-

Posts

1,449 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by cnoe

-

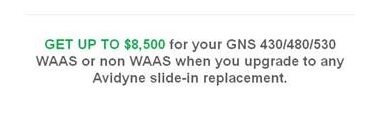

Nope, no fine print. After expressing my displeasure and requesting further explanation I was told that if I'd trade my unit in on a IDF550 they would give me $8,500, but that's NOT what the emailed offer stated. It said quite plainly "...when you upgrade to any Avidyne slide-in replacement". That's a crappy way to do business IMO.

-

Interestingly, the J's service manual originally stated "Use a yoke-frame jack under the propeller to lift the nose."

-

After viewing much discussion here I was swayed that the engine-hoist ring may impart too much stress on the aluminum engine case. The hoist ring was designed to lift the "engine" only, not a ~2,000# airplane. I believe a soft harness around the engine mount is preferred by many if using a hoist.

-

Yeah, everybody's gotta make a buck; I've been in sales for over a quarter-century myself. But it irks me a bit when Avidyne sends me THIS in an email in December: ... then when I inquire about my pristine, recently-overhauled GNS530W I'm told... "On your Garmin 530W, you can get $7,000 on the trade in." WTF? If that's not bait-and-switch I don't know what is! Sure, I'd like to have the IFD540 (maybe not as much as a GTN750???) but with the $6,450 I saved by keeping my trusty 530W I can almost buy the new GFC500 Autopilot System that's coming out! That seems like a better upgrade to me, and my budget won't allow me to do everything at once.

-

An 80# bag of high strength concrete mix yields approximately 0.6 cu. ft. of volume, which is approximately 13.5 gallons. I shouldn't have to say this but... be sure to add some rebar or other reinforcing steel into the mix. Also, make sure that your attachment hardware is appropriately attached to the embedded reinforcing steel. Lastly, also note that even 3 bags (240#) wouldn't be enough weight on any Mooney other than a 4-banger. And with that much (engine) weight on the nose I would seriously consider using a hoist up front as noted above.

-

You are correct, but it is still very common to see even reputable shops lift a Mooney with under-wing jacks and an appropriate tail-weight. This has been discussed extensively on MS and I am not making personal recommendations for the OP or anybody else to jack up their plane this way. He asked about jack construction and I felt obligated to mention the necessity of a tail-weight. I should have also mentioned the option of using a hoist on the forward frame too. I would advise against using the hoisting ring on the engine though. Absolutely Clarence; I agree that anything fabricated should be up to the task and of adequate structural integrity. Many of the MSers are likely capable of constructing something satisfactory while some are likely not. My comments about sacks of concrete were meant to describe a necessary weight and I apologize for giving anyone the idea that raw sacks of concrete should be employed. Still, concrete is an excellent source of mass for constructing a real tail-weight (if done properly with rebar and properly mounted hardware). If any of you are going to do this, DO IT RIGHT or know the risk you take. Even though my bases are constructed out of 3/4" plywood I find it more stable than some of the 3-leg versions I've seen. YMMV.

-

I've had some positive experiences with Avidyne over the past few years, and Chase with Avionics Source has been very positive in our discussions... ... BUT... These marketing emails I get from Avidyne seem disingenuous at best. Today's email reads "Avidyne will accept the trade of your old (and soon to be unsupported) GNS navigators ...". The only time I discussed a trade-in with them directly it seemed more like a bait-and-switch since I was told that my one-month-since-factory-overhaul GNS530W was worth a LOT less in trade-in than the current Ebay selling price. It wasn't a good deal and I didn't appreciate the attempted low-ball offer. So if you're inclined to do some dealing on an Avidyne upgrade I'd definitely talk to Chase instead of directly to the manufacturer. And though my trusty old (newly-rebuilt) GNS isn't the newest technology it still has great functionality and value. I also don't believe that Garmin is going to abandon the WAAS versions anytime soon either. If somebody has placed a bug in the Garmin boardroom and knows differently I'd love to hear about it though.

-

And don't forget you're going to need a tail-weight as well. I'd suggest at least 200#. 3 bags of concrete (240#) would be better. 160# is dicey at best.

-

What he said! And while you’re at HF pick up a big step bit to drill out the top of the ram to more securely accommodate your jack points. There are lots of examples of how to DIY online; search around. Mine are based on a 2’ square of 3/4” plywood, 4 support legs made from EMT conduit, and a large muffler clamp that secures the supports to the top of the jack. Works great and is rock solid. Sorry I don’t have a pic right now. https://www.harborfreight.com/3-ton-heavy-duty-long-ram-hydraulic-flat-bottom-jack-60393.html Sent from my iPad using Tapatalk

-

25 hours a year isn’t much time. Definitely take a close look at all the tappets and lobes since the jugs are already off. But being from the mid-90s you may have dodged a bullet and missed out on the Lycoming spalling epidemic.[emoji1360] Sent from my iPad using Tapatalk

-

Sabremech Cowling Mod Testing (Ongoing)

cnoe replied to Guitarmaster's topic in Vintage Mooneys (pre-J models)

It’s of no importance but minor interest that JPI recommends placing EGT probes 2”-4” from the exhaust ports, EI suggests 1.5”, and Insight says 2”-3”. I vaguely recall installing mine at 2.5” or 2.75” and my hottest cylinder peaks at ~1,510 F. Sent from my iPad using Tapatalk -

In one of the original threads about Dan’s misadventure there was considerable discussion about mounting options. A site search should turn up the answer and pics you seek. Many of us have it velcro’d low on the center pedestal, some on the panel, and at least one overhead near the speaker. The audible alarm is very weak (my only criticism of the Sensorcon) so it should be placed somewhere you can scan if not near your ears. Sent from my iPad using Tapatalk

-

The Century trim switch from that era has a stack of 3 microswitches under the yoke button that control its operation. That’s where my similar electric trim issues resided. It’s not an easy repair but following switch replacement I haven’t had a problem in 3 years now. Sent from my iPad using Tapatalk

-

Here you go. I’m not sure Lycoming handled this matter so well for all concerned. The advisory came out in mid-2015. Sent from my iPad using Tapatalk

-

Trim/Flap indicator in a ‘78 J. Sent from my iPad using Tapatalk

-

It’s disappointing how the celebration of my shiny spinner devolved into a discussion about Jose’s leaky pointer.[emoji51] LOL! Sent from my iPad using Tapatalk

-

Does Camshaft failure affect Crankshaft?

cnoe replied to cctsurf's topic in Vintage Mooneys (pre-J models)

Lycoming may not be saying it Mike but plenty of others are (including me). Here’s a pic of the 4 (previously new Lycoming) intake tappets from my less-than 800 hour engine. This engine was flown weekly, 150 hours/yr for the previous 4 years, though the prior owner only managed 40/yr for the 5 before that. I’m hoping the new DLC-coated steel tappets, frequent flying, Camguard, and my engine dehydrator get me well past the 2000 hour mark now. Like [mention=6924]KSMooniac[/mention] my previously unturned crank was fine having caught the warning signs early through a rise in Fe (iron) on a routine oil analysis. I had the case split within about 50 hours and 3 more oil changes/inspections. Being in south Texas I wasn’t too worried about bypassing the filter with a cold start but once the filter started showing obvious “visible” metal the engine came off. Sent from my iPad using Tapatalk -

Does Camshaft failure affect Crankshaft?

cnoe replied to cctsurf's topic in Vintage Mooneys (pre-J models)

Paul is right; pulling the jugs tells you nothing about the crank. But neglecting to inspect the cam and tappets while the jugs are off borders on negligence (on a Lycoming 360) since cam/tappet spalling seems to be an epidemic. Oil travels from the sump through the suction screen, the pump, and then the filter. With a cold start or plugged filter the oil will bypass and carry metal into the crank bearings. It’s a crapshoot, but if your crank hasn’t been turned too much already it can likely be reused (after turning, or not if you’re lucky). It’s very helpful to know what your current crank specs are (as noted above). A good indicator of contamination is to pull your prop governor and check for metal on its screen. Metal there means your filter has bypassed. Too much metal in the sump may cause damage to your cylinders and pistons from splash lubrication erosion. Oil analysis should put you on alert. Significant metal in the filter means repairs are in order. Sent from my iPad using Tapatalk -

Yep, that’s the stuff! Add the 1st step (deoxidizer) and you won’t be disappointed! Highly recommended on various aviation forums. Available on Amazon among other places: https://www.amazon.com/Purple-Metal-Polish-deoxidizer-Combo/dp/B005WWMP86/ref=sr_1_1?ie=UTF8&qid=1520395031&sr=8-1&keywords=california+custom+polish Sent from my iPad using Tapatalk

-

4’ 9”. In heels. Sent from my iPad using Tapatalk

-

Happiness is a freshly-polished spinner.[emoji16] Sent from my iPad using Tapatalk

-

Yes, that information is hard to find on the JP I website. In my application I can program 10 data fields on the right side. Sent from my iPad using Tapatalk

-

You’re welcome. Sent from my iPad using Tapatalk

-

This is what I went with for orientation. I like having it close by. Pay no attention to my groundspeed as I was facing a pretty good headwind from 30 degrees left on this approach.[emoji846] Sent from my iPad using Tapatalk

-

The probe on my J w/IO360 going to a JPI830 is 1/8” NPT. It screws into the galley port on the top front of the engine. Sent from my iPad using Tapatalk