-

Posts

5,715 -

Joined

-

Last visited

-

Days Won

24

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Andy95W

-

M20 Hydraulic Pump Flap Diagram

Andy95W replied to Nukemzzz's topic in Vintage Mooneys (pre-J models)

That POH was for 1962-1965. My first Mooney was a 1967 M20C, and it was also 4 and 1/2 (actually mine's probably closer to 4 1/4 pumps). The handle does stick out some at full flaps on landing, and when it hydrolocks it feels like it hits a physical stop. Maybe the extra half accounts for a little air in the system, and you were better at bleeding it out. I bet they changed the POH because too many people were complaining that they weren't getting full flap extension when they actually were. It was cheaper to change the POH than determine why individual airplanes differed! -

M20 Hydraulic Pump Flap Diagram

Andy95W replied to Nukemzzz's topic in Vintage Mooneys (pre-J models)

That's strange- I've had 2 different Mooneys with hydraulic flaps, they both required 4 and 1/2 pumps- which matches the Owner's Manual. -

I recommend calling up these folks: https://www.seatfoam.com/index.html They're a husband and wife who've been selling Confor-foam for a very long time, and have been exhibitors at Oshkosh for decades. Two of the nicest people you've ever met! They will be able to give very good recommendations when you describe your project. They know their stuff. They have three different foam densities that go from firm to soft. Don't go too much by their website, they're older folks who still prefer old-school methods like talking on the phone or in person. Good luck- post pictures!

-

Actually, Cliffy and I are talking about legally installing it as a minor alteration, which would only require an A&P's logbook entry. Adding lights such as these would not fall under the definition of a major alteration, since they would only be supplemental to the factory installed lighting. The issues: - the lights couldn't just be some POS auto store junk. I'd expect them to be manufactured under some sort of nationally recognized standard, and would prefer they be actual aircraft lights. If they fried themselves inflight- right next to your fuel tanks- you couldn't just pull over and un-ass your vehicle like you would your car. - mounting would have to be secure and absolutely, positively, not interfere with any existing system on the airplane or have the potential for disrupting aerodynamics. The most logical place would be the flat plate above the shock discs, and most secure would be to simply drill mounting holes into that plate. The issues then would be determining whether that plate is structural and whether it interfered with gear retraction. The easiest way to determine structural impact would be to ask the factory, but I'll bet they wouldn't answer the question even if you could find someone working there. - electrically, the installation is simple. Give it a dedicated switch and circuit breaker, and conduct a load analysis of the electrical system, just like you would with any installed electrical equipment. Use aircraft quality components and wiring and install it in accordance with AC43-13- just like anything else.

-

Cliffy, I completely agree that it would be a minor alteration. So long as the factory installed landing light was operational, this would just be "supplemental" lighting. I think the difficulty would be mounting them in a manner that would ensure security and positively not interfere with landing gear operation. Other than that everything else is pretty simple AC 43-13 stuff.

-

M20 Hydraulic Pump Flap Diagram

Andy95W replied to Nukemzzz's topic in Vintage Mooneys (pre-J models)

Well, maybe not necessarily rude, but a little sarcastic... twice... But my message to Nuke: Ross (Shadrach) is one of the 3 most knowledgeable guys on this site when it comes to hydraulic flaps. He's a really good person to listen to about them. And with that said- I've disassembled and repaired 3 hydraulic flap actuators. 2 of them actually needed it. I understand the system pretty well. And I still found your schematic sketch helpful in understanding the system better. -

As a former Infantryman, I agree!

-

That there’s funny as hell!

-

W&B fun...math's not for everyone (including me).

Andy95W replied to Ross Taylor's topic in General Mooney Talk

The "classic" Mooneys did not include engine oil in the empty weight. At some point, probably about the time the FAA started requiring a true POH instead of the old Owners Manual, they also started requiring engine oil as part of the empty weight. I would assume @Bob - S50 M20J would fall into that category, but not sure. -

M20 Hydraulic Pump Flap Diagram

Andy95W replied to Nukemzzz's topic in Vintage Mooneys (pre-J models)

Nuke, thanks for taking the time to make the diagram and post it here. Very helpful! -

Alex's M20D (continuous thread)

Andy95W replied to Raptor05121's topic in Vintage Mooneys (pre-J models)

But even if you do sell it, please keep all of us here at MooneySpace updated on your career as it progresses! -

You don't have to announce that you'll PM him, you can just do it. But if you did that, you couldn't show that you have information that you're not willing to share with the whole group. Pretty childish, but typical of your behavior over the past few weeks after you got your feelings hurt by people trying to help you. You've shown that you have absolutely nothing worthwhile to contribute here. So in 7 years, you are now the first- and only- person I've ever blocked on MooneySpace. Please do the same for me.

-

You could petition the FAA to change the rule, but I fear you would open yourself up to all kinds of unwanted attention from them...

-

And it'll have a TBO of 400 hours.

-

Can you imagine trying to use that thing in IMC in a Corsair at 400 mph? I think I'd be upside down and backwards in short order.

-

Manual Gear Rigging Annual Time

Andy95W replied to Tcraft938's topic in Vintage Mooneys (pre-J models)

Perfect, thanks for the update. Sounds like you have a good mechanic. I'm hoping the other 3 A&Ps were watching, listening, and learning. -

Pre-65 C model fuel system schematic

Andy95W replied to ragedracer1977's topic in Vintage Mooneys (pre-J models)

-

Manual Gear Rigging Annual Time

Andy95W replied to Tcraft938's topic in Vintage Mooneys (pre-J models)

I'd do it and stop worrying I was going to break my truss welds on rough strips. -

High CHT, 470 degrees +.

Andy95W replied to ragedracer1977's topic in Vintage Mooneys (pre-J models)

Full throttle gives a slight enrichment to the mixture due to the "economizer" function of the carburetor. Usually doesn't decrease temps much (if at all) due to higher power output = more heat. Probably a dumb question- what airspeed do you climb at? Our airplanes climb at a comparable feet per minute whether at 120-125 or at 100 mph. -

The problem is that the cowling is fixed, the engine is not- and it wobbles a lot on start up. It would be a shame to ruin either the cowling aluminum or the carb air box ($$$) because this owner produced part was too stiff. The biggest issue with the accordion design is the wire stiffener that will cut through the rubber fairly rapidly. The steel then rusts which just makes it worse. The question I would have for @GEE-BEE is whether or not the wire is even needed to avoid crushing caused by engine suction through the intake duct. The unsupported distance is 2" or less. EDIT- well, maybe 2-3" distance

-

Tail Art Thread (Mooney Aircraft only please)

Andy95W replied to 0TreeLemur's topic in General Mooney Talk

I’m not sure if Fred has been around long enough to know about Marauder's girls. At least it meets his criteria for Mooney Aircraft Only tail art. -

Tail Art Thread (Mooney Aircraft only please)

Andy95W replied to 0TreeLemur's topic in General Mooney Talk

Richard- you can always try this guy. He did my logos and owns an old M20C. http://www.aircraftstickers.com/ -

High CHT, 470 degrees +.

Andy95W replied to ragedracer1977's topic in Vintage Mooneys (pre-J models)

Well, dang. Wish I could’ve been more help. -

High CHT, 470 degrees +.

Andy95W replied to ragedracer1977's topic in Vintage Mooneys (pre-J models)

Your baffling really does look pretty good. If you'd like, here are two ideas to seal up in front of #2 a little better. -

High CHT, 470 degrees +.

Andy95W replied to ragedracer1977's topic in Vintage Mooneys (pre-J models)

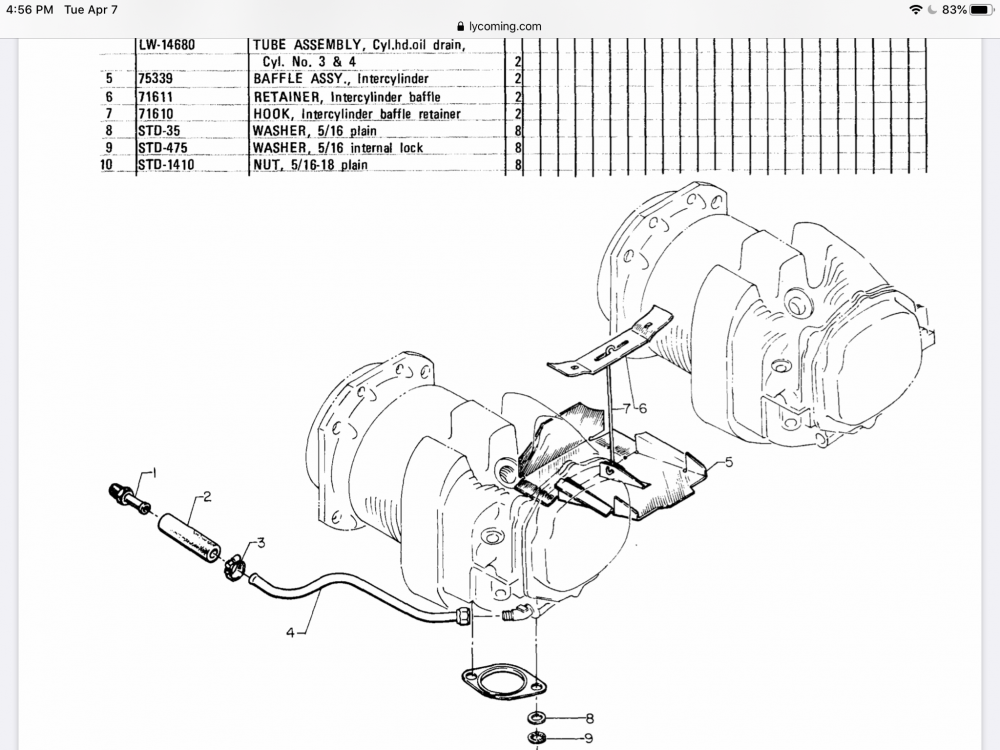

Looks good, Brice, but it looks like you might be missing the inter-cylinder baffling between your #2 and #4 cylinders. It's difficult to tell based on your photo looking down. The photo below shows a different Lycoming engine, from underneath the cylinder. The O-360 baffle is smaller. EDIT- this is the parts manual for the O-360. Ours are quite a bit smaller.