Leaderboard

Popular Content

Showing content with the highest reputation on 06/19/2021 in all areas

-

I finally got to do the torture GI 275 flight!! 1) Pitot tube failed.... AHRS and AI worked perfectly fine with IAS red-x'd 2) To further evaluate, removed all GPS sources so that no speed data at all for the AHRS 530W and turned MFD/stby ADI off so its VFR GPS would not give data to the primary ADI). Still worked perfectly through TWO coordinated standard rate turns. It never red-x'd or tumbled!! Shall publish video hopefully within a week. (It takes time to edit...) My conclusion is the Garmin has "rocket scientists" writing the AHRS software!! Chris5 points

-

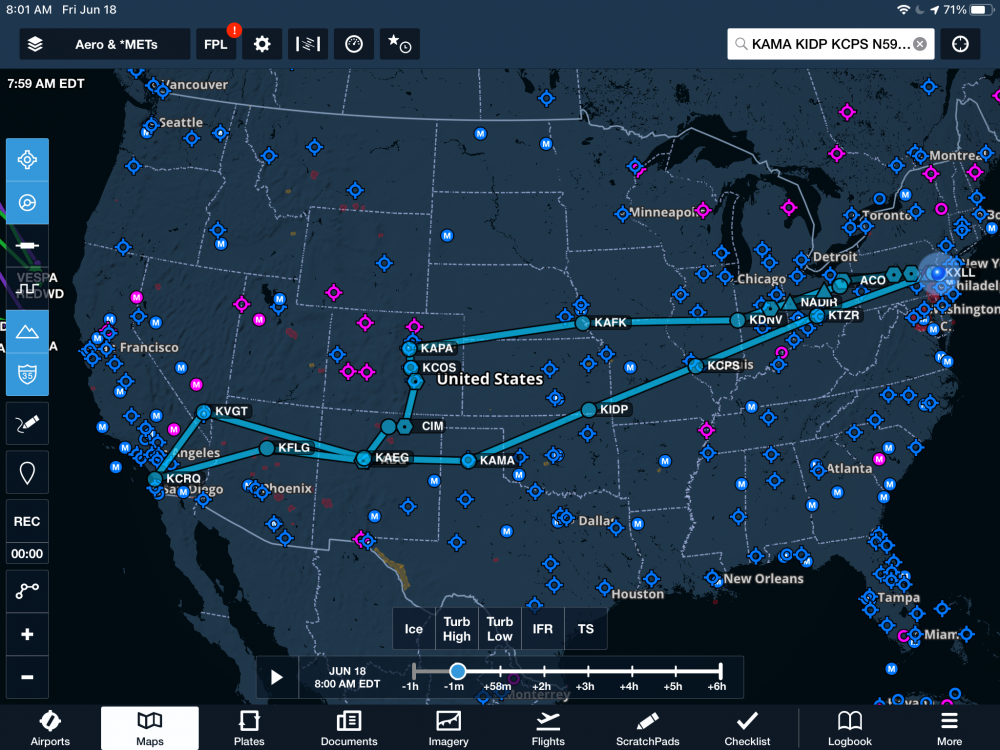

Flew my trusty C model across the USA and back in 14 days. Here’s a few numbers .. 8,700 - highest DA takeoff (Taos, NM) 5,137 - miles flown 328 - gallons of 100LL 40 - hours flown 17 - cats carried from a shelter in Illinois to a rescue in Colorado 1 - quart of oil added 0 - hours spent on autopilot (I don’t have one!) I was very fortunate. The weather cooperated and I flew VFR almost the entire trip. The plane ran like a Swiss watch. Except for a couple of hours around ABQ the air was mostly smooth. Without exception the folks in the FBOs were friendly and helpful. I can’t wait to do it again, next time I’m taking the northern route.4 points

-

I guess Mooney might have sold a few new planes these days if they were in the business of making planes...3 points

-

Installed weatherstripping yesterday in position 'B" above. The product seems to be almost perfect in terms of width, thickness, and stiffness. Must pull in on the door just a bit harder than before to close it, but not that much more. After I closed the door from the inside, co-pilot standing outside had trouble hearing me talk. Can't wait to flight test it. The one difference from position B that we noted occurred in the lower-forward portion of the door. After doing the original install, from inside using flashlight I looked into the 3/8" gap between door and aircraft and could see 3/5 of the seal. Before adhesive became super set, we removed the last section we added in that corner and positioned new seal considerably lower to increase contact between seal and airframe. The perimeter of the door in our C is 10'3" so buy two rolls. You'll have plenty. Lay it on, don't stretch product during placement. We used scissors to cut small "V" shapes from inner portion of seal to help it bend around the corners without torsion and excessive deformation.3 points

-

Hello All, I've been a lurker here for a couple of years. Back in March traveled to Durango, CO to do a pre-buy on a '67 F model. I ended up purchasing the aircraft and have put 100 hours on it since then. I have a bit of a unique situation - I'm Canadian, live in Mexico City, and do business between the USA and Mexico. Because my life is so spread out, I wanted an aircraft that could carry a decent payload, make it from the US border to Mexico City non-stop, and be fun to fly to the beach. The M20F beat out everything else I was looking at on price, simplicity, and pure fun. After signing the paperwork in Durango, I flew to Sandpoint, Idaho to visit friends, followed by a trip to my US base in Portland, Oregon, and then down the coast to Los Angeles where I picked up my mother (who got me interested in flying as a kid) and flew to Mexico City via Bisbee, AZ, Alamos, Sonora (I highly recommend the pilot-owned Hacienda Los Alamos as it has a semi-private strip), Zacatecas, and finally Mexico City. In Los Angeles I got my first taste of flying in a Bravo and even flew in IMC over the top of LAX on the way to Whiteman. Heading south through Mexico we flew over the famous Copper Canyon, a complex of six canyons covering 25,000 square miles. At first I was concerned that there wouldn't be anywhere to set down in an emergency, however I was pleasantly surprised to discover more airstrips embedded into the hills than I could count! I wonder what they use them for... I'm now on the tail end of a two week round trip from Mexico City to Bellingham and back during which I've had the opportunity to land in the Alvord Desert Playa, a must do if you're passing through Southeastern Oregon. The last 100 hours hasn't been without its challenges; the oil probe at the back of the WOLF oil filter relocation kit came loose at some point before arriving in Bellingham and started leaking about a quart of oil per hour. Advanced Aircraft in Troutdale got me sorted pretty quickly. On my girlfriend's first flight, I didn't close the door properly and it ended coming open mid-flight. Luckily we convinced the door to behave and my girlfriend still wants to fly with me. I'm attaching some photos of my adventures and will hopefully get a chance to meet some of you here on the forum or at one of the Mooney meetups this summer!2 points

-

2 points

-

I would say the issue is you are in FULL Fire Breathing Dragon Mode. I never flew mine for long periods of time in full fire breathing dragon mode. Even though it says max continuous is 27.5 inches of MP doesn't mean you have to run it like that. Your oil pressure is right in line for how you are running the engine in my opinion. Oil temp 215, #3 Cyl 398 and TIT 1410 all indicate your everything in your engine while "are within spec" but on the higher side of normal would force you oil to be hotter and thinner thus pressure would be on the lower side. There are better experts than me, but I would run mine at 25 to 26 inches of MP (most of the time lean of peak) and my cyl temps were always under 350 usually like in the 300 - 330 range. Simply my experience in my old M20F with a RayJay Turbo (I am not sure of your brand of turbo in your J model which of course has the better cowl etc).2 points

-

My 1100 hour IO 360 was sorted and running great when last August at Annual it showed metal in the filter. When I saw that I was perfectly willing to pull a cylinder and look around. All that revealed was a very slight line of corrosion on a cam lobe, but we couldn’t see the front lobes as well as the rear where we pulled the cylinder. My IA mechanic recommended flying it 15 hours and sending off an oil sample since we had not taken a sample at the annual. I did that and the sample showed iron. We agreed to start tearing it apart. Cylinders came off and revealed two front lifters spalled. Thought it could get cam and lifters and go back together good to go. Kept peeling the onion and found worn bearings and the crankshaft and case didn’t look great, so time to overhaul. I took the crankshaft, rods and other parts to Aircraftspecialties and the case to CSI. Sent mags to Missoula, MT. The lead times on both exceeded 8 weeks. I took the wide deck cylinders to Sal in Prosper, Texas. (if you go to Sal’s you won’t be able to leave until he shows you his pristine 1957, 270 HP Vette that he’s owned since he was 17 in 1961). The crankshaft had to be plated and machined and ended up .003 under. The case came out wonderful. The mags were back in short order. I was on waiting lists all over trying to get the new DLC coated lifters. It was beginning to look like I would have to put it back together without them when David at Aircraftspecialties came through with a set and a Lycoming cam. Sal thought the cylinders would work out well and I was glad because they’re tough to get new right now. They were nickel so he had to send them out to certify the nickel. He was calling them low time cylinders and said they came out great. They got it all back together and started it Thursday with only one full revolution. It really sounds great, but there was silicone seal on a baffle that he wanted to cure before I flew it. My schedule won’t permit flying it until Tuesday. Cant wait. If you see a plane flying racetracks above KOSA Tuesday, that will be me. I expect to get it tested and run in before our family traditional get together in Galveston for July 4th. There were lots of things that I got sorted on this plane before all this. It think it will now be a great plane!1 point

-

I forget where I saw this but some hedge fund manager walked thru many of the market crashes and said they were all largely brought on by a rise in the Fed's interest rate. As long as it stays low, I'd imagine this party will continue. It's going to be interesting when the Fed raises rates next year as they said they will.1 point

-

Welcome!! I was quite amazed at how they performed. Chris1 point

-

1 point

-

I guess I wasn't programmed to believe that bigger/more expensive is always better... I've sat in citation and Gulfstream cockpits and simulators. Even flown a citation on the right seat. Great machines... But nothing beats the thrill I had in the STOL Pilatus Porter landing on a tiny tiny strip...1 point

-

I have the same capability as the OP with the addition of a JPI eng monitor. So for me, I'm planning to slow roll any future upgrades incrementally. I prefer to install, test, fly.... install, test, fly... install, test, fly. So... the most I'm planning is to upgrade my older GPS antenna, replace the 430 with a clean newer 430W (or maybe IFD 440), and replace the AI with an AV-30 or G5 (AV30 is a simpler install); and call it done. My number two radio is a KX-155 with GS/LOC indicator and it's been overhauled by Mid Continent with a new display. These older radios are great backups. Should be able to do this for less than $10K.1 point

-

Absolutely agree. The GAMI's are the bomb for smooth running LOP. Takes a little time, a little work to get them all matched but once you do, it is really nice. Suggest you use the "GAMI" mode (that little circle "G" )to right on your graphing. GAMI will work with you on getting them matched up.1 point

-

1 point

-

I am incredulous. This is one of the most amazing things I have ever read. I would have never in a million years imagined it. That there aren’t enough cats in Colorado.1 point

-

27.5 at 2450 ROP is a lot of power. That’s the settings I use LOP. Your oil temp is kind of high for cruise, I see those oil temps in climb, but in cruise they always come down below 200.1 point

-

Long ago, I used to work with methyl cellulose at a chemical distributor. We blended methylene chloride based paint strippers. Methyl cellulose was used to thicken it, however, it had to be added in the correct sequence. Methanol was the final add to the mix and it quickly caused the entire mixture to dramatically thicken. I don’t believe that you could successfully add methyl cellulose to this stripper and have it gel. I think it would either 1. do nothing or 2. form many gelatinous clumps. Also, methyl cellulose seems expensive (sold by the pound) however, it’s a very low density powder. A 10 pound bag was quite large.1 point

-

The only other option was the three blade top prop. It had an rpm restriction, the two blade doesn’t. I hate removing cowling with a three blade.1 point

-

I bought my first plane, an M20E, from two “old guys” who were having trouble getting in and out, and they planned to get a 177RG for those nice big doors. Now, 30+ years later, I can understand their point much better.1 point

-

Same tray can be used. You need to upgrade to rg-400 coax if it wasn't used in the original install.1 point

-

here is a brief update on where this is landing for me… I would love to hear feedback, especially if I’m heading in a completely wrong direction I did quite a lot of research on options - GI275s, G3X and Dynon. Which ever direction I look, it’s a significant commitment. Surprisingly, both GI275s (old panel) and G3X (new panel) end up costing pretty much the same - this includes: EIS, new audio panel, new radio, upgraded GPS, ADS-B In/Out and AutoPilot (GFC 500). For those of you interested, those are the prices that I got quoted: GI275s, old panel: 65AMUs G3X, new panel: 70AMUs Dynon HDX, new panel: 44 AMUs including autopilot installation when/if gets certified Everybody suggests that doing upgrade at the same time is the optimal option. Given the costs, I came up with low budget option to last me for the next 2-3 years and help me to bridge to the target: upgrade non WaaS GPS - GNS 430 to GNS 430W + FS 210: 4 AMUs install JPI 900 with Cies senders (part of fuel tank reseal): 8 - 10 AMUs keep vacuum pump, use iPad as backup AI paired to FS 210 with Sentry as a backup The beauty of this option is that it does not commit me to the future path. I can still go either garmin or Dynon, the only downside is that it would increase Dynon option cost by 4 AMUs and I would spend extra 1.5 AMUs for FS 210 that is going to be a regret spend but most likely I can recover part of it. This option keeps my current panel going for the next 2-3 years, allows me to see what options are available in a few years and save up some more money to do big upgrade at once. Any thoughts, big downsides to kicking the upgrade can down the road? Thanks, Dominik1 point

-

will do! hartzell top prop two blade. i was level last night at 10500, and it was pretty warm. still making well over 160kts true. seems to work well at altitude! planning to replace the junk ignition harness lycoming supplied with the engine next week when i replace the mag. ordered a new maggie ignition harness. if it works as well as thier customer service, ill be thrilled.1 point

-

Just in case you're not aware, we have a local engine shop at CHD that is pretty reputable. They did the IRAN/teardown on my engine after a prop strike with the previous owner. It only had about 38 hours on that when I got it, and it's been good. My experience with them has been good when I've needed to consult with them. http://aircraftenginespecialists.com/1 point

-

Sealant stripper up to my balls. Made me laugh at the visualization not sure why. Maybe because i can empathize with getting too far into a project and just wishing my CB self had just paid someone else to avoid the personal misery.1 point

-

Raptor, I've got the Alpha Eagle system in my J, with the display mounted on the glare shield as far forward as I could put it. I'm a firm believer that they only help if the display is where you can see it quickly and/or in your peripheral vision. I find it very helpful and use it for primary reference for the most part. I would choose exactly this solution again, as well. I would not bother with one mounted on the panel or added to an EFIS display. FWIW, I did a supervised self-install and it was tedious, but not challenging. If we have some spare time in Madison, perhaps I can demo it for you. Sent from my LM-V405 using Tapatalk1 point

-

1 point

-

update to this thread. The electronic ignition was believed to be the culprit. i have the lycoming branded surefly. the aircraft is a 28V airplane and there is a known issue on the surefly side on some airplanes. I called surefly, but they couldnt give me a power conditioner since mine was a lycoming branded mag. I called lycoming, they let me know they sent me an old magneto when they shipped my new engine this march. they have updated the software on the mags to not be so sensitive to momentary voltage spikes. the revision on the new mag is L, and lycoming tells me the ligtning protection circuit will not activate until 60V know, and should cure my problem. Ill update when it is in next week.1 point

-

But but but, I bought that Sporty’s electronic E6B because Hal said it would make life easier in the cockpit! [emoji1787] Sent from my iPhone using Tapatalk Pro1 point

-

I’m currently balls deep into stripping the sealant out of my wing. I’m swapping out my wing because of spar cap corrosion. The wing is on a stand so it’s about as accessible as possible for stripping. I’m honestly thinking about putting in bladders instead of the wet wing. The money from the cost of stripper and sealant goes along way to paying for them and I will never have to do this again.1 point

-

Well that beats my Sun n Fun trip from SGU (St George UT) and back BUT I did my return at 1500 AGL until SAF and didn't talk to a sole except for towers we landed at ! Just like the old days :-)1 point

-

1 point

-

1 point

-

The filaments can break from the shock when the annunciator panel is removed and replaced. It was my gear down light also; likely because that one is on the most and the heat weakens the filament over time. Getting to the bulbs can easy or a PITA depending on if someone before you overtightened the screws. There are 4 phillips screws on the front panel of the annunciator. Remove the screws and the panel comes off and you can get to the bulbs. They are bi-pin types and just pull out. I just replaced the burned out one with one that was in an unused position. The front panel screws thread into standoffs that are swaged into a PCB. If overtightened, the standoffs come loose and just spin with the screws and the screws won’t loosen. If that happens, you will have to take the panel out and take it apart and fix it. Skip1 point

-

I've had a couple. My current AC has the heads up display mounted above glare shield and I find it very useful. My previous AC had the indicator on the panel and I flew AS and occasionally crosschecked the AOA. Now, with the indicator in my field of view it's the opposite. Pitch to the blue circle, crosscheck AS, and eyes back outside. For me, moving the indicator above the glare shield removed the system from the "gimmick" category and placed it firmly into the "tool" space.1 point

-

Bummer… To soon to go plane shopping? Or do we have to go through all the phases of loss first? Best regards, -a-1 point

-

I've applied several minor fixes to Bravo engines to even out the CHT's. You have to pay special attention to the baffle seals to the cowl, and to the forward seals around the alternator area. There are some large openings that need attention. I was able to run 80 to 85% power, with CHT's in the 340-375 degree range. I've done the same clean ups on Turbo Aztecs which share a similar engine, and similar heat issues.1 point

-

Will have owned my Bravo 29 years in August. On engine number 3. Have taken the APS Course and got a lot of value from it. While I believe in LOP and run some Continentals smoothly that way, in short tests my previous engines were not happy campers running that way. I have the GAMIs. First engine made it to 300 hours past TBO as a result of the change to the Bravo engine. The 2nd would have made it to TBO were it not for an incident during an Annual that made it financially practical to get a new Reman at 1600 hours. Turbos on the first 2 engines needed to be OH'd at mid time. In spite of running ROP l had expensive exhaust issues with both the 1st and 2nd engines. Run cross country 29/2400 (75% Power). From my perspective of 10,000 hours flying Mooneys and 5,500 hours flying Bravos, I'd stick with ROP. Keep a bucket of cash on hand if you rationalize for whatever reason and choose to run LOP.1 point

-

When I made my upgrade decision, I started with the autopilot. In three years, I repaired my intermittent KAP 150 computer twice and replaced it with a used unit when it failed the third time. So, I wanted a GFC 500 for reliability. The G3X is “newer” in the sense that in incorporates GFC 500 autopilot logic and integrates directly with the G5 standby. This means that you always have the autopilot if either the G5 or G3X fail. I believe that the TXi has more 3rd party interfaces and is going to the better choice if you want to integrate with non-Garmin equipment especially autopilots. If you use it with a GFC 500, you’ll need a G5 or GI 275 to drive the autopilot and you won’t have the redundancy if that device fails. Skip1 point

-

1 point

-

I have an engine stand and an assembly stand. If you want to drive over to CHD you are welcome to use them. I can give you some helpful hints about assembly that will make your life easier.1 point

-

You are citing SB240W. I believe SBs are optional for part 91 operations not mandatory. If you want to call it an overhaul you need to replace all the items listed. I did this on my overhaul. It says "AT OVERHAUL OR UPON REMOVAL:" and the SB lists 11 specific things some of which do not apply to the IO360 A1A engine. Below are the items I believe apply to the A1A engine. lock nuts and washers bearings main and rod camshaft gear bolts you getting a new cam and these are not very expensive anyway. connecting rod bolts and nuts. It could be argued if you do not unbolt the rods you do not need to change these i.e,. not removed. Unbolt the rods and yes you should change the bolts since they are stretch type bolts. Crankshaft gear bolt, it could be argued that if you do not take the crankshaft gear off you do not need to replace this bolt i.e. not removed. The next section states "AT OVERHAUL:" If you are not calling this an overhaul then these do not apply at all. However, anything internal to the case you probably should consider replacing. Again JMHO I'm not a A&P mechanic but I have identified as one lately. SB240W Mandatory Parts Replacement at Overhaul.pdf1 point

-

Regarding the GFC 500 and different Nav source boxes, I confirmed with Garmin that the Nav source needs to be manually switched on the missed approach. So, for example, with the GPS175 and GNC 255, after going missed from an ILS approach using the GNC 255: 1. Push the TOGA Button 2. Verify GA/GA 3. Add Power and properly configure for the go around 4. Verify missed approach altitude 5. Switch input source on the G5 to GPS 175 and verify GPS on the G5 6. Reengage NAV Mode on the GMC 507 to fly the missed approach 7. Reengage IAS or V/S 8. Verify AFCS Modes1 point

-

First, thank you everyone for the very kind words for the PMA450B. It is the culmination of designing audio panels since 1995. One IMPORTANT point regarding the above post, "IntelliVox(R)" is our registered trademark and is licensed PATENTED technology from the USAF. It is NOT the same that is used in any GARMIN audio panels. Additionally, one of the short comings of the GMA345 (in my opinion) is it does not provide music distribution. (NOTE: there is a switch on the rear right side on the chassis that if you flip it, then passengers will always hear Music #2). The only selection of sources is the one that everyone hears (Music 1, Music 2, BT). ALL of our audio panels provide various music distributions. The PMA450B with dual Bluetooth(R) that takes the distribution to the next level. The pilot can select to hear both a hardwired XM (GDL69 maybe) music while also listening to BT2 that might be connected to an iPad providing audio alerts from Foreflight. The copilot might want to hook up their phone to BT1 and listen to Music 2, while the PAX can select to listened to any one of the four entertainment inputs. Music 1, Music 2, BT1, BT2 This might sound extreme but in actuality, it is not. How often have you wanted to hear audio alerts from your iPad AND listen the XM music at the same time? Each station (pilot, copilot, and all the passengers are treated as individual stations) can select their own volume level and muting settings as well. The most important point in this post is to alert everyone that IntelliAudio(R) is nothing like GARMIN's 3D audio, completely different implementations. For example, we do NOT make the passengers intercom audio "appear" to becoming from the back of your head. We figured you already know and recognize the voices of the folks in the back. We kept the intercom MONO. Additionally, it is my understanding the the copilot's intercom audio goes to the pilot's right ear. That might be a problem when COM 2 comes from the 2 O'clock position while the copilot intercom comes form the 3 O'clock position. IntelliAudio(R) places all intercom audio at he 12 O'clock position, much easier to ignore when trying to listen to COM 1 or COM 2. The PMA450B allows the pilot to place COM 1 and COM 2 in the 9 O'clock near, 9 O'clock, 10 O'clock, 11 O'clock, 12 O'clock, 1 O'clock, 2 O'clock, 3 O'clock, and 3 O'clock near. Thank you all for allowing me the opportunity to clear up some unintentional misinformation. For years, people thought we made GARMIN audio panels. We never did except after GARMIN purchased UPS-AT, they continued to purchase the UPS-AT SL-15 but that ended after a year. However, we are very appreciative that other avionics manufacturers purchase our audio panels either under the brand name or ours. - Mark Mark1 point

-

Can't you just cut larger pieces of smoked plexi and put them the original factory holder? Cut up an Amazon box to see what fits your plane then trace into plexiglas, saw it out and sand the edges to be smooth. When you are happy, send a check for 1/4 of a set of Rosens, I'll spell my name for you . . . .1 point

-

STCs have AMLs (Approved Model List) associated with them. Since the M20R is on the AML, that's all you need. It's kind of interesting why they have an STC. The FAA requires that parts used on certificated airplanes come from the original manufacturer or be standard parts (like nuts and bolts) or be made under PMA as replacement parts. Since the Rosen sunvisors are not exact replacements for the originals, the FAA in whatever region Rosen is in made them use the STC process. The FAA considers STCs to be major modifications by definition (after all the form was created for supplemental changes to the type design) and that's why it needs a 337. It's stupid. I don't know the legality of installing them without the 337 and calling it preventive maintenance (or a minor alteration). I did that years ago and no one ever noticed, but maybe there's an FAA guy out there still looking for me. Skip1 point

-

1 point

-

It might be best to recall what flaps do: 1. They reduce stall speed allowing a slower touchdown speed reducing runway length required to stop and reducing tire wear. 2. They change the effective angle of incidence allowing a lower pitch attitude improving visibility. 3. They increase drag allowing a steeper descent for a given power setting. So, I use full flaps when I want any of those attributes (which is just about always). Skip1 point

-

Part II... Use the search box there are threads for tools people take with them... There are tools they use while flying, like portable O2 systems and related parts. Fire extinguishers, iPads and ADSB devices Stuff they keep in the hangar for planned Maintenance... Tire's and oil and oil additives have gotten a lot of discussion. Towels and drip protectors and cleaners when the protections fail... Projects they are working on... Even books or apps they are writing.... A couple people have their own spare airframes..... Keep in mind there are some interesting people that fly Moonies. Best regards, -a-1 point

-

You would be wise to keep your CHT 400 or less and your TIT 1600 or less. This will be kind to your cylinders and your exhaust system.1 point