Leaderboard

Popular Content

Showing content with the highest reputation on 05/08/2023 in all areas

-

I learned right here on MS that these can come loose and replacement was expensive. So every flight I check them. Sure enough one day one was loose, so I ordered the proper adhesive, and re-glued it. A total non-event due to learning from others.6 points

-

Everyone on the ground where he landed is dead.... (It's evidently a Cemetery) :-)4 points

-

Mostly the other way around, the declining oil pressure often first does in the turbo; especially when the oil pump starts to cavitate. But a common cause of the declining oil pressure is actually the turbo seal going bad such that the oil is being pumped overboard out the exhaust when it happens on the turbine side (most common). Sometimes its pumped into induction on the compressor side - but the latter will get your attention sooner since the oily induction air will affect combustion once it makes it way to a cylinder.4 points

-

Yes, I wasn't happy with the way WS was being developed and given that it wasn't scientifically valid and had other issues that I found to be dangerous, I developed my own progressive web app that uses your personal wx mins so you can quantify your risk for icing, turbulence, ceiling, vis, wind, thunderstorms...since we know that flying is all about identifying and quantifying risk...none of the heavyweight apps will do this automatically. Moreover, WS relies on a single model (GFS) using relative humidity which is a horrible and unscientific way to determine clouds. It also now uses the NBM for it's station-based forecasts - the NBM isn't ready for prime time as of yet in my opinion...the LAMP MOS is much, much better especially for ceiling, vis and wind so I don't know why he changed from LAMP to NBM. LAMP has been around for nearly two decades whereas NBM has just started to cut its teeth. Depending on the forecast element (e.g., ceiling, icing, etc.) I utilize a dozen or more models to make that forecast. Relying on a single model is not a good strategy in my opinion. And for the route, WS uses the "nearest" station which can be 20 or more miles away. My app uses 2.5 km resolution data which is much more accurate especially in mountainous terrain where stations are sparse and often local conditions are extremely important.3 points

-

3 points

-

I’ve been going to Byron @jetdriven in KGAI cause he specializes specifically in Mooney and particularly M20Js.3 points

-

3 points

-

The Mooney community (coMoonity?) is lucky to have CAV monitoring MooneySpace.3 points

-

A bit surprised to hear we have 2 Weather Spork app users. Don't get me wrong but Scott D, the meteorologist behind Weather Spork, divorced the developers and developed yet his next generation aviation weather product that he's continuing to grow. I encourage anyone to try it out https://ezwxbrief.com/ Its a website, but is easily setup to run just like any app. Scott also put out daily morning weather briefs on youtube which highlights using his app. The only limitation for me is that it only covers the US.3 points

-

Once a pilot, always a pilot. Never say you’re not a pilot, because you are.3 points

-

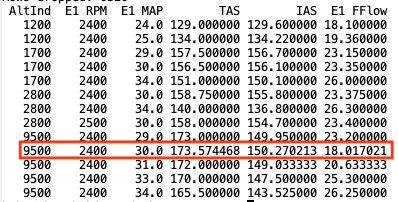

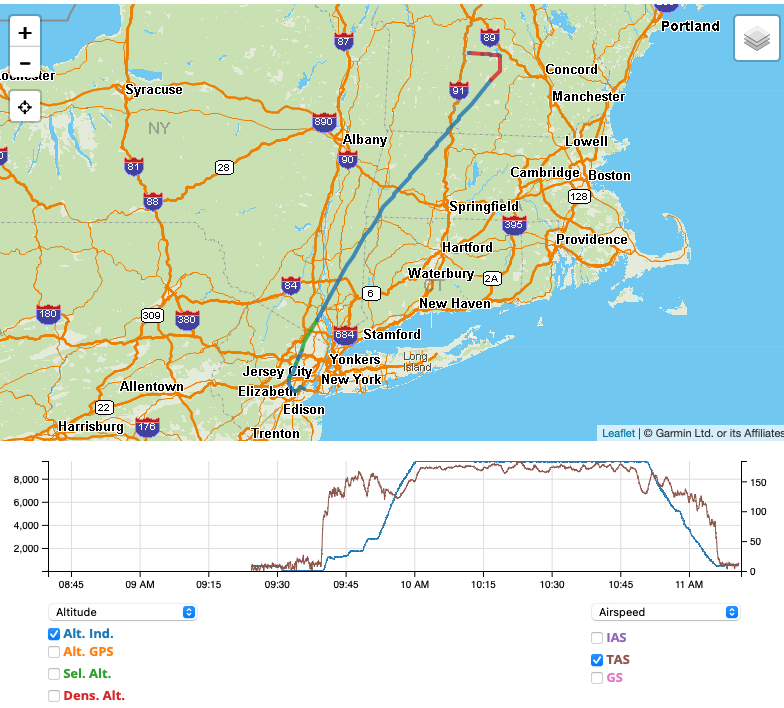

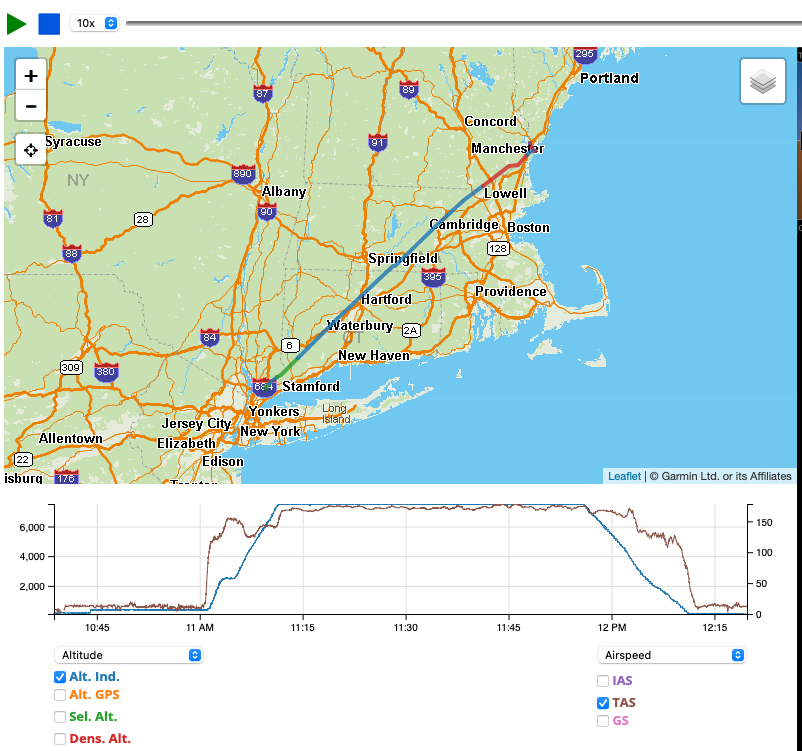

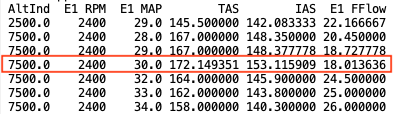

I wrote a program to analyze the EIS data to calculate performance empirically Here are two flights, and I now know that 7500' 2400/30 => 172KTAS at 18GPH 9500' 2400/30 => 173.5 KTAS at 18GPH my target TIT is 1550 this should allow me to: * do better trip planning * track long-term performance changes * compare my airframe against other Bravos * compare the efficiency of the Bravo fleet against the against, say, the Ovations Others could use this to compare LOP and ROP operations (I don't run LOP) Next up, calculating average weight for the segment using the BEW + the fuel totalizer + an estimated 2 pax (the other rows are the airplane settling down in cruise and adjusting MP/RPM/mixtture)2 points

-

2 points

-

2 points

-

2 points

-

Hello @Mooney in Oz, I can comment but not anything like what this poster put down. the first question we always ask when troubleshooting is what software the system is at as well as recommending the system be brought to the latest software level. I would not recommend this not be done simply due to it may point out an issue with the servos installed. as a matter of fact if I owned an airframe with a GFC 500 I'd want to know if a servo is having problems so I could get it taken care of as soon as possible. so updating the software is always a good thing at this point.2 points

-

The best ones…. Are artfully cut to include words like ‘GoodYear’…. Proudly displayed. -a-2 points

-

What is the oil temperature when the pressure goes down? High oil temps will naturally make the pressure lower. Even if the GI275 and the OEM gauge agree, I'd triple check the gauge accuracy with external instruments for both oil pressure and temperature before adjusting anything. And +1 to also check the suction screen. There are a number of things to check before adjusting the relief valve, not that that's a big deal, either, but you may just be masking a symptom of something else.2 points

-

How long since the suction screen was checked? It can get plugged up with carbon and restrict the flow. The oil pressure relief valve can get some small piece of junk caught in it that keeps the ball from seating. According to instructor for the Lycoming factory class, 90% of pressure problems can be corrected by replacing the spring and staking the ball in the valve. Lycoming also has a service instruction 11722 points

-

I always remove the cowling because I want to inspect the engine. Removing lower cowl on a J is easy single handed. Just get two short bungee chords that stretch from the lifting eye to a camloc socket for the upper cowl that is about midpoint the lower cowl on each side. Then disconnect the cowl flaps and landing light (if the light is in the lower cowl), put the prop horizontal, and then unscrew all the lower cowl camlocs. The bungees will support the lower cowl. Next, support the cowl with one hand while unhooking the bungee on one side, switch hands supporting the cowl and remove the remaining bungee. Then, just lower the cowl moving it down and forward away from the prop.2 points

-

2 points

-

On the J it is possible to change the oil without dropping the cowl. I had a quick drain, and when I completed the flight before the change I would connect the tube and activate the quick drain. A day or two later, as EricJ says above, all of the oil will have drained, including the oil in the filter itself. But yes, if you change the oil immediately after flight there will be a ton of oil all over the place. That said, it is always a good idea to inspect everything during the oil change. So I do recommend knowing how to drop the cowl. I would tie a 1/4" cord from one camlock hole, across the top, to the matching camlock hole on the other side. Then loosen all of the other camlocks. Put a 5 gallon bucket below the cowl in front of the nose gear. Once all the fasteners are un-done, untie the cord from one side and gently lower onto the bucket, holding the cowl on your side, and lowering the other side with the cord. Now that I have an Encore with the carbon fiber cowl, I no longer need the cord trick. It's light enough that I can un-do all of the camlocks and then stand in front and below the prop, wiggle it loose, and lower it on to the bucket.2 points

-

Getting the bottom cowl off just takes some practice. I do it routinely by myself, but I have a fairly decent arm spread, too. The safety wire doesn't need to be super tight if the filter is torqued correctly. It's mostly there to keep the filter from backing out if it does manage to get loose, which it shouldn't if it is properly torqued, and won't go far if there is safety wire there, even if it's a little bit loose.2 points

-

Some things to consider… 1) You can take the pilot out of the Mooney… 2) You can’t get the Mooney out of the pilot… 3) There are always Mooney pilots looking to share rides… 4) Keeping in the loop is important… Always welcome to discuss Mooney topics here. 5) Discussing Mooneys can be fun… while helping other people get to their next level… 6) Discussing age and health issues happens a lot around here… be sure to open that discussion to see if you can find more info about your situation… how other people have handled it, or something similar… 7) If you can navigate and talk on radios… you can make a great flying partner… Good luck with your current situation, and your next steps! I applaud you, sharing your situation. Way to go Steingar! Best regards, -a- The ‘Book of Steingar’ is oft quoted around here…. https://mooneyspace.com/search/?q=Steingar book&quick=1&updated_after=any&sortby=relevancy&search_and_or=and Is there really a ‘book’ written by Steingar?2 points

-

2 points

-

In my opinion, Henry Weber, in Lancaster, PA rocks for safety and peace of mind. That's why I fly from Las Vegas all the way to Lancaster, PA to get my annuals done. I've had too many dangerous close calls over the years with defective maintenance done at various other "Mooney Service Centers". Never again. Safety is too important.2 points

-

There is something missed on this thread so far regarding diagnosing a turbo charger failure in flight. I learned this the scary way - I had a turbo charger failure in flight! If you are at altitude where the turbo charger is making pressure well above ambient pressure - which is usually - then your engine will likely be too rich if the charger fails and this will cause the engine to turn off. I.e., I was in cruise at 16.5k running 30'' 2200 which is 18gph. Without the turbo - the pressure is so low inside the cylinders that 18gph is waaaaay too rich and it causes the engine to flood and shut off. So then it was very obvious something was wrong. I didn't figure out what until I had landed. There was also smoke because the turbo had started burning oil in the last minutes. So I assumed I had a fire and didn't correctly diagnose a turbo failure - a restart would have required a much leaner mixture to match the percent power of running without turbo MP at 16.5k. I think there is also a danger of a fuel fire with that much fuel pumping into a dead but hot engine? In any case, in my case I made a successful on airport landing, dead stick as there is plenty of glide range at that altitude. So I learned a lot that day....2 points

-

If I had your email address, I could send you a copy. Probably best to sent the address via PM.2 points

-

Since you have a three day window you’d most likely be able to fly part ways stop and then finish. Time is your best friend. I just flew from Texas to Delaware. Weather has been nasty every day on one end or another. Flew up to Memphis camped out in a hotel flew rest of way next morning. I’m instrument rated with new IPC but with different plane I took no chances and camped out. Welcome to general Avaition2 points

-

1 point

-

I believe it is the same pump and squirts into the same place. Low boost just has a dropping resistor so the pump runs slower. Prime is the same as high only with a momentary switch.1 point

-

There's an IO-360-P1A manual available on Lycoming's site now, too. There are a bunch of relevant Lycoming overhaul manuals available in the wild, arguably the most useful of which is the "Overhaul Manual Direct Drive Engine" document, which essentially covers everything without a gearbox. Getting the latest version of something might be more difficult, but I've been able to find an awful lot of stuff online.1 point

-

I've got NWFS on my list from some earlier research. Glad to hear another recommendation for them. My planes is in for interior right now, so won't be here for a while. But still trying to find a spot. I've got a lead that I hope works out.1 point

-

When I had high OT and low OP issues during cruise (IO360A1A), we tried many things over several years. If I remember correctly, we overhauled the oil cooler, reseated the vernatherm valve, adjusted the pressure regulator, tried multi-weight and single weight oils to see which worked best, even installed a fixed center cowl flap (I was flying in AZ desert temps a lot). Can't remember if we checked the suction screen but I'm guessing we did. Got used to climbing and cruising in the upper edge of yellow. Finally overhauled the engine for other reasons and magically, all the temps and pressures have been perfect ever since. So.... what would have been the remaining potential causes? Oil pump or ???1 point

-

Hmm, by airworthy do you mean, "Would it fly safely"? or "What would the FAA say'? The answer to 1 is : in my opinion, yes The answer to 2 is : Not sure about that. The strip was still attached. The tape held it firmly. Therefore, all parts were still present and in place. Technically, I suppose a ferry permit might have been in order but that's not what I chose to do.1 point

-

@PeytonM, this is not a bad thing, if the system software is up to the latest level and you don't have any issues from the new monitors this is a very good sign that the servos you have will last a very long time and you can wait to have them replaced per our latest SB and get the full advantage of the extended life policy1 point

-

Sounds like somebody’s forever-plane has come to market! Good luck with the PPI! Best regards, -a-1 point

-

Depends on the switch. Switch caps 5/16” or larger often snap on or screw on. Smaller ones with smooth shafts are designed to be glued on or they come off and get lost. Super glue is commonly used - just use a small amount so it doesn’t ooze out and glue the switch shaft to the case.1 point

-

1 point

-

1 point

-

I run that way now and have been for years - not a problem. Many Mooney's are. But someday there is always the option to upgrade the speed brakes to electric. I am putting that off as long as possible.1 point

-

Yes, I disconnect the left cowl flap, attach a hose, drain the oil. Then remove the oil filter from the top, I made a plastic drain to catch the oil. I still managed to spill sometimes, like losing a grip on the filter.1 point

-

Gary Main sent me these two articles on turbo inspection some time ago. Bearing Housing to Turbine Housing Clearance-Maint Tip #11.pdf Low Boost #2-Maint Tip #4.pdf1 point

-

The question is primarily for marketing by Angel flight ("our pilots have spent $XXXXXX in flight time to help others"), so it's mostly a guestimate. I would search for flight schools and clubs which have an airplane like yours and use their rental cost as a guide. (The question might also assist in determining the value of the charitable deduction - the only "compensation" the FAA permits - but while most agree that the amount you pay for a rental is deductible, the jury is out on whether anything other than direct costs attributable to the flight can be deducted in the case of an owner. An answer is above my pay grade.)1 point

-

Once you have paid to replace one, you see the need to include checking them as part of every pre-flight.1 point

-

One of these days I’ll be putting my E model for sale…2000 ttaf and 645 sfrm…with shiny new paint of choice for the new owner.1 point

-

Simple solution: see if Mooney has them in stock as @carusoam suggested. More complicated solution: remove the existing lenses and figure out how to fabricate a duplicate.1 point

-

ouch, those titanium stall strips are 1) hard to come by 2) expensive 3) did I mention they cost a lot?1 point

-

I know Mooney is currently manufacturing ten nose gear legs. I don't know what MLG parts they may have in stock, but you could check with Frank Crawford, support@mooney.com. Perhaps @M20Doc has seen this, but this doesn't seem a common problem here on MS and I would proceed under the assumption that the airplane may have been subjected to a very hard landing and inspect for other possibly hidden damage. I would not purchase an airplane in this condition -- it doesn't appear airworthy and the seller should fix it.1 point

-

1 point

-

50% heavier weights yet no other mention about why it’s ok in the SB other than new balance specs. No other aerodynamic changes made. Doesn’t this seem odd?1 point