Leaderboard

Popular Content

Showing content with the highest reputation on 11/17/2021 in all areas

-

6 points

-

My A&P/IA Dave, who has since left this world, once told me in a strong voice: "Never weigh your airplane, nothing good can come from it". I did it anyway. Then I learned what he meant.5 points

-

Putting a 200hp electric motor in a Mooney isn't that much of a technical challenge. Managing the extension cord it the challenge!4 points

-

Electric might be ok for novelty, but I don’t see it being practical without a new paradigm in battery technology. I think a FADEC turbo diesel jetA burner is a better option.3 points

-

Whelen informed me today that they are moving this up on the project list. They said that they are working on "Getting this pushed out hopefully by the end of the first quarter beginning of second quarter of next year." If I hear anything more definitive, I will let you all know.3 points

-

I know a few of you are already aware of my incident on 09/30, but I've been hesitant to post anything until the insurance company made their determination re repair vs write-off. Also, having a forced landing off-airport is an awkward situation to find oneself in, and I've needed time to process the event and my responses to it before opening the topic up for discussion on an open forum. Aircraft background: M5779R is a 1985 M20K (231) with many positive aftermarket mods, including GAMIjectors, intercooler and wastegate, 3-blade McCauley prop (hot), Aspen PFD, JPI 830, Garmin 430, and Garmin ADS/B In/out transponder. The engine was rebuilt in 2016 prior to my purchase, and had less than 100 hrs SMOH when I bought it in 2018. I have flown her nearly 500 hours since then. I had a great deal of work done at annual last year, including replacement of the #6 cylinder, Prop governor overhaul, new right-side exhaust header, replacement of ALL belts and hoses, new gascolator, and multiple other smaller jobs. At the time of the incident 79R had flown 143 hours since last annual. On the date above I was flying from KABI to KDGW in a clear VFR sky to do some hunting with friends. I had stopped for fuel at Borger, TX, and was about an hour into the second leg of the flight at 12,500' when I had a sudden partial loss of power. I had been cruising at usual settings, 32" MP and 2450 RPM and 11.0 GPH (approx. 50% power setting) with a 12 knot tailwind. With the power loss my manifold pressure dropped below 20", but RPM's stayed around 2400. My first thought was that I had a fuel flow problem, so immediately switched tanks and hit the low boost switch. No change. Airspeed had dropped significantly, but the autopilot was holding my altitude and the engine was still making some power. IIRC, CHT's and TIT were fine, but the JPI was reading 20% power output and dropping. Half of my brain was trying to puzzle out the cause of the power loss, but the larger part of my brain was saying, "Look for a place to land, establish best glidespeed, try to restart the engine, and declare an emergency," over and over again. So that's what I did. I looked around at the flat eastern Colorado terrain, saw no airport; looked at my Foreflight moving map, and saw the Limon airport about 25 miles ahead of me and no other marked airfield. My airspeed was still above best glide at this point. Looking back on it now, I estimate that the time elapsed up to this point in the emergency was about 20-25 seconds. The engine was still running, so a restart was obviously not necessary; so I pushed the prop control full forward and there was no change. In fact, I noted that my RPM's were starting to climb irrespective of the position of the prop control. This was my first clue that I had an oil pressure problem. I then looked at the oil pressure gauge, and it was pegged on zero. This was the "Aha!" moment, and I went fully into my power-off landing checklist that I've had stamped in my brain since my earliest flight training. I switched off the magnetos, which caused immediate slowing of the aircraft, and of course also meant no vacuum pressure, so I began setting my attitude manually to best glide (88 KIAS). I keyed the mic and informed Denver Center I was declaring an emergency. The controller, who sounded very young, immediately experienced a 2-octave increase in his voice pitch, by which I gathered he was pretty new to this situation. I advised ATC I had lost power and was descending without power, and intended to land on either a road or an open field, unless he could vector me to an unmapped airfield closer to my position. I started at 6500' AGL, and estimated I had about 10 miles maximum glide range. There were several roads and a paved highway ahead of me, so I simply maintained my heading and descended at best glide speed. As I got closer to the ground it was apparent that the highway was far too busy with vehicle traffic to safely land on, so I decided to try for the nearest east-west gravel road, which I estimated was just within my glide range. However, it became clear quite soon that I wasn't going to get that far. As I dropped below 1000' AGL, I lowered my landing gear (I still had lots of battery power for the gear motors) and advised ATC I'd be landing in a pasture. I maintained clean configuration for airspeed, and the mains touched down a about 70 KIAS. I kept lots of backpressure on the yoke to keep the nosegear off the ground as long as possible. When I could keep the nose up any longer I started braking, but almost immediately hit a shallow cowpath and the nosegear collapsed. I skidded to a stop within about 50 yards of the cowpath. When the airplane stopped, I made sure all switches were off, unfastened my seat belt, and exited the aircraft. There was no gasoline smell, and no smoke, so I didn't hurry. I found I was less than 100 feet from the county road I'd been hoping to land on, and about 150 yards from the paved highway. All kinds of vehicles were turning onto the county road to check on the "crash scene". One kind young man offered the warmth of his car to sit in while I dealt with the necessary phone calls. ATC at Denver called within a few minutes (to see if I was alive), and of course my first outgoing call was to my wife to let her know I was down but OK. ATC got emergency services on the way and I was soon talking to the sheriff's deputy, fielding calls from the FAA and NTSB, and so forth. Eventually all the ducks were lined up as well as could be, and the deputy gave me a lift to a hotel in Limon, where my wife picked me up in her truck the next day. My insurance company has decided to sell N5779R for salvage, and I've signed the bill of sale. Unfortunately, I hadn't anticipated the rise in airplane prices this year, or I'd have re-insured her for what I could sell her for today (about $80,000 more than I paid for her!). I was not injured in the incident. I attribute this to the sound construction of Mooney aircraft, and to the thoroughness of my flight instructor(s) who drummed the engine-out landing checklist into my brain. At no time during the incident did I feel scared or panicked... I just did what I knew had to be done and flew the airplane all the way to the end of the landing rollout. Easy-peasy. I know a lot of people don't have as happy an outcome when they experience an engine failure. I realize that I was fortunate to have perfect conditions for my off-airport landing, or I might not have had as happy an outcome myself. If I had been over rough country or mountainous terrain, or flying at night, or IFR over low ceilings, my landing may have been a crash. But because I had clear visibility and plenty of flat terrain to choose a landing spot on, it was relatively uneventful. On the other hand, if it hadn't been for the cowpath that collapsed my nosegear, I would likely be having my airplane fixed right now rather than shopping for a new one. I share this experience with my fellow Mooney pilots because it may help someone else in their aeronautical decision making process or in their flight planning process. I am an avid reader/viewer of aviation-gone-bad articles and videos myself, am constantly learning from them. I hope this experience might help someone else be prepared in case of an emergency of their own. Postscript on the engine failure: when I landed, the entire belly of the airplane was covered with engine oil. I did not remove the cowling then and there, as more than one helpful idiot has suggested I should have done (including the guy from NTSB that called me 20 minutes after my airplane came to a stop in the pasture) but when the salvage crew got it to a nice clean shop and pulled the cowling they found no sign of a catastrophic oil line failure, etc. What they DID find was an oil breather tube covered with oil, and a splatter pattern in the compartment suggesting that an oil passage blockage had occurred somewhere in the engine resulting in the sump oil being blown out the breather tube. There was still about 3 quarts of oil in the sump, and the crankshaft still turned, so my delay in shutting down the engine apparently did not seize it up. I was just informed yesterday by the insurance adjuster that the engine is going to be torn down and inspected as part of the salvage process, and he will keep me informed as to the location of the blockage. FAA and NTSB have both signed off on the incident as an engine failure, and I have not been cited for pilot error. So that is something of a comfort. Postscript on aircraft damage: in addition to the collapsed nosegear, the right main gear was damaged (framework within the wing bent). Two of the 3 prop blades struck the ground and were severely bent, which of course necessitates and engine tear-down and inspection. The engine mounts were not damaged, but there was some deflection of the airframe back of the firewall which the insurance adjuster estimated would require significant repair costs. At this time I still don't know what damage to the engine and/or turbo may have occurred to cause the power failure. So I'll be airplane shopping now. I love the 231/252 platform for a lot of reasons, and I am strongly tempted stick close to home in this respect. Jimmy Garrison at GMax (formerly All American) says he has a lot of options in that area if I'm willing to be patient, and can stomach the high current prices. But I'm somewhat concerned about the growing scarcity of parts for Mooneys, as the factory continues to not make them. So I may stray farther afield into the land of Bonanzas, Cessnas, or Pipers. I guess we shall see. PPS 12/19/21: I posted the following last week farther down in the thread, but I am copying and pasting it here to save folks having to scroll down. I received an unofficial report on the engine postmortem. The engine crew looked first at the turbo, expecting to find the exhaust to be full of oil, indicating the failure was in the turbo (as the loss in manifold pressure suggested). However, there was no oil. The turbo had seized, but that would be expected with almost any loss of oil pressure. The crankshaft had not seized, and still turned easily… they found there was about 3 quarts of oil still in the crankcase. The culprit proved to be a broken exhaust valve in the #4 cylinder, which fell into the cylinder and punched a hole in the top of the piston. I w@s surprised to hear that, as I heard nothing that sounded like any engine cylinder eating a valve I’ve ever heard before (in automotive and small engine applications). The engine guys suggested I might have had enough power to keep the engine going a bit longer, as it was still making some power… but if I had done so, and tried stretching it the 25 miles between the point of failure and the Limon airport, other nastier things might have happened, such as an engine fire. All in all, I think what was basically an uneventful power-off landing in a field was the preferred option, as opposed to a high-speed and high-angle descent in a burning airplane into a fresh crater.2 points

-

Hi all, Has anyone thought much about converting a Mooney to an electric motor? Might be a few years (decades?) away, but it seems like it might be feasible eventually. Some rough math for a J (using metric, sorry but its easier). Interested in whether anyone has thought more about it. 200hp (presumably at the output shaft) = 150kw. Electric motors are around 3x more efficient, but we still need 150kW going to the prop, so a 150kW electric motor is required Weight available: remove IO-360 engine 300lb, 64Gal fuel 384lb = 684lb (310kg). Might scrape together another 10kg in fuel components. Assume 50kg for (a theoretical 90% efficient) 150kW output motor, assume new prop same weight as old prop, 20kg for battery controllers gives 250kg available for batteries Power required for takeoff & climb (5 mins at 100% and 10 mins at 75%) = 31.25 kWh motor output (34.7 kWh battery input for 90% efficient motor) Cruise at 60% power = 90 kWh per hour of cruise (100 kWh input) Current batteries are around 250 Wh/kg or 4kg per kWh. Battery weight required: takeoff/climb 139kg, cruise 400kg/hr. With 250kg to play with that only allows 15 min takeoff/climb and 17 mins cruise (no reserve). Not very useful. Even if you throw another 200kg of batteries on the back seat, you only get 47 min cruise (no reserve). If (when?) batteries improve to 500 Wh/kg, that gets us to 54min cruise (no reserve) or 1.9hr (no reserve) with an extra 200kg of batteries. So it would take more like 2500 Wh/kg to get something comparable to what we have currently got (5.3hrs with 45min reserve). Charging rates would also rule out 2 long hops in a day, so we are probably never going to get anything comparable to what we have currently go, but I wonder what people's threshold would be to make it feasible.2 points

-

Let's be honest . @201er crafted the title of his thread specifically to entice folks who are primed to express "Brandon"-related concerns that extend well beyond the need for a clear guard frequency. As the original provocateur, he deserves to be the first to be enveloped within the voluptuous folds of Kate and Anne's mammoth (yet still feminine) ass cheeks.2 points

-

Things have been going well - got my CFII, started my IFR training again. During the last session, found the KX155 was not IDing the Morse codes and signal was off. Went to Meacham sure enough, failed the VOT. Contacted the radio shop and they pretty much knew what the issue was. So, pulled the kx155 out and shipped her off. Hoping to have it back in 2 weeks. The shop did say add cooling to the unit if it's not already there so, I'll be planning that. At this point, everything in the stack will be either new or refurbished. Flying great used 1/4 quart of oil in 2 hours so thing are looking great. Annual is right after Thanksgiving so I should get a December annual for next year. Did a short IFR x-country flight to Meacham at the busy time and I handled it good (not great but good) and shot the RNAV 16 approach with the dual G5s - still need to work on slowing down for the approach but, I now have a cheat sheet I found from @Skates97 - nice work and appreciate him sharing that. So, a lot of first year maintenance (to be fully expected since I'm flying the plane A LOT) and very happy with the plane overall - she loves to fly! Don2 points

-

One important thing to note- you really can't remove enough weight on a piston single to make any measurable difference. Even 50 pounds doesn't make a real difference. You would need to remove 100-200 pounds to notice any difference in climb rate or cruise speed. It's just not possible, even with the most minimal approach to equipment, lightweight upholstery, carpet, etc. Look at what crazy lengths the Alaskan Super Cub operators go to, to cut weight. And they still have a 2 place airplane that climbs great, but it is slow, VFR only, and it is completely uncomfortable. Great for dropping in on a river sand bar to go fishing, but that's about it. Worry more about the CG, that is more important than losing 2 pounds by replacing one radio for another.2 points

-

I looked through more than two dozen re-weighs that I've done after extensive avionics work on customer's planes. Including vacuum system removals. The average calculated weight loss was 22 pounds. The average actual loss, once on scales, was almost never a loss of weight. Due to previous errors, and due to paint & interior work, heavier tires, etc, that all added to the factory weight without being caught. One or two came in at a net zero weight change, even after having removed 20-30 pounds of old things versus the weight of the new equipment going in. The highest real weight loss was a Cheyenne 400. We removed over 200 pounds of original equipment & wiring. That was replaced by about 80 pounds of new equipment. So, a 120 pound useful load gain on a 12,000 pound plane. And it moved the CG back over an inch, due to the removal of all the remote mounted avionics and wiring in the nose. So the lesson is, if you want to see a weight loss after upgrades, calculate it, don't weigh it.2 points

-

Aircraft Spruce has links to the TCDS for both Tygon and Polyurethane tubing. The 3/8” ID tubing with 1/8” and 3/16” wall thicknesses are rated in the 25-30” vacuum range. Bend radius is listed, too. A little cheaper than -193 hose, although I don’t know what the service life is in comparison. I know traditional vacuum hose can look fine externally and leak like a sieve, but poly tubing, maybe not so much? Regardless, glad your AI issue wasn’t anything more serious.2 points

-

2 points

-

I just published a video of a flight from Montauk to Block Island. It was recorded with 2 cameras: One showing the panel and the other under the wing, looking outside. Please checkout the rising terrain in front of the threshold. This makes the flights to Block Island challenging. There may be downdrafts on short final but on the other hand, you cannot add too much speed because of the short runway. This video also shows how important a good speed management is during the approach to a short and challenging airport. As you can see in the video: The approach was flown with about 71 knots and then the speed was reduced to arrive with about 64 knots over the threshold. Flare was short and landing smooth.2 points

-

2 points

-

Not the same plane. The plane I overheard was N4328H - a J model Mooney. The pilot that day was Paul Doxey who did an excellent job of landing on a dirt road near Salida. The cause of that engine stoppage was a mag failure on a single drive magneto engine.2 points

-

2 points

-

2 points

-

Watch the TruTrak STC get approved for Mooneys but then not being able to order one until 2024.2 points

-

You really need to change whatever it is that makes your posts show up in that font. It's nearly unreadable on my display.2 points

-

If the reweigh is done in a shop or business "reviewed" by the FAA every year you can bet that the scales are certified as accurate every year just like their torque wrenches are every year. I know for a fact that my D model fuel tanks hold EXACTLY 26 gallons from dry empty. Not a tenth more will go in. A W&B report "should" use the unusable fuel and arm listed on the TCDS (or follow on STC). That all being said when I reweighed many years ago (my first on this Mooney) we found a 90 pound error on the first W&B done by the factory!!! It was in their math! Just because the factory did it doesn't mean it was correct Decades of 337s just compounded on that error What's the old saying? Trust but Verify?2 points

-

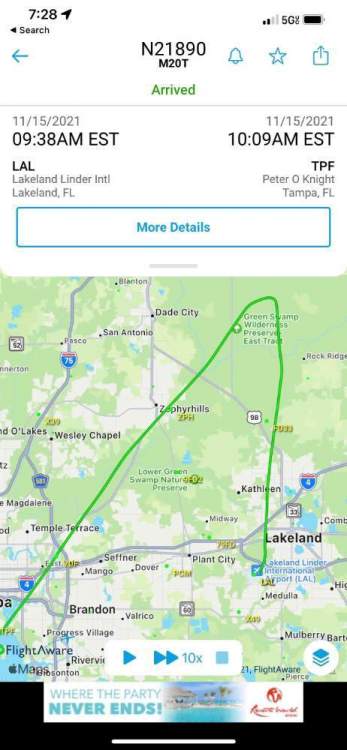

What I don't get on this one is that the news reports say he took off from Lakeland on the way to Gainesville, was having engine trouble so went all the way to Tampa (his home base?)? There were a lot of places to land in between and figure it out. I remember flying 20+ years ago from Georgia back to Texas with a friend, and the engine stumbled a little. He was a mechanic and I said, "What do you think?". He said. "I think I see an airport, that's what I think." It was good we landed. We landed at Peachtree DeKalb, spent the night and figured it out the next day. One mag failed. The lesson I took away that day is that I would rather be wrong and make a precautionary landing than be wrong when I continued on.2 points

-

I think you may want something like the Tanis cabin heater: https://www.gallagheraviationllc.com/tanis.html Never seen it installed, but from what I understand, you plug in one plug in the oil filler door and it runs both the engine block heater and the cabin heater.2 points

-

2 points

-

Yep. 82nd Airborne, 325th Glider Infantry. D-Day, Market Garden, Battle of the Bulge (which he fought again later in life) and Army of Occupation in Berlin. Greatest generation… Sent from my iPhone using Tapatalk Pro2 points

-

I am wondering if anyone can answer this for me. I am very fit 61y/o pilot. I don't scare easy and I love flying. I have noticed over the past few years that when I am above 17k my heart rate increases. on the ground my resting HR is 55-65. on a average day at work or flying up to 12K my HR is rarely about 75 maybe 80. however when I'm above 15k my HR is in the mid to upper 90's consistently. This is with o2 by mask or by Nasal cannula. I have a pulse ox and even if I put the o2 flow to a place that puts me at 95-98% sat my heart rate still is elevated. I am a physician and I have looked and looked and I cant fine any recourses to explain this physiologically. I am not in distress or having ANY trouble. My HR is just elevated. Thoughts? D1 point

-

Has anyone else noticed that it isn't possible to fly a few hours with the second radio tuned to 121.5 without being bombarded with unnecessary distractions like "let's go brandon", "meow", a lecture on radio etiquette, and an argument about politics. If you are one of those imbeciles that indulges in this childish humor, seriously shut the hell up! It could be you some day trying to get an emergency call out or hoping your ELT is picked up when it turns out pilots are muting 121.5 because they are tired of these distractions. I had to mute my 121.5 monitoring radio for a lot of my last flight because it has been an endless distraction. Stuck mic on guard for half an hour, an airline captain describing the weather at the destination and seat belt policy, a request for coffee and car rental, a discussion of the pros/cons of the president, and several pissing contests with the usual meows, let's go brandon's, and reprimands. Seriously, it got old before it even started. If you wanna screw around, do it somewhere else. Leave the emergency frequency for emergencies. Not to mention missed ATC calls on com1 because of being stepped on by 121.5 interference. Also think about the negative impact on our passengers hearing this kind of stuff coming from our radios. Doesn't exhibit the level of thoughtfulness and professionalism we want to exhibit to make them feel safer. It's bad enough that we have to deal with laser interference from the ground, but the last thing we need is this coming from other pilots!1 point

-

1 point

-

The power density of batteries is nowhere near the power density and mobility in gasoline, jet A or diesel.1 point

-

I bought my plane knowing it was burning about a quart every two hours. At PPI, filter was clean, borescope good, last oil analysis normal, compressions all in mid 70s. I flew it about 30 hours and put it in for annual. It was running fine. Compression in the 50s in #4. Metal in the filter. Part of a ring in the screen. Oil control ring broke and took out part of the piston when it finally let loose. Skip1 point

-

The STC says 27.3 max. More is ok up to about 31, but I've found the best place on my engine was 29.1. Edit: "engine" = IO550N8B, S/N 1010199 (if that matters)1 point

-

Fantastic! A spam post by spam pilot… Clearly not everyone has it wrong… And not everyone can read the type face. That’s pretty funny… Hope there wasn’t something important in there… Best regards, -a-1 point

-

1 point

-

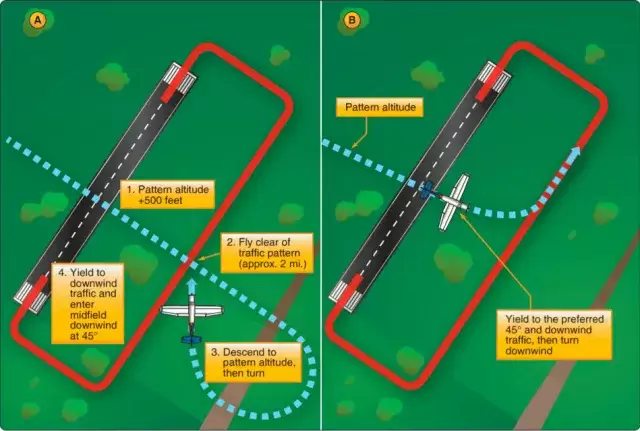

You REALLY want the traffic to be empty to do the midfield downwind entry. I did this once and suddenly spotted a NORDO plane on the downwind (flying 200 ft lower than pattern altitude). Now my options were: Turn left early to cut in front on the downwind. Rude, perhaps. Violates the concept of giving way to the right. Most importantly means you're turning belly up to the conflicting traffic and losing sight. Turn right to give way to the right. Also means you're suddenly turning against the traffic flow in tight quarters. Descend. He was already lower, but even if he was at pattern altitude, you don't know when people will start descending to land None of those were particularly good options, so I ended climbing above straight out past the downwind. I was still fast enough I could gain a couple hundred feet easily, but if I was slow this might have been trickier. Conversely, entering on the 45, you have more time to spot planes in the pattern and you're closing slower and have more time and space to turn back out. Kind of like how they tell you avoid approaching a ridge line perpendicular to it, so have more time and less turning needed to get away from danger. I still use the midfield downwind entry, but I always get a little nervous doing so1 point

-

I use ezwxbrief every day - even if I don't fly. I do other outside activities and this product is so helpful. -Don1 point

-

Looks like you prefer the left side of this picture, overfly the airport well above the pattern, fly away, descend, turn around, come back then enter the pattern. I prefer the right side of this picture, which I have just now had time to look up during lunch. You may want to download a more recent version . . . . It works well at most uncontrolled airports that are not busy; if the pattern is busy, then I'll deviate around and enter downwind on a 45, but without flying two miles away, descending, turning around and coming back--just kick the nose [in this picture] a few degrees right. Note that for the midfield downwind entry, it does say to "yield to the preferred 45º and downwind traffic."1 point

-

The Quality Manager at a previous job had a sign on the office wall: In God we trust. All others bring data.1 point

-

Thanks Art - of course all conjecture at this point. The reason I jumped on that was that there was an apparent diversion from the ori destination Gainesville, reported for “engine problems” and the aircraft appears to have passed by at least a couple of options. That “Land as soon as practicable” quote in the POH… A lot of these engines are going to be rife with mechanical issues after periods of relative under utilization during all the lockdowns. My plane with a blown up lifter is a good cautionary example.1 point

-

1 point

-

I've got a preheater that has a plug in the oil door, but that would require penetrating the firewall. Took me a minute, but finally found the thread. This idea from @squeaky.stow is what I'd do.1 point

-

Up until very recently I worked for a European technology firm that made everything from transponders for gliders to vending machine computers. Starting in the first quarter of this year, our CPU lead times from NXP Semiconductors went from the standard 12 weeks to an astounding 54+ weeks. I in particular worked in the industrial motors division, and what used to be my standard lead time of 4-6 weeks followed that trend and went up to 25+ weeks this last quarter. That said, it is only a matter of time until the supply chain crisis hits everything aviation. As Baker Avionics said, Garmin issued the lead time dealer memo last Thursday. I would not be surprised if this extends soon to other products, particularly those with color touchscreen displays and advanced RF components such as the 2in. slimline units and the GI-275's. The one saving grace for Garmin is that a lot of their equipment is manufactured in Taiwan - where TSMC is located - so this fact may contribute to Garmin being slightly more resilient than other electronics manufacturers. On the BendixKing side of things, Honeywell has been delaying multiple shipments to their dealers a great deal multiple times; I am currently waiting on a KX155A display replacement and the shipment for that has been delayed twice. I do have my own political inclinations, but having witnessed what I saw in my previous work, I am convinced the supply chain crisis isn't going away anytime soon even if whoever the right people make the right moves. As for me I've been stocking up on supplies, inventory, and tooling to lower the chances of me running into a situation where I can't get what I need on short notice.1 point

-

How could vandalizing a bunch of gas stations with politically-charged content possibly be taken the wrong way?1 point

-

It's rare for me to enter the downwind leg straight in, because it's so easy to deviate away a little bit and join on the 45--it also gives me extra time to level off at TPA and finish slowing down and cranking in Takeoff Flaps. On the other hand, I've been doing the midfield cross to downwind (turning left to join) since I was a student pilot. The field being short (3000'), I usually crossed near the numbers at the departure end, but when it's 5000' or more I'll actually cross at the middle or slightly toward the departure end. I try to be slowed down with Takeoff Flaps down before then, but sometimes the level turn gets me below Vfe . . . .1 point

-

1980Mooney, when I landed that day I thought it was no big deal to walk away from the wrecked airplane. It seemed to me that it was an pretty ordinary landing, other than the engine being off and their being no airport nearby... but as I spoke with various people from FAA and NTSB, the local sheriff (they have a lot of aviation in their county), my past flight instructors, and so forth, it became apparent that a lot of folks do NOT get to walk away from these things. Let me reiterate: the most important factor in this landing was that I had good training, and I give my primary flight instructor in 2013-14, my transition training instructor in 2018, my BFR instructors in 2015, 2017, 2020, and 2021, and my current IFR instructor ALL the credit for keeping my head where it needs to be, i.e., on having my emergency checklists memorized and frequently rehearsed (mentally, at least). When you KNOW what you need to do, and you don't have to dig for a checklist to save your ass, it gives you confidence and assurance. I called every one of those instructors in the past few weeks to thank them. The axiom is this: in an emergency you will default to your level of current training. If your training is not current, you will default to a level of training that may not be sufficient to meet the emergency.1 point

-

1 point

-

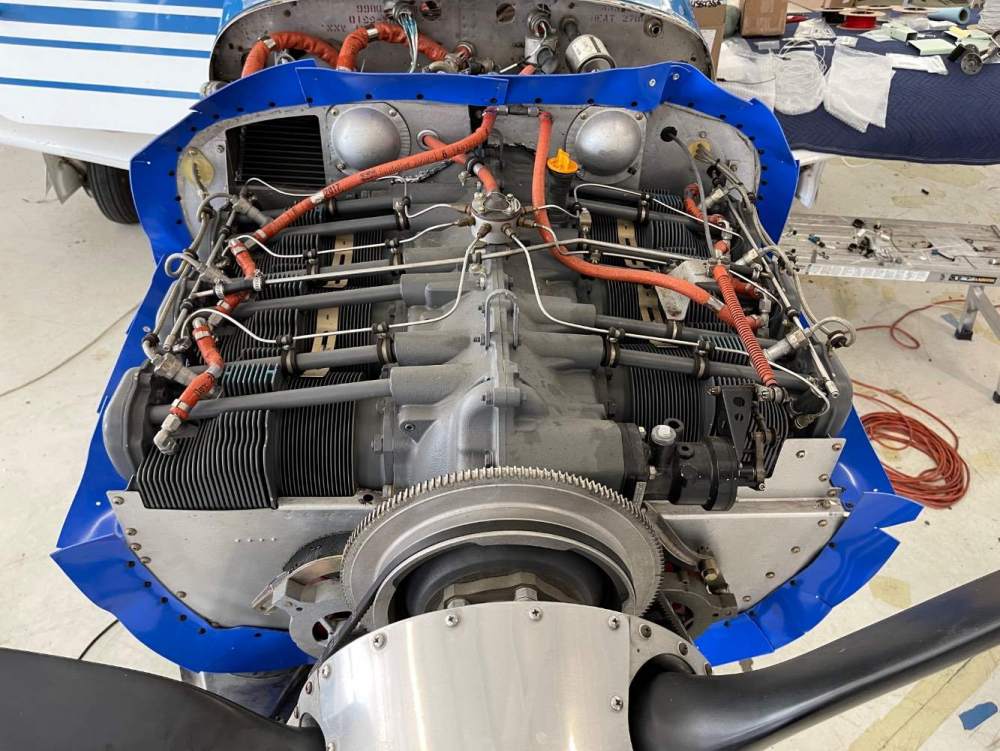

Evening, It actually went really well. I ended up not getting the guy from Wisconsin but two AP/IAs local from Bismarck who had previous knowledge as to what happened from the beginning. My thinking was I really didn't feel like re-explaining and justifying my every move. At the end of September I had a few weekends and nights available and between me and a few APs at the field we finished the windshield install and got it done. The paint is a shade or two off but hopefully Vanco Aviation will be painting the plane next fall so as of right now its a non issue for me. The last week of October I had the IA come up and we spent two days going over books and pages of every item in the logs and then spent hours combing thru the airplane. Barring a few discrepancies with regard to how I do it vs how they do it vs what is acceptable, it went off with out blood shed. Nothing failed and nothing was hidden or overlooked. If anyone of the three people involved didn't like something for how it looked, was routed, or installed it was fixed. On Nov 1 the plane was officially signed off and as soon as I get the cowl back from the painter for a touchup the plane will be in the sky hopefully burning tons of gas. It has already made several high speed taxi runs and did multiple run-ups. All with easier than ever before starting, idling and no oil leaking. It is amazing when work is completed correctly. I think I have removed all the previous sins and unless there is parts failure the plane should easily make the next annual with no major headaches. At least I am praying for that. I'll post pictures as soon as I get a chance to take some.1 point

-

I ran an avionics shop before I transitioned to a bigger company and a more engineering-centric job. The best part of the job was test flying after an install or to troubleshoot a problem. Money wasn’t great, but I didn’t know how good I had it. I got to fly a wide variety of aircraft. If I wasn’t comfortable, I would hire a CFI to go with me. Some of the most memorable were MU-2s and TBMs. I’ll admit to one or two that I wouldn’t fly, not because of our work, but because of the work we didn’t do, That said, many of my technicians and the mechanics in the shop were reluctant to fly. I don’t think it was because they didn’t trust their work, they just didn’t enjoy it flying as much as I did. My favorite line was, “I wish I liked to fly as much as you do”.1 point

-

Some of the mystery disappears with a bit of thinking about how the fuel injection system works. First of all, the engine will only start when the fuel-air mixture is within a combustible range. During start, the throttle controls the air and the mixture controls the fuel. It's best to crack the throttle and only mess with the mixture control so that you are only dealing with one variable. When you shut the engine down with the mixture control, you shut off fuel to the injectors at the fuel servo. The flow divider on top of the engine has a poppet valve that closes when the pressure drops and this shuts off the fuel to all the injector lines simultaneously to get a clean shutdown. This stops the flow to the injectors, but leaves fuel trapped in the lines. When you start the hot engine after it has sat for only a few minutes, the fuel trapped in the injector lines has been heated by the engine and some of it has formed gas bubbles which have expanded and forced the liquid fuel out through the injectors. It is the same as if you had primed a cold engine. This is why if you crack the throttle and crank the starter with the mixture in ICO it will start. Of course, if you don't richen the mixture it will soon run out of this fuel and stop. However suppose you let the hot engine sit longer -- say 30 minutes to an hour. The heat will have boiled all the gas out of the injector lines and it will have evaporated. Now the hot engine is not primed. In this case, crank with the throttle cracked and the mixture in ICO and if it doesn't start, keep cranking and slowly advance the mixture control until it fires. What you are doing is keeping the air constant and gradually introducing fuel until the mixture gets within the combustible range. Skip1 point

-

PIREP on the GFC500 with auto trim in a 74 M20C....it’s truly incredible. I have the dual G5s with Mu11, GAD29B, IFD440 and optional G5 GPS antenna. Completed ~ 2hrs of test flights and investigating various failure modes. Everything is working out the door as expected. I want to acknowledge appreciation to Freedom Aviation (Jason Moorefield) at KLYH in VA for coming in on quote and time on the job. All the approaches have been to the runway centerlines with needles crossed and the missed approach automation with the GA button is so easy feels like cheating. If you get this system, your biggest concern will be keeping your hand flying skills sharp which of course you must do. Picture of new panel posted earlier. Happy flying.1 point