Leaderboard

Popular Content

Showing content with the highest reputation on 03/03/2021 in all areas

-

3 points

-

By far my biggest vice is "it wont happen to me". I look back at myself with 250....500...750 hours and realized some of the stuff I used to do that was plain stupid and took me another 750 hours of experience to realize it. And I'm not talking about plainly stupid stuff like buzzing a house at 50AGL or loading 6 friends into a 4-seater- just regular day-to-day stuff that you don't realize. I've got a good story of how I don't blast off on a spontaneous night flight anymore and got a rude wake-up call, but that's something I'll only tell in-person over a cold one. Tomorrow I'm headed to Flight Safety in Wichita for 8 days on a simulator to learn the C208 and the amount of knowledge I've picked up over the past week of indoc alone is perplexing that little Private Pilot me didn't even know existed.3 points

-

The Bravo formerly known as N64HK is sporting a beautiful new paint job, shown here visiting KFXE.2 points

-

Well, I don't find the last statement to be true in my 231. First, yes, a turbo is an exhaust driven turbine, not quite accurate to say it is heat driven. What is it about the heat that drives the turbine, as opposed to the exhaust flow through the turbine. The exhaust flow is hot, of course, but if you blew an equal mass of cold air through at an equal velocity, the turbine would generate the same work. More importantly though, the degrees LOP vs. ROP is a difference in EGT, it is not a difference in CHT. The CHT's generally run quite a bit cooler at 25 LOP than at 50 ROP. It is the CHTs we are concerned with, not the EGTs. EGTs have value only as a relative number (when did that cylinder peak, and how many degrees from peak EGT is that cylinder now), CHTs have value to us as an absolute number. On the last statement, I am able to produce the same power in my engine whether ROP or LOP. When I cruise at LOP, I am at 71% or thereabouts. I have the ability, with a turbocharger, to vary my degrees LOP by increasing MP as well as by decreasing FF. So that is what I do to stay well LOP, I cruise at 34" MP and operate at 71% HP. I can operate at 71% HP on the ROP side also, if I want, but the CHT's will be quite a bit warmer, on the order of 80 degrees or more warmer. The reduction in CHT is not due to extra air being pushed through the cylinders when LOP, just as the reduction in temp when going further ROP than normal is not due to fuel flushing through the cylinder. What is happening in each case, for different reasons, is that the rate of combustion is being changed so that the combustion event is more of a push than an explosion, and less temp is generated. In the LOP case the fire takes longer to find the lesser available fuel, in the ROP case, the fire takes longer to find the lesser available O2. It is the varying of the fuel/air ratio that determines LOP or ROP. The amount of power being produced is the area under a curve, you can have the same area with a short, high peak, and with a lower and more drawn out curve. The lower drawn out curve will generate less heat because, among other things, the max ICP is lower. LOP is easier on an engine because the same power is produced with a less harsh power curve, than ROP. You could, in theory, make the ROP power curve about the same as the LOP curve, but to do it you would have to operate much more ROP than most pilots are willing to do.2 points

-

This is why my right hand is on the center bar above the glare shield on take off. It's very unlikely that my throttle/prop/mixture vernier controls will move by themselves, or quickly in any case. And there will be lots of indicators if they do start to move at all. But the seat letting go, would be an instant event.2 points

-

Reminiscent of Scott's post a while back "a nasty icing signature." The big difference is the big dry zone before we get to the inversion, suggesting that there isn't that much moisture to be trapped, and the temperature -30C. The saturation mixing ratio analysis doesn't seem applicable at 15k feet here. Interesting that you/Scott cut the CAPE from the numbers box. Looking at the chart the moist adiabat line would be to the right of the actual red temp line...i.e. instability...chance of convective clouds reaching 15k, hence icing possible? Robert PS: love these puzzles2 points

-

Now that your bird is fixed I guess they can reopen Oshkosh Airventure!2 points

-

@ basically $3k avg for just the kit, you’d have to sell 34 sets just to pay for the STC, can’t see that happening. Hoping Jose recovers - strokes are no joke... -Don2 points

-

Unless it is really in very bad shape, there are two routes: 1. Send it to Aerocomfort as Anthony @carusoam suggests. Hector will patch it and cover it and it will look very nice. However, doing that from France may be expensive and time consuming. 2. Repair it yourself. This isn't really all that difficult. It is made of ABS plastic. The glareshield is made of two parts. You can remove the underside by working it free with a putty knife and/or long bladed knife inserted between the two parts. Obtain some ABS sheet plastic and repair any damaged flat areas by gluing pieces of sheet plastic to the underside with ABS cement made for joining ABS plumbing pipe. Smaller defects or areas with compound curves or that need to flex can be repaired by cutting fiberglass cloth and covering the defect and coating it with ABS cement. Don't apply more cement than necessary to saturate the cloth to avoid softening the plastic too much. Use two or three layers of cloth. After it is structurally sound, turn it over and sand the top smooth. Patch any holes or low spots with plastic filler such as https://www.amazon.com/Permatex-84145-Permapoxy-Black-Plastic/dp/B00THUUVSU?source=ps-sl-shoppingads-lpcontext&psc=1 and sand it down. It may take a few applications. Once it is all smooth spray it with SEM texture coat (there are youtube videos for this) and afterwards sand it and spray it with SEM adhesion promoter followed immediately with SEM satin black color coat (again, there are youtube videos). Glue the two parts back together with silicone glue/sealer (which will hold the pieces together firmly but allow you to get it apart again if necessary in the future) clamping until cured. Skip2 points

-

39 CFIs so far on the list. Waiting on responses from a couple of folks on their model info and I’ll be cleaning up the list to post and send to @gsxrpilotfor the map.2 points

-

2 points

-

Holy smokes. I promise to get you updated! I am currently in Costa Rica and will probably clean up the list and be ready to post a good list here real soon for those looking for transition training and beyond. thank y’all so much for all the support and now I hope to see those folks buying new to them Mooney’s with a good resource to find an instructor to help.2 points

-

Spar Splice is in front of the rear seat, middle of the floor. Just where folks spill drinks in the back ;o)2 points

-

2 points

-

2 points

-

1 point

-

Yes, out of the exhaust stream... Edge Aviation in Commerce did the install. Great shop... -Don1 point

-

Scott, great discussion. I had a feeling this case was setting us up to disregard the instability producing the possibility of icing. The CAPE value is less impressive than I thought it would be, but I think the important point is that of the instability overshoot of cumulus clouds above 15,000 feet. Looks like 19,000 feet or higher would be better altitude option, but certainly not high enough with a significantly greater instability/ higher CAPE and higher temperatures.1 point

-

If that is the same stuff as in our 1976 M20F (and it appears to be), it is not paint or powder coating. It is a vinyl overlay that is glued to the backing metal. I know this because our panel has some locations where the vinyl is peeling away from the underlying metal. If you look at the attached photo, to the upper right of the gear switch, you can see a wrinkle in the material and a chip out of it. I do not know of a source for this material, but neither have I searched for one. Just thought it would be helpful to you to know that if you want to match the vintage panel, you're not looking for paint/powder coat.1 point

-

Trust me, it was not free I did turn lemons into lemonade. But I specifically do NOT recommend anyone purposefully get a prop strike at EAA: Not Covered by EAA (your insurance): -Prop strike on the runway -Prop strike while taxing on you own Covered by EAA event insurance: -Prop strike while being marshaled under the direction of EAA personnel/volunteers The further write up will include more information. -Seth1 point

-

I started putting an old pillow below fragile things that are likely to drop and be rendered useless.1 point

-

1 point

-

Buying BK general aviation gear is about as smart as marrying a stripper hooked on meth who has three kids from 5 different men. There is just no good reason to invest in them anymore. Some things need to just go away. BK is one of them.1 point

-

I'm glad, Seth, that the saga is over, and the results are beautiful! The only problem is that it will now be that much longer before my namesake comes home to me . . . . Looking forward to your flight reports, I'm sure it's even more awesome than before!1 point

-

Let’s see if that is going to work? We haven’t seen a full frontal attack using social media work just yet, but there is room for a first time... In case it doesn’t work, we can find out where Greg @Baker Avionics is at... he has had direct contact with Dynon recently... and has been quite helpful communicating the plan... The last thing you want is to be threatening... it becomes a sport on how to ignore certain potential customers... PP thoughts only... Best regards, -a-1 point

-

I got you covered Seth... But, a real friend stands in a rut up to his shins in water for you... -a-1 point

-

Alex Gertsen in his M20K was one of the last kits Jose made in 2018. Alex actually went down to Florida to help Jose with the process. Maybe you can get in touch with him and potentially work with Jose to get one more kit made. It's a great speed mod. PM me your contact information and I'll pass it to Alex. It's worth a shot. That or maybe offer to go down and help Jose while at the same time paying him more than the $3k. -Seth1 point

-

The motion of the forward gearbox (worm and worm wheel) is reversible. The jackscrew in the tail should not be. That's why jackscrews are used for this type of application. I didn't mean to say that there is no force on the trim system in flight -- just not hundreds of pounds as I first implied.1 point

-

I guess I don't know how I survived before the internet and iPhones. I presume now that I was in real danger flying from KVNY the KBFI and back in '65 in my Cessna 140 with only a SuperHomer radio with 21 crystals to transmit on with BFO tuning and a 1 weak VOR receiver and a paper chart. Time to start counting the beads (OH and they weren't called TAFs and METARs back then either :-) :-)1 point

-

I’m not going to mention the bladders option (whoops). Perhaps one of the reseal shops that has done a number of long range tank installs could work with a DER and you could do the install with 337? Sounds expensive. More expensive than bladders (whoops)? What about a hybrid system? A bladder in the outboard wing bay tied into the factory integral tank?1 point

-

1 point

-

Getting a rating to fly a powered lift Osprey... may take signing up for a few years... All things are possible... especially, if you were born into the right family... There were a couple of Harrier Jets in private hands... The insurance bill must be interesting for that... -a-1 point

-

1 point

-

No, but it is not that much in total. Probably about 10-15hp lost in the reciprocating motion. Think of it in terms of all the exercise people get from The Shake Weight.1 point

-

1 point

-

Welcome on board!! I really enjoyed your video! I am looking forward to learning more from you and your life in Turkey.1 point

-

In fact, no matter which engine this propeller means is mounted on, it turn that the Hartzell Type HC two-blade means ages badly with blades operating under large pitch, high torque and consequent diameter. This is typically the case with the 360 cu.inch operating at less than 2400 rpm on fast aircraft. The control by "penetrant" is indeed an alternative to that by induction as mentioned by Carusoam. The AD clearly specifies what brand and type of hub it is. Note that the same type of hub, in 3-blade version, offering a higher fullness to the propeller, is not concerned. Some" E "and" F " also use the Hartzell propeller and this offending hub.1 point

-

Why am I a pilot and not a doctor..... When young, I decided to go to Medical School . At the entrance exam we were asked to arrange the letters NPEIS and form the name of an important body part which is most useful when erect. Those who said spine are doctors today. The rest of us went to flight school.1 point

-

Actually, what happens when you get below 2 Qts. is it forms a little vortex at the oil suction hole in your sump like the drain in a bath tub and starts to suck air into the oil pump. This will cause wild fluctuations in your oil pressure along with pushing air instead of oil to your bearings.1 point

-

I FINALLY made it back to the Innovation Studio, (maker space), and have been making switch covers. Please PM me if you need any. For those who have PM'ed me in the past, I think I have already responded directly to everyone, but if I have missed you I apologize.1 point

-

1 point

-

Depends on altitude and conditions. But like @bluehighwayflyer said, 8-8.5gph LOP is the engine sweet spot and you try to pick an altitude (usually 6,000-9,000ft) that gives you 120kias and the best ktas you can get for it. I used to pay a lot of attention to degress LOP, and slowly leaning and all that. For most of my flying for the last 8 years I just do the big pull to the fuel flow and forget it. You do have to experiment a little in the beginning to know under which conditions this will work but at 8gph you can't hurt anything no matter how badly you lean it.1 point

-

Happy to help if I'm available when you need someone.1 point

-

In 2019 I used Aircraft Ignition Services located NE of Dallas in Honey Grove, Texas (not to be confused with Aircraft Magneto Service that @jetdriven recommends). AIS overhauled my mags and I also purchased new Maggie ignition harnesses from them. Phone conversations before and after made me feel like I had selected the right shop. Happy with their results and speed. https://www.aircraftignitionservices.com/1 point

-

B&C fit my '68 C model with no problem. Supposedly the most durable starter around.1 point

-

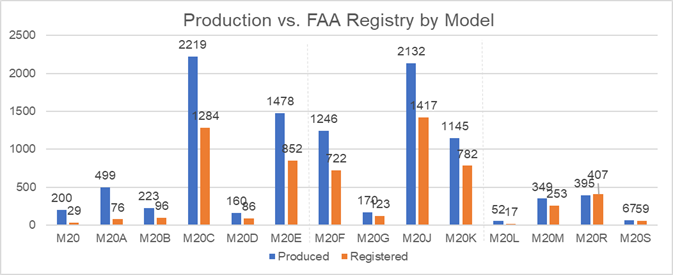

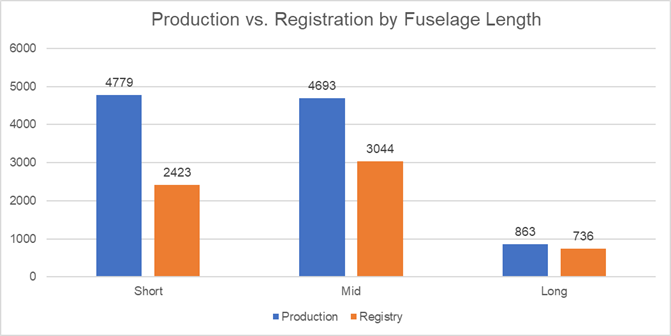

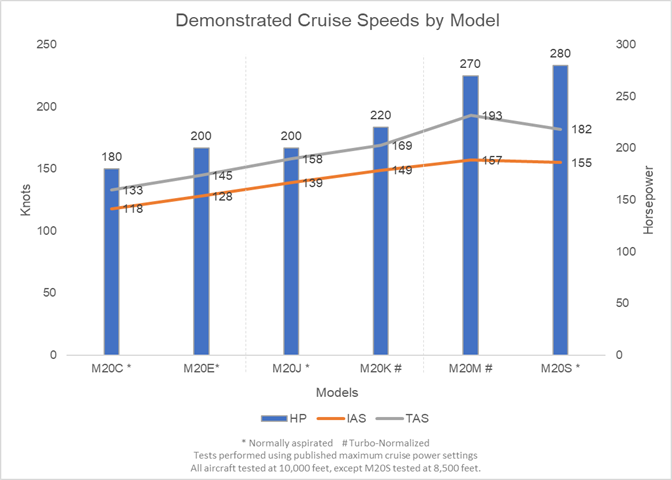

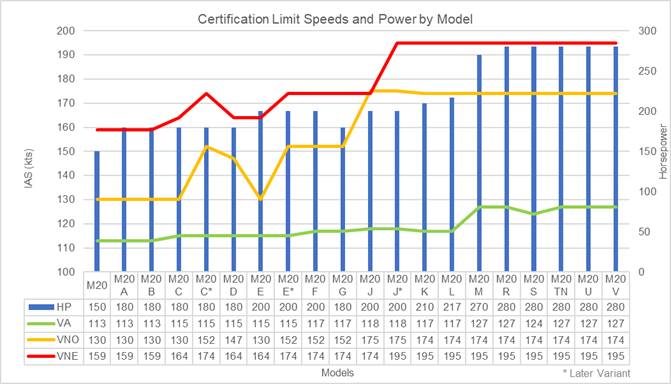

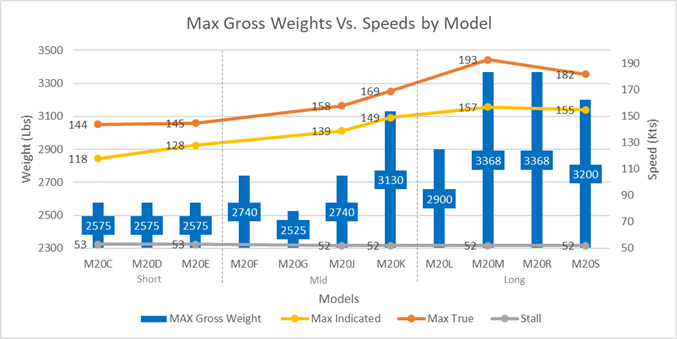

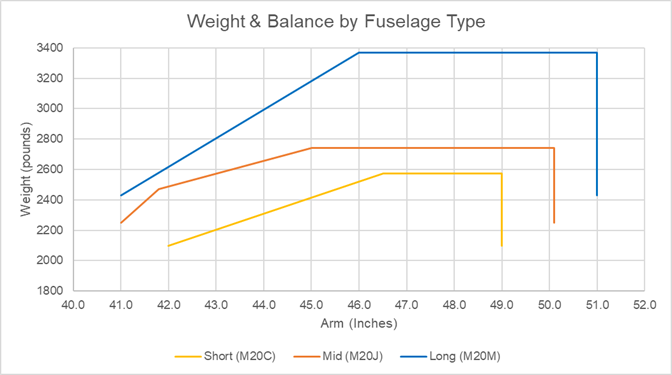

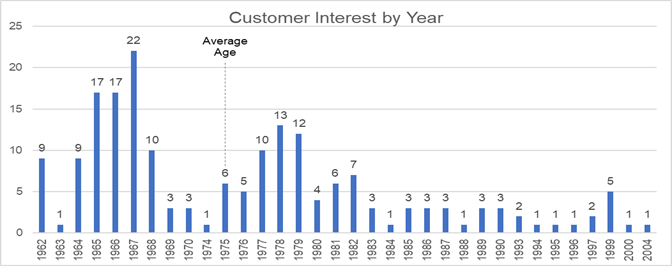

Thank you Carusom, I appreciate the offer for help. We may need it going forward. I want to mention that we currently have a 1979 M20J 201 in the shop for development of the Mooney autopilot installation. We picked this airframe because we believe we can substantiate with the FAA that the short- and mid- fuselage Mooney's fly more or less the same, as the cg ranges are similar, cruise speeds are similar, limit speeds are similar, and so are stall speeds. I gathered data that indicates the greatest number of M20's produced and still registered are the short- and mid-fuselage models. I will share it here as I think all of you may find it interesting: The mid-fuselage airplanes therefore represent the logical first group of Mooney airframes to certify, because they are the largest registered group. If we are lucky, the FAA will agree with us the our mid-fuselage M20K will satisfactorily represent the short-fuselage airplanes as well, allowing us to certify autopilots in both using one demonstrator airplane. The long-fuselage airframes all had heavier and more powerful engines, broader cg ranges, faster cruise and limit speeds, and probably faster stall speeds (although my research resulted in data indicating very similar stall speeds, for which I can't explain, as the long-fuselage airplanes have the same wing and weigh more). This chart shows demonstrated cruise speeds for models representing the different fuselage groups using data from Evaluation Reports published by Mooney Pilots.com: This chart provides the limits speeds and horsepower found in the FAA Type Certificate Data Sheets: The speed charts demonstrate fairly similar speeds for the short- and mid-fuselage airplanes. The next series of charts demonstrates how different the long-fuselage airplanes are from the rest: All of this is just to say that we believe the short- and mid- fuselage models are the airplanes to focus on first. This belief was bolstered by the results of data collected in the past from Mooney owners interest in the SkyView HDX. These chart summarizes our findings at that time: But, we also believe that our previous attempts to gather airplane-owner interest data may not have been penetrating the communities of airplane owners well enough to provide strong guidance. This is why I am here now. If you feel that our earlier conclusions do not adequately represent the wants and needs of the Mooney owners, let us know by completing the survey, and by providing feedback directly to me in this discussion or in private messages. And thank you all for so warmly receiving me and my company into this community! All the best, Rick1 point

-

FWIW, my IA and a couple other old, grumpy, experienced IAs that I've asked, say to use split lock washers. I got some new of the "proper" internal tooth lock washers because I knew we were going to have to adjust timing, and my IA just pointed to the split washer and said, "That one won't come off." I got the same advice from a couple of other trusted IAs, so I've kept the split washers on. I'm curious why magneto fasteners aren't safetied (lockwired or cotter-pinned). I'm sure there's a reason, but I don't know what it is.1 point

-

It should go without saying that this is the best course of action in almost all circumstances and almost any airplane. I mean if you're practicing go arounds in a C150...in August...then yes by all means firewall it. In my experience, most Mooney pilots carry enough energy on final to get them more than a third of the way down the runway before the thing will stop flying, it does not take a lot of added energy to transition from an approach to a go around and then to a departure.1 point

-

Thanks, I now see the 100, I think I had searched for Victory 20W50. Aeroshell botching of #6 grease formula makes me think the company is going downhill. Tom1 point