Leaderboard

Popular Content

Showing content with the highest reputation on 03/07/2021 in all areas

-

When I was contemplating purchasing my first airplane, a good friend and owner of a really nice TR182 told me that the best part of ownership is that the flying is free. "Free?", I asked. "Yeah", he replied. "It costs so much to hangar and insure and inspect and maintain the thing that the gas and oil to go fly for an hour is essentially free." Richard Bach once wrote that he wanted to buy a certain airplane but was struggling to justify the cost. But then he realized that he really wanted a twin and that burned a lot more gas and had two engines to maintain. So by not buying the twin, he reasoned he was saving enough on gas and maintenance to afford the plane he was considering. And, he figured, if he ever ran out of that money, he'd not buy a Learjet and that should keep him going indefinitely. Skip5 points

-

Nobody buys an airplane to save money. We buy them to save time. Going by the equation: time=money Maybe we do save money. But boy, does it cost a lot!4 points

-

Personally, I think insurance costs will continue to rise, but the value of a Mooney won't have anything to do with that cost increase. Sorry, but if you are basing even part of your purchase decision on the value increasing...you should NOT buy. That sounds too much like you believe buying a plane is an investment; it is 100% NOT an investment! A partnership might well be the best way to test whether full ownership is for you. The planes we own and discuss here are mostly for our own enjoyment; some may be a business tool for transportation and have tax advantages. But, even so, I doubt many of those business people view the plane as an investment as much as a depreciable tool that they enjoy using. Early on I realized I was buying an EXPENSIVE toy. As soon as I realized that I could afford it, l no longer felt any need to RATIONALIZE ownership: it's a HOBBY I very much enjoy...in the end that's all that matters to me. YMMV4 points

-

That cowling appears to be installed incorrectly. That U-channel with the cam loc should be on the inside of the firewall flange. That camloc will then go through the firewall flange into the u-channel along with the screw on the upper cowling.3 points

-

As stated elegantly above, an airplane is toy. Buy it because its going to bring you a lot of enjoyment and you have the resources or partners to cover the larger cost of operating and maintaining it. Purchase cost is only the cost of admission, the annual flying budget will quickly exceed the initial purchase cost. Which is one of the best arguments to buy as much airplane as you can afford, assuming your serious about flying, because subsequent upgrades will cost a lot more to fund new later than buy used now.3 points

-

3 points

-

Unfortunately.... When you perfectly match the hardness of both surfaces... they tend to wear each other out at an accelerated pace... Some oddity in metallurgy to explain that... In this case... the surface of the cam follower is the culprit... its surface craters, while the cam is fine... The cam stays fine, until the sharp rough cratered surface of the follower runs over it... The oil can’t lubricate the cutting tool like surface... PP thoughts only, not a metallurgist... Best regards, -a-3 points

-

3 points

-

When its below freezing dont use them. They get stuck. Once theyre out, no going back in until it gets warmer.3 points

-

An airplane is a depreciating asset, just like an automobile. It requires a lot of ongoing expense for maintenance, inspections, insurance, hangar/tiedown, etc. What you get for it when you sell it is strictly a matter of supply and demand rather than any intrinsic value. One theme you find on MS is the high cost of parts to maintain the airplane. But Richard Collins used to note that the cost of maintaining an airplane is more tied to the cost of a new airplane than a used one. A $1000 part for a $750,000 airplane doesn’t seem as outrageous as the same part that you might need for a plane worth $100,000. There are lots of good reasons to own an airplane. Except in rare cases, they just aren’t financial. Skip3 points

-

3 points

-

2 points

-

2 points

-

One last real piece of Mooney advice... There is one last new Mooney for sale still at the factory... It just got released from development duties... announced this past week... Best regards, -a-2 points

-

Pretty unlikely. Insurance costs seem to run in cycles like most economic measures. And, increases and decreases will hit the entire market. So if your question is: Will insurance become so expensive that no one buys small airplanes any longer?, then historically, that hasn't happened. If your question is: Will Mooneys be singularly disadvantaged by insurance costs relative to competitive models? then I don't believe history has shown that to be the case either. Skip2 points

-

Truth! My first Mooney was an M20C. A couple of years later I'd worked out that I could fly a 252 for the same OpEx. The CapEx was about 2.5x more. But the OpEx has been the same. (It's actually a little cheaper on fuel to fly the 252 rather than the M20C) And so since the true cost is in the OpEx, why not fly a 252?2 points

-

Actually this is an area of personal expertise, so it’s nice that I can actually chime in. I spent two months researching and evaluating cameras, gear and procedures and have photographed natural disasters for FEMA and GEMA (including a massive F5 tornado track aftermath). I understand most of the ins and outs of this. I’ve shot thousands of frames. The good news is that your smart phone includes geotagging every time you snap a photo. The bad news is that even the very best smartphones still only have a chintzy little lens, and while your megapixel count is high, the optics aren’t much. Smartphone cameras have a rather wide angle lens setting as well, which is not what you want. If you’re looking for top quality results, you’ll be looking for an SLR camera that will ideally have geotagging. This is a process by which your precise latitude, longitude, altitude and the direction the camera was pointed (!!) are recorded within the meta-data of the photographs that you take. (Hence the need for a three axial electronic gyrocompass included in the needed GPS.) The GPS and gyrocompass will be particularly important later when you’re trying to later figure out exactly where you were located in the air and which way you were pointing the camera as you took the photograph. (Trust me when I tell you just how much you will want and need those features.) Best all around package we found was one of the later model digital Nikons that accepts an external front plug-in GPS input with electronic gyrocompass. But don’t use the Nikon GPS- it’s mediocre at best- we tried it, and found the aircraft cabin sometimes blocked GPS signal, and when you pointed the camera down to take photos often their chintzy two-axial gyrocompass stopped working. We selected the Solmeta, who makes a superb 3-axial gyrocompass GPS that slides into your shoe mount on top and has a cable that plugs into the front of the camera. No lost signal from the aircraft cabin. I’ve been using that combination for six years to excellent results. Strong Nikon optics, fast shutter speeds, crisp imagery- and each frame properly geotagged with direction of photo. Message me if you want to discuss. I love talking shop.2 points

-

2 points

-

I think all C models had the doghouse. Mine is a mid year, 1975 with the doghouse. I think the F models went to open baffles in 1967. Maybe the E models too, but not the Cs. My airplane had cowl flaps maybe from a K were added to my airplane by Mod Works. Don't remember if that was an STC or 337 without looking it up. It was just adding salvaged Mooney parts. The flaps open much more than the older C cowl flaps, about 3" at the rear edge. They are either open or closed, no in-between. Cylinder temps always are fairly cool, oil temps always over 200 in climb on a warm day.2 points

-

Based on my three separate experiences with JPI about this on two aircraft, they might ask for documentation to support any change(s). As an example, on the IO550G to IO550N engine replacement, and IO550G engines with governors adjusted to 2700 RPM based on the related STC, JPI gladly made the change, but wanted proof (in my case, the STC paperwork) before they would accept the unit for readjustment. Suggest you run the iron over it with their tech support folks. They're pretty helpful. Steve2 points

-

You’re thinking of the AeroCruze. The Aerocruz is a different product that automatically flies direct to Cancun.2 points

-

Its not the source of the material you're having but learning how to work with the material. These, like the majority of airframe parts, require final trimming to install because of the nature of our hand made airframes. The main source of windows and lenses is, but it's also where LASAR and Mooney get them: https://www.glapinc.com/Mooney/m20K.htm But recognize you can't use a regular drills for wood and metal to drill acrylics without continuing to crack them. You'll need to follow the drilling and trimming instructions located on their website here: http://www.glapinc.com/instructions/index.htm#general Specifically, though many of prefer to use a single unibit drill for drilling different sized holes in acrylics - they make it simple and easy and don't require multiple drilles - see this more detailed except of 43.13.1b they provide: http://www.glapinc.com/instructions/pdf/AC43.131BChapter3.pdf2 points

-

Rick, I appreciate the more detailed explanation. I think this explains things a little better. Hopefully Dynon will not abandon the short body guys as there seems to be a lot of interest from them. Maybe Dynon can share how many units it would take for you to break even on the STC certification costs. One point of contention here is that a lot Mooney guys seem to love your product, myself included. And being put behind the Seneca and Barons feels akin to a kick to the ol’ Johnson bar. There are simply more of us by numbers... almost as many combined Senecas and Barons made as there are Mooneys made. I know you have to gauge the market, that makes total sense, and there’s a difference between guys who say they’d buy your product and those who will buy your product. When Tesla was developing the model 3, several years ago, some of my coworkers willingly and happily plunked down $1000 deposits to guarantee a delivery position, without even knowing the end cost of the car. Dynon has been around a little longer than Tesla and I, for one, would feel confident enough in your company to put down a deposit, as a sign of commitment to buy your product, if I knew it would get me ahead in the line to get a Dynon AP and help in the costs towards the advancement of the development process. I’m not sure how many would agree with me but allowing or asking for deposits might be a way to separate those who say they would buy your product from those who will buy your product. I’m a J guy myself so I’m really looking forward to the autopilot and a D10A replacement. I realize Dynon doesn’t have the deep pockets Garmin does to certify dozens of aircraft at a time and I don’t know if my proposition would help much but it’s a thought. Good luck to you guys.2 points

-

Just talked to an Mooney Driver who lost power at 200 feet on final and dead sticked it in. Problem was a clog in fuel vent which caused a vacuum, and after 15 minutes the pressure was enough to completely stop the flow. Uses one of these T-handle Allen keys to make sure it’s clear now. On ground he heard pssssssssssstss when he stuck the allen in the vent. Adding to my preflight.1 point

-

My wx-11 storm scope looked like this: “+” and running a drill by the antenna had no effect. I researched online and Valentine https://www.stormscopes.com/avionics.html sells refurbished processor boxes and i almost fell out of my chair when i realized he is located less than 45 min drive from where i live! So i zipped down there and bought one. When i swapped it out my WX-11 went to this on the drill test: All for $295! Dirt cheap in airplane AMU’s. The sad part is that he is no longer taking cores or refurbishing the processors due to lack of parts and support. He used to sell them for $595 but is trying to get rid of inventory so once these boxes he has left are gone that’s it. I thought about buying a spare since they are so cheap. If you need one better order sooner than later. What is the life expectancy on one of these systems?1 point

-

I’m not sure something from amazon, just looked it up it’s unavailable. ‘It’s actually a 50 pint and I bought it in 2016 to put in our boat, since then they are rated differently now so my 50 is likely a 30 now.’ But you can get a 70 for about $300, be sure to get one that you can connect a hose to or the internal bucket will fill up twice a day. ‘If needed there are some with pumps that can pump uphill, I just drilled a hole in the wall and ran the drain hose out that way. The 50 is working for me, but a 70 would work better1 point

-

Not necessarily. The Mooney still senses that there's some money remaining in your wallet and wants to help relieve you of it.1 point

-

I figured it out... The size of my Firefox window happened to cut off your page right under the rotating map. So I did not see any of the names below the map and thought that was the end of the page. When I then used the Search field it took me to a page that didn't really help. Even the items I found in the search that referred back to your site brought me back to the same view of your page and I had no clue all the name were just down lower on the page. Might I suggest that you change that search field to search only your page/site, not go out to do a web search. And it's a great idea. I looked at it because someone was asking about a Mooney CFI a few days before I saw your post.1 point

-

By the way, I wanted to add that gauging the glass panel market by how many you see on Controller is a poor way to gauge how many are our there. Typically guys who invest glass panels with fully coupled autopilots, engine monitors, etc do so because they plan to keep the plane forever. That’s why these really nice planes rarely come up. I know guys like Maurader and Don Kaye have very nicely equipped planes that will probably never appear on Controller. Unfortunately there is no centralized database (That I’m aware of) that keeps track of which glass units like the Skyview, G500, G3X, or Aspen end up in which airframes. That would be good information to know for marketing purposes. Also, as I said before, it would be nice if Dynon let us know how many AP units they would have to sell to short body owners to turn a profit if they went through the trouble of the certification process.1 point

-

Hello all, Old rusty vfr pilot ready to go flying again. And since have been in love with Mooneys since I first flew one oh say 25 years ago, I figure this is the place for me. I'm now looking for a model C-J. Something I can get into and possibly out of without having too much at stake. I have secured a hanger (no easy feat) and am ready for the plane. I have been lurking here for about 2 years so I feel I have gained a good bit of knowledge, but no experience. One should not confuse the two. I'll be using the plane a bit for business (I own the company so no one can holler at me if I don't show), but mostly for pleasure. 300-600nm trips seem appropriate. I do reside in the intermountain west (SW Montana at DLN), so without a turbo and an IR, I'll have to pick my flying days. No biggie, I'm actually semi retired ish. As I have said, I have learned a lot here and feel I actually know a few of y'all. Thank you all for sharing your wit and wisdom. jb PS If anyone has a nice C-J they are willing to part with, please do let me know.1 point

-

The ultimate attraction at SnF... would be a fly in, of one particular Mooney, that used to live there... The one with tiger stripes all over it... https://www.google.com/search?q=mooney+with+tiger+stripes&client=safari&hl=en-us&sxsrf=ALeKk01xnwTi1kVYQt_trxegGUyQtEXqUw:1615090653872&tbm=isch&source=iu&ictx=1&fir=_LU1x1Whj14SjM%2Crl9MmkF-uRcbrM%2C_&vet=1&usg=AI4_-kQq5SIHLpnWlodHIs595Hftp2FCWQ&sa=X&ved=2ahUKEwi-p9DFqZ3vAhX9FVkFHVLxBOcQ9QF6BAgLEAE#imgrc=_LU1x1Whj14SjM We would have to ask Pmax if she is ready to fly... Best regards, -a-1 point

-

I have been there a few times and snapped plenty of pics previously so didn't take any this time. Sorry to disappoint will look for the ones I have and update.1 point

-

I assume you'd be more interested in the upgrade path to the Aerocruze 230 - this thread is really about the Aerocruze 100 - which is a fresh install (very simple AP and very affordable as mentioned - I think this was previously known as the TruTack)1 point

-

Flaps way open may help some... The inherent air flow control of the dog house is the crummy part... Send another update request to David, regarding his cowl update... PP thoughts only, not an air flow scientist... Best regards, -a-1 point

-

Check the chain tension as you rotate the wheel. Mine had a worn bushing where the trim wheel shaft rides, but even after replacing it, there was a slight eccentricity and I found I had to adjust the chain a bit looser to keep it from being too tight and binding at the tightest point of the trim wheel rotation. Keep some light oil on the chain (Mooney calls for grease which makes no sense since the grease won’t get down into the rollers). Skip1 point

-

Does your C have the doghouse? If so, I'd start by looking for cooling leaks in the doghouse and adjusting the baffling before I'd take on the complexity of moveable cowl flaps. I'm not sure where to start on converting the cowl flaps.1 point

-

There’s a lot to this discussion, but one thing to try to wrap your head around... your purchase price and future sale price will be much less than your yearly cost after just a few years. Buy the $100k airplane, spend $20k/year for 10 years. Sell for $120k. You’re down $80k plus inflation. It has to be enjoyable because it’s definitely expensive. No, they don’t cost $20k/year every year, but at some point you’ll do $30k avionics or $40k engine. You will have years at $10k for 100 hours, and you’ll have years at $40k for 50 hours. It’ll average out in the $15-$20k per year ballpark. Maybe more for your insurance as a non ifr pilot and for a hangar on the west side. I have an F in Spokane and my hangar is cheap compared to what you guys have.1 point

-

There are many shades of DIYers on MS... I achieved the level of successfully drilling holes in acrylic sheet for installing windows...I bought the drill bit and the windows at the same time... Which is probably a 2 on a scale from 1-10... Rich, on the other hand... a 10+ with the ability to fashion a plane from it’s basic materials... including boxite... aka aluminum ore. The tough news for the OP... check your skill level... it may make sense to hire a mechanic. Many of the skills that look easy, take training and an attempt at doing it the first time... You have probably learned enough to get it right the second time... It is possible to pre-drill the acrylic, but none of the suppliers will take the risk of putting the holes in the wrong place... Mooney would be able to do this...but, that adds more hands on the project... As for the size mis-match... IIRC, that allows for airflow.... so the acrylic doesn’t melt in front of the hot bulb... if you are using an LED bulb... the temps will be much cooler... Now... about that Lexan... it is tougher, more impact resistant, and less thermally sensitive than the traditional acrylic sheet... PP thoughts only, not a polymer processing or manufacturing guru... Best regards, -a-1 point

-

I was looking at your list just out of curiosity. How is the Search supposed to work? I put in my city, where there is no actual airport, and just NY and did not get any hits. Does it only work if you happen to search the airport the CFI is actually located at? So if I put in an airport 20 miles away, I won't get a hit? Again... just curious.1 point

-

For all those yelling at a vendor about FAA certification delays, I encourage you to try getting a new autopilot approved yourself. Or get anything approved at all, through a byzantine bureaucracy that still gets paychecks no matter what it does to the people it serves. Then, you'll be grateful than anyone even wants to develop a new autopilot for a 30-50 year old plane, where there are fewer planes and customers everyday. In fact, you'll question the sanity of attempting such a feat.1 point

-

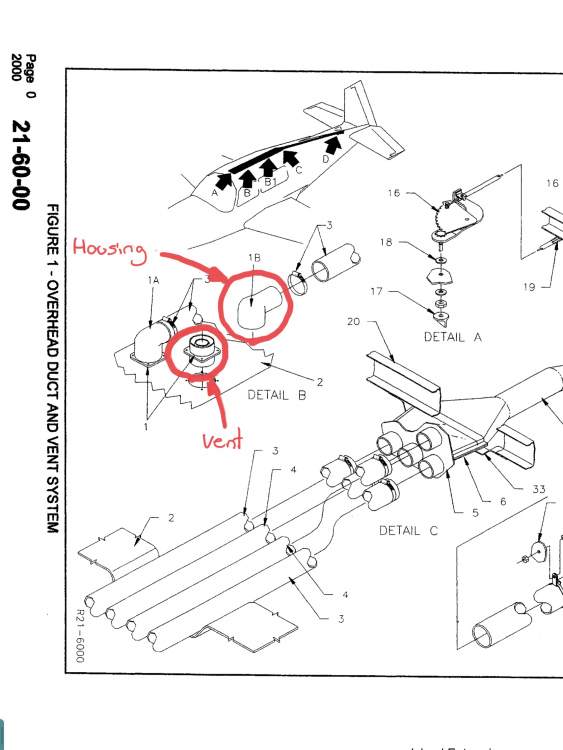

Hi Freddy, Are these the overhead air vents you are talking about? If so, I went through this recently with my 252. Older but similar. Repairing them is fairly easy, but getting access to them is a huge PITA. Let’s talk about the easy part first. The butterfly valve is opened and closed by turning the outer ring of the nozzle which turns a ring clip that has a u-shaped tab with a slot in it. A little rod attached to the butterfly valve sits in this slot in the tab and as the ring clip turns in the housing, the changing geometry opens or closes the butterfly valve. See first picture. There are actually two parts to the ring clip that both fit in a circular slot around the inside circumference of the housing. There is a spring clip that looks like a bent bicycle rim that keeps tension on the assembly, then the ring clip with the u shaped tab. Both sandwich into the little circular slot, but if the ring clip falls out then all the pieces just rattle around inside the vent. Once you get the vent out of the plastic housing it is very easy to reassemble and put a drop of Loctite on the ring clip to keep it secure. Now for the hard part. The vent assemblies are attached to the back side of your headliner and the metal Wemac valve is inside a black plastic housing. In my case I had the headliner out for an avionics upgrade so that was my opportunity. For the first one I cut the entire housing out of the headliner, only to discover that the metal valve is actually glued into the black housing so I still couldn’t get it out, and the offending ring clip is on the back side of the vent, inside that black housing. I actually had to cut the housing in half to get access to the back of the vent, but it was easy to glue it back on with plumbers ABS cement. For vents 2, 3 and 4 I left them in the headliner and just cut the black housing. There was no point in cutting them out of the headliner. In picture 3 you can see the vent with the housing cut open and the loose ring and spring clips. In the last picture the housing is glued back on. You can see the cut line. Your part numbers are different from the 252 so your valves and housings won’t be identical but they look very similar from the pictures in the IPC so I think your job should be similar. Regards, Mark1 point

-

Hello Mooney-minded friends, As all of you could probably imagine, the FAA is paying special attention to autopilot and flight control systems in the wake of the 737 Max accidents. This has presented Dynon’s Certification team with new challenges, which in turn has diminished our confidence in our earlier timetables. The result is the increased conservatism in our messaging. We’ve been successful in gaining approval of similar aircraft models in the past, namely the Bonanza P35-V35B, an approval based on our singular Bonanza V35B demonstrator. That continues to be our certification approach with the Mooney M20 series. However, given the FAA’s increasingly conservative stance as of late, the only certainty is that Dynon will present a 1979 M20J to the FAA for autopilot compliance-finding. We are very hopeful that our effort will result in the certification of the mid-fuselage aircraft, and potentially the short-fuselage aircraft as well. But, because of the above, and the fact that Dynon has no control over the FAA's decisions, we feel compelled to adjust our expectations and messaging. Some of you have requested schedules for the remaining Mooney autopilots. Our plan continues to include generating the evidence necessary to satisfy the FAA that the mid-, and short-fuselage Mooney models are similar, and could both be represented by our 1979 M20J demonstrator for certification. This plan has risk, but the worst predicted outcome when we initiated this plan would have been the rejection of the short-fuselage airplanes from the certification project. If that happens, we would likely react by circling back to certify the short-fuselage Mooney models at a later, yet to be determined date. Unfortunately we cannot promise any schedule for the remaining Mooney models at this moment. We hope this explanation helps you understand why our message has changed. We continue to be optimistic, and believe these obstacles will be overcome. But please, do not make your purchase decisions based upon a future that Dynon can not guarantee. This is the bottom line of our new message. We absolutely do not wish to disappoint anybody. We understand that some of you may already be disappointed, for this we apologize. Sincerely, Rick Ludtke Marketing Product Analyst Dynon 425-402-0433 ext. 1152 www.dynon.aero Dynon Certified | Affordable Avionics For Certified Aircraft1 point

-

For a simple explanation of alignment look here, https://townfairtire.com/information/wheel-alignment/caster-camber-and-toe-alignments/index.shtml Toe in self corrects and keeps a vehicle going straight. Each tire turn the vehicle toward the other tire. Wears from outside in in a feathered pattern. Toe out causes a pull to the side that has the most traction. The tires are turning away from each other. Not self correcting, heads you toward the weeds, car or plane. Wears tires from the inside out in a feathered pattern. Even negative camber creates higher traction in turns and tends to be self correctin directionally. It wears the inside edge of the tire. Even positive camber causes a directional pull is not self correcting and wears the outside edge of the tire. a car set up with 1/8” toe in and 1/4 degree negative camber will be stable and won’t wear tires excessively. Caster is a bit more esoteric and hard to describe. Think of a shopping cart the center of the wheel is behind the turning point of the suspension. It makes the wheel follow. It is what centers the wheel when you release the steering wheel. Caster does Not cause tire wear but if uneven it causes a pull to the side with more caster. A shopping cart has 15 degrees of caster while a car has about 1 1/2 to 2 1/2 degrees. Too much caster causes the wheel to wobble with increased speed. If you run with a shopping cart you will see them wobble. Here most roads are crowned. A crowned road will cause a car to pull to the right side. (Gravity sucks) A slight amount more caster on the left tire can compensate for the crown. as steering components wear additional toe in will help compensate for the looseness. When loading and unloading a trailing landing gear like a Mooney the suspension absorbs the load by changing caster. The tire points straight forward on our Mooneys no toe in. The tire sits vertically, no camber. This is why our tires wear more evenly than Cessna aircraft. Spring gear is used on Cessna, the above mentioned Grumman, Vans kit planes, and Cubs etc. Spring gear uses the flex of the landing gear arm to absorb the weight of landing. As the gear arm flexes the alignment angle of the tire changes. The unloaded gear will have positive camber. As the gear arm flexes the tire will be pulled to negative camber. Toe also pulls out as weight is added. To maintain directional control they need to be toed in further to begin with. This effect is worse on a tail dragger. If a tail dragger is toed out it will be hard to keep on the runway. The slight camber wear on the above Grumman is normal. The under inflation is the wear problem.1 point

-

Awesome! I'll be checking the calendar and I hope to attend..this will be my first Mooney summit as well!1 point

-

Let’s see what we have here... 1) Utterly slanted... check! 2) Personal... yep! 3) Experienced.... hmmmm.... that’s a tough one... score that as a maybe! 4) Opinions... everyone has one... and they may change with the weather, or age, or phase of familydom... 5) If you have family.... the mid-body J really rocks! 6) If you are a retired couple... the short body E is the ultimate retirement plane! Do you want to build your own panel, or buy it already assembled? Best regards, -a-1 point

-

1 point

-

1 point

-

There may be enough electrons in the battery to continue illuminating the light (low amps) even after it can no longer drive the motor (high amps). But that's beside the point in this particular thread, because the OP said he doesn't turn the crank to the green light even under test conditions on jacks at the annual with a good battery. The assertion that "if the green strips line up, the gear is down regardless of the light", is an oversimplification - one that assumes perfect rigging of the both the gear system and the indicators. The strict definition of "gear down and locked" is when the preload torque on the over-center locks is within the tolerances specified in the service manual. In a perfect world, the green light would illuminate and the floor indicator would exactly align, when the preload torque is precisely in the dead center of its range. In the real world there can be differences, and it sounds like that's the case in the OP's airplane (and likely all of our airplanes, to some degree). If you read the service manual for electric gear rigging, preload torque is checked on the basis of the green light, *not* the floor indicator. This is because the switch that illuminates the green light is part of a two-pole switch, with the other pole being the switch that actually turns off the motor. Assuming the OP's gear is correctly rigged, it sounds like the floor indicator is slightly "off", such that it appears aligned when the preload torque is a little shy of the recommended range. It may also be that the floor indicator is good, but the gear is mis-rigged such that it slightly overdrives past the recommended preload torque. Suggest at the next annual, the OP crank the hand-crank until the floor indicator is aligned but the green light is not on per his usual practice, and check the preload torque there; then continue cranking until the green light is on, and check the preload torque again. If both values are within the service manual tolerance range, then either indicator is "good enough", despite the fact they're associated with two slightly different preload torques. If not, then the gear needs to be re-rigged and/or the floor indicator needs to be adjusted.1 point

-

They're small tube pointing into the wind on the bottom of the wing to the side past the tank. In the modern Mooney's they are in a small NACA duct embedded into the wing bottom pointing into the wind. Vintage Mooney's they can be aluminum tubing come down and making a 90 bend into the wind. Those with bladders will see a de-ice mast directly in front of the vent tube. This usually happens from insects nesting in the tubes when parked on the ramp. I personally wouldn't insert something as large as a allen key wrench into the vent tube. Instead I recommend using some .032" safety wire to wiggle it in the tube and break up any debris without allowing any chance of ramming it further back into the vent or give it any chance of getting sucked into the tank by the vacuum. I fear the tool will break it up by pushing most of back in, rather than allow it come out. I can probably get a picture of a modern one later today.1 point

-

I will add that - Currently there are NO AP options for the short and mid bodies. First to market with a AP for these airplanes is guaranteed to drive sales.1 point