Leaderboard

Popular Content

Showing content with the highest reputation on 11/23/2022 in all areas

-

The announcement came before official publication but this morning (November 22, 2022), the FAA published a Direct Final Rule which changes the current 3-year aircraft registration expiration to seven years. Absent a substantial objection, it goes into effect January 23, 2023. It will apply to all registrations valid in January, whether issued before or after the effective date. For example, if your registration was issued in March 2020 and expires March 2023, the expiration date is automatically extended to March 2027. You do not have to obtain a replacement registration, but those who travel out of the country may want to avoid validity questions about why the registration says it already expired by obtaining a duplicate. Also going away are the 90-day extensions of temporary registrations which have become ubiquitous due to delays at the FAA Registry. Instead, your temporary registration (the copy of your application) is valid for 12 months. The text of the Direct Final Rule can be read here.6 points

-

I’ve heard of C blocking but not D blocking. As usual I’m out of the loop.3 points

-

@brandt. To try to answer your question, whether an engine is operated LOP or ROP there is unburned fuel in the exhaust. It burns in the collector of a TCd engine and I am told by engineers that it burns hotter there than in the cylinder. The objective of either LOP or ROP operation is to slow the combustion cycle, which means of course that combustion is occurring later than at peak. So some unburned fuel will always be pushed out. For that matter some unburned fuel would be pushed out even at peak, or at the point where the combustion cycle is quickest which is somewhat after peak, just less of it than if the combustion cycle is elongated. There are three things that cause TIT to be higher than individual EGTs. The first is the measurement effect that has been discussed. The second is the secondary combustion event that occurs in the exhaust system. The third is that the exhaust flow is restricted at the turbine (it hits the fan), meaning higher pressure, and higher pressure equals higher temp. Of these, I am told that the measurement effect is the greater. I should hasten to add that I have heard different explanations of the secondary combustion event from engineers, one being the delayed combustion event that I described and the other being some kind of catalyzation of the exhaust gases themselves as opposed to burning of residual fuel. That is over my head, ask an engineer, which I ain’t. Lance is right this question has come up many times and has been answered many times by people smarter than me. Try searching on “secondary AND combustion AND TIT” and you will see some of the discussions from the past. I found one that I was involved in in 2016 and I know there were discussions even before that. None of it is very important. Simple is that TIT will be hotter than individual EGTs so you know what to expect on your monitor, but other than that it does not mean much. Just understand it is normal. Now if yours suddenly isn’t that should get your attention and lead to an immediate emergency landing post haste and a check of the connection between the collector and the turbocharger but that is another story.3 points

-

Great news! i’ll be applying for that duplicate soon even though i just got my new one. I am not trusting an “expired” on paper, even though not officially, is going work without delay out of the country. Sent from my iPhone using Tapatalk3 points

-

The individual cylinders only get a pulse of hot gas occasionally. Turbine inlet gets hot gas from all cylinders — almost continuously.3 points

-

Hello all, I figured I should update the 7 year old topic regarding donations to Mooneyspace and how to upgrade your membership to "Supporter" status since there has been some confusion regarding this shared with me lately. Anyone that makes a donation of $10 or more will get Supporter status on the site for 12 months. While $10 is the minimum more is always appreciated! The average donation is $25 which seems to support the site nicely. In the past year we upgraded the hosting package to a dedicated virtual server at a 400% increase in hosting costs and the forum software we use has raised their subscription pricing many times over the years. However, we have kept the same $10 minimum donation since 2009. Supporter level will give you: No ads on the website - note that you will still see ads when using Tapatalk as that is separate software from our forums. Ability to post in our classified sections to list personal aircraft/parts/items for sale. Note that this is *only* for personal items and we do not allow businesses to use the forums as a sales platform. 5x Increased storage space for uploads such as attachments in your posts (1GB vs 200MB) To donate you can use THIS LINK. If you wish to mail a check or if the link does not work please send me a message on the site for my address or direct PayPal email address. I would like to give a BIG thanks to all of the members here that have supported Mooneyspace over the past 13+ years. It would never have been possible without YOU! Craig2 points

-

I don’t wish for this thread to be deleted so no need to rehash the recent discussions regarding you know what.. what I want to know is who/what is driving the deletions. Hard to believe the authors of two threads opted to delete. Can anyone say who is doing it and why?2 points

-

2 points

-

The unemployed Twitter censors have made their way to Mooneyspace.2 points

-

If this thread goes away, know that its end was as likely self inflicted as Epstein’s.2 points

-

Curiouser and curiouser. The whole topic is disappointing on so many levels. The first rule of D block club is we can't talk about D block club.2 points

-

2 points

-

If you look at my numbers, you can see "TIT" is higher.....except........ I don't have a turbine. This is an Ovation. The "TIT" number is the probe on the collector pipe and collector is exactly what it infers. It collects all the exhaust gas on that side with no break as opposed to individual EGT probes. You can prove the additive aspects in that the "TIT" temp when running full rich is about 30 degrees higher than the highest EGT(#4). When at peak EGT is it about 90 degrees higher than the highest (#4). At 50 LOP it is about 60 higher than the highest, again, #4. If there were secondary combustion the flame is longest at full rich (we Beech 18 guys you to play with flame length with the mixture when bored) While one could argue that long flame is cooler due to excess fuel it cannot amount for the very large difference at peak, especially when viewed in light of the LOP differential.2 points

-

someone asked about the reference to pulling the prop back, It actually states in this POH in regards to glide distances to pull prop back to increase the glide ratio.. http://www.avsoft.com.au/ext/m20tnpoh.pdf2 points

-

2 points

-

I just recently caught this thread but had to respond. As I have been reaching into retirement age, I have seen more and more of family, close friends, and others who have been leaving this world in increasing numbers and making me realize more and more how valuable our time is. How much time have I wasted sitting in a vehicle on the road trying to get some place that the airplane could get me to so much quicker and with so much pleasure. I attest that some of the money spent on this venture is just COP money. (Cost of Pleasure). Life is, for sure, shorter than we realize sometimes.2 points

-

What are your oil temperatures during all this? If pressure is inversely tracking temperature then the issues may be more related to oil cooling (too much or too little) or a lazy vernatherm (oil temp regulator). The 6qt thing is because above that level there is oil high enough in the crankcase to be subject to crankshaft windage, which aerates it so some just goes out the breather. Usually a film on the belly or gunk on the belly antenna leading edges will show this more than usual. I'd be cautious about cranking the oil pressure up until you're certain about what's going on. My airplane is pretty sloppy about regulating oil temperature and under certain circumstances I'll get either high or low oil pressure alarms, so I don't really have room to adjust it either way without compromising something more than it is. Because you're in a cold climate you'll likely have oil pressure on the high side during warmup, so that's worth paying attention to to not make it worse.2 points

-

Sometimes those pipes will move even when tightened. The pipe vibrates and eats up the recess in the collar. You can sand the collar and restore the pinch fit for the gasket. Also. Coat those gaskets in copper spray or aviation sealer. They aren’t air tight dry.2 points

-

The pipe flange can get pinched outside of its groove like that and then it won't seat completely. When starting to tighten the collar down you can take a screwdriver or a plastic tool between the pipe and collar and wiggle the pipe around until it pops into the groove or seats properly, then torque the fasteners. You can often tell by visual inspection whether it seated properly, e.g., in your pic above it isn't. With the collar off and the pipe moved down a bit you can check whether the flange is flat or has been bent. Cleaning any old gasket material or gunk out of the groove in the collar is a good idea, too. A pressure check with a shop vac and some bubble solution will show whether it is still leaking or not. I just did this on my airplane, too, so it's fresh in my mind.2 points

-

Just now realizing that Ron Blum and @Blue on Top are one in the same. Truly a man with a wealth of knowledge and a willingness to share. So very sorry to learn of this tragic turn.2 points

-

no where near the cowling or engine but out under the wing where your OEM OAT probe is located. Otherwise back by the tail on the fairing under the elevator also works real well. Sent from my iPhone using Tapatalk2 points

-

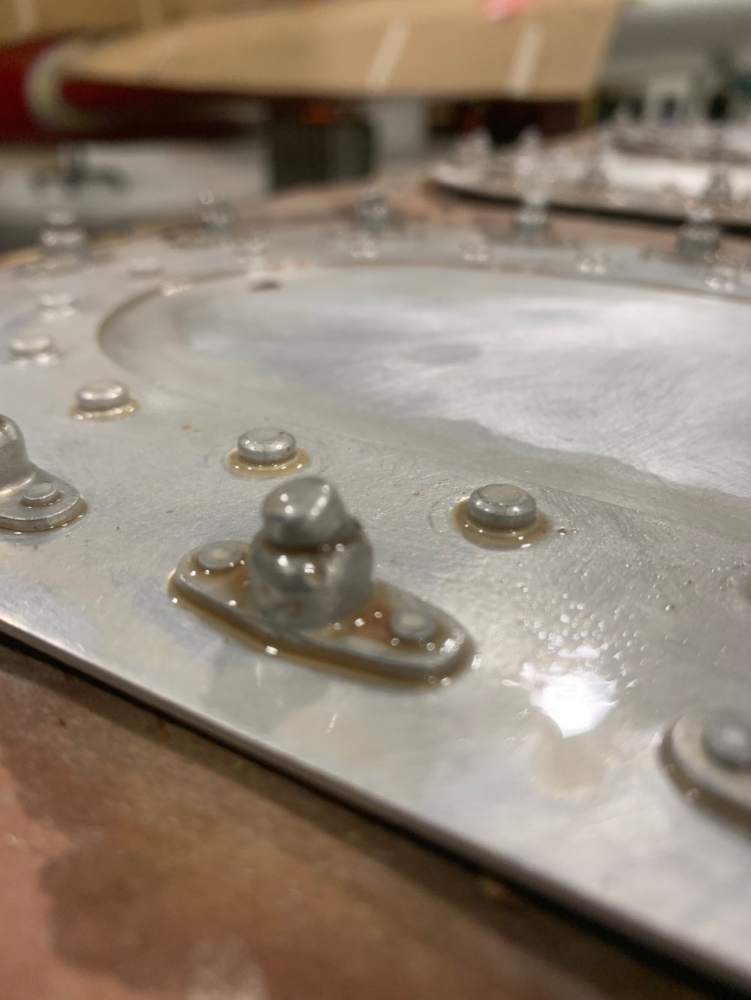

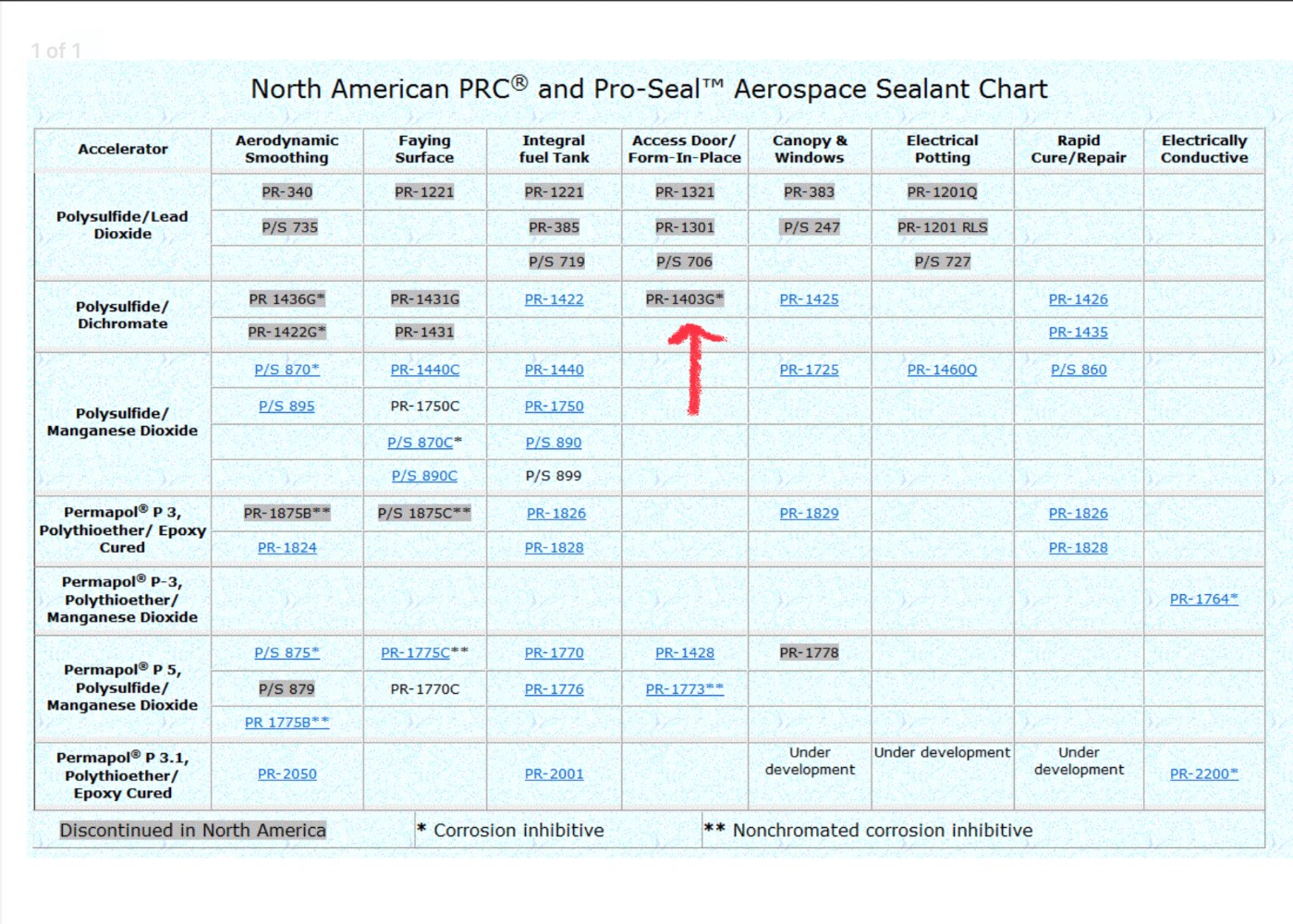

I haven’t got to the materials part yet. Busy with other airplanes. I will post the information as soon as I get to it. Now, here are some pictures of what using the wrong hardware ( too long ) to your access panels. can do, creating more leaks in the process. That’s also PolyGone at work on the access panels with original sealant.2 points

-

No worries. Terms get misused all the time, and it can help reduce confusion, both present and future, to point out common misconceptions when terms are misused. There's a difference between a manufacturer's part number and a standard part number, although they can sometimes be the same when a part does get standardized. It can get even more confusing when third parties make replicate parts using the original manufacturer's part number or a similar part number even when there is not a standard for the part, and that has happened with this particular part. And "standard" has generic meaning as well, like when marketing materials claim something is "an industry standard" in a generic sense and not any sort of actual standardization sense. So there's plenty of room for confusion, which is why it can be useful to point out the difference when it is misused. Doing so always runs the risk of hitting a nerve in somebody sensitive to such feedback, though, as the case in point. For our airplanes it is an important distinction because the FAA allows repairs using "standard parts", i.e., parts that conform to a formal standard, as defined by the FAA (which is a reasonably practical definition of an industry standard). Parts that do not conform to a formal industry standard as defined by the FAA are not standard parts and do not have standard part numbers and must have some other means of approval for use on an aircraft. Mallory, as a manufacturer, is pretty clear that they generally don't deal with standards or environmental certifications and that it is up to the final equipment manufacturer to obtain whatever standardization or certification is needed. They even state this specifically for FAA certifications, that they are not PMA but will provide supporting data to anybody who wants to use their parts in a higher-level assembly that seeks PMA or other FAA approval. See under "Environmental Issues": https://mspindy.com/faqs/transducers-external-drive-electromagnetic/ The Mallory Sonalert parts are not standardized and do not have standard part numbers, SC628 is a Mallory part number, although, sadly, other suppliers (usually offshore) have made replicate parts under the same part number. I've got a bunch of different such parts in a box here. Such replicate parts are not approved for use in our aircraft even if they use the same part number. So the pedantry is not without point, especially when maintaining an aircraft where standardization and "standard part number" (or not) can make a difference as to whether a part is approved for use or not. In this particular case there is no standard, so the source of the part matters, not just the part number.2 points

-

https://www.legacy.com/us/obituaries/kansas/name/ronald-blum-obituary?pid=203275788 Please let me know if anyone else plans to attend! It would be nice to have our little part of the Mooney world together to help honor Ron. I'm sure going to miss him. Sent from my LM-V600 using Tapatalk1 point

-

I appreciate the low level of moderation activities here! Guess we just behave better than people do at other aviation forums . . . . .1 point

-

You’re braver than I. I’d be very afraid of anyone using a powered brush in my tank might round off rivet heads and render them unairworthy.1 point

-

The picture I see in my head is a piece of exhaust pipe chucked up in a vice. Fire up your torch (American torch burning gas, not UK “torch” with batteries) and wave it across the pipe just once. Count to 5 and you can grab the pipe with your bare hand. Now hold the torch on the pipe until it glows a nice red. That’s the difference.1 point

-

Ahh, you’re one of those “because I said so” types… I’ll be watching you from now on…1 point

-

Ok, we’re going to try the bolt first. If that doesn’t work, I guess we’ll have to check the fitting and bushing… Hopefully it’s just the bolt! Thanks for the advice everyone! Sent from my iPhone using Tapatalk1 point

-

Now that they have reduced their workload, maybe they can process registrations in a timely manner.1 point

-

1 point

-

There is also a secondary combustion event that occurs in the collector after the exhaust gas leaves the cylinder and is allowed to expand.1 point

-

The G1000 uses the GTX-345. My Foreflight is connected to Stratus 2.1 point

-

I have not looked at them side by side, but the issue might be brightness. I keep the G3X at 100% and that is just barely bright enough at some sun angles.1 point

-

Same here. As near as I can tell, the G1000 was designed before FIS-B and is incapable of displaying TFR's from that data source. It only can display from Sirius1 point

-

I’ve had my Mooney since 1995 and only experienced carb ice once. 1997 on approach during February in light snow, realized I didn’t have it on so I applied heat and suddenly got the back firing and popping associated with the ice melting. Sure was a attention getter. It only took me that one time to never forget to put on barb heat in visible moisture. With a temp gauge I rarely ever use it on VFR days.1 point

-

The Piper P46T does about 23:1 glide up high and 15:1 near sea level, but only with the prop feathered. With the prop flat it will glide about like a Robinson.1 point

-

I visited a private strip today. It's 3500' long and paved, but it is very bumpy with a hump in the middle. So did I use the "Mooney pull" on takeoff? No. If I had done that the first bump or two would have surely launched me into the air prematurely. Did I hold the nose down for a higher takeoff speed? No. If I did that I would risk the airplane skittering around the runway on the verge of LOC (did I mention this strip is also narrow?). What I did was use the rough water seaplane takeoff technique and "flew" the elevators to maintain a constant pitch attitude as nearly as possible as it accelerated to the point where it could lift off. The airplane was fully under control during the entire takeoff run, and though it was bumpy, it did not leave the ground until ready to fly. I think the point of this whole thread is that no one technique works in all situations. Sometimes more flap is better; sometimes less. Sometimes the Mooney pull is appropriate, sometimes not. Skip1 point

-

1 point

-

1 point

-

1 point

-

1 point