high elevation airport or during climb, roughness or loss of power may result from over-richness. In such a case adjust mixture control only enough to obtain smooth operation - not for economy. Observe instruments for temperature rise. Rough operation due to over-rich fuel/air mixture is most likely to be encountered at altitudes above 5,000 feet. Always return the mixture to full rich before increasing power settings."

-

14 C change is equal to 14*1.8 = 25 F change. Unfortunately, 25F is what I have been using for rich of peak based on my old M20F manual. Here is a notional temp plot from the general IO-390 manual. Looking at the plot, I've likely been peaking my cylinder head temperatures. :-( Hopefully, cruising above 8k has kept me out of trouble.

-

I have a IO-390 in my 1976 M20F, and I just found the engine's manual at https://www.lycoming.com/sites/default/files/IO-390-A Op %26 Install Manual 60297-34.pdf. When leaning, I have always used rich of peak by -14C. The engine manual recommends leaning to peak for economy when below 75% power. "Best Economy Cruise (approximately 75% power and below) – Operate at peak EGT". Anyone else run their IO-390 at peak?

-

Does Anyone Land their F or J with No Flaps?

Derrickearly replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

My perception is that I get a better angle of climb for obstacle clearance. Also, I prefer to have more margin against stalling. -

Does Anyone Land their F or J with No Flaps?

Derrickearly replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

Angle of climb (AOC) could be a bit more complicated. AOC = (T-D)/W Drag is proportional to velocity squared, so reducing climb speed could help AOC. Looks like I'll be doing some flight testing once my flaps are fixed.