-

Posts

300 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Posts posted by Supercop0184

-

-

13 minutes ago, Sabremech said:

Hi Supercop,

I would need to make another order with the shop for a set for you. You might send AndersJ a message and see if you can contribute still to the drawing fund and the metal testing.

That would allow me to place an order specific for you as the group order is closed and I can’t add to it.

Thank you,David

I’ll get on that - thank you

-

1 hour ago, Sabremech said:

Sabermech I had posted early on about wanting a set but there was so confusion at the point I posted about the moneys needed/ is there a way to get a set at this point?

-

14 minutes ago, MilitaryAV8R said:

If indeed your opportunity has passed I hear that LASAR has them in stock once again. I have not confirmed that, but it would be worth checking out if this opportunity is gone.

Thank you much I sure will

-

Nooooooo so I missed the window? No way to sneak an extra order in?

-

Just now, David Lloyd said:

About $950 for the truss from LASAR, plus shipping and returning your well-oiled old one, plus installation--a couple or 3 hours.

Well it certainly could be worse - lol - I’ve got a call in for them to call me back tomorrow. Thanks

-

Well, looks like I’m in the family of people who get to do this now. I just picked it up from the shop, but admittedly I don’t check this trust nearly as often as I should after I pick it up from places. I have no way to determine who did this. The shop was super nice, and I’m not One to name blame and less I know for sure where the blame lies. I guess I’m looking at about $1000?

-

Vacuum pump problems - AI doesn’t work well when power is pulled in the pattern - It’s erratic - before I threw money at a pump - I decided to hook a gauge up to my pump to see what kind of vacuum I’m getting straight at the pump. Bought a basic gauge at the recommendation of one of my AV gurus - hooked it up and noticed it doesn’t even have the values I’m looking for. Should be between 4.5 and 6.5 vacuum. My suction gauge shows 6 when full power - 5.5 in cruise - but at idle the airplane suction gauge shows nothing!

When hooked up directly to the external vacuum gauge - it shows 20 at idle and up to 24 in HG at 1500 RPM. is my external vacuum gauge missing a decimal point? No way it should be registering 20-24 in HG when the suction gauge in the airplane shows max 6 in HG. Suggestions please. Thanks!

-

On 2/17/2020 at 11:00 AM, gsxrpilot said:

I had about 300 hours in a Cherokee when I got a ride in a Mooney M20C. I've owned Mooneys ever since.

@Supercop0184 showed up on the ramp in San Marcos one day in his Cherokee. I was there fueling my M20C. He was interested and I offered a quick ride in the Mooney. It was a matter of days and his Cherokee was sold and he's been flying a Mooney ever since.

Definitely the truth right here!! And never looked back!!!

-

1

1

-

-

I’ll take a set also one of each!

-

4 hours ago, gsxrpilot said:

I assume you're established in the Hold and now want to go back and attempt the Approach a second time? I would scroll up through the flight plan and select the Fix you'd like to start the approach from. Hit Direct to that Fix. You should be able to then activate the approach and have it fly the approach from that fix.

Yes, you’re exactly right. We actually figured that out, but what I found was by doing that, it would not automatically switch over from GPS to VLOC like it did the first time while making the inbound turn on the procedure turn. However, once you select exit to hold an approach that fix, go in and activate the final leg, it flew correctly down and even went into the missed - Just wanted to make sure I wasn’t missing a better way of doing itJust wanted to make sure I wasn’t missing a better way of doing it

-

1

1

-

-

Let me try to make this as short as possible. My attitude indicator had been dying for about a year, getting noisier and noisier as the time went on. I am getting ready to finish my instrument rating so I said the attitude indicator in for overhaul because it finally started tumbling. Got the attitude indicator back and reinstalled, and flew numerous flights with it. It did great. Then the directional Gyro started to precess way too much, so we removed it and sent it off for overhaul. Got it back and reinstalled. Took the airplane out for a flight today. The directional Gyro worked great, but I found that the attitude indicator seemed to not like doing steep turns or holding turns. The attitude indicator seemed to float more than normal. I can’t really Peg it to a certain power setting, my vacuum is right between 4.5 and 5.5 where it’s always been. The directional Gyro works great. We had six eyes on the vacuum lines as we were reinstalling them, so I don’t know that that’s the problem either. Any ideas? I’m trying to get this puppy instrument worthy for my check ride it’s in a month and a half. LOL thanks for the help

-

1

1

-

-

Reviving a really old thread here - I’m wondering if that SIRS is drilled the same as the whisky compass mount I have In there now that mounts to the center bar.

-

So here’s my issue - VOR / DME RWY 17 approach into F00 airport using ATTER as my IAF. Coming from the SW. use ATTER, do HILPT - come back inbound - 440 automatically switches to VLOC DURING inbound turn. Fly the approach to missed - MAN SEQ Reqd - I’m assuming due to the “climb 2400 then right turn to ATTER via BYP 022 radial and hold” make it into the hold — THIS is where it gets sketchy. Once in the hold - there is no way it seems to re activate the approach without it wanting to do a weird re entry and then another HILPT - there has to be a way to re activate the approach once in the hold - also - what about, while holding - you want to activate a flight plan and approach to your alternate? How would these things best be done?

instrument check ride in a month and a half. Wanna be confident in these areas!

thanks!

!

-

1

1

-

-

If we find some - count me in for one too

-

Great!! Thank you!!!

-

-

I emailed you but didn’t receive a response - are these the reclining type? A friend of mine has a 62 with seats that look like that and they have different degrees of lean back. If so, I’d like them and will figure out a way to come get them.

-

Manifold pressure still available and is it accurate? How much For it?

-

56 minutes ago, HRM said:

When I redid the interior of my E with Bruce Jaeger (Jaeger Aviation 'Spatial Interior'), it was all considered (according to Bruce), owner maintenance. Yes, the headliner 'console' is complicated, but it is just air vents and projector lights (and the never used speaker).

Surprisingly, with all of the stuff that Bruce has done to Mooneys, he is not an A&P/IA. That said, he knows far more than many that do. He showed me quite a few things during the install, particularly places to look for corrosion.

Hey!!! I use my speaker as I’m announcing our descent to passengers and asking the flight attendants to prepare the cabin for arrival to our destination.

-

2

2

-

-

1 minute ago, Andy95W said:

Outstanding!! So all I need to do is log something like

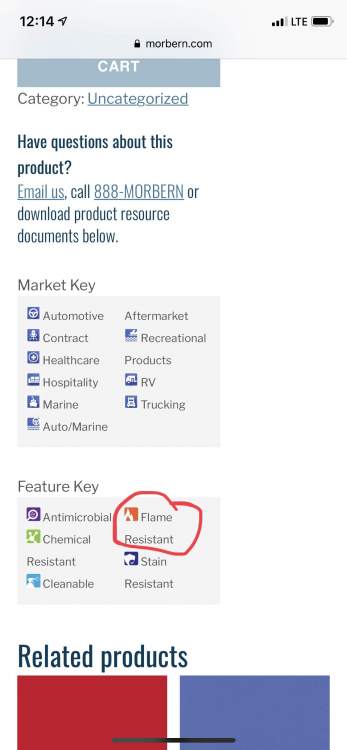

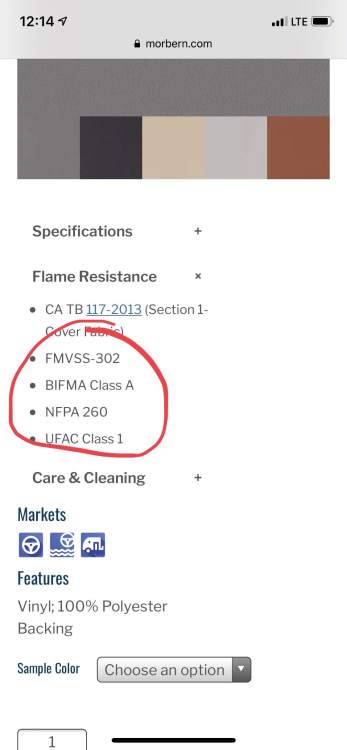

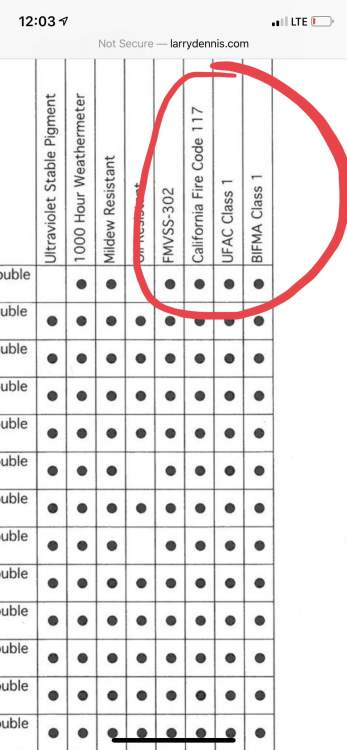

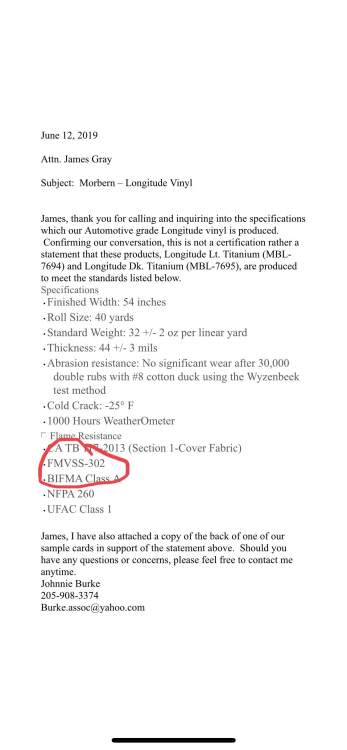

“replaced interior seat coverings, side and rear panel coverings, and headliner in accordance with CAR 3.88 / AC 43.13B using Morbern longtitude light and dark titanium which meets the federal motor vehicles safety standards - 302 and is considered by the manufacturer to be flame resistant. The manufacturers statement will be placed into the airplanes maintenance records and documentation?

-

-

On 5/1/2019 at 8:10 AM, steingar said:

Whats the big deal. The ones in the photo look perfectly readable. Besides, they're on the ceiling. How much time does anyone spend reading stuff on the ceiling?

The big deal is I painted all my trim, which means I painted over the writing. And now I want some labels.

-

On 5/4/2019 at 6:34 PM, Tcraft938 said:

Go to a local sign shop that can make decal signs on a special computer/printer. I just took a picture of mine into them and they made it. After 2 hours drying it looks painted

Fantastic - I’ll try that thanks.

-

On 5/4/2019 at 5:33 PM, dcrogers11 said:

If you're re-doing your headliner, you might consider getting some paint for plastic and repaint your trim. When installing mine, and not painting the trim, it stuck our like a sore thumb. There are some shops in our area that can screen print small stuff like that and looks like factory. Also, don't screw in the back left screw in too far as it will lock up yuur air vent mechanism. Don't ask me how I know.

Don

Yessir - I’ve already painted my trim - which of course covered up the old markings for the vent and light. Now I just gotta get me some labels for those

Looking for a up lock and down lock block for CNC owner produced

in Vintage Mooneys (pre-J models)

Posted

I’d like a set too