Leaderboard

Popular Content

Showing content with the highest reputation on 05/09/2022 in all areas

-

7 points

-

For those of you not familiar with SB M20-289A, or those who just haven't gotten around to performing it, here are before/after videos on our 1976 M20F. We've been aware of the issue for a while now, but it was only within the last year that our original installation actually began to have the clearance problem described in the S.B. Ordered the kit from Mooney, and installing the new spacers does make a significant difference. Before: After: Video link https://youtu.be/MqET4p8saMI4 points

-

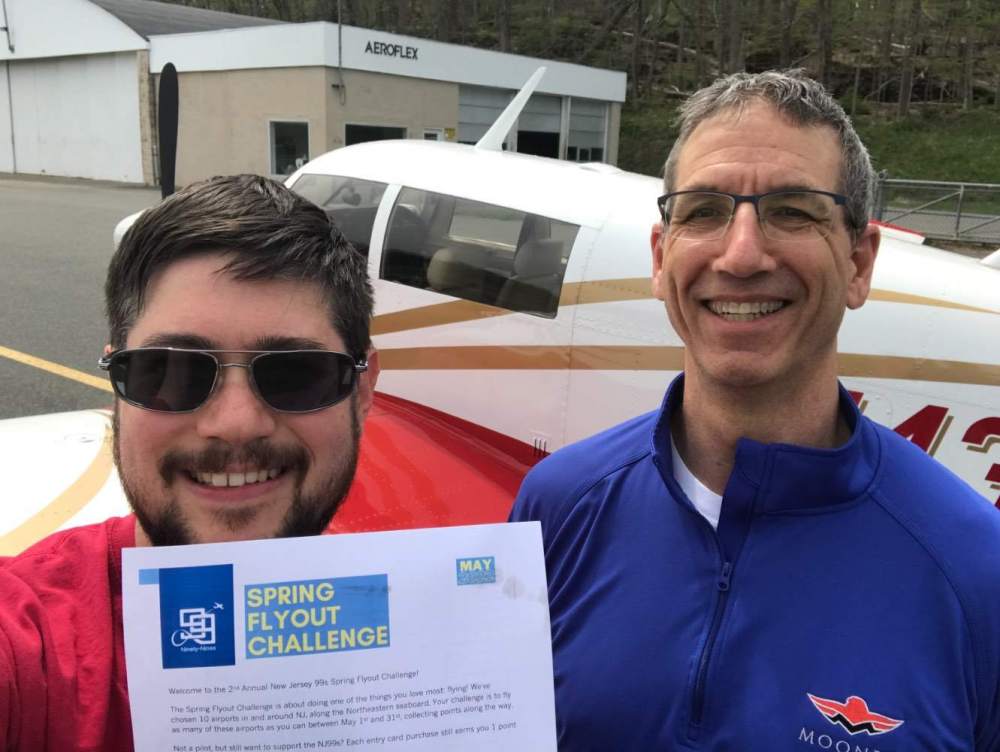

Had a really close call with a Turkey Vulture on final to Andover Aeroflex with 2000ft runway. Had to make an urgent evasive turn. Surprised I was able to still make that landing. Then had a near miss with a Red Tailed Hawk on departure. And then a close encounter with a Bald Eagle on base. Of course @carusoam was slow with the phone to get any pictures so blame him. But we did get lunch and each got 2 points in the NJ99s Spring Challenge.3 points

-

Be careful about non-bendix key blanks used for your ignition key, like you would find at Lowes or Homedepot etc, This may sound overly anal at first, but the only airworthy ignition key is a Bendix key for your Bendix ignition switch and here's why. Use of a non-bendix key in the ignition switch has been shown to be able to removed from the ignition switch without the key being moved to the Off position - in other words in a position where the one or both mags are still hot. I unfortunately learned this after someone at my home base died because of it. A student pilot pulled the key after shutting down, got out to push back plane back and was hit by the prop when moved it. The Mooney door lock is merely a $3 Chicago Cabinet lock and I know the use of cabinet lock keys for ignition switches is prolific. And folks aren't likely to replace with them with a Bendix key blank after hearing this, but be sure to test any ignition key you might be using to ensure it can not be removed without the key in the Off position. Otherwise its a set up to see a repeat of the above needless tragedy.3 points

-

Well at least we’re not alone! (But mine is still steady after an unknown cure…)2 points

-

My fuel pressure gauge started vibrating in 2017 after I installed my new avionics. The only connection is I removed the gauge during the panel work. I have replaced or overhauled every component between the fuel tank and the gauge and nothing has stopped the vibration. The engine runs fine, but I wonder how long the gauge can take it. I replaced all the hoses, all the hard lines. The fuel pump has been replaced with a rebuilt pump. The servo was overhauled when I did the engine. The engine was overhauled. I rebuilt the selector valve. OK, it is the same Weldon boost pump. I replaced the gauge with two other gauges. Nothing has had any effect on the problem. I have blown out all the fuel in the line and it gets better a little. I have filled the line with fuel and it doesn't change. If I leave the mixture in ICO, it will have the same pressure a week later. Its driving me crazy!2 points

-

2 points

-

I don't think so. I examined the fittings pretty carefully and they looked sound. Also, my system will hold pressure for a long time. After shutdown with a hot engine, the pressure will actually rise as the fuel in the lines boils off. A day later it is still holding several pounds of pressure. Assuming the internals of the Avstar is similar to the Precision Airmotive servo, the ICO valve is just a flat plate covering an orifice and they generally leak some depending on how well the mating parts are finished during manufacture.2 points

-

I was allowed to use my drone at the local airport. So I am sharing the end product here... Hope you enjoy it. Oscar1 point

-

Agreed. Fixed mine which had several issues. I have the original Parker part numbers, supplied by Brittian, for the poly flex tubing and compression nuts. May have uploaded them already but reach out if you want them. Hoses and Fittings, as well as others carry them. Just don’t tell them it’s for an airplane.1 point

-

The usual cause of a broken fuel selector housing like the one shown, is over torquing the bolt that holds the fuel bowl and screen onto the bottom of the fuel selector. Ask me how I know. As far as I know, the options are to find a replacement from a salvage yard, or to pay a hugely exorbitant amount of money to convert to a newer style fuel selector that is still made. Hopefully you'll be successful with the former route. If you are, be extremely careful torquing that bolt, so as not to break your replacement!1 point

-

I wish you could figure out what it was. I might hire a witch doctor to dance around it.1 point

-

mine held shutdown pressure before and after this change as well. I would think if any bubble at that connection had already been pushed out, and it was holding ~30psi (or increasing like yours), then this hypothetical air leak could still exist if it didn’t let fuel through?1 point

-

I’m at a loss to explain it, did you just change oil? I ask as that pic looks like very fresh oil Smell the oil, does it smell like fuel? To be honest I’m reaching at straws here, and by posting that brings your post to the top of the list for more to see too, maybe someone else knows the answer. I’ve seen things like excessive blow by overheat oil etc, but I’ve not seen high oil temp come and go with altitude. Initially I was thinking you were running the snot out of it, and the engine was running hot, but not with those cyl head temps.1 point

-

Ok folks, new theory coming your way! You guys are smarter than me on this though, so you won’t hurt my feelings if you poo poo this…. Supposedly the fuel lines can leak air and not fuel, which is why they can suck in bubbles (prior to the pump) but not show a fuel leak. We’ve established that the line to the transducer will always have air in it because that drains out between starts. The air in the pressure transducer line may or may not act as a “snubber”. What if you have a small air leak at the transducer connection? When you start the engine, fuel goes into the line but the bubble between the fuel and the transducer is pushed out through the leak. Now your fuel is right against your transducer and you see oscillations from the pump. If the line is tight, the air buffers out the oscillations. So far I am four flights in after removing cleaning and tightening that connection and I have no more fuel pressure fluctuations. @PT20J is there any chance there’s a small scratch or other possible tiny air leak on your fuel line to transducer connection? You just had a new one with your new panel? Perhaps it’s letting out the air bubble each time you run the engine.1 point

-

Did they check the brushes? As the brushes wear they can hang up in the holder causing a failure, as the gear motor gets bumped around while removing/handling the brushes free up and the motor starts working again1 point

-

I did the same love it and changed the door and baggage door locks to an aircraft security barrel and key. They give you a code and if you need you can reorder a key based on that code.1 point

-

1 point

-

1 point

-

You fellows have thoroughly convinced me that when my brake fluid needs to be changed/bled, I will take my airplane to a mechanic!! LOL!!1 point

-

I have done repairs like this. Not very difficult for someone with a little experience. I would repair rather than replace an entire skin. Use flush rivets and you can for aerodynamic purposes filled the seam with fiberglass putty, repaint and you won't even see it externally. Much quicker and easier than a full skin.1 point

-

The KG-258 Attitude indicator is sold so the package price has been reduced to $2,500. Guys, I've upgraded to a GFC 500 and removed the KAP-150 from my '92 M20J. Autopilot controller, Attitude Indicator, and servos were all working fine when removed. I have these on ebay KC-191 Controller $2,200 KG-258 Attitude Indicator $300 KS-177, 178, 179, $750 each. However, I will sell the entire package for $2,500 if anyone is interested. These are great spares if you are keeping your KAP-150. PM me if you have questions, Lee1 point

-

Hope all you mothers out there have a wonderful day. Here is a picture of me taking my mom Edie up for her first time, and a pic of her next to my Mooney. I would like to see any of your mommy pics as well. Sent from my iPhone using Tapatalk1 point

-

This was correct for me at first, but now after getting them copied my door keys now start the airplane as well.1 point

-

1 point

-

Lately my son has been fascinated by airplanes. Any time a jet passes overhead, he points and says "doo-goo-doo." It's his first conscious concept. He says the same sound for a jet, a Mooney, for the sound of a jet flying over the house, for a toy airplane, and in response to the word airplane. He's about 18 months now. So, it seemed like a fitting time to bring him to the airport for his 3rd flight ever. Unlike the first 2 times, he was particularly interested in all the activity at the airport. He was pointing out jets departing from Newark as well as the airplanes at the airport. Had to run to keep up with him. Did a short sightseeing flight up the Hudson and around New York City.1 point

-

sign up for a Mooney Pilots Safety Foundation PPP. Fun weekend and you come back with IPC and flight review. https://mooneypilots.org/assets/pdf/ppp-mapa-sf-2022-schedule-compressed.pdf1 point

-

Wow, you were well paid! $556/month for my first "real" job. I did a lot of planning and calculations to determine that if I ever got to $1,000/month, the money would just start piling up, because I couldn't think of what I would spend it on. I learned.1 point

-

Look closely at Mikey’s shirt…. Its an original Boots tee! It came with the great documentary…. -a-1 point

-

1 point

-

Awesome day of flying… Believe it or not, Mike knows something about wild birds too… At 100kias, it takes sheer determination to snap a photog of anything flying by… The Bald Eagle is quite large… and… I got him! (You just have to squint to see him…) Go Raptor! Feast your eyes upon nature’s beauty… The tiny spec in the top right corner is actually THE afore mentioned Bald Eagle. best regards, -a-1 point

-

I have an Aspen EFD with an electric back-up attitude indicator and the vacuum system solely runs the positive control.1 point

-

I had Aveo wingtips installed, and I could not see into the first bay in the wing. I realize that there are various wingtips, but unless they went looking with a borescope I doubt they would have found it from the inside. On the outside, it would look like a bit of body filler on some hangar rash. It was a pretty sh1tty repair, but I wouldn't put too much on Dmax. If I bought plane like that and the previous owner did that repair, I would not be happy. Just fix it and move on, it's not a perfect world. Aerodon1 point

-

All, 1965 M20C. My flaps will not hold pressure. Aerodynamic forces, or even spring pressure, will retract the flaps with the switch in the down position. My preferred aircraft mechanic is planning on looking at it in the next week. According to the maintenance logs, this issue has been addressed at least twice before. In the meantime, does anyone have any experience with this issue? Brakes work fine. Flaps extend and slowly retract. If I extend them prior to takeoff, they are fully retracted sometime between power application and before I am off the ground (I don't watch them while I'm taking off.) If I put them down in the pattern, they are retracted almost immediately. If I can't get this fixed, how extensive/expensive it is to change to electric flaps? Thanks in advance for any insights!1 point

-

I would start with the the up/down cable first. It operates a cam that actuates a plunger that unseats the ball on the return circuit. Disconnect the cable from the armature and ensure the cam is not actuating the plunger (See attached image). Pump the flaps down. If the stay down, the cable needs to be adjusted/indexed upon reassembly. If that fails, then there is likely a check valve issue that will need to be addressed. Dirt and or a valve seat issue is the likely cause. If the fluid is decades old, gelling can cause problems. The pump will require disassembly to correct these issues. Unfortunately, new problems can be introduced when performing a rebuild. If your local MX pro is not familiar with the system, it might be cheaper and easier to send it out to Maxwell for a rebuild. @Andy95W has covered all of the possibilities. However, if the malfunction is caused by a leak at the actuator, you would have an obvious mess and the fluid level would need constant replenishment. You may find small leaks that need to be addressed but are not the actual cause of the malfunction.1 point

-

1 point

-

Well, about half the time I am in Bend which not much more than a touch and go away from Prineville. I'll mosey over and have a look and report back next time I'm down there.1 point

-

Hey Chris - Just picking up on your thread now. The shop rate is $120/Hr. But as for your specific situation, if you have a mechanic you love that knows your airplane, you should definitely stick with him. Especially for an older plane like a 1967 C. On a separate note, if you did reach out to the factory and didn't hear back, please let me know. That would be a problem. Jonny1 point

-

Hi all, Long time lurker. Finally decided to join. I had this problem a couple of days ago. I couldn't get the gear down and had to bring it down manually. It's funny because when I bought my Mooney, that was my biggest fear - being alone and not having the gear extend. I will say, however, that it wasn't really a big deal to extend the gear mechanically. It was a bit strange to land with the fire brigade standing by next to the runway. Apparently the problem was - as you have pointed out - the actuator motor and associated brushes / brush caps. FYI, my Mooney is a 1977 with 3700 hours.1 point

-

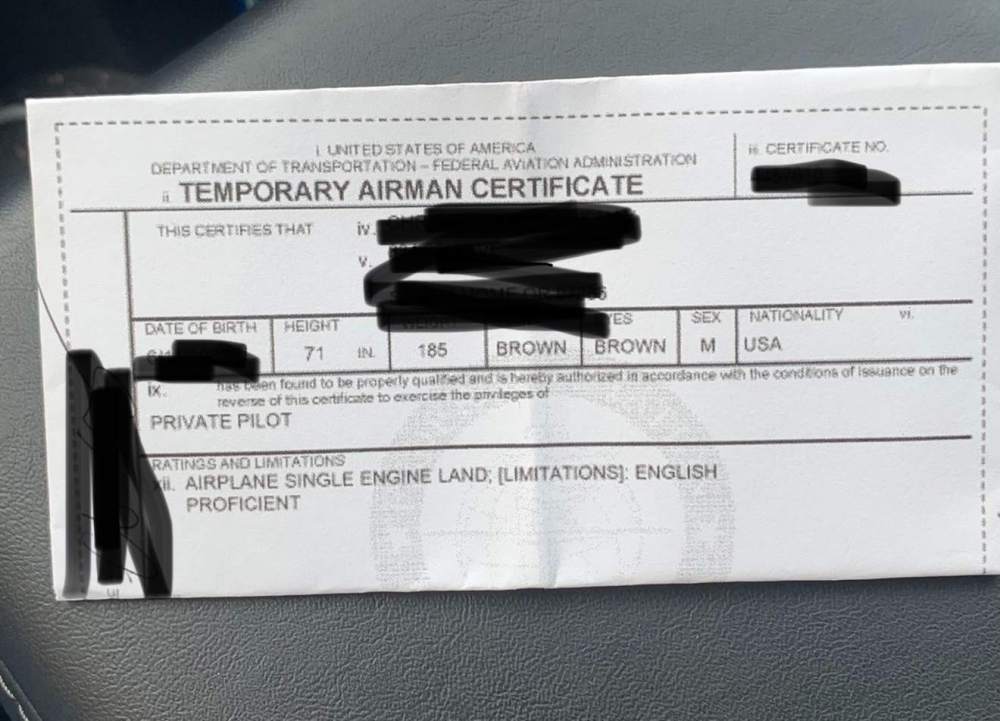

Woo-hooooo!! Congratulations! Getting your PPL is an accomplishment! Finishing it in your own Mooney is exceptional!1 point

-

In the paper entitled "Effect of 406 MHz ELTs and COSPAS-SARSAT Cessation of 121.5 MHz ELT Monitoring on Search and Rescue Duration for General Aviation Aircraft Accidents in the Contiguous United States", located here: https://works.bepress.com/ryan_wallace/7/ Dr. Ryan Wallace (Embry Riddle) and Dr. Todd Hubbard (University of Oklahoma) found that in 139 missions reviewed, the mean search duration for 121.5 MHz beacons was 14.2 hours, 11.8 hours for 406 models, but only two hours for 406 beacons equipped with GPS position input. This paper was published before the MEOSAR capability was up and running. I would wager the time-to-search deltas are even greater in favor of the GPS-enabled units now. To see how difficult it is to find a 121.5 signal due to signal factors that are not in the control of the pilot or the installation view the CAP training video here: https://www.youtube.com/watch?v=JlB5u49FvzY In my opinion, it is far more important to make sure the OP (and others who are considering a new installation) installs the GPS interface to the 406 ELT than it is to worry that an approved antenna installation (on a unit whose 406 output is a 5 watt burst, while now only putting out .025 watt on 121.5 instead of .1 watt like the old 121.5 ELT units) will somehow be a negative determative factor in a rescue. Yes, there are older 406 ELT units that don't have a GPS position input. The OP is talking about a new 406 installation so the GPS input capability will be available in the unit. Yep, it is a pain to run the RS232 GPS input wires from the GPS in the panel back to the ELT unit (I did this on 201JX while the seats and left sidewall panels were out) but it's worth the effort, as evident by the citations above. I have to thank Philiplane, EricJ and others for motivating me to learn more on this. Having done so, I am even more confident in my recommendation to the OP. Also thanks for reading through this whole thread to those who have persevered!1 point

-

I successfully did this very thing on N201JX and used SIM20-116 as the authority to do it. Tested the installed antenna for VSWR using the internal 406 ELT diagnostics and then ran the tests here: https://www.acrartex.com/406test/ . I ran about two sweeps as stipulated and the satellites reported back through the 406test system in under two minutes with good results, with the fairing clecoed back in place in case the tests did not work. Note the clecos were omitted in the area of the antenna so as not to corrupt the results. Of course with that caution the tests ran great! Anyone who says a 406 ELT won't work under a dorsal has no idea what they are talking about. Here is the dorsal removed and the detail of the ELT mounting hole. Note the diameter of the antenna base on the skin has been propped for electrical bonding and corrosion proofed with an Alodine pen. The ELT tested perfectly again under the new paint:1 point

-

1 point

-

You might want to put a washer under the bolt and nut to get the cotter pin in a better place.1 point

-

Okay, it seems I did misinterpret. In that Hank, Erik, Ross and Scott are essentially echoing the comment I quoted from Hank above. Although I can agree with that sentiment, that every chute pull would not be necessary for every pilot, but I find it difficult to second guess or deny a pilot that did pull the chute from counting it as a save. I say that fully realizing that we have all seen some crazy saves. One that I recall many years ago, was a new pilot that flew into an area on the east coast with a low marine layer and could not land - yet had plenty of fuel to make it to a VFR destination. But in essence, with myopic vision, the pilot panicked pulled the chute and came down in the fog while if I recall correctly, used the engine to try to steer clear of some obstacles in the descent. Clearly this would be an example of a wasted or unnecessary chute save that wasn't really necessary. I can't be sure, but I even recall from memory that after the event the pilot or pax was quoted to say something to effect that they proceeded in part with the flight because they had the chute as backup. So I don't disagree with any of you that some of these were not necessary at least with a different pilot on board with superior ADM in a less panicked state. But I am going to assume if the pilot pulled it was most likely because that particular pilot at that time believed it was his/her best chance for saving their bacon - so be it. If it can save their life or (most of the time) prevent serious injury, I am all for it. Each time it was successful deployment (such as within the envelope) it made a difference IMO. Also I don't think the NTSB ever collects enough data on pilot state of mind for anyone to ever do justice to determining if a pilot was truly capable of saving their bacon without the chute, since the majority of pilots will be as brief as possible in providing details; if they're even telling only the truth. Sure I'd like to see BRS on Mooney's someday, but I can't see it happening till we see a huge weight loss in the airframe or breakthru in improved lift since we're pretty much at max Vso now. Meanwhile I still prefer my Mooney. Thanks for clarifying but I guess it come down to the fact that as long as it does save lives, its a worthwhile safety device. But given the compromises required, I don't want to give up my very efficient and highly capable Mooney to have a lesser capable and lesser efficient aircraft with one. Nor am I going to knock anyone for choosing to do so.1 point

-

I think this chute vs no chute discussion to be overworked. I think that virtually all of us would take a BRS if it were free, had no weight, and required zero maintenance. Once you take those into account, then it becomes a question of value vs all three of those, and thus a personal decision.1 point

-

Just proves he's a normal human. When ABS brakes first came out, accident rates for equipped cars went down, enough so that I got an insurance discount for about three years. Then human nature asserted itself, people realized they could stop better without sliding and started driving faster and following closer because they had an "out." Accident rates went back up to where tbey had been and insurance discounts went away. Chutes in a plane are tbe same way. Long term accident rates will stabilize at normal levels as pilots figure out tbey can take those riskier fligbts, because if it doesn't work out, they can pull the chute. Like Mr. Breathless and his selfie video, which to me was more of an ad for his personal location device. In my Mooney, I'd have kept the gear up and aimed for that nice lake in the background, close to shore. That's not a good option with fixed tricycle gear, but it looks like the trees weren't, either. I'll say it again: look up Risk Homeostasis. It's human character, period, and it applies to all of us in varying degrees from one activity to another. Reminded me of the Cirrus pilot I read about in AOPA magazine who departed into low IMC, became disoriented and pullled the chute, landing a couple of miles from his point of departure. Betcha in a chuteless plane, he'd have stayed in the ground until conditions improved. So how much "safety" did his chute add to the flight? It emboldened him to make a risky flight, then kept him alive when the house won, which happens a lot when you bet against the odds . . . .1 point

-

Thank you! It has been an awesome day so far. Of course yesterday I got to fly the best airplane in the world and hang out at Oceano airport. Today was church in the morning, kids/nephew/nieces in the afternoon and topping off with a movie with the girls. To any other Pilot Moms or honorary Moms: Happy Mother's Day!1 point

.thumb.png.7c67574d7b28f67b0b4a17760919b1ac.png)