Leaderboard

Popular Content

Showing content with the highest reputation on 03/04/2021 in Posts

-

In my airplane, the PIC determines the mask policy. And at the moment, that means you'll be wearing a mask, regardless of your credentials. And if I'm in your airplane, I'll be wearing a mask out of courtesy to anyone on board. All of this will be behind us soon enough... but I'd like to still be around, with a valid medical, and flying an airplane, when it's all over.6 points

-

FAR 91.213 is your guide. The answer is, as is often the case, “it depends.” An example: In the FIKI Ovation both alternators are required for flight into icing conditions. That requirement is not in a MEL or Kinds of Equipment list. It is found in the AFM supplement for the TKS system as part of the STC. Similar type question: Must the PIC sit in the left seat? Probably not for most Part 91 operations. But wait — the 2000 Ovation with a KFC225 autopilot has a requirement buried in the AFM autopilot supplement that the PIC must be in the left front seat.6 points

-

5 points

-

This would be right in line with my previous prediction. The AV-30's were approved once I gave up and within a week of me tearing apart my panel to put in the Dual G5's. My plane is scheduled to go in for the GFC500 on April 26th so expect the TruTrack to be approved within a few weeks of that date! You're welcome in advance.4 points

-

SOP Having a bunch of ifs, ands, and buts can complicate things. If you pop your hand off the throttle and reach for the center bar out of routine and habit while flying wing during a formation flight, that can be critical. You haven't convinced me. Unusual procedures should not serve as a band aid for proper maintenance and checklist procedures. Maintain the seats properly. Check that it is locked before flight. Keep your hand on the controls and focus on flying. Those are my priorities. Be careful about that lousy seatback too.4 points

-

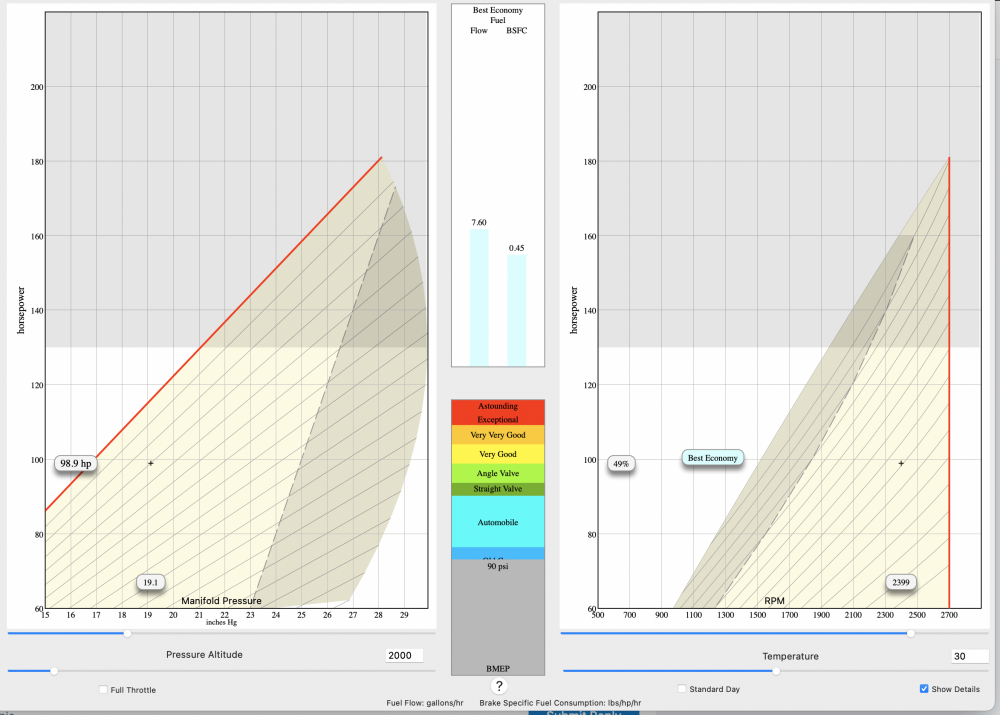

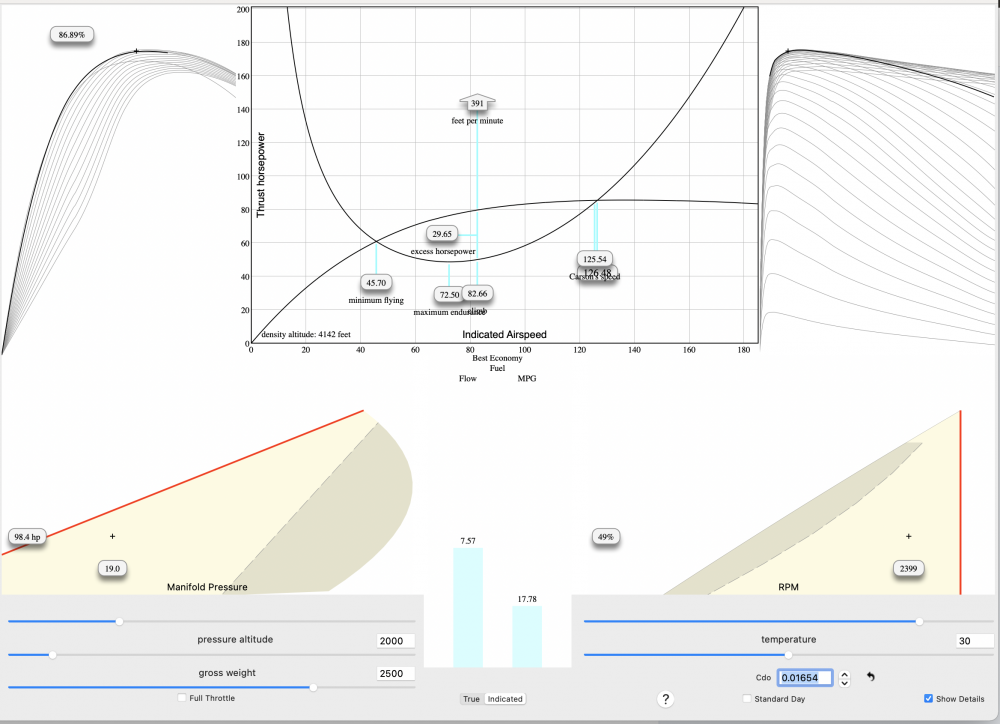

Hi AH64pilot I'm the guy that wrote the Vz thesis that was referenced earlier in this thread. For 120 knots or so you will be about 45-50% power. You did mention that 2350 rpm or less was problematic, so 2400 rpm and about 19" MP will get you 120-125 KIAS or so. That will be about 7 1/2 gph leaned roughly to peak. This information can be gleaned from your POH (1223E, I think), performance pages, Best Economy at 2000 feet. But no one like to interpolate tables, so.... I ran the Benchmark engine model for 2000 feet and 30 deg C for a jaunt around Lake Weir, the temperature was chosen to provide a good opportunity for sightseeing the, uh, personnel likely to be on boats and what they are wearing (or not) under those conditions. I know how you Army rotorheads think. And here is a better performance prediction for those conditions, how about 2500 lb GW on the airplane: There is a massive amount of information in this model, and it touches nearly every aspect of the discussion in this thread thus far. If your airplane is pretty close to the drag of the baseline used to create the POH (where this Benchmark model is derived from), you will be going about 125 knots indicated or so. Hope this helps. LMK if I need to run the model for a higher gross weight airplane, e.g. you are having a squadron reunion and there are 4 retiree Apache vets on a ....reconnaissance mission....in the plane instead of just one. :-)4 points

-

3 points

-

Masks, we don't need no stinking masks..................just kidding! Easy to accommodate by keeping one in each car and each airplane...........they really don't take up much room in the flight bag! Happy Mooney traveling.3 points

-

This is true, except that if there is a dual alternator in a 231 it is an aftermarket alternator, and the event of failure of the backup would not be covered in the main body of the POH because the POH was written before the aftermarket item was installed. It might be in the STC for the backup alternator, of in the flight manual supplement that is supposed to be inserted in the POH, and it might also be in the STC for any mission critical navigation equipment, like a GPS/Nav comm. There would also be the possibility that it would be in the 337 that allowed the backup alternator to be installed, because in the rare situation they are (I am aware of only one, and that is on a 262, not a true 231), the alternator would go on the vacuum pad and the vacuum system would be removed. The same is likely true of some but I don't think all 252's, that any backup alternator is an aftermarket item not covered in the POH. Most Mooneys of that vintage do not have a true "Required Equipment" list, meaning a list in the POH of equipment that must be present and operable to fly the aircraft, with instructions about what to do and whether it is legal to fly if a particular piece of equipment is not functioning. I am aware this statement is a little controversial. There is an "Equipment List" in Mooneys of that vintage. It would list equipment present when the plane was manufactured, and might possibly be amended if some piece is installed later (some 252's, for example, might show a backup alternator on this list). However, it was intended as a weight and balance list, meaning the equipment needs to be present in the aircraft for the w & b to be true. Whether particular equipment must be operable is generally governed by the Type Certificate, the regs. on VFR and IFR equipment required for flight (91.205), and material, if any, in STCs and flight manual supplements. Because there is an "Equipment List" in some of our POHs, and there is the confusingly similar regulatory concept of a Required Equipment list, which really is not what the Equipment List is for planes of the vintage of the 231 and 252, it has unfortunately never been crystal clear whether something listed in the POH has to be working to fly your Mooney. The answer, in my opinion, lies in the POH wording for the Equipment List, which does not say the equipment in the list has to be working. There are also catch-all provisions in the regs about airworthiness and reckless conduct, "catch-all" meaning that the FAA can interpret them pretty much however the FAA wants to interpret them to catch all pilots. Generally I agree with Paul, there is no requirement I am aware of that a backup system needs to be functioning at takeoff, but I would read all the possibly applicable materials and not take anything for granted, and if a piece of equipment like a backup alternator is not working, I would fly the aircraft only long enough to get it somewhere to be repaired. The factory alternator is not the greatest, can and does fail, and takes with it all of your panel instruments, so with that in mind, would it be careless to fly in hard IMC with no other way of operating your AI than the one alternator that is known to be subject to failure? That would be a judgment call that could be monday morning quarterbacked by the FAA and might depend on what other backups you have, such as backup batteries in the electronics.3 points

-

Good points all. But I don't do anything in my airplane out of routine or because it's SOP. So for me it's not an unusual procedure. Everything I do is on condition and as needed. I'm not suggesting this is for everyone... but it works for me.3 points

-

3 points

-

No one ever accused me of being tall. And so it would be very uncomfortable and likely difficult for me to get out of the left seat without sliding it back. Often when we travel, my wife will put a bag behind my seat as it's an easy location for her to reach while sitting in the right front seat. She now knows to move it at the top of descent so that on landing I can slide my seat back and exit. If no one is sitting behind me, I'll pull the bar and slide my seat all the way to the back immediately after the prop stops turning. It's then easy to exit the cockpit. Fortunately Mooney has provided a very solid hand hold in a good place, that eliminates the need to carry 2x4's around in the back of the plane to hold things together. Of course the seat rails get checked at every annual and the tracks cleaned out. I also vacuum the plane regularly to keep the holes in the rails clean and free of debris. But my right hand securely holding the center bar for a few seconds at a critical time of the takeoff is easy, simple, and completely effective.2 points

-

When I had my avionics upgraded, I told my shop to remove all the vacuum related stuff firewall aft. They removed the peanut gauge, wired the vacuum light such that it illuminates when you hit the push to test but it otherwise doesn't illuminate (I may need a placard for this or cover it at some point). And as far as I can tell they removed removed all the vacuum tubes under the panel. However, they left in the vacuum regulator (the one with the garter filter) and another vacuum filter that I'm not sure was even plumbed to anything before the mod. I had to then remove these two items that were bolted to the cockpit side of the firewall. I believe they didn't want to touch these as they would create a hole in the firewall once removed. This and everything firewall forward me and my IA handled. Of note: my engine cover installation for my IO-360-A3B6 looks a little bit different. It turns out that you have to keep the vacuum pump adapter (and consequently the drive gear) for it to seal right. I was hoping to save the extra couple of pounds. Bruce2 points

-

If you read Lycomings literature, they even state pretty often that engines operated at 65% power or lower will last longer. ‘Ever heard of TANSTAAFL? It’s from one of my favorite Science Fiction writers, it’s “There Ain’t No Such Thing As A Free Lunch” Simply stated it says there are advantages and disadvantages to every single way that you can operate an engine, so pick a way that fits your desires and to Hell with all the supposed experts, most of us fly less than 100 hours per year. my aircraft is 41 years old and has 2200 hours on it, and that’s not all that unusual. Engine was overhauled 10 years ago and has about 400 hours on it, It may never reach overhaul while I own it. So it’s likely that for most of us that we won’t ever fly an engine for a full overhaul period, so making changes to the way we want to fly to get 10% longer life from an engine does what? ‘But for instance I’m going flying today, the mission is just to fly, and hopefully to introduce our little dog to flying, so why bore around at high speed, burning fuel? Slow down burn less fuel, make less noise and make the turbulence more comfortable?2 points

-

The portion of your BFR that occurs at an airport would be covered; an airport is included in the definition of "transportation hub." People at a flight school operating at an airport would be covered. If you're inside the flight school building, I don't know whether you're technically at the airport. I believe it would not apply during the BFR or check ride if that occurs on your private plane, as that would be a "private conveyance[] operated solely for personal, non-commercial use." This order is clearly aimed at encouraging compliance out of respect for the law rather than encouraging compliance through enforcement of penalties. For that reason, any ambiguities are unlikely to get adjudicated. To the extent that flight schools, BFRs, and check rides aren't covered by the order but the persons running the flight schools and administering the BFRs and check rides impose a mask requirement, you're always free to take your business elsewhere if you don't want to comply. It is perfectly reasonable for a service provider to impose mask requirements that go beyond those imposed by government order, much like "no shirt, no shoes, no service" or, at some restaurants, the requirement to wear a coat and tie (does any restaurant still require this?). Mask wearing when you can't maintain distance from others appears to be effective and seems like a small inconvenience to ask people to bear to promote the common good. I look forward to the day that it's unnecessary, but I'm happy to do my part while it is necessary.2 points

-

Well thanks to the beechcraft forum they had a continental fuel injection install pdf that explained very nicely with pictures of how the turbocharged fuel injectors are assembled, thus allowing me to not only understand how to take them apart but also listed the o-ring and rubber washer i needed to order to replace them. Once i replaced them and tested again to verify i did not have any soap bubbles and that sealed the airleak. Also did another fuel pressure test and no leak! Finally! Took it up for a test flight and it’s running smoother than when i bought it. Also TIT was lower in flight and i especially noticed at idle before shutdown as before i struggled to get the tit below 800 d F but now it was at 750 and pulling back on the throttle it dropped to below 700 at low idle! Also swapped bottom #5 spark plug with top #1 and top #3 spark plug with bottom #3 and the rough lean mag check moved from the left mag to the right mag so i ordered a new tempest fine wire plug as one of those is faulty and i think it’s number 3 too as i noticed the ceramic Insulator looks like its in 2 pieces. Will have to post pictures when i get the new plug to replace it. Only 24 hours on all 12 plugs but guess that one was infant mortality.2 points

-

I don't know whether you saw my previous thread. I am 82. Parker could not find any carrier who would offer me hull insurance on my Mooney. Some would give me a policy if I flew a non-retractable plane. Liability policies are available. I wound up buying a liability policy and self insuring the hull.2 points

-

Rick, Could you be kind enough to fill us in on the schedule details for the rest of the Mooney line up? There are many Mooney Owners from M20A-Z that are looking to buy a Dynon auto pilot... They are holding off from buying the GFC that is already available... There are several Dynon Skyview customers around here... Two have posted pics of the empty space where their Dynon AP is schedule to fit... the YouTube Chanel clearly says FlyDynon right on the instrument panel... What could be better than showing how Dynon supports its customers than a schedule of STC releases for all Mooneys? Especially the existing the customers with that sad empty space in their predominantly Dynon panel? See if you can help put an end to the stress level the latest press release has caused... From a regulatory viewpoint each Mooney model is different... From a healthy autopilot builder viewpoint each Mooney just gets better than the next... all very related in design, construction, and flight qualities... The competitor you mentioned has done a great job of communicating what to expect next with regards to their schedule... We have seen one Mooney model after another work it’s way through the flight testing... Amazing how quickly they flew through the flight testing... The side benefit for Dynon... somebody gets to do a fair amount of Mooney flying... Best regards, -a-2 points

-

There is a lot I like about the Dynon product and I really like the Dynon installation approach. Not having a realistic idea on when the autopilot will be available makes it a no-go for me.2 points

-

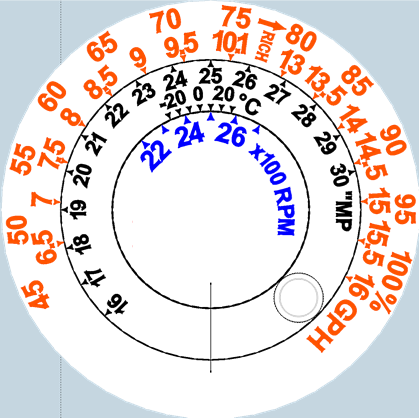

Because somebody asked how I do it: here is my self-made leaning calculator for the Lycoming IO-360. The outer ring and center are fixed, the ring with the black numbers can be turned. When flying ROP (right side of "RICH"), I use the indicated gph or MORE. When flying LOP (left side of "RICH"), I use the indicated gph or LESS. Keep in mind that 10.1 gph corresponds to 150 HP (in ideal conditions, in the IO-360 at 1:8.7 compression), thus 75% power of the IO-360. Because of that, 10.1 gph or less will NEVER put you inside the "red box", and that is the reason I don't use EGT for leaning anymore, since I am more concerned about getting optimal power than anything else. My CHTs in cruise are 300-320°F at this time of the year.2 points

-

My how time flies. I came across my link to this forum and thread and thought I'd post "the rest of the story." This oil leak problem occurred in 2016 and never re-appeared, so with the help of the posters we solved the problem. In fact, I flew this plane about 100 hours a year until early 2020 when I sold it. In 2019 I took the plane from Texas to Alaska and back on a month long vacation. The problem never appeared again. My thanks again to all who helped me troubleshoot it, come up with correction options and gave moral support.2 points

-

I FINALLY made it back to the Innovation Studio, (maker space), and have been making switch covers. Please PM me if you need any. For those who have PM'ed me in the past, I think I have already responded directly to everyone, but if I have missed you I apologize.2 points

-

Oh okay, but I wouldn't say the STC doesn't apply, Jerry gave a good example with the Ovation that the STC effectivey changed the required equipment list to be FIKI. "negates that argument" is confusing. If your saying the STC means you can't just look at the min equipment list/KOELs and stop there I completely agree and believe that was the point of Jerry's post. Rather than saying it negates the min equip list or other limitiations in the original POH, I'd say the AFMS in the POH can modify the original POH and now the POH is incomplete without the AFMS - since its been modified by the AFMS. Hope I am not just adding confusing - especially if we're saying the same thing.1 point

-

1 point

-

Masks stop flu just as well as they stop COVID, as does social distancing. I suspect I will be engaging in more liberal mask use going forward. Influenza sucks.1 point

-

I doubt I'd even mention my vaccination on my medical. Don't plan on going to my doctor's for it.1 point

-

Sure hope this goes through and is available for earlier C’s...1 point

-

I’m not arguing with you, but in fact HP, fuel economy and emissions have never, ever been better. Today’s cars are the most powerful ever produced, pollute the least, and are capable of phenomenal mileage. ‘My Wife’s car is the fastest four door coupe that’s ever been mass produced, a CTS-V Cadillac. We get almost 25 MPH on the road, spark plugs last 100,000 miles so no tune ups for 100,000 miles, and it passes emissions, idles smooth etc. Our other car that the Daughter has in College is a 2010 Toyota Prius that’s closing in on 300,000 miles, and when I drive it, it gets close to 60 MPG, my best was 72.3 MPG hypermiling it. Autos that will easily last over 250,000 miles carrying four passengers and luggage while getting in excess of 60 MPG and exceedingly low emissions is easy, was done over a decade ago. But it’s not what people want, if you built it, it wouldn’t sell. People want huge impressive four wheel drive SUV’s that may on a good day get 20 MPG. Even the last generation of the Prius when Toyota was faced with making it way more efficient chose instead to make it bigger, heavier and with a larger more powerful engine and leaving fuel economy the same. Now People want big impressive four wheel drive electric SUV’s that will use at least three times the energy of an efficient sedan would.1 point

-

Honestly, if I had a dynon system already installed, the only viable option going forward is to install a single g5 along with the gfc500. For those who haven’t jumped yet the best investment would be a couple G5’s and the gfc500. Keep in mind both G5’s and all the wiring for the AP can be installed by the owner (IA sign off). Only requirement for “expensive” dealer work would be the AP install.1 point

-

Check the manual aspect of the switch - in the above picture the micro switch is attached to the bracket with a plunger. If that plunger is stuck or sticky it won't let the microswitch return to its non active state. You may want to check that plunger to make sure its free.1 point

-

Meanwhile, after a year and a half into having the Garmin GFC 500, it's the best autopilot I've flown. For a net $19K for the 4 servo model, why would you consider anything less, especially if that anything was vaporware?1 point

-

I seem to recall a story told to me by the late, may he rest in peace, Bill Wheat during a Mooney fly-in about 15 years ago. He talked about a time when they loosened up the tail on an A model, I believe, to the point where it was just basically flopping around. When he flew it, he said it flew just as stable as it did when the tail was tight with no mobility. He was the most interesting Mooney guy to talk to.1 point

-

Me too. I thought they found everything important, which is what you want on a prebuy. It's been 8 months since, the plane is in for its annual now, and there hasn't been anything surprising I didn't already know about or expect, knock on wood. The only things that need fixing that weren't on the prebuy squawk list have been quoted a grand total of about $500 in labor to fix. I'll take that in a prebuy every time.1 point

-

Sad to hear what is the end to what arguably was the best Mooney speed mod there ever was. I am sure @Piloto has his reasons but seems a shame to end yet another legacy.1 point

-

When Cessna had the seat sliding ADs, one of the solutions was an inertial reel strap mounted to the seat structure with the strap end attached to the floor structure. Looked much like an inertial reel shoulder harness, just doing the opposite job. Cessna even paid for them for some time. Under normal operation, the seat slides back like there is nothing there. Under accelerated loads, it prevents the seat from sliding. My friend has one in her 177 and it seems to be an elegant solution to the problem. Can’t find the manufacturer now and I don’t think it was ever certified for anything but Cessnas.1 point

-

It's thermodynamics. Heat is a form of energy. The turbine extracts heat energy from the exhaust gasses and converts it to mechanical energy to spin the compressor. The effect is that the temperature of the exhaust leaving the turbine will be lower than the turbine inlet temperature. There are, of course, details to actual process by which the energy transfer takes place, and there are additional factors like the kinetic energy of the exhaust gas. But the basic idea of thermodynamic processes is that energy cannot be created or destroyed (First Law) and so the heat energy and mechanical energy of a system and it's environment must balance. Skip1 point

-

Yeah, my thought is that if the seat broke loose while I'm rolling down the runway, it's not nearly such a problem. It might not even slide all the way back. I don't need to manage pitch attitude. And I can probably get back to the throttle, or mixture, and get it slowed down and maybe even stopped. The worst case scenario is I run off the runway and wreck the plane. But from rotation to pattern altitude is to me, the critical time. With a hand on the yoke, the natural split second reaction will be to stop your fall to the back, with that hand. That would immediately create a pitch up, departure stall, and spin back into the ground. With my right hand on the center bar, that becomes the default reaction, save myself from falling backward, hand. I can hold myself with that hand long enough to push the yoke forward, reduce the angle of climb, trim down, reduce power, or ask my right seater to take over. Whatever happens, it won't involve me pulling hard back on the yoke at an already critical angle of attack. So what's the alternative? What am I missing by not having a hand on the throttle once rotating for take-off? Any scenario I can think of from blown engine oil on the windshield, engine fire, airplane coming the other direction, airplane crossing on intersecting runway, etc, etc,... all would be best handled by immediate and quick control inputs but slower more deliberate power changes. Once flying, it would be yoke first, throttle second. So moving my right hand quickly from the center bar to the throttle/prop/mixture, is still not a problem. I'm not saying I have it definitively figured out, but several CFI's a few high time ATP's and a very experienced DPE haven't been able to find a flaw in the logic yet.1 point

-

1 point

-

This would not be the end of the world for most. If your willing to pay 200 bucks a year to fltplan.com you can have PDC sent via email or direct to garmin pilot (providing data or cell coverage). If I did a ton of IFR flying in to the following airports I would absolutely pay 200 bucks a year to not have to write down and read back clearances. FltPlan PDC Premium Service1 point

-

Take away’s for me since it’s all speculation, let’s mitigate those potential causes in our community. 1. When seat is positioned where you want it—-gently -rock forward then back to FEEL you are hooked. I do this religiously because I had seat slip back when pushed rudder to turn while taxiing. Happy it happened on taxi. 2. Run-up— Exercise the Trim stop to stop. Admittedly I slack here. But not so moving forward. 3. A MS’er /A&P/AI posts pics and guidance on that AD from 2012. Hope all have complied, but again?1 point

-

It does! I'll list the reasons why I chose it in a future post. However, believe it or not, I was not keen on the 4 blade look. I was worried it won't look right on my airplane. As it turns out I LOVE it and looks really cool. Again, that was not the original intent, but it's pretty awesome and in just a few hours of flying time it's already getting comments such as "I've never seen a four blade prop on a Mooney!" I just need to come up with a "I bet you've never seen a Mooney pilot that can . . ." I don't have anything good for this yet. You all can help me with that one! -Seth1 point

-

Buying BK general aviation gear is about as smart as marrying a stripper hooked on meth who has three kids from 5 different men. There is just no good reason to invest in them anymore. Some things need to just go away. BK is one of them.1 point

-

Unless it is really in very bad shape, there are two routes: 1. Send it to Aerocomfort as Anthony @carusoam suggests. Hector will patch it and cover it and it will look very nice. However, doing that from France may be expensive and time consuming. 2. Repair it yourself. This isn't really all that difficult. It is made of ABS plastic. The glareshield is made of two parts. You can remove the underside by working it free with a putty knife and/or long bladed knife inserted between the two parts. Obtain some ABS sheet plastic and repair any damaged flat areas by gluing pieces of sheet plastic to the underside with ABS cement made for joining ABS plumbing pipe. Smaller defects or areas with compound curves or that need to flex can be repaired by cutting fiberglass cloth and covering the defect and coating it with ABS cement. Don't apply more cement than necessary to saturate the cloth to avoid softening the plastic too much. Use two or three layers of cloth. After it is structurally sound, turn it over and sand the top smooth. Patch any holes or low spots with plastic filler such as https://www.amazon.com/Permatex-84145-Permapoxy-Black-Plastic/dp/B00THUUVSU?source=ps-sl-shoppingads-lpcontext&psc=1 and sand it down. It may take a few applications. Once it is all smooth spray it with SEM texture coat (there are youtube videos for this) and afterwards sand it and spray it with SEM adhesion promoter followed immediately with SEM satin black color coat (again, there are youtube videos). Glue the two parts back together with silicone glue/sealer (which will hold the pieces together firmly but allow you to get it apart again if necessary in the future) clamping until cured. Skip1 point

-

A flight review is FAA-speak; a biennial flight review is former FAA-speak. It was "biennial" by the way. Bi-annual is twice a year, biennial is every two years. It used to be you could only do a BFR every two years, now they let you do them as often as you like.1 point

-

Will, You definitely found something to chase there... That is one plug, attached to one cylinder and the one mag being tested... What spark plugs do you have..? (Log check...) If champion, test their resistance... If the other brand, check to see if the center electrode is still there... PP thoughts only, not a mechanic... In cruise, What TIT do you usually see or use? This spark plug issue is probably independent of the gov... Notice how few data points you have during the run-up..? you might consider doing the run-up using time, not just an aural check... it looks like it happened in a few seconds, which isn’t enough time for the JPI to collect enough data points... it takes about 10-15 seconds on each mag to see all the temps rise evenly catch a few data points at the peak, for a good comparison... The data is barely showing two independent peaks. And, with good timing, it looks like the peak didn’t get captured... Some JPIs get left on their 6sec interval...when 2secs is available... newer ones have a 1sec option... Primary flight training doesn’t use engine monitors... so many of us use an old style of doing a run-up... NA PP thoughts only not a turbo guy or mechanic... Best regards, -a-1 point

-

Actually standing up for others is something I do in real life too. Sometimes its a fault. Sometimes its a virtue. Its not a hobby but in my opinion standing up for people is a moral duty. I am sorry if you see that as a hobby.1 point

-

Hmm, I've found that ALL pilots are quite full of themselves.....It's almost a prerequisite1 point

-

I gave up last year and put dual G5's in in preparation for the GFC500. My plane goes in the end of April to have that installed. At the time I had AV-30s on order for about 18 months but gave up and halfway into the installation of hte G5's the AV-30s were approved. If that logic holds true then sometime at the end of April or beginning of May when the GFC500 is going in the TruTrack should be approved.1 point

-

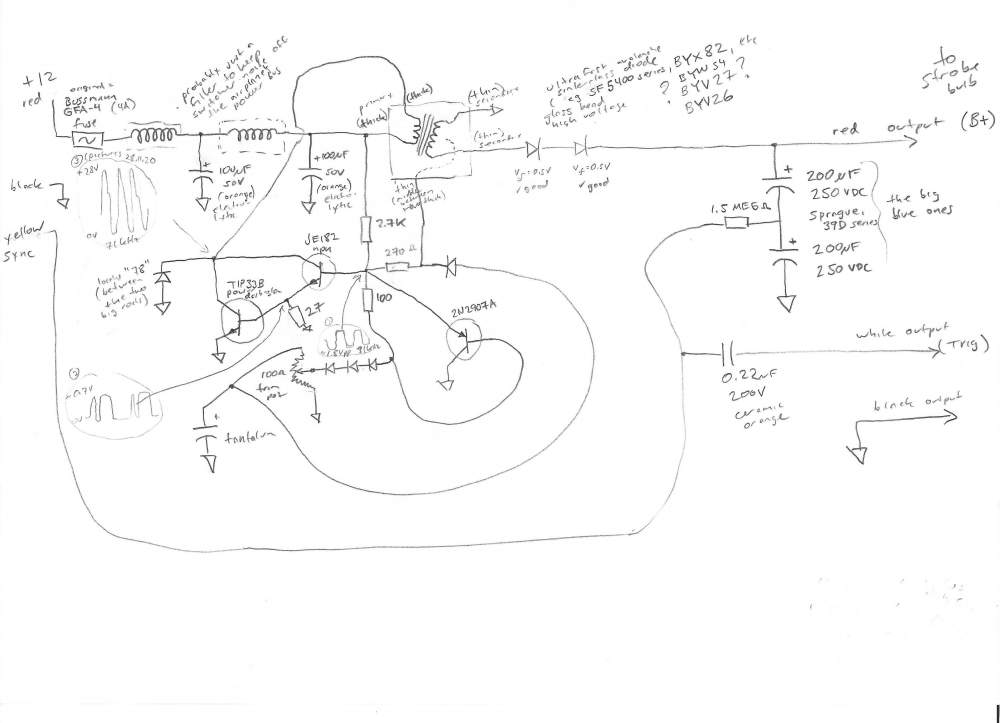

Here's a hand sketched reverse engineered schematic in case of use to anyone else repairing these themselves. I've had to replace the two big capacitors twice on one unit, since I neglected to reform the identical (Sprague 39D series) "new old stock" replacement units I bought from Mouser. The first (not reformed) set shorted out after a few months in service. The second set I reformed overnight on a high voltage power supply before installing them, so hopefully they'll last longer. The original soldered leaded small glass fuses are Bussmann GFA-4 and quite expensive.1 point

.thumb.png.7c67574d7b28f67b0b4a17760919b1ac.png)

.thumb.jpg.44bc5ad17b44ec09b48bdca2a82f7a76.jpg)