Leaderboard

Popular Content

Showing content with the highest reputation on 11/25/2022 in all areas

-

Here's some pics, there will be a full review write up in the December edition of The Mooney Flyer.3 points

-

In September I dropped the plane off at Art Craft in Santa Maria for painting. Arrival time was about 9:30am and the forecast was for clear skies by 10am, so there was a chance it would be broken up enough to arrive VFR. I departed KFUL VFR to do a little formation flying enroute with my friend. The marine layer had not broken up at all, solid from about 2,200' MSL down to 1,000' MSL. Picked up IFR enroute from Santa Barbara Approach and flew the RNAV 12 Approach into KSMX. Full video from the request to touch down. Countdown timer shows flight time remaining. All coms between myself and ATC included, the video is sped up between coms.2 points

-

Well I got the 818 and 805 back from Kevin, everything is working as designed! He turned around the parts FAST and was great to deal with. thanks for the help everyone!2 points

-

Found the blown fuse, after looking three days. They’d been moved. Once we found the transistors they were protecting, fuses were mounted upside down close by. Ordered a fuse and a spare from Newark Electronics, who had a decent price. $20 each plus shipping. Thanks again everyone! Ross2 points

-

I should visit more often. I miss out on all these opportunities to lay out a few overly obese challenges to Hank’s eyes. As a long time Mooney owner, I have had to cross this chasm a number of times. By definition, an OPP is a part or component that is no longer commercially available from the manufacturer or PMA provider. I have always used the same approach to obtain these parts. 1) I verify that the component in question is no longer commercially available. This means that OEM doesn’t make or source them anymore. Sometimes this means finding an MSC who has old stock of something that the OEM no longer manufactures or sources. In the worst case scenario, it means, heaven forbid, digging one up at a salvage yard. 2) If option 1 is or isn’t available and a PMA equivalent is available, I look for the component through the PMA environment. Especially when the OEM charges way more than the PMA equivalent. This is where it can get challenging. There may be an updated version of something that is different enough in design and function but still fills the functional need of the original OEM design. This is when I engage the IA input on whether or not they feel it is compatible. 3) If the component is no longer commercially available through the OEM & PMA network, I then engage the OPP process. An old time IA helped me by saying that to comply, I needed to be the one directing the engagement of a provider to have the part made to my specification. He also said that it is important that owner documentation is provided to the manufacturer of the part to satisfy that I am directing and authorizing the manufacturing. And to this day I follow the same recipe. > If the part can be sent to someone to be duplicated, I send it with my specific instruction to manufacture it to the exact specification of the item I sent. At times, the part needs to be made of an alternative material. An example is a component made of Bakelite. It is up to me and my IA to determine if the new material is acceptable for use and I provide a document to the manufacturer authorizing the OPP. > If the part cannot be sent, I photo it, take measurements and call out anything specific (ex. material it is made of) and my authorization to make it. Where things have gotten interesting is with the newer technologies like 3D printing. As someone who has worked with government agencies on a regular basis, it is all about the paper trail. Sent from my iPad using Tapatalk Pro2 points

-

The FAA doc indicates they're looking at the fabricator, not the owners. I suspect making multiple of something looks too much like "manufacturing" or whatever to the FAA. If so I'd question how many times somebody has to be asked to make the same part, or over what time period, suddenly creates a problem, or why multiple people going to the same fabricator proven to make safe parts should be discouraged. My understanding has always been that McFarlane makes the custom/OPP/experimental cables to order, and given the differences between the ones I had made custom and the one I got PMA I suspect that's true. They were significantly different. The mechanic determines that the part is properly designed, produced and documented (e.g., by an owner logbook entry), and appropriate for installation. The installer has to determine suitability for installation with any part, whether it's PMA or TSO or otherwise "approved", so that's not really much different for an OPP part other than making sure the owner has properly documented production of the part. At annual the IA then also determines that the aircraft conforms to type design with the OPP part. As always, though, the FSDO can reach their own determination regardless of what went before. It appears in this case that a MIDO has an issue with something, which a FSDO or whoever else may act upon. Yeah, we'll see if this blows over. So far the most affected parties are the fabricators cited on the document. If it becomes an issue for them and there's not some hidden malfeasance or something I'd put money in a gofundme or something to help defend those guys.2 points

-

2 points

-

I think as long as whoever made the complaint let’s it go, it’s over, no further action. See someone made a complaint, FAA had to investigate, they find credence to the complaint, so they issue a letter, issue resolved. Unless the complainant won’t let it go. My opinion only of course2 points

-

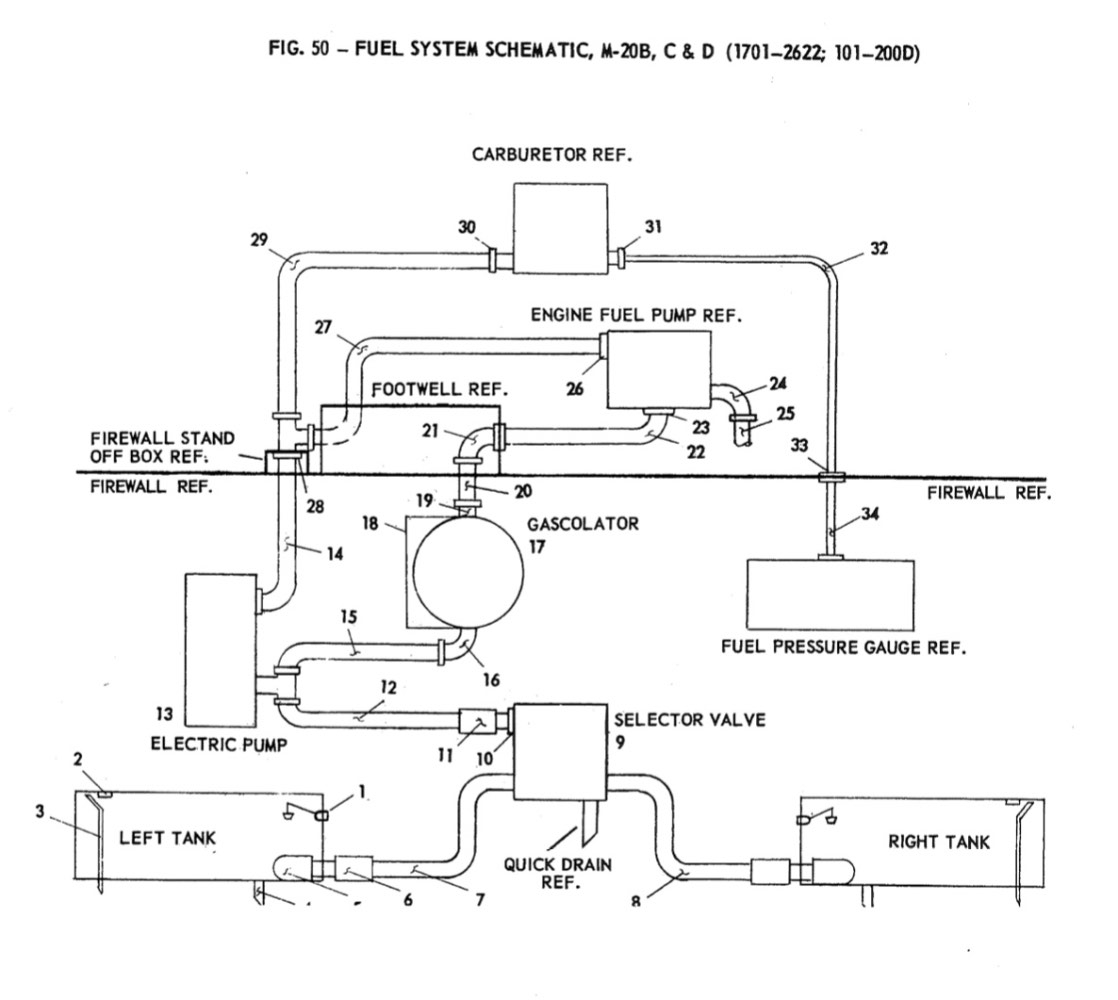

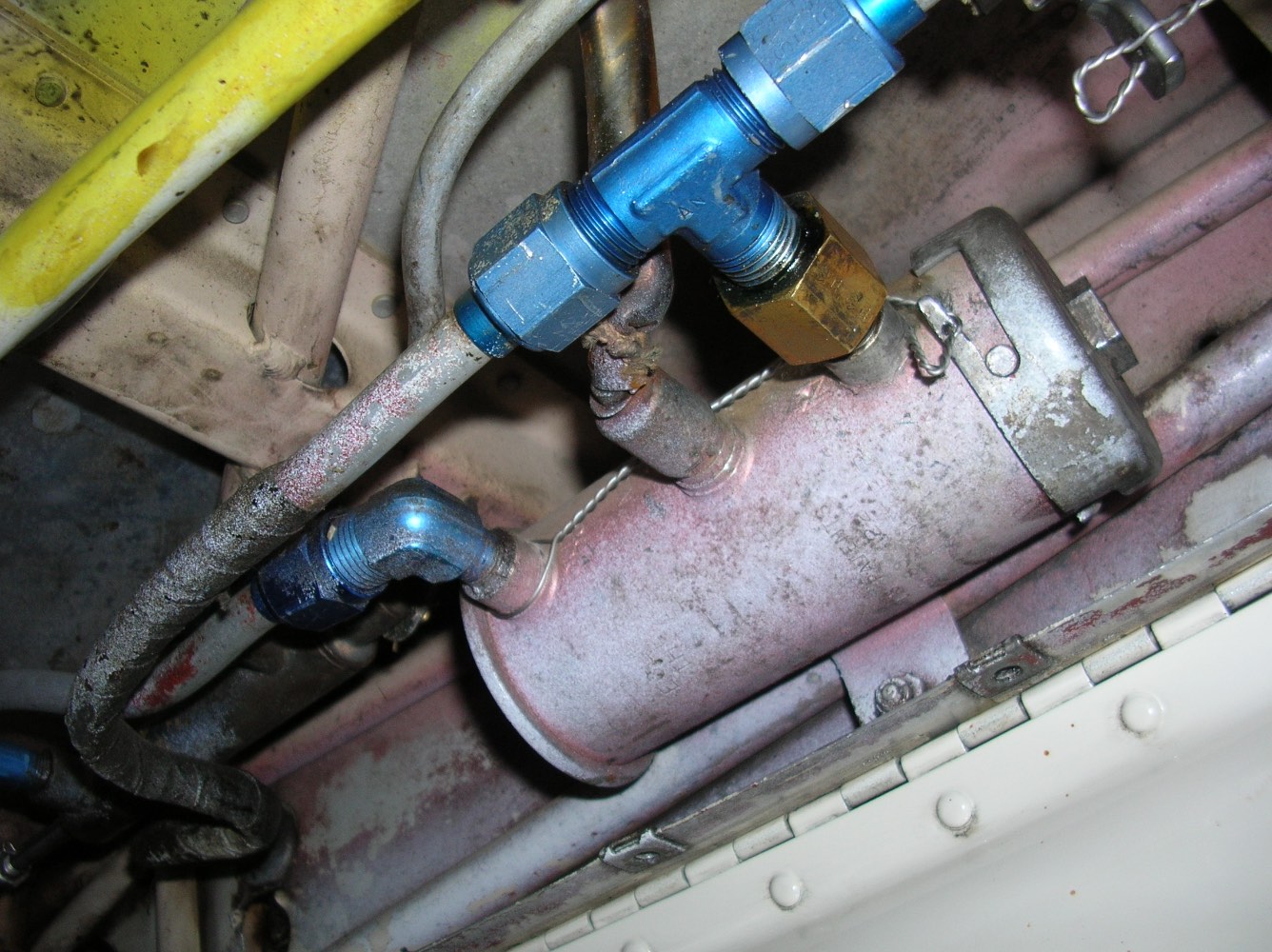

Welcome to MooneySpace! We need pictures! You probably have a slow leak in the gascolator drain, or the bottom cork gasket. There’s a gasket at the top of the bowl, too. The inlet line to the gascolator might be leaking, also, but you’ll need to drop the left side cavity panel next to the left nose gear door. There’s about 1,000 C and D model serial numbers with a parallel-flow fuel system. There’s a T fitting at the electric fuel pump inlet that sends fuel through the nose wheel well to the gascolator. From the gascolator it the line enters the cockpit at the forward end of the nose wheel well to an elbow fitting in the pilot’s footwell. Then a -6 hose to the engine driven fuel pump and the output of the engine driven pump rejoins the fuel from the electric fuel pump in anther T fitting at the lower left firewall. And a single -6 hose to the carburetor. That’s why running the electric fuel pump doesn’t fill the gascolator bowl. This is the T at the electric fuel pump inlet. The T supplies fuel to the gascolator. The outlet of the electric fuel pump goes to the T at the firewall. Fuel line in the cockpit from the gascolator to the elbow in the footwell. This line is subject to cracking because no one uses a backup wrench when tightening the -6 hose on the other side of the firewall. Erratic fuel pressure and fuel flow (if you have it) means the fuel system is sucking air… somewhere. Hose from the elbow in the footwell to the engine driven fuel pump. If this hose isn’t positioned ‘just right’ it will impede removal of the oil sump suction finger screen (right side of pic). Your fix is probably pretty simple… congrats on your D/C ownership!2 points

-

Hello all, I figured I should update the 7 year old topic regarding donations to Mooneyspace and how to upgrade your membership to "Supporter" status since there has been some confusion regarding this shared with me lately. Anyone that makes a donation of $10 or more will get Supporter status on the site for 12 months. While $10 is the minimum more is always appreciated! The average donation is $25 which seems to support the site nicely. In the past year we upgraded the hosting package to a dedicated virtual server at a 400% increase in hosting costs and the forum software we use has raised their subscription pricing many times over the years. However, we have kept the same $10 minimum donation since 2009. Supporter level will give you: No ads on the website - note that you will still see ads when using Tapatalk as that is separate software from our forums. Ability to post in our classified sections to list personal aircraft/parts/items for sale. Note that this is *only* for personal items and we do not allow businesses to use the forums as a sales platform. 5x Increased storage space for uploads such as attachments in your posts (1GB vs 200MB) To donate you can use THIS LINK. If you wish to mail a check or if the link does not work please send me a message on the site for my address or direct PayPal email address. I would like to give a BIG thanks to all of the members here that have supported Mooneyspace over the past 13+ years. It would never have been possible without YOU! Craig1 point

-

My thoughts exactly. I flew regularly from age 18-30, then got married/kids/job/mortgage and all that. Airplane ownership seemed entirely out of reach. Except for a wonderful six month stint in Australia in 2002, I flew only occasionally after that. Then I woke up one day at age 53 and realized I could afford to own an airplane! Discovered Mooney's and haven't looked back. Buyin' and ownin' ain't the same thing. Buyin' is the easy part! Nobody who can afford to own a personal airplane does it to save money. They do it to save time! It helps if you enjoy spending money on your hobby.1 point

-

I remember a question on my A&P general test was about what limits the taxi speed of an airliner, and the answer was the speed of the slowest wing walker.1 point

-

There pretty much has to be a screen as it's what keeps any debris from jamming or damaging the oil pump gears. The holes in the screen are sized to match the cavities in the pump, so if it makes it through the screen it'll make it through the pump and wind up in the filter.1 point

-

There are (or at least were) cheaper sources for those fuses. If need be, I can look to see if I can find my notes.1 point

-

1 point

-

Infer was the wrong word. What I meant was “incorrectly state”. Knowing exactly how the process went, I can’t understand how it could be done any better to meet the documented method of OPP. I wonder if they know how it actually went. The only thing the owners didn’t do was press start on the machine or supply the raw aluminum. this whole thing meets OPP a whole lot closer than ordering a pre-fab cable from a vendor… Also, as I understand it, it’s the owner that determines the eligibility to install and the mechanic that confirms and signs it off. So hasn’t the eligibility been determined for those already installed and logged as OPP? I do not have any of these on any airplane I own, but I do have parts on my plane that have a letter just like this floating around. No one, including the FAA, has required removing them1 point

-

It came from the MIDO they do PMAs that’s their thing.1 point

-

They didn’t infer anything. They stated clearly “The production of these parts does not meet the FAA requirements for “Owner-Produced Parts.” From the statement above, I am inferring that the parts are in limbo. We understood they were not PMA parts at the outset. Why PMA status is such a large focus of a notification regarding OPP parts is not clear. What is even less clear is how/why the FAA has determined OPP ineligibility. They simply made a blanket statement with no qualification. The statement below seems to indicate that eligibility for airworthiness is yet to be determined. “the FAA recommends that they be quarantined to prevent installation or use until a determination can be made regarding their eligibility for installation, or replaced with FAA-approved parts.” It’s a goat rope in my opinion.1 point

-

Obviously it can be done, but you’re prudent to be cautious and think it through. The only time I’ve broken down on the road was a master cylinder leak. I found a mechanic on the field who had the proper O rings on hand and rebuilt the brakes the next morning. I had soft/squishy/50% effective left brakes until my home mechanic spent an hour with the plane tilted back working on it. It was fine after that. So clearly it can be done ok, but, yes, it can be a pain if you’re in a rush.1 point

-

Like @A64Pilot mentioned above, the trick is to push enough fluid through (with out stopping) from the bottom (caliper). I've done mine several times and never had an issue side note: I use an oiler (shown below), and clear tubing between the oiler and caliper so I can make sure I'm not pumping air into the system, I also use clear tubing (4 foot or so) from the reservoir to a catch can on the hangar floor, laying under the plane you can watch for the air bubbles to stop showing in the tube going to your catch can, a few more pumps and close off the bleeder...keep the fluid moving up and out until no more bubbles1 point

-

Sometimes it's about somebody's personal career advancement in an organization. Sometimes it's just somebody being vindictive. Sometimes it's somebody who thought they were doing the right thing but didn't have all the info. I suspect we might never really know.1 point

-

1 point

-

They are the manufacturer they have to provide notice the same way they post SB’s, AD’s, etc.1 point

-

See that’s just it, he wasn’t. He bought the spar caps himself but fabricated the rest of the kit, but when he put the wings together he signed off signing off installation of CK-AG41, the Custom kit we had designed and tested to prove it was fail safe, if your interested I’ll give you a link that explains the problem and the kits etc. https://thrushaircraft.com/support/technical-publications/Service Letters/sl-ag-110 WING SPAR STATUS UPDATE.pdf So Thrush assumed the liability for parts they didn’t even make. He was counterfeiting parts. Funny thing is the FAA FSDO inspector showed up at his place to investigate, he was told I can make any part I want to for my aircraft, show up here again and I’ll shoot you. FAA left and that was the end of it. Later as he was renting a hangar from his county to run his shop I guess they locked him out for not paying rent, he broke in and trashed the place tore it up. He went to jail for that. I don’t know what he’s doing now, I Retired out of the business.1 point

-

Then you certainly should know how hard it is sometimes to get your oil temp up high enough to cook off the moisture1 point

-

1 point

-

I wonder when McFarland is gonna get a notice.. I remember ordering a throttle cable from them. I had to provide them the length etc of my old cable so they could “produce” it. The new one arrived in a bag with a manufacture date from before mine had even broken…1 point

-

I’m with A64Pilot… unless there’s an issue with corrosion on the gascolator bowl seats that cannot be cleaned up so that the top and bottom gaskets don’t leak, I don’t see a need to change it.1 point

-

Yeah, I think there’s about 4 different published legit ways to put this together. That SB is from 1968 though and my parts catalog is newer. It shows 2 different ways depending on year/type. I talked to the parts people at Lasar since the steering horn came from there in 2003. They are sending me all new hardware, bushing, etc. They are sending a bolt, castle nut, cotter pin to go there, so I think it will be what you guys were talking about.1 point

-

1 point

-

My J is the same, with orifices on the side of the cylinders, and I had heard stories so I worried. But I had no problems at all, the reason why I feel pretty sure is because my bleeder looks like an insect sprayer and you pressurize it with a pump, attach it to the bleeder nipple at the bottom of the slave cyl and open the valve, then you get a steady flow of fluid, it’s the steady flow that I believe does the trick, if you do the oil can route you get squirts of fluid, start, stop and I believe a constant flow flushes out the bubbles better. https://www.aircraftspruce.com/catalog/lgpages/hydraulicBleedertank.php I drained the tank in the back, then bled the left brake until the tank overflowed, disconnected the bleeder and moved to the right brake, drained the tank and bled until it overflowed again, sucked fluid out until it was at the right level and have had perfect not soft brakes since. I think flushing the system ever so often if you use 5606 is important as that stuff given enough time turns into a gel. If you use 83282 then that’s not an issue, plus it’s fire resistant.1 point

-

So in my opinion if I wanted seat rollers for instance, all I would need to do is contact someone who knows how to make them and have the plastic drop shipped to them from Mcmaster Carr or whoever sells the raw material. I agree many people can exceed the factories quality, I’ve seen seat rollers built to internal engine component tolerances, where I would likely have cut them with a band saw1 point

-

People who actually manufacture an OPP are certainly allowed to make a profit doing so just as people who install an OPP are allowed to make money from doing so. While it may seem silly to some, but the Owner MUST be the manufacturer, I’m sure that came about as a liability concern, plus a way the FAA could allow an non PMA or TSO airworthy part to exist. I’m pretty sure the rules were written for Commercial operators as a way they could keep their aircraft in service and we benefitted from it, but can’t prove that and it doesn’t matter anyway. They in my opinion set out VERY lenient definitions of what instances the owner could become the manufacturer, pretty much all they have to do is participate in the manufacture of the part, this can be as simple as handing a machinist a piece of metal and say make it out of this. But ordering and paying for a part isn’t participating. However there are logbook entries also that are required to be made, and I suspicion that some don’t want to make those entries on the basis of it could reduce resale value maybe. But skilled people with the equipment and training are allowed to do the work in making an OPP, but the owner must accept the liability and they do so by becoming the manufacturer and they become that by participating in the manufacture of the part. A&P’s and IA’s have been making parts since time began, taxi into a post and one will sit down and make ribs and cut a skin doing the repair, the line has always been vague, left to the interpretation of the repairer as to how far they could go. OPP has no limits that I can see, if I had some kind of antique engine from what it looks like I could have a new crankshaft made.1 point

-

Just bought modified marine jacks from Minderman marine in Port Clinton , OH. Pictures to follow. I worked with chief machinist Dan to modify the tip of the lifting rod to fit mooney hoist point. He said they’re willing to make aircraft jacks and would post on our vendors forum…1 point

-

What Eric said. If 15 people with identical part numbers do the work to measure and recreate a part, those 15 people should come out with identical parts. When 15 people all need the same identical part and as a group work together to recreate that part, it’s still an owner produced part. when the owner produced part requires a process like cnc, it makes sense for those owners to band together and use the same machinist to lower costs. Either that or you had better also ground all those airplanes with those Lasar 6pack replacement panels also being sold as owner produced parts at a hefty profit as well.1 point

-

That's correct, but I don't think any owners that had parts made sold them. The FAA doc isn't citing any owners. An Owner Produced Part doesn't have to actually be made by the owner, as long as it has at least one of the attributes described in the FAA guidance (e.g., inspection, quality control, etc.). So it is expected that an owner may pay someone to do the actual fabrication, and this is allowed in the FAA guidance. For example, before McFarlane started producing Mooney engine control cables to Mooney part numbers, it was common to fill out the McFarlane spec form or just send them the old cable and pay them to make a new one as an OPP. If many people independently ask the same place to make the same part (as I'm sure they did to McFarlane), it shouldn't matter, imho, but I've long had the sense that there is diversity of opinion about this within the FAA. Just like some people have had bad experiences getting grounded in one FAA region for a modification approved in another, different people there interpret things differently. Without knowing any more than what's come out here and elsewhere and in the documents so far I suspect this is more of an FAA issue than a Mooney owner or a part fabricator issue. Remember our friend at Gee-Bee products had a very long engagement with the FAA about his part production and ultimately came back doing the same thing he'd been doing all along. The FAA doesn't always get this right, and there's definitely been more than one way for them to interpret their own rules.1 point

-

Heat after shutdown turning the fuel to vapor? Gascolator should be the lowest point, gravity should not have fuel from it running anywhere, fuel tank is uphill, so are the tanks. Any leak with the fuel selector on won’t drain the bowl, it will refill from the tanks. Tanks are vented there should never be any vacuum or pressure in them, but check the vents anyway1 point

-

They will come down. I’m pretty much shocked that prices of any or all high buck non essential items haven’t already, am I the only one that thinks what’s happened to the market and current inflation is very serious, serious as in I think worse than 08 if it doesn’t correct soon. Average new automobile cost 42K one year ago, it’s approaching 50K now. This article was written in Jan, I bought a Tesla 1 yr ago, its blue book value one year later is more than I paid for it, that’s unsustainable. https://www.caranddriver.com/news/a38748092/new-car-average-sale-prices-47100/ All I can contribute it to is the media essentially ignoring the economy and the fantasy that’s it’s strong. Somehow people have adapted, I think by running up debt, but I don’t think that can last as I assume debt is increasing and for an individual there is a limit to that. https://www.cnbc.com/2022/11/15/household-debt-soars-at-fastest-pace-in-15-years-as-credit-card-use-surges-fed-report-says.html When the fall happens if you have cash you can get a Bonanza for pennies on the dollar, the longer it is before the fall, the harder it will be1 point

-

Good evening everyone, I'm hoping I can address all the questions on this thread in regards to the recent service alert for the GFC 500 we had to issue. the problem very rarely happens, but we've had a couple of reports of it from the field and did verify there is an issue with the system where the pitch trim can go into a runaway condition when the autopilot is first engaged. this can be quite uncomfortable with the plane trimmed out and on a flight plan and then engaging the A/P and it could do this. We've been working closely with the FAA on it and as it has been mentioned is able to be corrected with a softrware update for the G3X, GI 275 and G5 systems. we're diligently working on this as you can imagine to get this all completed, submitted to the FAA for approval and then to the field. the plan is to have this completed by the end of the year. in the meantime the recommendation is to pull the breaker on the GFC 500 or have the Garmin dealer disable the pitch trim function in the configuration of the GMC 507. as for how the dealers are alerted to problems and bulletins like this, no we do not bundle all of the bulletins and send them on one given day. when these are posted to the dealer resource center website for our service centers, it is also sent to the email address we have on file in our system. unfortunately if this email address has not been verified it may not get to the right person(s) at the dealership. but we do our best to re-iterate this when the dealers call into us as well to get the word out to the field. I know I've been working on a couple of things for some Mooneyspace pilots and as you can imagine when this hit a head we had to put our undivided attention on it, but I can assure you I've not forgotten and will get with you as soon as I can on the issues we're working on. Please let me know if there are any questions on this issue and I'll do what I can to get any details out to the group.1 point

-

It's kinda both. Energy in the form of both heat and kinetic mass goes into the turbo. That energy is used to compress the intake air, which heats the intake air up quite a bit (by PV=nRT as previously mentioned), so the energy level of the exhaust is lowered by what is extracted to do the work of the intake compression. So there's energy into the turbo, both heat and kinetic, and there's energy out in several different directions: compression of the intake air, heat to the turbo itself (some of which is radiated and some of which heats the bearing oil due to friction and conduction), and heat and kinetic energy out the exhaust. The exhaust temp is lower than the input temp since some of the heat energy has gone to do work compressing the intake air, and some has been radiated or been absorbed by the oil. The lower exhaust temp indicates that intake heat energy from the input went somewhere else to do something else before it went out the tailpipe. Energy is always conserved, so whatever goes in goes out somewhere. Since the idea is to use as much of it as possible to compress the intake charge, less will go out the exhaust pipe. The exhaust air will have both less heat and less kinetic energy. The intake air temperature increases primarily due to the compression, as it doesn't spend enough time in the turbo to be able to absorb much of that heat. The intake temperature increases due to the pressure increase regardless of whether the compressor is attached to the hot turbo or separated mechanically to isolate them. Superchargers driven by mechanical means have the same temperature increases of the intake air charge.1 point

-

1 point

-

1 point

-

Just because you don’t want to discuss doesn’t mean everyone else doesn’t either. It’s a public document and it affects quite a few people.1 point

-

1 point

-

1 point

-

What seemed strange to me about this is why they found the problem during the servicing part of the annual rather than the inspection part which was also the pre-purchase inspection. One would normally expect the corrosion to be evident in the wheel well since that is the side of the stub spar that is exposed to the elements. I don't know how many shops would remove that access panel during a pre-purchase inspection. Maxwell didn't remove those when they did mine. Maybe the shop removed them as they said; maybe not. I looked in the service and maintenance manual and it states that these panels are for access to wing attach bolts (true) and for lubrication of control guide blocks (which is a mistake -- there are no control guide blocks there). But if the mechanic was going by the servicing chart in the manual, he/she/they may have removed the panels for lubrication and discovered the problem then. Anyway, it sounds like you are on your way to getting if fixed. Maxwell or Dugosh should be well equipped to take care of it. Good luck! Skip1 point

-

So blame the customer instead of the prebuy shop. Who conveniently found the corrosion a couple days after the plane changed hands. They couldn’t possibly find it until they did. MSC pedigree. Ok…1 point

-

Damn! This is a NIGHTMARE scenario. I feel terrible for you. My opinion is that pre-buys are a crap shoot. The 'experts' here will condemn anyone that fails to get a pre-buy; then those same 'experts have zero problem telling you after you DO get a pre-buy that you can't expect the shop to find this stuff! WTF??? I paid for a pre-buy at a MSC, but frankly, I suspect I just got lucky. Honestly, the fact I bought a plane that was consistently flown by the same owner with his family on-board for the previous 13 years had more to do with the plane being in great condition than anything else. Good luck!1 point

-

Completely incorrect, please stop propagating this old wives' tale. The certification standards require fuel gauges to be accurate throughout the complete range of the indicator. The myth comes from a misunderstanding of the sub-part dealing with usable vs. unusable fuel. I don't mean to be a jerk about it, but propagation of this OWT is a substantial reason fuel gauges get signed off when they're actually unairworthy. This just further propagates the myth they're less reliable or less important than other critical indicators. I'm sure this drives the professionals absolutely nuts. The OEM fuel gauges in your Mooney and other GA aircraft are designed to be reasonably accurate throughout their range. They need to be, because gauges are the only mechanism that will detect a developing, in-flight fuel system leak. Totalizers and timers are of course excellent safety guards against fuel starvation, but they're meant to supplement the gauges, not replace them. If your gauges are inaccurate, your aircraft isn't in compliance with its type certificate, and it needs maintenance. Kudos to the OP for wanting his fuel gauges to be accurate, and to businesses like CIES for providing technology that improves accuracy and reliability.1 point

.thumb.png.7c67574d7b28f67b0b4a17760919b1ac.png)