Leaderboard

Popular Content

Showing content with the highest reputation on 05/28/2023 in all areas

-

The liability has changed because now that there is insurance available for IAs , the lawyers have found out and automatically sue for the limits of his insurance if anything happens. This insurance runs about 7K a year. I am an IA and thought that I would do annuals as a part time retirement job. I have now decided against this as I do not like the idea of performing multiple annuals each year just to turn around and hand the cash to the insurance company. If I don't get the insurance, some pilot's wife could get my house, 401K and pension. All it takes is one.4 points

-

Well, I feel pretty stupid. All of the wiring chasing I did, I decided to finally test voltage at the cigarette lighter plug with the engine running...14.18V, while the EIS showed 13.5V. So, seems like the charging system is working fine, but my voltage drop is somewhere either in the avionics bus or in front of the EIS...3 points

-

The electrical system is designed to supply a constant voltage to power the electrical equipment on the airplane. The battery is primarily for starting and secondarily for backup power if the alternator or generator fails. The electrical system charges the battery by applying a constant voltage higher than the battery open circuit voltage. There is no float mode. Batteries self discharge. A battery maintainer (or a charger with a maintenance) applies a float voltage to the battery which is just high enough to offset the self discharge and maintain the battery charged at full capacity.3 points

-

So, the regulator will regulate to its sense terminals, but the important voltage is the voltage at the battery. Most electrical systems have a low impedance wire from the alternator, through the alternator breaker to the battery cable from the master switch. The connection from the alternator breaker to the battery buss is usually where the sense wire is connected. Of course the ground path back to the battery can screw everything up. The cigarette lighter plug is as good a place as any to measure the battery bus voltage, it is connected directly to the battery bus through its breaker or fuse and there would only be an IR drop if current was being drawn from the lighter plug.3 points

-

I used to be car crazy until I started flying. After that I didn’t care about cars anymore.3 points

-

If you're really trying to understand/fix bus voltage in the range of tenths of a volt, then one critical factor is how (where) you measure the bus voltage. Ideally you'd connect the measurement device to the sense terminal of the voltage regulator to start, then sample a few other points: circuit breaker busses, power input of instruments, etc. It's common to have a few tenths or hundreds of millivolts IR drop between the regulator and other locations. Note that cigarette lighter plug-ins and other cheap, portable voltage measurement devices are especially susceptible to IR drop. You don't want to crank up your regulator based on measuring a voltage that's electrically "far" from the output of the regulator itself.3 points

-

So I thought I'd come back to this now that I've passed my Private check ride in my 1963 C. Just to recap, I had 20 hours in my log book when I bought the C in August. 10 months, 4 CFIs, 3 weather delays and 176 hours later, I passed in a check ride that took 2.5 hours from start to finish, including the oral. A lot of my hours (probably 50) were real XC trips from Kerrville to Atlanta, a few to Dallas, several to CC, etc. for things I needed to go do or lunch with my dad, some of it solo, some of it with the CFI and I've flown 57 hours since my first check ride date was cancelled, so I was really ready with 50 - 60 hours of training in the Mooney (plus the previous 20 in the 172 and Cherokee). Getting a private in a Mooney is totally doable. Yes, I had a few hard landings early on, including some bounces but, once I learned to manage the energy, that stopped. The hardest part was learning how to slow the plane down and realizing that although it flies fast, it lands just as slow as a trainer. After figuring that out, there really isn't that much more to manage and the muscle memory comes quickly. So, if you're considering buying a Mooney before you have your private and finishing your training in it, I say go for it. I'm super glad I did.2 points

-

2 points

-

Heck no, they are more expensive than a gfc500 with all the trimmings.... The only reason i can afford a plane is because i have no copilot2 points

-

Sorry, there is no such loophole for certified aircraft. Anything touching the control system is a major alteration in the FAA's eyes and that triggers all sorts of required substantiation. I thought we were on the verge of a new wave of approved autopilot systems for many models, but the FAA got pantsed by Boeing with the Max fiasco and now almost nothing is getting approved in a timely fashion. Sent from my LM-V600 using Tapatalk2 points

-

Leaks are not usually the cause of high oil consumption. I quart of oil is a HUGE leak.2 points

-

With modern glass cockpits and capable autopilots, I let the autopilot fly to minimums. This is the way professional pilots do it. The reason is that it relieves you of the mechanics of flying and gives you the ability to monitor what's going on increases situational awareness. I keep a hand on the yoke in case something goes awry with the automation, but I can monitor the autopilot and control airspeed while devoting more time to looking ahead for the runway environment. The autopilot will fly more precisely than I can - that's why autopilots are required for operators authorized for minimums below 200'. It's still a good idea to fly some approaches manually to avoid becoming automation dependent. But if the weather is really down to minimums, I use the autopilot. I fly my approaches at 90 KIAS and TO flaps. From 200', it's really no problem to stay on the GS/GP and add full flaps and slow to Vref. Skip2 points

-

Stall and gear warnings in my Mooney are two separate Sonalerts in the ceiling. Don't think they go through the speaker or headsets.1 point

-

That's why God gave us track days and race clubs. Back to the BMW car ownership experience, which is entirely suitable for a drifted thread on a Mooney site, my last race car was a 1998 BMW 328i. My first two race cars were Ford Taurus SHOs, and they were both very cheap to run and and race. Chassis parts were cheap and plentiful in junk yards, and there were just enough SHOs in junkyards that engine and drivetrain stuff was cheap, too. A junkyard motor in those days was $200, and they were pretty bulletproof. They were also very reliable, even when run very hard, so they were very economically efficient as far as race cars go. So after a few other cars and seeing people have very good performance and reliability success with the BMW E36 series on track, I bit the bullet and got one, figuring I'd just be paying the BMW tax and would have to suck up the expense. I'd had a Cadillac CTS-V and the "Cadillac tax" was a real thing, so I was just prepared for the BMW to be expensive to run. I raced the BMW for eight years, just sold it last year, and it was by far the least expensive and most reliable car I ever raced. That was a very pleasant surprise. It was also very competitive in the classes I competed in, until a rule change made it non-competitive. I'm not so sure about the more modern BMWs, though. They don't seem quite so attractive.1 point

-

Yes, I was saying that there is a such thing as float voltage, but our VR’s I believe are dumb, not even temperature compensated, but then they have been working just fine without all the bells and whistles for decades. However if his voltage is really that low he’s likely killing his battery, a slow death from sulphation.1 point

-

1 point

-

Eric Rudningen in Willmar, MN KBDH) is an outstanding Mooney CFII. He’s also an A&P IA and the owner of Oasis Aero, a Mooney Service Center. He’s a terrific guy and a great mechanic. (320-214-9669).1 point

-

SEM color coat is highly durable. It needs to be properly prepped and sprayed on to create a wet coat. Your overspray might be too light a coat and, depending on when you hit it with the alcohol, may not have bern fully cured. For best adhesion, clean the panels thoroughly (SEM has a product called SEM Soap). Then spray with SEM Solve to soften the surface and promote adhesion and then spray with Color Coat. There are Youtube videos by SEM that have all the details.1 point

-

I found out a long time ago that all that stuff just gets me speeding tickets. There is nothing more frustrating than driving a high performance car slowly (like the speed limit). And if you are going to drive the speed limit, why do you need a high performance car. I'm not completely out of it. I do own a Yamaha FJR1300 that I have proven will do the Salt River Canyon at an average speed of 75 MPH. The speed limit is like 35. In high gear the bike hits the rev limiter at Mooney speed. That being said I consider good driving skills is getting the highest gas mileage possible, which I practice on every trip.1 point

-

For my filiform corrosion, after initial paint removal, I use scotchbrite dipped in Alumaprep 33. It helps the SB cut better and preps the aluminum at the same time. Rinse, Alodine and then paint as desired. I’m headed to paint not too far in the future, so this is just stop gap to get the corrosion under control until then.1 point

-

The utility of a speaker is pretty obvious, and an obvious failure mode that it will mitigate is the failure of a headset during single-pilot operation.1 point

-

1 point

-

I am not in the twin cities area, but I welcome you to MooneySpace.1 point

-

You can, if you return the plane to a certified/conforming airworthy state, along with an accompanying inspection and airworthiness certificate showing that. Experimental R&D or Exhibition doesn't allow normal GA use to go fly whenever you wish, cross country, etc. That forces an applicant to finish a project and get an STC to approve the changes, or remove the non-conforming mods and return to the previous state,. Sent from my LM-V600 using Tapatalk1 point

-

1 point

-

You should have quoted the next line, which captures FAR 91.21(b)(5): Section 91.21 permits the use of specified PEDs and other devices the operator of the aircraft has determined will not interfere with the safe operation of the aircraft.1 point

-

From the Op Manual for the PS8000: Push button switches selects one of the communication transceivers for the pilot and copilot position, and allows radio transmission. In "Split Mode" the PMA8000 has the ability to allow the pilot to transmit on com 1 while the copilot can transmit on com 2. A fail-safe mode connects the pilot headphone and microphone to COM 1 if power is removed for any reason, or if the power switch is placed in the Off (Fail-safe) position. ... The intercom system incorporates pilot isolate, all and crew modes, two independent stereo music inputs with "Soft Mute," and flashing LED indications for transmit indications. Intercom control is through two concentric front panel volume controls and a pushbutton intercom mode switch. The small volume knob controls the intercom level for the pilot and copilot, while the large knob controls the passenger intercom volume. Intercom squelch is automatic Many modern audio panels have split modes and isolation modes and entertainment distribution that can be selected differently for different stations. The G1000 does this, too. This means that the headsets are wired independently, so a jack short or stuck mic on the pilot or co-pilot won't affect the other.1 point

-

It absolutely is. The bellows are part of a previously certified system that control the airplane. If you believe in the idea that much, you can create a plan and present to the FAA, create a project with them, move your plane to the Experimental category for R&D and give it a try. Your plane would not be usable for normal everyday uses, though, until it is returned to a certified state. Or you can build an experimental plane and develop it there, much like TruTrack did. Sent from my LM-V600 using Tapatalk1 point

-

This, and is there any accompanying degradation of performance, such as W&B or runway performance. There is a Service Instruction document SIM20-133 with new limits for flying as heavy as 3873#. It is interesting to note the expanded GC envelope limits: 2 fat boys in front and full full fuel will never work. the current 3200# MLW means that with PAX and bags, I don’t want to land with more than 20-25 gallons, which is fine, but it requires careful fuel planning. Being able to fill the seats is a “nice-to-have” rather than a “need-to-have” for me. Were it not, I would have bought a different plane. I suspect than many LB owners are in a similar spot. However, better load carrying would open up the LB for consideration by the many buyers that “must have” the ability to carry four. I’d pay $50,000 tomorrow for another 200# UL. -dan1 point

-

1 point

-

Life's too short for boring cars. Most vanilla car I ever bought was my 76 Corolla SR-5. As it was basically some cosmetics over the base car. All my other cars have been the performance model of the line. And every car I have ever owned, I ended up modifying and upgrading. Mostly suspension, but a number with engine mods also.1 point

-

For smaller areas to touch up, with a hard edge, like a chip, the best way to paint is with an artist brush and fill the chip. I have watched pros at the BMW factory touch up chips and you can't see the fix.1 point

-

I went to the plane today and tested the lights as asked above. With the pulse lights on I turned on the split switch taxi lights. The pulsing did stop, the taxi lights remained on steady, and the recognition lights turned off. I then turned off the taxi lights and turned on the recognition lights. The recognition lights turned steady, but the taxi lights continued pulsing alone. The above is nice to know, but I'll continue to use my lights as I have in the past, as I don't see any benefit of using those configurations as opposed to the original methods.1 point

-

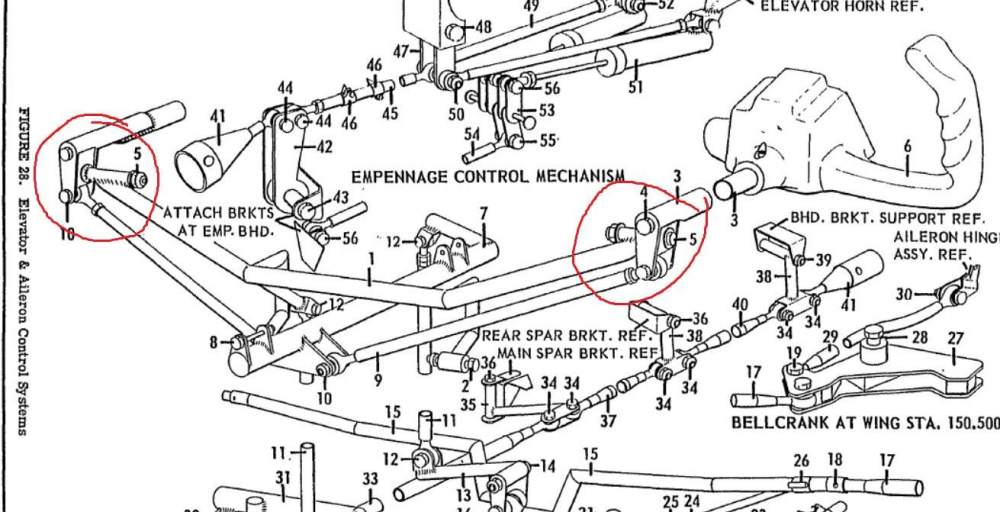

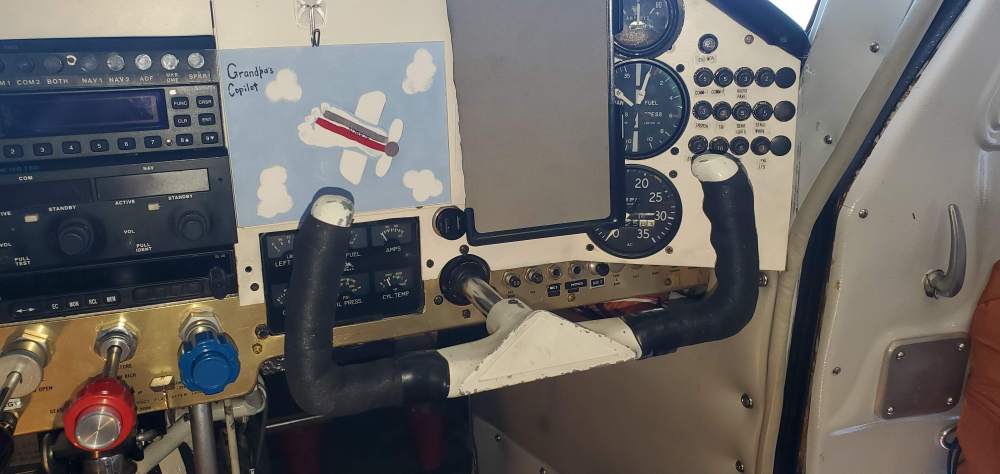

If you have a vintage Mooney you know about AD 77-17-04 which requires removing the control wheels every 500 hours and inspecting the shafts for cracks with dye penetrant. All M20 control shafts are the same outside diameter. People talk about the newer planes having a thicker shaft, the difference is in the thickness of the wall of the shafts, with the older M20's at 0.04 and the newer M20's at 0.06. The difference in the thickness of the shafts obviously results in a smaller inside diameter. The AD does not apply to the thicker shafts. Every now and then a set of control wheels comes up for sale, offering the opportunity to upgrade your old control wheels and remove the AD. I recently was able to buy a set of control wheels, shafts, and the yoke from a 1996 M20R to put in my M20D. If you have a chance to acquire a set, I highly recommend doing so. I did not think there was much of a difference, and mine actually feel pretty good with the bike tape on them, but once I wrapped my hand around the newer style wrapped in leather I wish I had done it a few hundred hours of flying ago. I want to share a few things that you will need to know if making the swap. The new control wheels mount to the shafts with a bolt going horizontally from 9 o'clock to 3 o'clock. The old control wheels mount to the shafts with a bolt going vertically from 12 o'clock to 6 o'clock. To replace the control wheels and use your old shafts would require drilling horizontal holes in the shafts. Even if you could find an IA willing to sign off on it I feel it would be extremely foolish to add a hole to a shaft that already has an AD to inspect for cracks... Depending on the shafts that you are buying you will likely have to also replace the yoke. The control shafts have a half circle piece on the end where they attach to the yoke. This piece is what allows the shaft to rotate and provides the stops so that it can't rotate too far. The ones coming off my plane have this half-circle piece on top, centered at the 12 o'clock position. On some models Mooney has the shafts that still had this on top of the shaft, and at one point offered these shafts for sale when upgrading control wheels. I do not believe it is possible to get them from Mooney anymore, and it is likely you will have to replace the yoke. On the ones that I got off the M20R these are rotated 90 degrees with the LH side centered at 9 o'clock and the RH side centered at 3 o'clock. If your new shafts are like that you will have to replace the yoke. In this drawing that Mooney put out for replacing the control wheels and shafts you can see circled in red the end of the shaft and circled in blue the piece on the end of the yoke that mounts vertically into the shaft. You can also see it in the parts catalog drawing circled here in red. I had hopes that I would be able to just remove the ends off my yoke and replace them with the ends off the new yoke, that will not work. The ends are held to the old yoke with a bolt through the end, then through the yoke, and a lock nut on the end of the bolt. The new ends have the bolt integrated into them and are held on with a castle nut and cotter pin. The diameter of the bolt on the new ones is too big to fit in the old yoke. You can see the differences in this video. Having established the requirement to replace the yoke, here are a few tips for the rest of the project. Remove the front seats, you are going to be spending a lot of time on your back under the panel, it's much easier without the front seats in the plane. There is not much to replacing the yoke (aside from contorting yourself and laying on your back under the panel) You will have already removed the control wheels and shafts so there are only the two bolts holding the yoke to the tubular frame and the one holding the push rod going to the elevators. Once you remove those you can remove the yoke and put the new one in. (The one off the M20R has a big bob-weight on it. The M20D does not need it so I removed the weight.) You do not have to replace the pheonolic blocks that the shafts go through. In fact in my case the new ones won't even mount to my panel. On my plane they are held in place with two screws at the bottom (about 4 and 7 o'clock) and one at the top (at 12 o'clock). The new blocks only have two at the bottom that don't line up with the holes. I had removed mine and had to reinstall which was a waste of time. Take a look at yours in your plane and the new ones before removing them. After you have the shafts in, the wheels on, and the shafts attached to the yoke you need to connect the push-rods that go to the ailerons. You will most likely have to adjust the length of them by turning the end to make them shorter so that the wheels are level. You will need to take the slack out of the ailerons before doing this. We used the plane jacks with a piece of wood on them under the ailerons to lift them (lightly) so that they sit even with the flaps. After that you can place a straight edge or level across the shafts and line up the wheels with it. Simply slide the bolt through the shaft and the aileron push-rod (no need to put the nut on yet) and then climb back out from under the panel and see where they are at. Go slow, a half turn at a time of the rod end, put the bolt back through and take another look. Continue to do this until you have them level. Once they are level put the lock nut on and snug them down. Make sure you work the new wheels and shafts through their full range of travel to ensure that they do not get caught up on or rub any wiring or the ducts for your vent/heat and defrost. I did this while laying on my back under the panel to make sure nothing was rubbing or binding. Because they are M20 parts your IA "should" sign it off as a minor change in your log book. Mine listed the part numbers that were replaced in the log book entry. (Disclaimer - I am not an AP nor an IA but I did work with mine on this project and this is the process we went through) I am looking forward to now having a push to talk on the RH control wheel and flying with the new control wheels. There really is no comparing the way they feel in your hand compared to the old ones. Old control wheel (wrapped with bike tape to make the summers less sweaty and winters less cold...) New control wheels (Need to make a plate to cover the top of the left side of the right weel)1 point

-

Find shafts from an older J model that match the front ends of your existing ones. You can find them from time to time on eBay, FB groups, or salvage companies. I found mine at Wentworth Aircraft by calling. You can have the factory make them for you as well but be prepared to wait a while and pay a lot. The control wheels themselves are easier to find but can also be pricey. But boy do they update the look of the panel and the AeroComfort leather is so very nice. It’s the one interface that you touch the entire time you fly so it’s something you’ll notice and feel good about each time you fly.1 point

-

I am sadly pretty sure there are some serious family health issues involved so I am guessing not, but I was going to call him next week anyway to see if he had people to suggest. FWIW, I forgot to feel inside the exhaust, but it looked clean. I'll double check that tomorrow and keep looking elsewhere, I just had to quit today because I was getting high on mineral spirits1 point

-

1 point

-

You want the LASAR stainless steel combination tie-down and jack-points. https://lasar.com/mods-squarespace-test?rq=tie down They make a tie down for the tail that you may need too - called a skid.1 point

-

I don't think that minor seepage is the source of your 1 qt in 4 hours vs. 8 hours. Something else is leaking, IMHO.1 point

-

All normal to me. Case Studs and through bolts leak after time. Need to pull a cylinder off to fix it properly. I’d leave it alone. -Matt1 point

-

1 point

-

My experience was that it cost me about 2x as much to own/operate in EU as it does in US. Regarding ACG Air-Craft, I realize that there is only one drawback that I could think of (reverting to previous topic): If they work on your plane for a while, it will sit outside in the damp German weather. My plane sat out for a very long time, with no chance to be hangared because the local hangar was full at that time. The service is great, I appreciate how they operate and they let me participate, but my plane experienced some heavy weathering due to Germany's humid/rainy climate.1 point

-

Strictly speaking, no. Once you've taken and passed all of your exams, you get the same A&P certificates and credentials that anybody else has, and are fully authorized to sign off anything an A&P can sign off. There is no additional requirement or warming up period or anything like that. That said, outside of GA a fresh, certificated A&P will still go through a ton of training and mentoring (akin to an apprenticeship, but formalized only to the extent required by the employer) within a given employer or industry. The airlines have a ton of additional training. A classmate of mine was a Southwest employee, running their parts department here, and on graduation, with his full A&P cert, he got sent off to another year or two of Southwest training in order to be a SWA A&P. That seems to be typical, and even classmates who went to flight schools or 135 outfits wound up getting a lot of training within their new jobs, even with their A&P. It works pretty much as it should and as you'd expect. Within GA, since so much runs on reputation and word-of-mouth, a fresh A&P with no experience is not going to get their hands on a lot of business without doing a lot of work in the field, probably for somebody else, first. Me, though, since I mostly work on my own airplane, I've been doing everything on my own since I got the certs. So do most people in the same boat, BUT, I'll also say that I've not yet seen anybody in a similar situation, including myself, that doesn't research the hell out of something they're not sure about and engage other experienced people when needed. So that seems to work reasonably well, too. In my experience when you find some kludged up horror that some A&P did to an airplane that needs to be undone and done properly, it wasn't done that way by some fresh new A&P, it was done by some grizzled experienced guy who thinks that's how it should be done, or just shoved it out the door hoping nobody would notice or something. Inexperience doesn't seem to be the bigger issue in maintenance errors down here.1 point

-

Call Aero Space and tell them they can supply an Attorney at their cost to deal with this lien or you'll get one and anything you pay for the lien and the Attorney's fees will come back to them. This is exactly why you pay for the Title Search in the first place.1 point

-

1 point

-

1 point

-

I installed an Avidyne IFD 540 in my Bravo and really liked it. Very intuitive as well as the ability to load more information on the screen then the Garmin GTN 750. I liked that when flight planning the prospective route or procedure it was on the screen immediately enabling you to make the best decision for your route. I had the gtn 750 in my J and liked it but can say that they're definitely different but I don't think that one is better than the other.1 point

-

The third cowling is getting ready for the mold to be made. This will be a cowling for the E, F and a PMA for the J. Baffling is being drawn to cut out multiple sets. Air induction parts are manufactured and waiting for the rest of the parts to be drawn and cut. I will have 10 new air induction boxes for E and F models. Moving forward slowly but parts are being manufactured and drawings made for the PMA and STC process. Thanks, David1 point