Leaderboard

Popular Content

Showing content with the highest reputation since 03/16/2024 in all areas

-

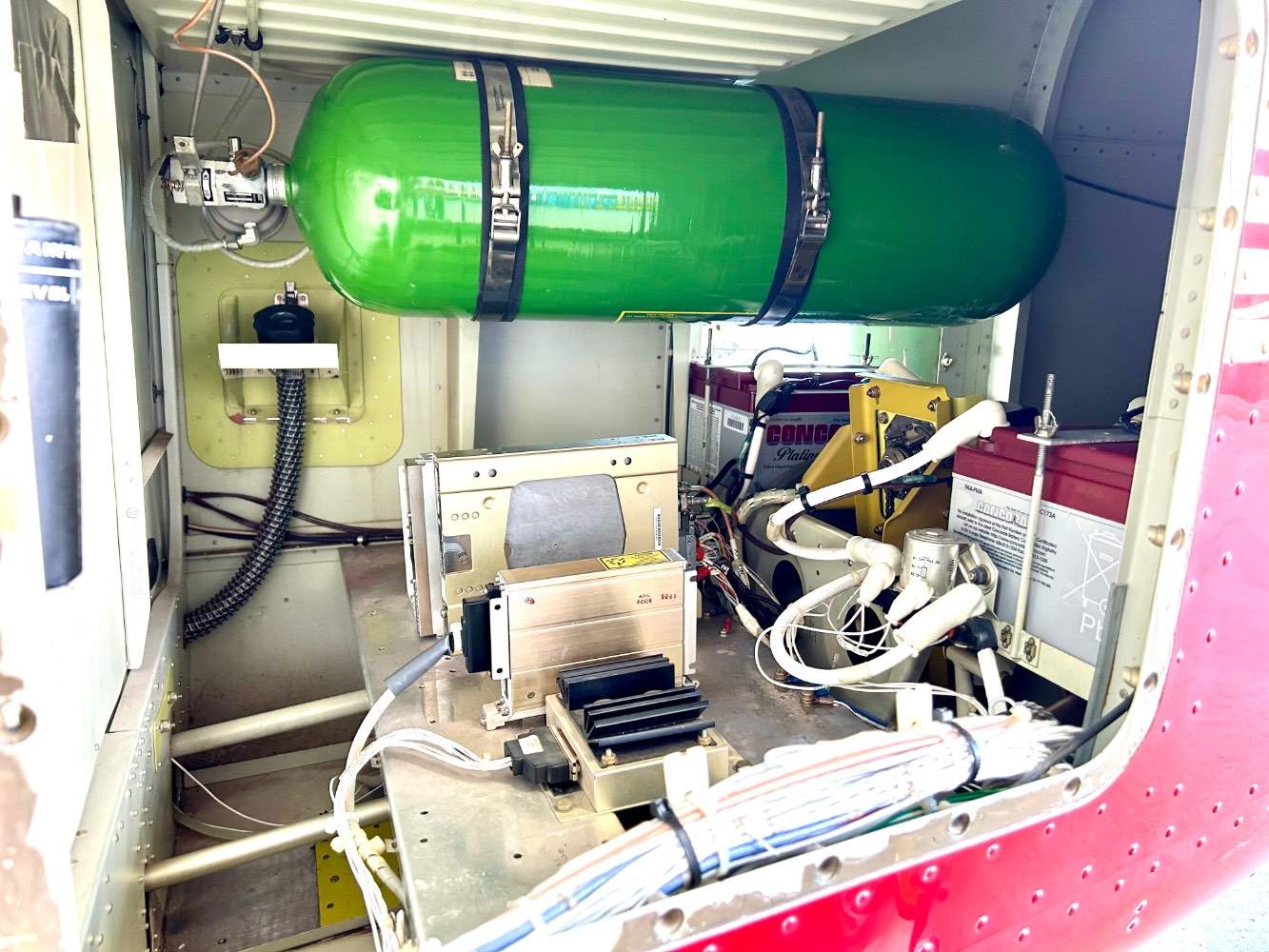

The Story: I bought an Ovation last October that needed some attention. My son and I are going to travel in it and he is building time for a flying career. It had a new and very nice glass panel in it but everything else was well used. The airplane flew about 35 hours in the last 5 years. The paint was very oxidized, carpet old and dirty worn through and the seats looked like a frat house couch. Both wings had fuel leaks. It had been well maintained but it was tired when i bought it. I used the Winter months from then until now to refurbish the airplane. I tackled a bit more than i wanted to but my thinking was to fix everything now and fly it versus fly-it-and-fix-it etc….. So, this is what we did: Firewall forward is all new. Every line, hose and connector. Factory new IO-550. New engine isolators. Stripped and painted the engine baffles. Prop Governor Overhaul Prop Overhaul to include new internals. Compete external light conversion to Whelen (WATT) LED’s. New wingtip and taxi/ landing light lenses. New tires and tubes. New batteries (2) New O2 bottle and fill. Polished the spinner and took the dents out. 18 hours with a buffer and ceramic wax to bring the paint back to life. Complete fuel tank seal scheduled for this year. New Interior. (I started with the just carpet but I had to take the seat out to take out the carpet………and one thing led to another and i just took everything out). I also removed most of the old adhesive, cleaned every inch of the inside and added insulation and sound proofing to the interior. FIRST FLIGHT: Accomplished the first flight and first two hours of engine break-in yesterday. The new engine and prop are powerful and smooth. Everything else mostly worked as advertised. After the first hour I landed. We took the cowlings off to inspect. No leaks. We adjusted the prop governor for full take-off thrust and the gear warning horn on the throttle cable. We flew another hour and I got two more landings in since it had been awhile in GA for me. I would have added 4 more hours to the break-in except i was limited to lower altitudes and high power settings for the break-in and it was VERY windy. TAS was 176-178 on 24/24 at 3500” so I am guessing 180-185 higher. It was a rough ride. I have a fuel pump that needs overhauled so that is going out. I also have a small box in the avionics bay that controls glareshield and panel lighting that needs overhauled. Maybe one EGT probe as well. Otherwise, for the amount of work we did on the airplane……everything went well.9 points

-

9 points

-

Also remember that the stall speed will be lower in ground effects. It's kind of hard to look out the window to make a good touchdown and look at the airspeed indicator at the same time, but if you are trying to hold it off for a full stall landing (which I do), you will probably find that it settles to the runway at lower than 55 KTS. I check the airspeed on final, but after I'm over the runway I just look out the window. There is nothing inside that will make your landing any better.8 points

-

Couple flies from Germany to Australia AND back in their Mooney This is a very detailed long read https://euroga.org/forums/trips-airports/15530-down-to-oz-and-back-agin-the-whole-story?fbclid=IwAR1apQ8rnMdHiskPhuUPdIRDUyMV9X6CMrhD-iIrbI-RfFOqHMiy0YhwG3E_aem_AZp_IhINaL9hczkSFgErtgEAK-PdBuWee6SbC2lmBZRuuYn1rnRWrj9ch9djQMK2DhVQk3H9rzK4aZ5muUbCEjJ47 points

-

I thought this was an auction for oxygen equipment and was wondering why it was so expensive.7 points

-

I have owned my Mooney since 2019 and every year have tried to upgrade or improve on everything. Airframe has 2910.7 hours with no gear up damage history. Engine has 1134.2 TSO. Compressions 3/18/24 #1-76, #2-74, #3-71, #4-73. New (12/20) MT 3 blade Propeller has 71.7. Garmin Dual G5s Garmin GNX 375 GPS/Transponder Garmin GNC 255 Garmin GTR 225 Garmin GMA 345 Garmin GFC 500 Autopilot JPI 900 Primary Engine Analyzer Whelen LED Orion 650 Nav and Strobes CIES Digital fuel probes Mid-Continent digital clock/timer and USB charger Garmin GSB 15 charger ACK ELT Model E-04 Aircraft BEW 1702.0 lbs Arm 44.06 Useful Load 1038 lbs Main landing gear shock discs replaced 06/21 New Sky-Tec 149NL starter 04/22 RH Magneto overhauled 04/22 Main Door seal replaced 05/21 New Prestolite Alternator and Zeftronics regulator 07/19 Replaced NLG Steering horn 06/19 Bruce custom fuselage cover Aircraft is currently in maintenance at KIND (March 18) and will be returned to service with fresh Annual, 91.411 (Altimeter IFR) and 91.143 (Transponder) checks. Also installing Microkit Solutions Landing Height and Gear Warning System LHS-200-C. All Garmin software (G5s, GFC and GNX) will be updated to the latest versions. This was to be my “forever plane” and I have treated her as such. She has taken my wife and I all over the Midwest, the Southeast and to the Bahamas. I have upgraded everything I could and next on the list was to be an updated interior. Nothing wrong with the current interior but it is a bit dated looking. I am only selling since I don’t have the opportunity to fly her as much anymore and my wife and I have changed our long term plans. I will also provide manuals and Mooney specific tools if you want them. Offering her for $124,900 OBO7 points

-

I did four cowling modifications initially when I started my project. I’m still working on two different cowlings but am in the process of moving right now. Many other issues with composite shops have hampered progress for quite a while but I am too far into it and too much money invested to walk away from it. Thanks, David6 points

-

6 points

-

6 points

-

A low(ish) pattern, overshooting final, heavyweight, unexpected return, new owner, distraction from wind/noise… there are lots of things stacked against them. None of them should be fatal by themselves or even together, but they do increase the risk.6 points

-

6 points

-

Totally subjective at this point, but if the base leg did have a 10 knot tailwind, then with some anxiousness to get on the ground, an overshoot of final (and from the track that looks to be the case) could have caused the classic cross controlled base to final stall? Just hypothesizing with no basis in fact... Obviously, we need the final accident report to shed more light on the situation. The pilot seemed pretty calm initially about a simple return for landing and closing the door.6 points

-

Thank you for your feedback and concern. It's worth noting that the original design for the E/F models does not incorporate any wire in the ribs. To address potential concerns about the induction coupler collapsing, I've conducted a Computational Fluid Dynamics (CFD) study and subsequent Finite Element Analysis (FEA) at twice the expected volumetric flow rate. This allowed me to estimate the aerodynamic loads and predict a maximum deflection of approximately 1 mm for the chosen material. Additionally, in the event of inadvertent flight into icing conditions, the air filter bypass valve is designed to automatically open, preventing engine starvation. I also plan to monitor the part's deflection during ground operations, particularly during full power run-ups, to ensure structural integrity.6 points

-

I've made some progress, and the urethane part is slightly stiffer than the original using a shore 90A material. I am considering switching to shore 80A as might be a closer match. Currently I'm using amber urethane to spot air bubbles. Once bubble elimination method is sorted, transitioning to black. Seeking feedback on this progress.6 points

-

Hello Mooney world. When the time comes to seal or repair your wing fuel tanks I highly recommend working with Edison and Wet-Wingologist East (KFXE) as the THE place to receive high value for your investment and excellent results! My previous PIREP was after Edison resealed the tanks in both wings in March 2016 for my 1990 J Model. In that PIREP I recounted my high satisfaction with the value delivered and results achieved. This update covers my recent warranty leak repair experience, 8 years later, during which Edison worked my airplane into his rather full schedule on a Saturday morning, charged me nothing the, and had the airplane ready for pickup by Sunday. If you prefer short PIREPS, you can stop reading now. Otherwise, below are additional details in the spirit of contributing to the knowledge of the Mooney community. After the initial, reseal the right wing periodically (and inconsistently) developed minor seeps in 2016 and 2019 in the same outboard tank area that would not last and I could not find the conditions to replicate them. In each case after discussions with Edison, I decided to postpone taking the airplane to him and continue to monitor instead. Edison was always ready to schedule the in-warranty repair without question. There were no signs of leaks between 2019 and late 2023. During the November 2023 Annual Inspection, my A&P/IA found signs of a small leak at the bottom of the outer right wing fuel tank, none evident on the outer wing skin, and we could not determine for certain if it was old or fresh. I called Edison, who suggested letting the airplane sit in the hangar with the right wing filled to where it could take no more fuel. After a flight that started with full tanks and included left/right steep turns and maneuvering flight, I topped of the tanks as suggested. After a few hours in the hangar with the right tank completely full the leak was evident in the area my A&P/IA found. Edison thought a sealant bubble at the top of the outer tank had broken and was allowing the fuel to leak when the tanks were left sitting and completely full, and that it would require a small repair. I confirmed this by draining fuel to where the fuel level was 1-2 inches below the fuel cap, and the tank did not leak after a day of monitoring. Following discussions with Edison, and setting a date for the repair, he called me back a few days later to explain the leak could also be coming from the fuel sensor gasket located on the vertical outer wall of the outermost tank. Before taking the airplane down several days for repairs, and the added cost of the trip to/from KFXE, Edison recommended that my A&P/IA replace the sensor gasket and check again. After replacing the gasket and topping the tank, the leak returned after a few hours. At this point I decided with Edison it was time for a repair, and we agreed on an earlier date than planned provided I could get the airplane to him the next Saturday morning. I flew to KFSE early Saturday morning and taxied the airplane directly to Edison's shop; Edison started work immediately; the airplane was ready on Sunday, 8 years after the initial reseal; Banyan Air Services towed it to their ramp late Sunday; and I picked up the airplane on Tuesday 4/9/24. My assessment is that the source of the inconsistent seeps in 2016 and 2019 was the same repaired by Edison in 2023, with the fuel just finding its way out to the bottom wing skin by the path of least resistance. Finally, fuel is expensive at KFXE, but Banyan gives a discount to Edison's customers, so I added the 10 gal minimum they require to wave some of the ramp fees, and flew the airplane home early Tuesday afternoon. The folks at Banyan were a pleasure to work with. With dry wings and in great appreciation of Edison at Wet-Wingologist.... Hank5 points

-

The tbm is a really nice plane. It is a completely different class from any piston, and even the meridian. It is built like a military plane. It is solid and quality everywhere. I was surprised at how tight it is for the pilots, and you miss the position of the Mooney as well as have limited recline on the backs of the seats, but I logged some time in one, flying to Alaska and back from south Florida.5 points

-

Interesting side note. Statistically this pilot was super lucky. The fatal accident rate for the Lancair is 10X the GA average and ~ 40X that of the ubiquitous C172. That data came from the Lancair Owners and Builders Organization.5 points

-

After a two year wait in line to get my Ovation painted. I picked up my Mooney back from Lancaster Aero in Smoketown Pa. I am pleased with their workmanship and their timeliness. The downtime was one week less than I had anticipated. I chose to stick with the original paint scheme and colors. It feels good to get my wings back. Norm N995K5 points

-

5 points

-

Most of the capabilities are driven by software and Garmin has more software updates than Microsoft or Apple . The only way to be sure is to get with your avionics shop and carefully review the frequently updated proprietary installation manuals which should describe the limitations. The current version 6 of the G3X AFMS still says that the GI 275 will not drive the GFC 500 If the G3X or GSU 25D fails (the G5 will), and the G3X will not display comparison alerts from between the GSU 25D and the GI 275. The G5 is cheaper, better integrated with the G3X, and has a longer battery run time than the GI 275. Personally, I would still choose it if I were designing a G3X panel today.5 points

-

I could be wrong, but I don’t think the mesh in the original part adds any rigidity. As far as I can tell, it’s cotton or a similar material. It certainly adds shear and tensile reinforcement. I think those that are focusing on the mesh as a component of rigidity that prevents collapse have not fully examined a failed boot in a while. They tend to tear from the shear stresses that come with start up and shut down. They tend to fail in same place and the resulting tear tends to look like rubber coated denim that has a hole in it with frayed and soft fabric at the edge of the tear.5 points

-

Years ago I was flying home and while planning my flight realized there was a 70knt tailwind at 25k, directly on my tail. Pretty hard to pass up in a plane capable.. I was alone, had the nice blue silicone mask with a microphone, so I filed for 25k and off I went. I was cruising along and I looked down in my lap and saw this little black disk. At the time the plane I was flying was an ultra with the precise flight conservers, and I thought the disk looked like the adjustment dial on the outside of the unit. After a few seconds of fiddling with it, I realized I was trying to put it back together, but it wasn’t apart…. By the grace of god I realized that what I was doing made no sense whatsoever and I engaged the vertical descent for 1400fpm and still to this day do not recall the next two or three minutes. What I do recall is being level at 8,000 ft with atc calling me asking intentions. I hit replay on the g1000 and listened to me responding to them and taking instruction. I did not sound like myself, but I was responding. I do not remember any of this… After my wits were about me again I looked down and realized my arm had gotten wrapped around the o2 hose going to my mask and had inadvertently pulled the grommet out of the front of my mask at 25,000ft. The disk was the grommet, and if one was completely cogent, would never had mistaken it for anything else. I don’t know how long it had been pulled out, or how long it took me to notice something was wrong. The flight recorder only goes back about 2.5 minutes on a constant loop, so that’s all I could listen to. I don’t know how long the entire event lasted, but I did realize how close I came to being a bad story. There is certainly more elevated risk at those altitudes, and one must be very vigilant, aware and have some routine to check yourself very regularly. I personally stay 19k or below if I am alone, and will only go to 25k with someone else and if we pick up enough time to really make a difference. This isn’t my recommendation or suggestion, it’s merely a personal minimum in my Mooney, or any non pressurized airplane. Things can deteriorate much quicker than you would like to believe… Last thought on this story… I was embarrassed by this. I felt foolish, like my arrogance and confidence led me to a bad choice that could have killed me. I finally opened up and told the story to a pilot friend of mine and he told me I should share, because perhaps someone could benefit from hearing my mistake. I sure hope it does, because I still feel foolish.5 points

-

We've flown into the SLC area a lot over the past 7 years. I haven't gone into KSLC but have heard they are GA friendly. Depending on which family we are visiting determines where we fly into. In the Salt Lake Valley, South Valley Regional (U42) is the easiest. It can be busy but everyone seems to make good traffic calls and you can coordinate for a rental car to be there waiting. I think the overnight is around $10. The fuel is the same price if you pump it yourself or have the truck do it so we just let them fill it up. There isn't much space under the Bravo, the shelf is just above TPA but it is doable. Looking at my logs we have been there 15 times and it is my preferred airport for the Salt Lake area. You can easily get an Uber if you don't want to rent a car. If you are coming from the south stay over the 15 freeway going past the point of the mountain. It will keep you away from the restricted area over Camp Williams and away from the paragliders and powered gliders that are directly above the point. We've been into KOGD as well because it's 5 minutes from our family up that way. It is convenient if you are going to stay in Ogden, but the drive to Salt Lake is not as good as going from U42. Skypark (KBTF) is just north of KSLC, we've been there once. It's a friendly little airport but is very tight to the Bravo surface. Provo KPVU is great, they have Go Rental on sight, but they are more expensive than going into U42. We use it if we are just going to be visiting family down there but I would not use it if you are going to Salt Lake. It might not look like a drive but the traffic at the point of the mountain can be a mess. Not CA traffic mess but still a pain. It's only about 10 more minutes of flying to get to U42 and saves you 45+ minutes of driving.4 points

-

We disassembled mine in January of 2020 and had it in the air by July. My case was fretted and no longer airworthy so I jumped on the refurbished case from Divco. I was fortunate to get all of the parts before the major supply chain disruption, including the new camshaft and DLC lifters. Cylinders, gears, rods, pistons, and everything else were serviceable. I removed the engine and but nothing in the field overhaul and engine assembly itself, but I did the entire installation by myself with oversight and sign-off. I learned a ton about my airplane, and I cannot place a value on what I learned. All in, it was around 25K.... with a lot of sweat equity. Since then we have made multiple long haul trips including my eclipse trip with a stop in Destin FL. This is my longest adventure, over 2,500 NM round trip.4 points

-

I will be sorry to see this go. Very good flying airplane, nice IFR platform, good cross country flyer. Upgraded it to where I wanted it. Have flown nearly 400 hours in the last 3 years. Will be for sale by Jimmy Garrison at GMAX - 2108721110 - jimmy@allamericanaircraft.com - gmaxamericanaircraft.com times will increase as still flying. 1966 Mooney M20E 3600.1 ttaf 746.1 smoh (400 hrs last 3 yrs) 531.3 snew Hartzell Top Prop Mooney 201 windshield cowl closure aileron gap seals flap gap seals flap hinge covers 231 enclosed wingtips with LED nav/strobe lights LED tail nav/strobe light alternator/digital voltage regulator skytech starter electric autostep stc precise flight electric speed brakes removed vacuum pump O&N fuel bladders (54+gallons) leather seats (pilot/copilot seats reupholstered 2023) mags overhauled 2022 new goodyear tires 2022 G100UL stc GI275 ADI GI275 HSI both with synthetic vision GMA345 audio panel with bluetooth GNX375 touchscreen GPS and ADSB in/out transponder with bluetooth KX155 nav/com w/gs KX155 nav/com w/o gs JPI 730 engine monitor with fuel flow GFC 500 autopilot with pitch trim servo 848 lb useful load last annual 6/2023 last pitot/static 2/2024 prop strike 2011 - engine iran and new prop4 points

-

4 points

-

If there were no injuries and everyone walked away I wouldn't second-guess anything you did. Good job! You did everything right.4 points

-

I'm pretty sure it's impossible for Lm/n to be 5 inches greater than Lm/r. I have a page for the nose gear steering adjustment from the a M20K SMM, not an M20J, but I think it's the same. It says that the nose wheel axle centerline should be no more than 0.06 inches forward of the trunnion leading edge, measured with a plumb line. It's interesting that the difference in your diagram is exactly 5 inches, the same number as the trunnion distance from the reference datum. Measuring Lm/n is easy. Measuring Lm/r requires that a plumb line be dropped from the trunnion centerline. If we assume that Lm/n was accurately measured and Lm/r was not measured and is off by approximately five inches, your actual CG would be somewhere around 44 inches aft of the reference datum. I suggest that Lm/r and Lm/n be re-checked. Pages from MAN134 SMM M20K.pdf4 points

-

Today flying from Eastern Maryland back to Alabama, I was forced by icing to take a more southerly route. Took this photo looking south-southeast towards the mouth of the Chesapeake Bay and the Atlantic Ocean. The Patuxent NAS is lower right. Horrible turbulence and headwinds all they way to the GA-AL border after which things smoothed out a bit. The shocker of the day happened when CLT approach allowed me to fly over the field at 5,000.4 points

-

Maybe you're having difficulty with your landings because you are too concerned about your airspeed indicator. Sure, check it on each leg, but once you get 50-100 feet above the ground, just look outside the plane and fly it. Slowly add back pressure to round out just above the runway and then hold it there as long as possible. It will land when it's ready at whatever speed is right for the given weight. On the flip side, you can almost guarantee a bad landing if you are checking your airspeed while over the runway.4 points

-

Figure out the stall speed envelope and then you can interpolate based on estimated weight. For me landing weight can vary between 1950lbs (pilot, 1 hr of reserves, oil) and 2740lbs (MGW). At MGW stall is 55KIAS. That means 1.3Vso (72KIAS) on final slowing to 1.2Vso (66KIAS) crossing the fence. At 1950lbs stall is calculated as follows: (1950/2740)Sqrt * 55 = 46KIAS 46KIAS * 1.3 = 60KIAS on final slowing to 55KIAS across the fence. This gives a VFR approach speed spectrum of 60 to 72KIAS and a threshold speed spectrum of 55-66KIAS. Fairly easy to interpolate the numbers in between. The truth is many just fly too fast for any legal weight. There is rarely a need to cross the threshold above 70KIAS, yet many do as a matter of practice.4 points

-

4 points

-

Yes Mike, many new owners want to knock out the insurance-required 5 or 10 hours on the “new to me” cross-country ferry bringing the new airplane home. This works against actually learning how to fly your new bird and handle cross-wind, bounced landings, and other scenarios. Personally, I always try to incorporate a cabin door unlatch on every checkout I do, as it’s something likely to happen to a new Mooney owner at some point in their pleasure flying. I want them to experience it with a CFI in the right seat. As others have noted, it’s a non-event. And knowing your aircraft’s “gaits” (power+pitch=performance) helps alleviate whatever weird indications one may get. Personally I’ve never seen a 10-KT diff in IAS from a cabin door — but l would be working with my tech to troubleshoot if I did. This is sad, and avoidable. Let’s work to prevent future incidents.4 points

-

Do they enter via a road or is the Airport open and they just walk in anywhere? If they walk in at a more confined area, put up some decent size sings they have to actually walk around that have some official sounding warning. AIRPORT RUNWAY, TAXIWAYS AND ADJACENT GRASS AREAS ARE NOT SAFE TO WALK ON. THESE SPACES ARE FOR AIRCRAFT OPERATIONS ONLY! LANDING AIRCRAFT MAY NOT SEE YOU AND CANNOT MANEUVER TO AVOID YOU!!!4 points

-

0.032 is the most common and used for most things, like securing the oil filter. Once on a while there's something more heavy-duty that requires 0.041, and some little-bitty things use 0.025, especially if 0.032 would be too thick to maneuver in the available space. The 0.020 is mostly used for things like emergency windows and throttle limits (on engines with emergency power), where the wire is mostly just a tell-tale whether it has been used, since it can be broken easily if needed. e.g., on some WWII bombers there was additional "emergency power" that was available by just pushing the throttles past the 0.020 wire and breaking it. The mechanics needed to know if it had been used because it changed the overhaul time limits on an engine where the emergency power had been used, and the wire let them know. An MS member with a C310 discovered a couple annuals ago that the pilot emergency egress out the side window was safetied with thicker wire and probably wouldn't have been usable if needed, because it probably wouldn't be possible to break the wire that was used. The SMM often says what wire to use if it is something other than 0.032.4 points

-

4 points

-

I let everyone make their own decision, but, I personally, deliberately do not lock mine for the reason stated above. Some people insist on locking it and I'm fine with that, just not for me. A properly latched baggage door being held down with the two latching pins is not going to come open.4 points

-

Another simple, rough-ish starting point to check flap rigging is just to put a straight edge down the top of the wing. The upper surface of the flap should align reasonably well with the back portion of the wing surface. That'll give you an idea if something is significantly off, and be able to compare the two sides. This works anywhere along the wing, but obviously isn't a precision measurement.4 points

-

Hmmm . . . Premiums went down for Shadrach and up, but went up for Meshach. What happened to Abednego? Sorry if those jokes are getting old . . .4 points

-

Installing the MVP-50 was one of the best decisions I made with my upgrade. In my opinion it is the best stand alone engine monitor out there. Yes, JPI is worthy, but the MVP-50 has more versatility for my usage. I've attached my worksheet to show how I set mine up. With the M20C you won't have TIT. The small box between the MP and RPM turns red and shows gear not down, if the gear is not down below a certain MP. There is an extra register on the fuel page that displays trip totals and resets on engine shutdown that I find extremely useful. There is the ability to set 2 automatic fuel levels when adding fuel; in my case 89 gals to the bottom of the neck and 100 gals topped off. There are too many other benefits of the unit to mention in this small space. At the time I upgraded my display the cost was a little over $1,400. If you are buying new, you will get the new display. The functionality also increased with the upgrade, in particular the ability to see time to destination instead of time to waypoint--to me a MAjOR improvement for trip planning. and execution. MVP-50 Worksheet 8:23:2013.pdf4 points

-

Just buy the plane then get your transition training. Whatever money you spend on renting will be far more than insurance savings (if any)4 points

-

There is a software bug in the G3X (v9.15 and earlier). According to the AFMS, if the GMU 11 fails the G3X is supposed to display a red X over amber HDG and display magenta GPS TRK on the HSI. But, instead, it continues to display white HDG as normal. What is happening is that the logic is not switching to TRK upon GMU failure and the ADSU 25D is continuing to compute HDG but without GMU input so the heading will drift over time. The G5 does properly switch to TRK. I don't have a GI 275, so I don't know how it behaves. I reported it to Garmin and after some back and forth, Support was able to reproduce it and passed it on to Engineering for resolution.4 points

-

Add to that… they may well have had a full bag of gas, which is way cheaper at St. Augustine than at Homestead. Speaking only for myself…. I seldom land at max landing weight and NEVER at 3368 MTOW. Stall speed really goes up at heavy weight and high bank angle. 57 KIAS at a normal wings-level 3000# landing vs 72/85 @ 45/60* bank and MTOW. AOA warning, if installed, would have been screaming if this is what happened. -dan4 points

-

Here's the real scoop: "Despite false rumors and misinformation that the hugely popular Garmin GNS-series navigators are at the end of their service life, Garmin says that 99 percent of GNS users can keep using their units. Moreover, the Garmin factory will still continue to support common repairs and refurbishments as it has for the past 25 years."4 points

-

I have used the time tested method to improve speed. Wax, stickers and lying on the internet. Much cheaper than new engines and real speed mods and you can add probably 20 knots. Ha ha4 points

-

You must be in Canada. If we had an AME looking over our shoulder in the U. S. he would be doing our physical, and I'm not sure I'd want him back there (https://www.faa.gov/ame_guide/standards)4 points

-

I'm not a fan of removing things that are perfectly functional plus the KFC150 was the best GA autopilot of its time. However, although it may be working very well now, the truth is it's close to 40 years old. At this stage, spending good money on an extra GI-275 plus all of the additional labor to interface Garmin equipment to the King a/p would be much better spent toward a GFC500. The first time you need to have your King A/P repaired you will kick yourself for not doing it all together.4 points

-

These shops all basically use the same suppliers. if one shop is telling you they can have it back in less time, it sounds great, but it might mean that they are overly optimistic or it could mean that they are short on work (cash flow). Getting a deposit might be paying this month's overhead and your airplane may sit in the corner of their hangar or outside until the parts are available. The best shops, which are the ones you want to do your work, have quite a wait.4 points

-

Someone sent me a worn out duct for a C Mooney. I disassembled it and figured out how it was made. It is actually made like a scat tube. A wire is spiral wound around a form. Then a single sheet of fabric reinforced uncured rubber is wrapped around the wire with a 30% overlap at the top of the duct. Then an uncured rubber coated string is wrapped around in between the wire spirals. It appears the ends were left to extend a few inches and were cut at the corners. The ends were sandwiched between two die cut pieces of reinforced rubber. Additional pieces were added to seal the corner cuts. This whole sandwich appeared to be clamped into a metal press jig of some sort to form the ends. I assume the whole arrangement was put into the curing oven and vulcanized. After curing, the ends were trimmed, and part numbers were pad printed on the end flange.4 points

-

I attended our airport pilot's association pancake breakfast this morning, which is usually fun and always interesting because our ATC peeps, the airport manager, and some of our local vendors often speak and share the latest relevant info. Our self-serve fuel vendor usually shows up and today he provided some insight on his perspective on the current state of the unleaded fuel situation. One very interesting tidbit is that he's sensitive to the liability concerns, e.g., if somebody has an issue because the new blend weakened a gasket and a leak caused an accident, he could be affected. He said his insurance covers the first $1M of a claim, which doesn't go very far in an aviation accident, and the distributor adds $50M of coverage on top of that. GAMI does not have a distribution system which adds any coverage, so that is a serious issue. He also indicated that Swift is actually pretty far along and may have distribution rolling soon. The expectation is that once their 100 octane is being produced that they'll drop their 94UL and sites currently selling 94UL will instead sell the 100 octane. He also said that the Switft blend is very different from GAMI's, in that while GAMI uses aromatic solvents (xylene) which may affect finishes (paint) and gasket/seal integrity, Swift uses oxegenates. I took this to mean that the potential issues with finishes and seals, etc., would be expected to be less. Anyway, just passing it along. Don't shoot the messenger, and I don't really know any more than I'm passing on.4 points