Leaderboard

Popular Content

Showing content with the highest reputation since 04/11/2024 in all areas

-

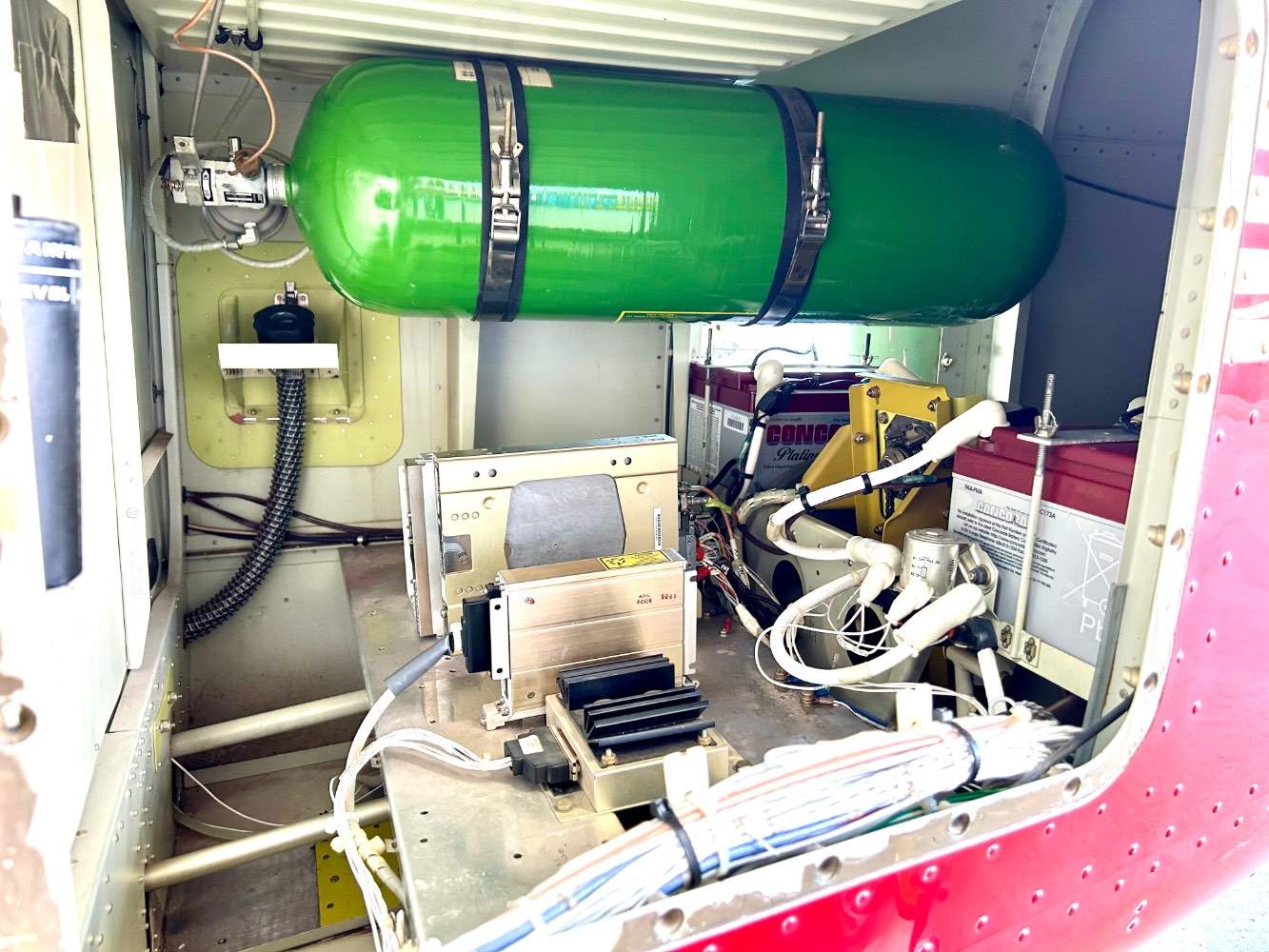

The Story: I bought an Ovation last October that needed some attention. My son and I are going to travel in it and he is building time for a flying career. It had a new and very nice glass panel in it but everything else was well used. The airplane flew about 35 hours in the last 5 years. The paint was very oxidized, carpet old and dirty worn through and the seats looked like a frat house couch. Both wings had fuel leaks. It had been well maintained but it was tired when i bought it. I used the Winter months from then until now to refurbish the airplane. I tackled a bit more than i wanted to but my thinking was to fix everything now and fly it versus fly-it-and-fix-it etc….. So, this is what we did: Firewall forward is all new. Every line, hose and connector. Factory new IO-550. New engine isolators. Stripped and painted the engine baffles. Prop Governor Overhaul Prop Overhaul to include new internals. Compete external light conversion to Whelen (WATT) LED’s. New wingtip and taxi/ landing light lenses. New tires and tubes. New batteries (2) New O2 bottle and fill. Polished the spinner and took the dents out. 18 hours with a buffer and ceramic wax to bring the paint back to life. Complete fuel tank seal scheduled for this year. New Interior. (I started with the just carpet but I had to take the seat out to take out the carpet………and one thing led to another and i just took everything out). I also removed most of the old adhesive, cleaned every inch of the inside and added insulation and sound proofing to the interior. FIRST FLIGHT: Accomplished the first flight and first two hours of engine break-in yesterday. The new engine and prop are powerful and smooth. Everything else mostly worked as advertised. After the first hour I landed. We took the cowlings off to inspect. No leaks. We adjusted the prop governor for full take-off thrust and the gear warning horn on the throttle cable. We flew another hour and I got two more landings in since it had been awhile in GA for me. I would have added 4 more hours to the break-in except i was limited to lower altitudes and high power settings for the break-in and it was VERY windy. TAS was 176-178 on 24/24 at 3500” so I am guessing 180-185 higher. It was a rough ride. I have a fuel pump that needs overhauled so that is going out. I also have a small box in the avionics bay that controls glareshield and panel lighting that needs overhauled. Maybe one EGT probe as well. Otherwise, for the amount of work we did on the airplane……everything went well.9 points

-

I was playing my daily crossword puzzle and it occurred to me if you rearrange the letters in Mooney C you get economy.7 points

-

Hello Mooney world. When the time comes to seal or repair your wing fuel tanks I highly recommend working with Edison and Wet-Wingologist East (KFXE) as the THE place to receive high value for your investment and excellent results! My previous PIREP was after Edison resealed the tanks in both wings in March 2016 for my 1990 J Model. In that PIREP I recounted my high satisfaction with the value delivered and results achieved. This update covers my recent warranty leak repair experience, 8 years later, during which Edison worked my airplane into his rather full schedule on a Saturday morning, charged me nothing the, and had the airplane ready for pickup by Sunday. If you prefer short PIREPS, you can stop reading now. Otherwise, below are additional details in the spirit of contributing to the knowledge of the Mooney community. After the initial, reseal the right wing periodically (and inconsistently) developed minor seeps in 2016 and 2019 in the same outboard tank area that would not last and I could not find the conditions to replicate them. In each case after discussions with Edison, I decided to postpone taking the airplane to him and continue to monitor instead. Edison was always ready to schedule the in-warranty repair without question. There were no signs of leaks between 2019 and late 2023. During the November 2023 Annual Inspection, my A&P/IA found signs of a small leak at the bottom of the outer right wing fuel tank, none evident on the outer wing skin, and we could not determine for certain if it was old or fresh. I called Edison, who suggested letting the airplane sit in the hangar with the right wing filled to where it could take no more fuel. After a flight that started with full tanks and included left/right steep turns and maneuvering flight, I topped of the tanks as suggested. After a few hours in the hangar with the right tank completely full the leak was evident in the area my A&P/IA found. Edison thought a sealant bubble at the top of the outer tank had broken and was allowing the fuel to leak when the tanks were left sitting and completely full, and that it would require a small repair. I confirmed this by draining fuel to where the fuel level was 1-2 inches below the fuel cap, and the tank did not leak after a day of monitoring. Following discussions with Edison, and setting a date for the repair, he called me back a few days later to explain the leak could also be coming from the fuel sensor gasket located on the vertical outer wall of the outermost tank. Before taking the airplane down several days for repairs, and the added cost of the trip to/from KFXE, Edison recommended that my A&P/IA replace the sensor gasket and check again. After replacing the gasket and topping the tank, the leak returned after a few hours. At this point I decided with Edison it was time for a repair, and we agreed on an earlier date than planned provided I could get the airplane to him the next Saturday morning. I flew to KFSE early Saturday morning and taxied the airplane directly to Edison's shop; Edison started work immediately; the airplane was ready on Sunday, 8 years after the initial reseal; Banyan Air Services towed it to their ramp late Sunday; and I picked up the airplane on Tuesday 4/9/24. My assessment is that the source of the inconsistent seeps in 2016 and 2019 was the same repaired by Edison in 2023, with the fuel just finding its way out to the bottom wing skin by the path of least resistance. Finally, fuel is expensive at KFXE, but Banyan gives a discount to Edison's customers, so I added the 10 gal minimum they require to wave some of the ramp fees, and flew the airplane home early Tuesday afternoon. The folks at Banyan were a pleasure to work with. With dry wings and in great appreciation of Edison at Wet-Wingologist.... Hank5 points

-

Just to update those who haven't checked, but the dates (from the website) are September 27th and 28th. My wife and I plan on arriving on the evening of the 26th so we don't miss the first half of the event like last year. Registration is open! -R4 points

-

I flew my F model today for the first time since annual was completed last month. My plan was to do a timed climb to 10k and gather speed data. It was 81° so I opened the vent in climb. To my surprise, I was blasted with high heat. It was like running a heat gun in the cockpit. I closed the center vent, but by 4500’ the heat radiating from the duct itself caused me to RTB. On the ground I started trouble shooting. It turns out, the cable mount was disturbed while reclocking the prop governor. This prevented the internal flapper valve from fully seating in either the open or closed position. A simple repositioning of the Adel clamp holding the cable rectified the situation. Those of you with heater issues would do well to simply ensure that the valve is moving over its full range of travel. As you can see the heater box and the seal are in fine condition even at 57 years old. The seal material look like table tennis racket rubber. Heat on heat off Adel clamp after repositioning.4 points

-

Posting a little late, but here’s a little write up from the trip to Arkansas to meet up with @0TreeLemur to watch the eclipse… https://wordsaloft.substack.com/p/flying-far-for-four-magical-minutes Hats off to Fred for picking the winning destination. Clear skies, ramp space, and a fresh grilled lunch courtesy of the local maintenance shop.4 points

-

Figured I would dust off the cobwebs on this thread. Still own the old girl. Many avionics updates, fuel tank reseals and everything in between. 380 hours logged now since this thread started. The biggest question everyone was always worried about and asking….”is it still the same original engine? Yes. Top end was overhauled as a precaution a few years ago. However, No metal. And SOAP sheets are looking good still to their day. Flew her into Sun N Fun this past week for the first time. What a great product we all have and get to play with! #teammooney Will post some before and current pics of the panel. Thanks for following along. before: After:4 points

-

We've flown into the SLC area a lot over the past 7 years. I haven't gone into KSLC but have heard they are GA friendly. Depending on which family we are visiting determines where we fly into. In the Salt Lake Valley, South Valley Regional (U42) is the easiest. It can be busy but everyone seems to make good traffic calls and you can coordinate for a rental car to be there waiting. I think the overnight is around $10. The fuel is the same price if you pump it yourself or have the truck do it so we just let them fill it up. There isn't much space under the Bravo, the shelf is just above TPA but it is doable. Looking at my logs we have been there 15 times and it is my preferred airport for the Salt Lake area. You can easily get an Uber if you don't want to rent a car. If you are coming from the south stay over the 15 freeway going past the point of the mountain. It will keep you away from the restricted area over Camp Williams and away from the paragliders and powered gliders that are directly above the point. We've been into KOGD as well because it's 5 minutes from our family up that way. It is convenient if you are going to stay in Ogden, but the drive to Salt Lake is not as good as going from U42. Skypark (KBTF) is just north of KSLC, we've been there once. It's a friendly little airport but is very tight to the Bravo surface. Provo KPVU is great, they have Go Rental on sight, but they are more expensive than going into U42. We use it if we are just going to be visiting family down there but I would not use it if you are going to Salt Lake. It might not look like a drive but the traffic at the point of the mountain can be a mess. Not CA traffic mess but still a pain. It's only about 10 more minutes of flying to get to U42 and saves you 45+ minutes of driving.4 points

-

We disassembled mine in January of 2020 and had it in the air by July. My case was fretted and no longer airworthy so I jumped on the refurbished case from Divco. I was fortunate to get all of the parts before the major supply chain disruption, including the new camshaft and DLC lifters. Cylinders, gears, rods, pistons, and everything else were serviceable. I removed the engine and but nothing in the field overhaul and engine assembly itself, but I did the entire installation by myself with oversight and sign-off. I learned a ton about my airplane, and I cannot place a value on what I learned. All in, it was around 25K.... with a lot of sweat equity. Since then we have made multiple long haul trips including my eclipse trip with a stop in Destin FL. This is my longest adventure, over 2,500 NM round trip.4 points

-

I have seen this airplane in stages of completion and it is a “better than new” Ovation in every possible way. With Steven’s attention to detail and Brian’s workmanship you will not find a better Ovation on the planet. You couldn’t come close to duplicating it for the asking price.4 points

-

Time for me to move on from Ovation ownership to the next chapter. Cockpit and exterior pics are shown before the below list below was completed. More up-to-date pics as soon as I receive them. Aircraft is presently in San Marcos, TX while this work is being completed. ETA to complete is roughly 2-3 weeks. PM me to discuss. Price negotiable. -Steve N21625 (1999/2000) Full Specification Sheet - Offered at $359,500 ENGINE/PROP No damage history – No corrosion – Hangared – One previous owner 1296 TTAF – Complete logs since new Engine – 8 hours since factory new (test/break-in runs only) 310HP Continental IO550-N8B, 2700RPM 2200-hour TBO Iridium fine wire spark plugs installed Prop governor overhauled to new specs New 20A backup alternator New exhaust system (muffler proactively rebuilt by Acorn) New Mooney factory metal baffles New Mooney factory silicone baffle seals Real Gasket Corporation rocker cover gaskets to replace Continental factory gaskets Prop – Hartzell PHC-J3YF-1RF /F7498 (Acclaim Type-S prop STC) Inspected, lubricated & re-sealed by Jordon Propeller 3/2024 AVIONICS 5. Garmin G3X Touch with synthetic vision Garmin GTN 750xi WAAS with GA 36 antenna (2nd GA 36 antenna installed, and cockpit cabled for future GTN 650Xi installation) Garmin GFC 500 autopilot (3-servo installation) Garmin G5 backup ADI Garmin GDL 69 XM weather + dedicated antenna Garmin GMA 35 audio panel Garmin GSB 15 dual USB chargers – 3.0A ports (qty. 4 – 2 in the front, 2 behind rear seats) Garmin GTX 345 panel-mount transponder Mode-S Extended Squitter (ES) ADSB In/Out TIS traffic L3 WX500 Stormscope JPI EDM930 engine monitor CIES digital fuel senders Artex ME406 ELT (antenna relocated to embedded position under vertical stabilizer) Bose/LEMO plugs at all four seat locations AIRFRAME TKS known ice-equipped (windscreen, prop, heated stall warn, ice light, 20A standby alternator) PreciseFlight speed brakes 102-gal certified usable fuel New 51-USG filler necks installed + cockpit fuel selector placard All Whelen (WAT) LED lighting: OR650E wingtip white anti-collision + NAV (ACL synced with “b.”) OR500 tail white anti-collision + position (ACL synced with “a.”) Model #908525D lower red anti-collision beacon Parmetheus Gen3 landing lights Model #78013 baggage light A508-24 wingtip trailing-edge lights Reiff TurboXP full engine heater + oil cooler heater strip option 115cf Scott 4-place oxygen system – current Kevlar bottle good for 10+ years (15-year life) Two Concorde RG24-15M batteries (#1 new in 3/2024) Landing Gear no-back spring replaced (3/2024) New Michelin tires and Airstop tubes (3/2024) New static wicks (3/2024) New landing gear shock discs (1/2024) New brake linings (1/2024) SafeFlight Stall Warning tab replaced with factory-new (3/2024) Medeco high-security locks on both main and baggage doors New GLAP wing landing and taxi light lenses installed (3/2024) Fuel cap O-rings replaced with blue fluorosilicone (replace on-condition) Paint 7/10, Interior 8.5/10 Useful Load – 1007 lbs. Fresh annual signed off by Brian Kendrick – 4/2024 Fresh 91.411 / 91.413 certs completed – 4/2024 ADDITIONAL CATCH-UP MX AND WORK PERFORMED BY BRIAN KENDRICK RECENTLY CB panel removed and electrical systems inspected Two breakers replaced with new All CB collars reinstalled to correct CBs Emergency buss operation adjusted to confirm correct operation GEAR DOWN light intensity adjusted to display correctly with all-LED lighting installation (previously an issue with nearly all Mooney aircraft having a combination of LED/non-LED lighting installed) New, tougher XPDR IDENT switch installed Low boost pump FF set to between 7 – 9 GPH Brakes down bled and reservoir refilled All charlie weights removed New paper induction air filter installed (3/2024) Added 1GPH to takeoff fuel flow Replaced oxygen control inner cable Relocated StormScope antenna to proper location at belly of aircraft Landing gear rigged and preloads set appropriately3 points

-

There is a little chain that connects to the trim wheel. The chain can pop off if it isn’t properly lubricated, and when it pops off the wheel will spin freely. Definitely talk to an A&P because you’ll want to rule out a need to lubricate the trim jackscrew. But this might be a 5-minute fix.3 points

-

Y’all are not true CB’s. I use the packing paper in Spruce boxes to making an oil drain channel. Since the paper isn’t rigid, it is easy to push up under the oil filter. I also usually wait a day to remove the filter. Lee3 points

-

3 points

-

I'd think it'd be a minor alteration to take that out with a logbook entry. It weighs less than a pound, so won't affect WnB. As always, though, your IA has the opinion that matters.3 points

-

It bothers me that most people I do transition training with aren't comfortable with crosswind landings. They are actually the most fun landings. They're relatively easy if you just think "rudder for alignment", "aileron for drift", both done simultaneously. It's the "both done simultaneously" that creates the issue for most people.3 points

-

It would make sense to check on the ground against known runway direction prior to takeoff before jumping to any conclusions.3 points

-

We had a race safety seminar years ago where one of the reputable manufacturers went through the history of belt/harness safety development, and much of the driving research on material was Army aviation and other military aviation research into harness aging. The Army had particular issues since the main aging mechanism turned out to be UV, and their helicopters spent much of their life on the ramp parked in the sun. They had apparently had some failures, too, but I don't have anything to cite on that. There have been failures in racing, with Dale Earnhardt being a notable case, which was aggravated by an installation issue. FWIW, in racing harnesses age out fairly quickly and are considered one-time use. The track safety guys typically chop up a harness after a crash so it can't be used again. I got a nearly new harness handed back to me in pieces once after a crash. Since airplanes tend to get used for a long time, it can definitely be an issue if the belts aren't refreshed once in a while. Edit: Just to be a little more complete, a harness is designed to stretch/yield a certain amount in a crash as part of the energy absorption characteristic to let you decelerate at a more survivable rate. Over time both use and age affect the stretch characteristics of the material so that it can no longer be expected to perform as intended. Re-webbing with new material or replacement of the harness restores the intended elasticity/plasticity of the harness.3 points

-

Aviation Consumer at Sun and Fun this week… promoting a 200hp DeltaHawk variant (actually showing a picture of a Mooney as the 200hp example application).3 points

-

3 points

-

Savvy Breakdown, which is now included in the lowest tier (SavvyAnalysis?) of paid subscription, has been useful to me twice. I'm an involved and knowledgable owner but I'm not a mechanic so having a number to call for assessment and recommendation saved me from two AOG situations away from home. Knowing I have them to recommend a good shop if I need one away from home is good peace of mind for me. I don't subscribe at the SavvyMX level but I probably would have benefitted from it earlier in my ownership. I do recommend the SavvyAnalysis level subscription for the regular Report Card and FEVA Reports, as well as the detailed engine data analysis available on request. Cheers, Junkman3 points

-

There is lots of good info here which is provided by some sharp people but please allow me to add my two cents from personal experience. I started studying the system after one of my speed brakes would not deploy at the end of a long cross country. When I learned that annual lubrication is recommended I first tried to take the easy way out by extending the speed brakes on my Ovation 3 so I could reach the gear to lubricate it. That’s when I realized that I could only access about 90 degrees of the gear and none of the worm drive. Then it occurred to me that the gear only rotates about 90 degrees during deployment so the grease I applied May never come in contact with the worm drive. Also his method would not remove the contaminated old grease which is exposed to the environment. That’s when I knew I would have to remove and disassemble the speed brakes in order to do he job right. I still don’t believe it is necessary to do this every year but the following YouTube video shows how I cleaned, lubricated and inspected my Precise Flight Speed Brakes. Once I did this maintenance the speed brakes worked great.3 points

-

If it’s the chain, the indicator will move with the electric trim. If it doesn’t, the trim torque tube is disconnected somewhere.2 points

-

Here is a link to a recent revision (-28) to the Parker Manual referenced by Shadrach, just in case. https://www.parker.com/literature/Aircraft Wheel & Brake Division/AWB Static Files for Literature/AWBCMM0001.pdf2 points

-

2 points

-

Oscar… LASAR website says the STC is limited to open baffles (no doghouse), 1967 and later E / F models. https://lasar.com/stc-kits/laskit1262 points

-

They all fail sooner or later. I have had new bladders, 3 years since leaving the factory install, fail. I've seen wet wings last for years. You never know because humans make and install them. It part of maintenance.2 points

-

2 points

-

No, he said to test the gauge, hook up a 15 ohm resistor to ground is it should read 1/2 tank.2 points

-

BTF just north of SLC. I flew in 2017 and needed to leave the plane a while / month and take airliners home. I asked the guy in the FBO how much for a monthly rate. He asked " you buying fuel ? " i said yes and he said just tie it down over there...... There was no charge. That's where ill go back. BTF Tom2 points

-

This is one reason I am not planning on painting my airplane. Right now it doesn't matter if anybody scratches it a little bit, and life is just much easier that way. That said, even in A&P school we were often reminded to not put tools on the airplane surfaces, cover stuff up if you need to be on it, etc., etc. Some shops and mechanics are just better at it than others.2 points

-

Seems like you could take a clean shop vac with a fresh filter and pressurize the intake and spray all the connections with soapy water same as testing for exhaust leaks.2 points

-

Very happy with the service. Occasionally, their serving as an intermediary slows things down. That drawback is more than mitigated by knowledge, having a second ear, troubleshooting, break down service, etc. Last year, I saved so much money on a complicated problem, after their negotiation, the service easily covers itself for over the next decade.2 points

-

Hats off to you! I underwent a similar project but found a local custom car outfit to do mine. The hardest part of doing the interior is contorting into the fuselage to remove and then reinstall the pieces you took out. If you can measure and use scissors and a screwdriver…….you can redo your interior. The upholstery part is real skill so if you are interested in good results, I would find a good one. Otherwise, take it slowly, take notes, take a ton of pictures, put the screw from each section into baggies and label them. Good luck.2 points

-

@wombat, et al. The problem with interpreting regs the way the pilot wants to, or even based on what the language of the regulation appears to plainly say, is that it does not work that way. There is a doctrine called "Chevron deference" (named after a Supreme Court case) that says that whatever understanding or interpretation the regulating body (here, the FAA) applies to the regulation is the correct interpretation unless it is arbitrary or capricious. "Arbitrary and capricious" is a very high bar. In short, if a regulatory body such as the FAA issues a regulation, it gets to say what the regulation means, not you and me, or other pilots who may have to operate under the regulation, or even the Federal courts. The result has been some really crazy interpretations of regulations as regulatory bodies seek to expand their authority and jurisdiction, and the Courts have felt bound not to interfere. There has been speculation that Chevron deference will be limited by the Supreme Court and that perhaps Chevron itself will be overturned, but today that is not the case. In other words, if you were in an accident because you failed to use a mask above 18k it would not matter much what neat arguments you could come up with about the language and structure of the regulations, or how a reasonable pilots would understand them, the FAA's understanding of them would apply. Thus, for example, if the agency said that, to be airworthy under 23.1441 et seq,, the aircraft must have a functioning O2 mask for the pilot, and therefore to fly such an aircraft above 18k the pilot must use the approved equipment, then that interpretation would be the governing interpretation. The FAA brochure pretty much says that is the case. And the FAA could reasonably conclude that 1441 is not limited to aircraft "certified" under part 23 because 1441 is broader than that, it covers an "airplane [that is] is approved for operations at or above altitudes where oxygen is required to be used by the operating rules... ." Don't get mad at me, I am just the messenger. When I first looked at those regs I had the same thought, that nothing in the regs requires the pilot to use a mask above 18k, the regs simply require that one be on board. But it is likely that the FAA would not see it that way. If you have a concern you could write a letter to the FAA's Office of General Counsel and request a formal interpretation.2 points

-

The ALT breaker is on the output of the alternator. The ALT FLD breaker is for the voltage regulator. If you pull the ALT FLD breaker, you will turn off the voltage regulator which removes excitation from the alternator so it will not make any power. It is mostly there to protect the regulator. Sometimes if the alternator stops working, power cycling the regulator will reset it and it will start working again.2 points

-

Too wet. That's our monsoon season, generally, and the humidity gets high enough that the swamp coolers don't work very well. Swamp coolers got deprecated here partly because of aesthetics in new neighborhoods. I had a swamp cooler at my old house, which we used all the time and only ran the a/c during the monsoon when the humidity got too high, which you knew inherently because suddenly the house wasn't comfortable any more. We had the current house built 27 years ago and they wouldn't let us put a swamp cooler in...the view was that they're ugly since they're a big, chunky thing that sticks up from the roof and is hard to hide. They don't work as well if they're not on the roof and benefit from down draft. My attic is huge, so I tried to figure out how to put one up there, but eventually gave up. If they leak, which they do from time to time in normal maintenance, it's a mess if it doesn't have a roof to leak onto.2 points

-

I fly cross country a couple times a year and fly to Alaska occasionally and fly the Mooney for business and breakdowns can be a huge issue. I've had a flat tire on a runway at night (Savvy breakdown advisor told me to go to Walmart and buy a car moving dolly and we got the plane off the runway!) Another time I had a gear door broken hinge and need a double check that I could continue the trip with the gear door removed (I was advised to take both sides off so the plane was symmetric) and so the savvy breakdown has been a good value for me. I don't use it for annuals and routine service as I like to do my research about which shops I use so my annuals always come in on time and at the estimate.2 points

-

2 points

-

I use Savvy's second tier "SavvyQA," through work I know several A&P's but most of them have only been wrenching on Jets for the past 10+ years and while all of them are excellent MX they take a while with researching Piston issues. Having Savvy recommend and provide documentation for jobs or help with the trouble shooting has been very nice as well as recommending shops to send parts for overhaul. And Savvy analysis has also been insightful.2 points

-

The Bogart Towbar is flawless. It stays connected when you need it and it "retracts" into a very compact lightweight bar when you travel. The padded double handle is simple, but elegant. This bar is pricey, but it is just flat out awesome in form and function. I LOVE MINE and wish I had gotten one WAY earlier than I did.2 points

-

Everything I've read indicates that if you really want it to last, you ought to look into a grind prep, honestly. You might search the topic on beechtalk.com or garagejournal.com. Years ago at my first house, I used an over-the-counter 2-part epoxy floor coat kit on brand-new concrete. I did a muriatic acid etch and good rinse/dry and thought that would be sufficient since there was no oil or grease exposure. It failed in places after a couple of years... next time I will pay a pro to do the best process and use the best products.2 points

-

Current logbooks go in one binder, old logs go in another. 337's in another binder by ATA code. All releases, ICCs and 8130 in a binder by ATA code. ATA code is your friend. It is the Dewey decimal system for airplanes.2 points

-

I considered adding it to one of the other threads but thought having the thread title that an order was getting placed might be helpful instead of someone thinking it was just a discussion on the part.2 points

-

I prefer autobiographical! ha ha. Sorry, couldn't resist. (plus High Fidelity is a classic)2 points

-

To clear things up - no it is NOT cool to post anything on a persons classified listing except for questions or comments about the item for sale. You are not allowed to post trying to promote your own item - you need to start your own topic for that.2 points

-

Perhaps there is no simple way, but it could be better. When there are 50 owners pissing up multiple ropes in order to install an improved landing light that is not STCd but is an OEM part for at least one certified aircraft manufacturer, the agency has lost the plot. The up side to dealing with multiple resubmissions for the same 337 is that I have never once since landed without a lighting landing light nor ever needed to replace a bulb. I was able to make my plane safer, more visible and more reliable with less draw on the electrical system despite my FSDOs best efforts to make it difficult.2 points

-

The gathering on April 8 for eclipse viewing at 42A (Melbourne, Arkansas). The crew of that large grey military airplane (single engine turboprop) landed just before the totality started. They landed long and filled the air with tire smoke as the pilot slammed on the brakes with the end of the runway rushing towards him. I've never before seen an airplane fishtail like that! There were four Mooneys in attendance, including @Pasturepilot and family!2 points

-

Not as much as Americans, here is a 5 seconds summary Cousin Avi (Snatch film, Guy Ritchie)2 points