Leaderboard

Popular Content

Showing content with the highest reputation on 06/13/2021 in all areas

-

Pilots apparently need something engine-related to worry about. 30 years ago it was shock cooling. Today it’s red boxes. Shock cooling was supposed to be the cause of cracked cylinder heads (I believe the real cause was reconditioned cylinders that reused head castings for who knows how many TBO runs. The problem seems to have evaporated when the factories lowered their prices for new cylinders and most overhaulers started providing them as standard with an overhaul). As someone noted, it’s not entirely clear exactly what calamity operating in the red box is supposed to precipitate. Here’s something to ponder: Cessna 172s don’t come equipped with CHT gauges. They don’t have cowl flaps. There is a flight school in my area with a fleet of old but exceptionally well maintained C-172s, mostly C-172Ns. Recently two were upgraded to include a G3X with EIS. For the first time in 45 years, everyone could see that the CHT on some cylinders well exceeds 400F during a climb. Now CFIs are scrambling to avoid this. Red box! Red box! But for many years, this operator has been regularly exceeding TBO on it’s O-320 engines powering these same Skyhawks with everyone blissfully ignorant of the CHT in a climb. Skip4 points

-

Glazing is caused by low power operations after an overhaul, where the rings fail to seat seat. Camguard would have no effect on that unless you used a massive amount from the moment of overhaul. The anti-wear properties would inhibit break in.4 points

-

My 1100 hour IO 360 was sorted and running great when last August at Annual it showed metal in the filter. When I saw that I was perfectly willing to pull a cylinder and look around. All that revealed was a very slight line of corrosion on a cam lobe, but we couldn’t see the front lobes as well as the rear where we pulled the cylinder. My IA mechanic recommended flying it 15 hours and sending off an oil sample since we had not taken a sample at the annual. I did that and the sample showed iron. We agreed to start tearing it apart. Cylinders came off and revealed two front lifters spalled. Thought it could get cam and lifters and go back together good to go. Kept peeling the onion and found worn bearings and the crankshaft and case didn’t look great, so time to overhaul. I took the crankshaft, rods and other parts to Aircraftspecialties and the case to CSI. Sent mags to Missoula, MT. The lead times on both exceeded 8 weeks. I took the wide deck cylinders to Sal in Prosper, Texas. (if you go to Sal’s you won’t be able to leave until he shows you his pristine 1957, 270 HP Vette that he’s owned since he was 17 in 1961). The crankshaft had to be plated and machined and ended up .003 under. The case came out wonderful. The mags were back in short order. I was on waiting lists all over trying to get the new DLC coated lifters. It was beginning to look like I would have to put it back together without them when David at Aircraftspecialties came through with a set and a Lycoming cam. Sal thought the cylinders would work out well and I was glad because they’re tough to get new right now. They were nickel so he had to send them out to certify the nickel. He was calling them low time cylinders and said they came out great. They got it all back together and started it Thursday with only one full revolution. It really sounds great, but there was silicone seal on a baffle that he wanted to cure before I flew it. My schedule won’t permit flying it until Tuesday. Cant wait. If you see a plane flying racetracks above KOSA Tuesday, that will be me. I expect to get it tested and run in before our family traditional get together in Galveston for July 4th. There were lots of things that I got sorted on this plane before all this. It think it will now be a great plane!3 points

-

Shockingly, your premise does not hold up to scrutiny. The only thing you need to buy into is that the guy who was largely responsible for the formulation of Exxon Elite (Ed Kollin) thought he could improve upon his previous additive packages and/or have more freedom to formulate a superior additive blend (CamGaurd) without being encumbered by the policies of the marketing and accounting departments. I’m not beating up on corporations but sometimes good ideas don’t fit into the boxes created by corporate policy. Understanding this does not mean you think oil or engine manufacturers are stupid, it merely means that you understand that sometimes innovation doesn’t thrive under corporate policy. Do you think Ed should have dropped his mic and walked off stage after Exxon Elite? No chance he could do any better? Or is it just that he went out on his own that discredits his work on camguard?2 points

-

For a non precision dive and drive approach it’s plenty good enough. Actually you add a little to the descent rate for that. On a precision approach your flying the vertical needle anyway, so it’s only a guideline. It works wonderful for me. I’ll make note not to waste time flying with you while you’re focused on getting numbers to the last digit rather than focusing on a safe approach.2 points

-

I find the Intellivox to be useful for picking up ASOS or ATIS while working a busy approach controller. Also useful when making an approach to an uncontrolled field. You can listen to the traffic in the pattern (assuming the field is VFR) and make a report before you get too close. A couple of weeks ago I was number 5 in the pattern at LMO. Everyone in front of me in turn reported downwind, base leg and final. As we were turning base a 182 broke out of the haze on an instrument approach just outside of our position. The student apparently had not been monitoring the unicom so he was surprised to almost hit us. On straight-in approach you need to be informed.2 points

-

My concern with carbon fiber is that the modulus of elasticity is almost zero once it’s over stressed. Under design load, and optimum conditions it is absolutely as advertised, but once it’s damaged it tends to fail completely. I saw many examples of this with bike frames, both in racing them for 10 years, and while in college with our senior projects. An aluminum frame that’s damaged, you finish the race, a carbon tube breaks in the same fashion and you are carrying it home. While metals have a large range of strength loss after exceeding tensile, it always retains a large portion of its strength. Composite airplanes have been around a while and it’s obviously not a very prevelant problem, but it’s still one I would worry about when buying a used plane composite plane. For the cirrus fans reading this, I am NOT denigrating the airplane, and metal planes certainly have their own challenges. I also realize I am in the minority, and probably an anachronism... When there are a fleet of 70 year old composite planes flying around, I will likely feel different. Until then I prefer to observe from the sideline.1 point

-

I like the cut of your jib, 1980Mooney. I also don't think I should pay more to subsidize others' risk taking. So... here's a list of risky behaviors many Mooney owners do not engage in: flying at high density altitude flying over mountains flying over water flying at night flying in instrument conditions flying IMC with less than 3 independent attitude indicators flying IMC at all, regardless of equipment flying without an engine monitor flying without ADSB-IN for traffic and weather flying without an angle of attack indicator choosing not to sump the tanks before every single flight choosing not to run a specific W&B calculation before every single flight taking off or landing on runways with less than a 50% margin vs. book performance performing touch-and-go's in a complex airplane It's easy to find accident reports associated with each of these behaviors. So please let us know which of these actions you engage in, and how much it's appropriate to raise your rates, so the rest of us are not paying to subsidize your deliberately risky behavior. Yeah, yeah, I know... the risks you take are perfectly reasonable, it's only the risk others take that are unreasonable and should put them in a separate insurance pool. I hope the list above illustrates the problem with this way of thinking. Shared risk is the bedrock of insurance, and separating buyers into smaller and smaller pools eventually kills the whole concept. You already pay an adjusted rate that takes into account the type of airplane you choose to fly, how much it's worth, your ratings, and your experience. How much more do you really want to carve up that pool? Are you sure doing so is actually going to benefit you?1 point

-

I'm pretty skeptical that an exhaust valve can reach the point of failure without showing clear visual evidence of a hot spot at a rim well in advance. That cannot be said of the SAVVY FEVA signature on the EGT trace, which is often a very late event when failure is imminent [also I believe they check for it for free when you upload data to their site, though they don't publicize this.] I suppose the hours you fly between annuals makes a big difference - if it's a lot, getting your own borescope and checking every 50-75 hours is a quick, easy, cheap do-it-yourself option that most any owner can avail.1 point

-

Lube the gear really well. pull the actuator apart and lube it. While you are there with open panels lube the u joints and chain in the trim. It is amazing what quality maintenance and a little lube will do for parts that move.1 point

-

Another thing that makes owning more appealing than renting is hard to put into a spreadsheet but very real. Your own airplane is always available exactly when you want it, and if you decide that you want to stay at destination X for an extra week, nobody is phoning you up and telling you that they need the airplane back home for another renter, or charging you daily minimum rent for sitting idle.1 point

-

A 3 inch instrument is too small IMHO to have useful SV. I've used it to great effect in larger displays.1 point

-

If it won't move in either direction, that points to the motor itself. I had that happen once and one of the brushes fell out. I hope your repair is as cheap as mine was,1 point

-

Oh, how do I wish there was a magic additive that would reduce wear 30% and therefore add 30% more hours to an engine1 point

-

1 point

-

The only way that flying a drone at that altitude would be legal would be under an FAA waiver, or certifying the aircraft under existing rules (like part 135)...and I’m not aware of any that exist for what was described. Not only was the pilot of that drone in violation of the 400 foot limit, they were clearly violating the visual line of sight rule that is at the center of the exiting part 107 rule. The remote PIC must remain in visual contact with the drone and avoid other aircraft. Doing so using a camera or first person view does not count. They have to see the drone with their eyes. I hope that RemoteID will help reduce these types of encounters and make it possible to make flying in the airspace safer. Eventually there could be rules that allow drones to fly at those altitudes, although it would be rare, most missions like package delivery and surgery will be a lower altitudes. The RTCA and ASTM standards bodies are working beyond line of sight navigation requirements for drones. It will be up to each country’s regulator to adopt and build on the recommendations once released. The goal would be safe and reliable integration into all types of airspace and altitudes. In addition to the navigation requirements are “detect and avoid” and “traffic management” recommendations to ensure that ALL aircraft can fly safely. My personal view, not those of the standards body, regulator, or any company.1 point

-

Why do any of you believe someone woud be stupid to use Camguard or any other additive during break-in? Never seen a bottle of Camguard myself, does it say that on the bottle? I don’t believe in additives, I’ve heard so many times, it’s FAA approved, it must do what it says,which is not true, all the FAA cares about is proof that it does no harm. On edit, I don’t believe non detergent oil is specified for break in because it allows more wear, I believe during times of excessive oil use the detergent can cause combustion chamber deposits, it’s not to allow more wear or faster wear, turbo motors run detergent oil for break-in. why? to keep the turbo center section bearing clean, but they break-in just as well. Detergent additives are not a lubricant additive. The whole “good oil” is too slippery to allow break in is not true, but you hear it every day, “don’t use synthetic oil in your car for 10,000 miles” etc., but higher performance GM cars factory fill has been synthetic forever, and many new cars require 0W-20, which I believe is only available as a synthetic. I wish there was an oil that was so good that it prevented wear so well that it wouldn’t allow break-in, imagine how long a motor might last?1 point

-

My mom says I’m smart and handsome too.... Good for your mechanic. Being a highly experienced IA does not necessarily translate to being knowledgeable about petrochemistry (nor many other things involving airplanes) although it can lend an air of confidence to one’s own anecdotal opinions. Given that Aviation Consumer’s independent tests have shown that Camgaurd adds a significant level of corrosion resistance, I’d like to know the “why” behind his opinions. The inventor of cam guard Ed Kollin, worked for Exxon’s Aviation lubricant division and was one of the principle researchers involved in the formulation of Exxon Elite aviation oil. The man did a tremendous amount of Q&A on various aviation forums for many years. My take away from his comments are that camguard is his version of a “cost no objective” additive blend.1 point

-

I'm getting close to wrapping up my dual G5 install with a 430W. Since the ADI is supposed to be on the "Battery Bus," what I did was split my Avionics Bus and put a diode in-between the two bars. This is controlled with a dual position Avionics Master switch: UP is ON through the Relay while DOWN is ON just for the three position bus bar directly through the Battery. My 430W GPS circuit breakers are on this bus as well as the G5 ATT. This accomplishes two things: On the ground, I can power up the GPS and enter my flight plan and get weather / clearance. In the air, if I have a generator failure or an avionics relay failure, I can quickly isolate and run the Attitude Indicator and 430W from the battery. Note that, without the GAD, you can't control an autopilot nor feed ARINC data to the G5. But, and I confirmed this with the local avionics shop, the GPS data is fed via RS-232 to the G5. So, long story short, this will keep the G5 in fully functioning attitude indicator mode and have GPS navigation, and a radio, in an emergency.1 point

-

Oh yeah, auto-muting of a monitored comm channel is awesome. I now tend to set my next frequency very early and just set it to active. knowing it'll eventually start working but not be in the way of the primary channel. USB PORT is KILLER.1 point

-

Frankly before I would trade my IFR equipped C model for a Cirrus, I'd go twin. As here in Europe there is the paywall of 1999 kg, I would most likely go for a Seneca II or a Turbo Twin Commanche if I can find one with de-icing. The Cirrus is a fantastic airplane, no question about it. The market has spoken abundantly clear, it is the only viable travel plane to sell new these days. I would say 80% of this is the shute, the rest is whatever else it has to make it attractive. Ramp appeal, it is large on the ramp, it is relatively comfortable to sit inside and it has that all important shute. For me it is perfectly clear that no SEP traveller which is expecting to carry wife and kids will be able to sell any significant numbers unless it features the shute.. The only Mooneys I'd upgrade to from my C is a J or K. The J has the better range the C lacks and slightly better speed with almost identical cost. The K is useful here in Europe due to the mountains. I've had the chance to sit in an Acclaim Ultra. For me, the Ultra would not be a plane I'd consider. The payload is absymal, the cabin looks nice but is as tight as any other Mooney and the panel is way too high even for me at 6'2, I can hardly see over the panel when taxiing. Yes, it has a superb performance but if I spend close to 1 million for a new airplane (or half for a recent used one) I'd have to ask myself if for this kind of money, if I stay in the SEP range, I'd not rather go for one with the parashute but very much rather go for a FIKI twin, which I can pick up for 10% of the price of a new Mooney or Cirrus and which gives that safety of the 2nd engine and a comfortable cabin for my family. Personally I think the J and the C were the two models which made Mooney the hit it was at the time. 180-200 hp, great performance and affordable for the lower income class of pilots. That is why I have a C and why I can afford to have it despite being in an income class where others wonder if they can afford a new bicycle. What I like in the J vs the C is the larger fuel capacity and the speed mods, which gives that magical 1000 NM number in range. They provide 150 kt for the money of a Cherokee 180. That is what I thought made Mooney really great. When they started to go into the Lamborghini class of airplanes, expensive, huge engines, much worse economy, one can easily choose something else. For me, dumping the J was the reason they went bust over and over again. So if I'd upgrade it would be either to a J or, with the money needed for a Cirrus or current Mooney, to a twin.1 point

-

Everyone makes their own choices, you are correct. I was just pointing out that recently others @RobertGary1 have experienced dual GI-275 failures, which Garmin was just made aware of. Also if your engine baffles are set up properly in a Bravo (I've owned three of them), you can keep your CHTs below 400 and your TIT at 1600 easily, with your cowl flaps closed. If not, air is escaping past your top baffles in the back.1 point

-

I will print cover plates that fit flush in the holes. Received the plane back and had to leave the next day.1 point

-

1 point

-

I wouldn't worry too much about what equipment you must have as a buy/ no buy decision maker, you're going to put a bunch of things in no doubt. The only thing you should think about pre-buy is FIKI vs Non FIKI. I personally don't have FIKI, I would just prefer to stay grounded in icing conditions as my missions are not that crucial. But if you need to be in that, its easier to buy an airplane already equipped with FIKI and then add other gadgets, than to upgrade a Non FIKI airplane into one that is.1 point

-

I replaced a kma-20 and intercom with the pma 8000G, step up from 7000 but not quite a 450. Intelliaudio, is just nice. makes it a lot easier to monitor multiple sources. bluetooth in and out is killer. makes it real easy to call up and get clearances on the ground. beyond that, i never bother with all the other features. the install cost of the 450 will dwarf the purchase price. they have to rewire the plane for stereo along with reconnecting all the other components. if i had had a kma24, i'd have bought the 7000 and spent the upgrade monies elsewhere1 point

-

Great! If you get one you'll love it. When I was transitioning from rental to owning an airplane I thought about buying an arrow or an archer which I had lots of time in, but realized I would outgrow that in around 1 year. I have not outgrown my Bravo yet and I don't think I ever will. (okok. unless they develop a pressurized Bravo one.. maybe On a side note, I was once flying at around 18,000 feet at 230+ knots and ATC kept referring to me as King Air 0RA, I corrected him and told him I'm Mooney RA, he replied "You're in a Mooney?" (He said in a tone that sounded like, yeah right you can't go that high or fast in a Mooney, you must be in a twin) I answered yes and chuckled for quite some time.1 point

-

1 point

-

1 point

-

In early 2016 i was upgrading an early 90's panel and trying to get it into the 21st Century. It had a KMA-24 so I used the same logic you did and saved a few dollars on the unit and a few dollars on the install. Although the 7000 with BT works well, I've kicked myself ever since for not just doing it once and doing it right. I'm sure I'll end up putting in the next version of the PMA450X. My avionics shop says it will take about a day to re-pin everything, plus of course the cost of the new unit.1 point

-

I put a 450A in my Bravo years ago and have enjoyed it. It will BT to my phone or iPad so I have music. The audio quality is great and the intellivox is a useful feature. I tried the intellivox on the Garmin panel and found it very inferior at the time. Garmin may have improved it by now. You can probably find a used 450A for a reasonable price and the wiring is not that big a deal. Good luck!1 point

-

From your described mission profile, you should seriously think about an M20M (Bravo). You will have density altitude restrictions on buying a non turbo airplane flying into and out of high elevation airports. On a long distance flight, you can fly as high as 25,000 feet with oxygen to take advantage of tailwinds and exceed 250 knot ground speeds. This would get you the speed for time to do business travel, and flexibility to get above obstacles and sometimes weather without issues. The tradeoff cost is fuel. A Bravo is not very fuel efficient burning about 17-18 gph in cruise, whereas a J is the most fuel efficient Mooney out there. An acclaim will do the same thing and a few knots faster than a Bravo, but the cost is much more than a typical M, as you can get a great M for under $200k, whereas a similar Acclaim would be $450k and up. Proficiency would be a big determining factor though. Would highly recommend getting a Mooney Specific flight instructor to do your transition training which is crucial if you want to fly any of these models. Good luck!1 point

-

1 point

-

Can you BT in the audio from Foreflight? Some of that seems useful. I also like the USB charging capability (probably no interference like lighter usb chargers) and the separate BT inputs which can be separated out to passengers so the kids get their own movie audio. Finally the ability to turn off the radio to pax is nice for those that want to read or whatever, but not be “isolated”. I’ve been trying to convince myself to put in a 450B for my current GMA340 for a while. Super easy swap, but It just hurts so much to take out something that works perfectly and put in something new that costs a couple amu. If your current audio panel is struggling at all, I’d definitely pull the trigger though. How much can you get for a used gma340?1 point

-

Why did you replace the cylinders? That seems like a lot of money to spend when new rings and a rehone would have done the job.1 point

-

http://Zoom.earth Found this the other day. Pretty cool satellite overview1 point

-

OK, there are pretty much three ways you can get low compression and high oil consumption, oil turns black in a hurry and high oil temp from excessive blow by, one is glazing, glazing is a physical clogging of the cross hatching on the cylinders, it’s what it sounds like they are glazed by something, a varnish like coating. The other way is bore polishing which is pretty much just wearing away the cross hatching, and babying the engine during break in. ‘Sometimes glazing can be recovered from, I’ve seen it, liberal use of Marvel Mystery oil and running the snot out of it, but keeping it rich. ‘Whatever MMO is or isn’t, it seems to have detergent like properties, but then of course mineral spirits is a good cleaner Glazing can be caused from overheating by excessive ground running at 1200 RPM or so warming up the oil, there is very little cooling air flow and 1200 is high enough to get the cylinders smoking hot, not the cylinder heads. but cylinders. Babying the engine can sometimes keep the rings from seating, but shouldn’t glaze them, pretty much takes heat or some added substance that can bake into a glaze, OK if they don’t seat and you keep running it, then I guess they can glaze. I’ve never let one get that far Rare for glazed cylinders to need replacing, if they are glazed then a good honing and new rings will get you back like new, never seen them needing to replaced, but that does of course get you to new. ‘Until we know what Camguard really is, I don’t think anyone can claim anything about it. I wish I had a quarter for every time I’ve heard a claim of what caused this or that that had no bearing on the case. Often a cylinder’s rings just don’t seat, it’s got to be blamed on something so it’s glazing, you can see glazing in a bore scope, it literally looks like varnish, what I have seen had a slight brownish color to it. Pop the jug off, have it professionally honed, but I have seen some use a dingle berry hone and it work, new rings and run the snot out of it for 10 hours, if they haven’t seated in 10 hours I doubt they will.1 point

-

I felt like an idiot trying to figure out how to get to the navigation page the manual talks about. In hsi mode that page is disabled but the manual doesn’t say that.1 point

-

Yep. I wonder how long before that will be the law (especially here in the People's Republic of Kalifornia)1 point

-

I do not think you will get accurate azimuth from the compass in any location except in the original factory location.1 point

-

1 point

-

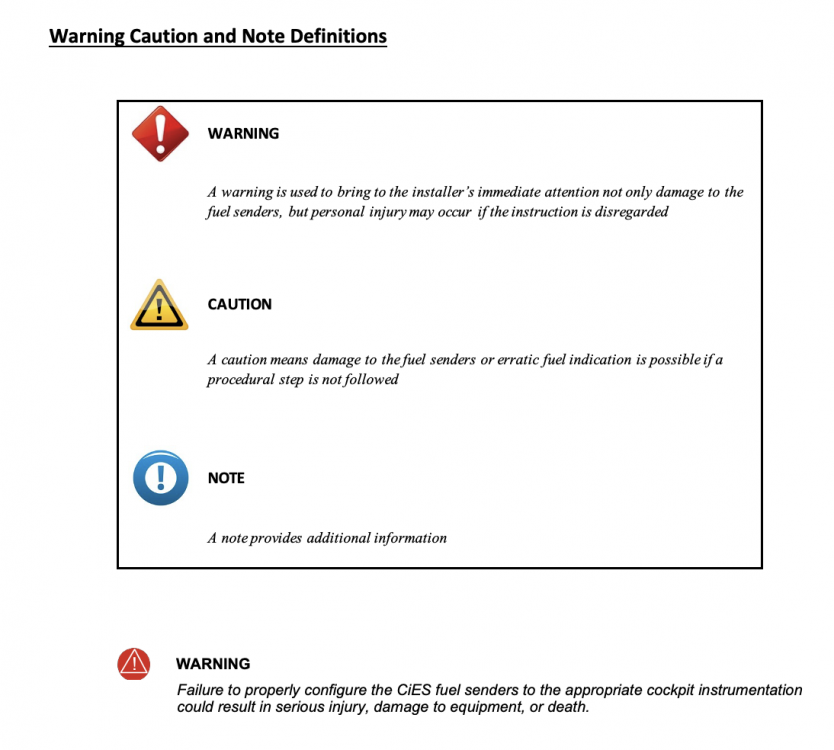

One - there is an amazing number of variations in aircraft - even between serial numbers. When we have consistent information we make changes. But this is on Page 10 The insert in the box lets the installer know that this document is available online. In the beginning we make sure we highlight items the installer should pay attention to This is an industry standard warning - typically found in Garmin install manuals.1 point

-

It’s not you it’s the Market. I have 1000 in type and mine increased by 40%. It’s not your broker. There’s a good chance your previous carrier chose not to renew and your broker found you the best deal he could from the shrinking number of carriers willing to underwrite GA policies. @Parker_Woodruff may be able to help you.1 point

-

The biggest difference for me... flaps/no flaps... Stall speeds around the traffic pattern get adjusted... Tighter attention to bank angle... and un weighting the wings.... I tend to use flaps specifically to avoid stalling the plane. I also fly out of a medium sized uncontrolled field... PP thoughts only, not a mechanic... Best regards, -a-1 point

-

Thank you for the report. It *is* useful to hear what shops are being told. And believe me, us Mooney owners are interested and cautiously interested. But understand that Bendix/King for the last year and change and TruTrak for at least two years before that have been completely unwavering in stating "we almost have it certified; it will be available in six months". They would say that no matter what. They said it in these forums, and I have chains of emails of the same claims. So yes, I'm hopeful too, but I'm going to stay jaded until I hear the words "available for order, what's your model and serial number?". The only reason I'm not completely angry and disillusioned is that the story *sort of* changed a bit when BK took over the product. When I talked to Bendix-King last fall, they said they were deciding between Mooneys and some other model to pursue pursue certification for internally. Once I got over my rage about realizing that TruTrak was basically flat-out lying the whole time, I realized that possibly this was different in that they were telling me slightly real (if incomplete) information. Later in the winter, I talked to them again, and they said that the Mooney certification had actually be contracted out to an external company and they expected it would take six months, and it would be "done" round about June. I talked to them earlier this spring, and targetting in June hadn't changed. Now if I talked to them at Oshkosh at they say "we'll have it in six months" I'm going to be sad and angry all over again. Let's also be very careful and understand that finishing the paperwork is not the only thing that has to happen. They have to be able to produce product. There's a video by "Jimmy's world" on YouTube about him waiting for months for an AeroCruze (for an airframe that it's already certified for) and not being able the get it because it wasn't available. So I think questions we need to ask of Bendix-King (and any manufacturer of a new thing) are: "How long do you expect the STC to take from right now?" "What are the steps that need to happen between that and having availability of actual certified airframe-specific install kits?" Finally: "From the point that you deliver the first install kit, how long will it take at your current unit production rate to fulfill all of the back-orders for that product so that the kits will start to be immediately available?" If someone can answer those questions with a straight face and more detail than "it'll be available in six months" maybe I'll hold out a bit of hope.1 point

-

What causes exhaust valve failure? Inattention. This stuff doesn’t pop up overnight, so building a library of borescope images at 50 or 100 hour intervals will show when something is going bad. It’s not hard, even on the TN with the intercoolers blocking access to the top plugs. -dan1 point

-

The thing that bothered me the most- and I suspect others, as well- is that there is good information out there that the Caravan didn't divulge to those who aren’t members of their group. Like many members here, I’ve done some simple formation flying generally for the purpose of in-flight photography. I would love to know more about how to do so safely, but for a variety of reasons I have no desire to join the Caravan. I suppose I’ll just infer the lessons I need from the scant information that is available. It all struck me as a little petty, like when chriscalandro had a fuel tank problem and refused to share the resolution here because of some childish snit he had with some of our members. ———————————- EDIT: after reading @N9201A‘s post above, I looked at the safety section of the Mooney Caravan website. There is a lengthy write up of the incident and lessons learned. That wasn’t there the last time I had visited. Thank you to the Mooney Caravan for posting that information to the website. https://www.mooneycaravan.com/web/Mooney/Pages/Safety/2019.asp?Zr07Pyvpx=FDEM V0pvqr06 f6n6rzr06&Zr07TPyvpx=fnsr6B1 point

-

As an outside observer, it would be difficult to assess anything except what’s posted here. So that’s understandable. Posting to social media is not a viable safety management strategy. The Caravan has implemented significant additional internal processes and safeguards to enhance safety at future events, not just the mass arrival flight. Participants are using them now, and future participants will be aware of them. In addition we have a specific presentation “Ruminations of a Midair Survivor” that has been presented at clinics. It is a detailed analysis using the Reason model and NTSB methodology as well as group discussion that has been well-received. If you’re at OSH, look for it. It’ll be presented there and announced here too. And for those who are interested, come out and fly with us.1 point

-

There a similar table in the front of the Government approach books. In Foreflight, it's in Documents in the FAA drive: Digital Terminal Procedures Supplemental, last page. Here's a trick I use: Define the "Speed Factor" (SF) as nautical miles per minute. So a groundspeed of 60 kts is a SF =1; 90 kts is SF =1.5; 120 kts is SF =2, etc. The required ROC (ft/min) is the gradient in ft/nm x SF. So climbing at 120 Kts with a required gradient of 350 ft/nm requires a ROC = 2 x 350 = 700 fpm. The Speed Factor is also useful for planning descents. The altitude you need to lose (in thousands) multiplied by the Speed Factor gives the distance to top of descent at 1000 fpm. If you want to descend at a more leisurely 500 fpm, just double the distance. Say you need to descend 9000' at 500 fpm and 180 kts. 9 x 2 x 3 = 54 nm. Skip1 point

-

While it is true the older Cirrus SR-20s had an IO-360 engine, they are six cylinder Continentals, not four cylinder Lycomings.1 point