-

Posts

250 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by jclemens

-

Some of you may or may not know that we recently completed a Garmin Ambassador project with Aviation101. It is a four part series showing what is involved in a full avionics refurbishment from start to finish. I don't think a lot of aircraft owners have any idea on what it takes to complete the gorgeous panels we all drool over. This is a chance to see for yourself. I hope you enjoy it. Big shout out to Garmin Aviation, without their support this project could not have happened. Also, if you feel so inclined click the like and subscribe button and help support the Aviation101 channel. We may be good at avionics, but it was his cameras that captured it all and made it worth watching! https://youtube.com/playlist?list=PLZUu ... yAfHBcJGnm

-

I spoke with the unfortunate owner this morning. We can fix it, the problem is moving it. De-mating the wing to and transporting it will add 20K to the repair cost. I only trust one company to do that and they are as busy as can be, as are we.

-

S-tec 30 autopilot system, brand new in box, complete.

jclemens replied to jclemens's topic in Avionics / Parts Classifieds

This is long gone and all the documentation that went with it. -

Paging Mike Elliott. I highly recommend getting in touch with him and have him do your initial training at my place when you pick this up. I don’t know who the J driver you found is, so I can’t speak to his/her qualifications. But I certainly can Mike’s. This is an intercooled and wastegated 231, a hamfisted Pilot/instructor can destroy it in one flight.

-

It's not a Mooney...But....Check it out!

jclemens replied to jclemens's topic in Avionics/Panel Discussion

Just to be safe,I'll send a couple of my guys over to your hangar to check your pockets.....:) -

It's not a Mooney...But....Check it out!

jclemens replied to jclemens's topic in Avionics/Panel Discussion

-

It's not a Mooney...But....Check it out!

jclemens replied to jclemens's topic in Avionics/Panel Discussion

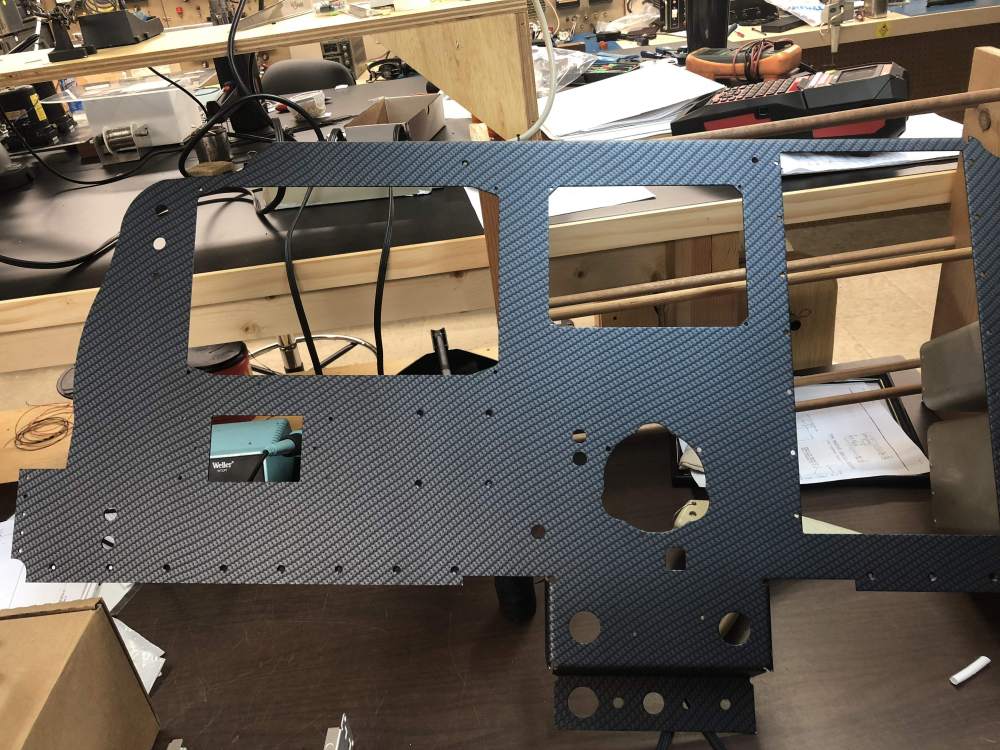

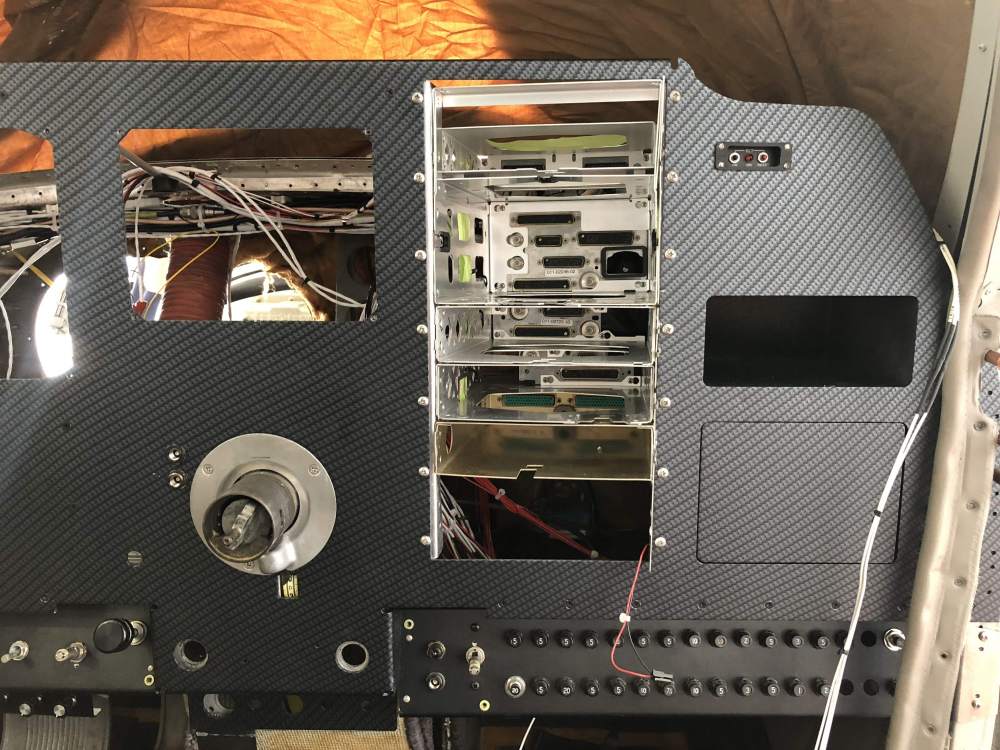

Sorry, here's a copy/paste: We have been working on our company demo aircraft, a highly modified N35, for a bit now. I thought it was about time to post some photos documenting the build. The pre-existing avionics that are staying:Garmin GMA35c Audio PanelGarmin GTN 750 GPS/Nav/ComGarmin GNC255A Nav/ComGarmin GTX345 ADS-B TransponderS-tec 55X AutopilotEverything else is coming out and being replaced by:Garmin G500 Txi 10.6" PFD w/ Synthetic VisionGarmin EIS Txi Dedicated 7" Landscape EIS DisplayMidContinent MD302 SAM for backup instrumentationAll of this is going in a trick new custom instrument panel. The panel started life as a blank from DeShannon Aviation. It was designed and cut in house on our Panel Pro 5925 CNC router built by Buller Enterprises. It is finished in a carbon fiber hydrographic and coated in clear CeraKote ceramic for durability. New reverse engraved circuit breaker and switch panel overlays, as well as placards were also manufactured in house utilizing the Panel Pro 5925.And now for the photos.... -

https://www.beechtalk.com/forums/viewtopic.php?f=21&t=153831

-

Daytona Beach Aircraft Services

jclemens replied to Jim Peace's topic in Miscellaneous Aviation Talk

-

1981 M20J Restored by Daytona Aircraft Services **SOLD**

jclemens replied to jclemens's topic in Aircraft Classifieds

No need to drop the price on this one, it sold a while ago As far as I know, the new owner is pleased with his purchase. -

Manifold pressure gauge on moritze gauge

jclemens replied to JULIUS LEE's topic in Avionics/Panel Discussion

Radiant Power (http://www.radiantpowercorp.com) bought all the intellectual property that entailed Moritz gauges. Last time I contacted them they were either unable or unwilling to repair any of them. The time before that they took one of my customers units in for repair, had it for a very long time, and returned it after failing to repair it. My advice is to ditch it and put in a JPI primary. -

Mooney land article on how to land a Mooney

jclemens replied to Desertdoc75's topic in Vintage Mooneys (pre-J models)

Try letting the prop drive the engine in a C-421 (or any other gear deducted engine) and see how expensive it gets. Most pilot's strive for bigger and better things, learning bad habits that won't harm the plane your in is not good for that goal. -

We have rebuilt several TSIO-360's in the last year, zero issues sourcing parts.

-

1981 M20J Restored by Daytona Aircraft Services **SOLD**

jclemens replied to jclemens's topic in Aircraft Classifieds

Bump -

Umm, I may be slightly biased, but the guys over at Daytona Aircraft Services at KDAB are fantastic! Tell them I sent you.....

-

They are just hand fabricated flat pieces of plastic cut to match the original and drilled to take the original fasteners. I don't have any kind of drawings or anything like that, we just copied the existing panel in plastic. Send me yours and I will make you one and send it back with your original, and you can screw it on.

-

The rocker arm end of the pushrod, and the rocker arm. The roller tappet engines do not have round tappets, hence they don't rotate. They don't rotate, the pushrods don't rotate. These were removed from a first run factory IO-360 roller tappet engine. 7/8 are junk. Dry tappet clearance was way out of spec due to the wear. Engine made TBO though.

- 87 replies

-

- 1

-

-

No, not a common failure. I have seen it happen once in 20+ years, and that was on an engine that had a rod that was not torqued (probably not at all, just hand tight) and it failed immediately after the engine was started for the first time. That was a 520 in a bonanza I had just finished installing, scared the hell out of me when it happened.

-

Torqueing stretch bolts is simple. You torque them to an initial value (38 ft/lbs for the part number I picked as an example), then measure the length of the bolt (standard micrometer) , if it falls within the accepted length range (2.255 -2.256) your done. If it's too short continue torqueing until it falls in that range (max torque 55 ft/lbs). If it's too long already, replace bolt and try again. If it's still too short after hitting max torque, replace bolt and try again. But again, most bolts are not torqued by stretch, just to a value. See SI458G, attached. Every rod Lycoming produces has a service bolt that is a torque bolt, as well as a stretch bolt. Most people opt for the one you don't have to measure... SI1458G Connecting Rod Bolts (1).pdf

-

The bushings that failed the test were OEM Lycoming, they were in factory engines affected by serial number. The others may or may not be, the SB was performed on them because there was no way to tell what bushings were used. All that could be determined is that they were replaced during the affected timeframe. I suspect they were mostly Superior PMA bushings, but again, no way to tell.

-

The tool is not $3700. We have two of them, I want to say they were like $120 each. The large majority or rod bolts are not stretch bolts. Properly torquing the ones that are is not a black art, most head bolts in the automotive industry are of the same type. Have some faith in the A&P community, most of us are not incompetent. We have performed this SB/AD on 8 engines in the last two weeks, there were bushings that failed. The ones that did are scary, they need to be removed from service. This AD is a good thing, it will increase safety. The cost is, well, part of being in aviation, I won't argue about who should be responsible for it. Just know that there is a problem that is being dealt with, and in the end the fleet will be safer.

-

1981 M20J Restored by Daytona Aircraft Services **SOLD**

jclemens replied to jclemens's topic in Aircraft Classifieds

If you think it would help, I can throw in a couple dozen donuts....;) -

1981 M20J Restored by Daytona Aircraft Services **SOLD**

jclemens replied to jclemens's topic in Aircraft Classifieds

I won't ever list another one here unless the rules are changed. Other forums strictly forbid coming into a sales thread and making posts other than asking pertinent questions related to the sale. -

1981 M20J Restored by Daytona Aircraft Services **SOLD**

jclemens replied to jclemens's topic in Aircraft Classifieds

At this price all my previous offers are null and void -

1981 M20J Restored by Daytona Aircraft Services **SOLD**

jclemens replied to jclemens's topic in Aircraft Classifieds

I am dropping the price to $105,000.00 if it doesn't sell in a few I will pull the engine off and overhaul it and put it back on the market for 120K again.