Leaderboard

Popular Content

Showing content with the highest reputation on 11/29/2020 in all areas

-

3 screws ain’t nothing on a Mooney, if hubcaps would have been installed at the factory you’d have to remove 307 points

-

I've always said we are paying top line prices for a third rate show. This guy has broke the code. What is needed is volume to amortize the certification costs. https://airfactsjournal.com/2020/11/the-20-an-hour-cessna-172-experiment/?trk_msg=C221B64EFR7KH3AU4TLITUU47C&trk_contact=PI3IG216Q2GFB19F8ETMFI1S8S&trk_sid=Q8OMEEVENKHGD1IT6LPG6TAO50&utm_source=listrak&utm_medium=Email&utm_term=READ+MORE&utm_campaign=A20114C&utm_content=Fast+Five+-+November+283 points

-

The issue is not an automotive conversion although that is what has been done here. The issue is what CAN be done with engine technology in our airplanes that is not being done. We have a thread on this board about an engine failure induced by a spun bearings because the case halves were mis-assembled. Equally so, we see spun bearings from cylinder replacements. Why are we building 1930's engines with split cases? Why don't we have have mono block cases with the cylinders bolted on such that removal of the cylinder does not threaten to compromise the main bearing assembly? We continue to struggle with air cooled engines when the benefits of liquid cooling are well known and engine technology has advanced to create light weight aluminum blocks. Go back to 1963 and GM created an aluminum V-8 that weight about the same as an O-320. This not to mention the increase in power to weight ratios. We see new 6 cylinder engines putting out 400 hp, unheard of 10 years ago. I have not even touched upon ignition, fuel etc. As is pointed out, the Corsair engine can limp home on 4 cylinders, try that with your IO-540. Point is this. There is some very good and established technology and we in aviation are not getting the benefit of it. We continue to struggle with a 19th century ignition system, and early 20th century fuel systems and a design, horizontally opposed air cooled that even VW left 40 years ago.3 points

-

3 points

-

I figured I'd post a picture of my new panel here in case anyone has any questions about the setup or is looking at doing something similar. I've only flown with a few times now but the GFC500 is living up to its reputation so far in flying approaches, IAS climbs, ect... Since I didn't have a big JPI prior to the upgrade I really like using the MFD during cruise flight to put the full engine instrumentation. I put a bunch of the legacy equipment for sale in the classifieds section but feel free to PM if you're looking for something else I didn't list since it may still be in a box. Top pic is on A/P while testing out flying holds...3 points

-

If it were me, and I was evaluating a new mechanic, I might not give him the details up front, even if he hasn't performed this particular adjustment before. The learning curve is only a few minutes of leafing through a service manual he should already have and be pretty familiar with, considering he "maintains a couple of J models". It's a good test of whether he has and uses the factory manuals to maintain the airplane, vs. winging it.3 points

-

Hi Joe, In portrait orientation you have two options for the display. One gives you up to ten fields to display in the right side column but the trade-off is a narrower EGT/CHT display with only the digits for CHT displayed. The other gives you only five fields in the right column but a wider EGT/CHT display with both digits shown. Section 14 of the manual provides some guidance on how to set it up but it is not the most helpful manual I have used. Standing by for @carusoam to correct my crappy photo editing..... Good luck, Mark2 points

-

Frankly, I like the straight slot ones best, as you can see at a glance that they are all locked in place if all the slots are aligned.2 points

-

His panel says TAS is 180 and GS is also 180. When bragging speed it is exciting to talk GS but not a great indicator of the airplane as much as it is the wind and the luck of the direction of travel. A balloon will do 200GS with "enough wind". My top ground speed I have seen is 327GS. I know though that at 6500 a missile is much more efficient and likely faster than my rocket. I have ridden in Seth's beautiful machine and I am very impressed. The IO550 is fantastic. As far as I have seen watching people report their speeds across many threads over time here, the acclaim, ovation, and missile will easily do 180 at 6500 and on less fuel than a rocket which can also do 180 at 6500 but on lots more fuel.2 points

-

Some of us have trouble hitting the hole with our long poles and the leverage to get full penetration isnt for the young or weak.2 points

-

I just bit the bullet, bought all the tools and all the Camlocs needed to maintain the airplane. When one is needed I break out the "Camloc" kit and replace. Quick job when you have all the right stuff. Also on my Ovation for the 2700 series around the stacks and the air scoop I went to Mil-Spec 2800 series with a thin washer underneath. Stronger, but the main thing is if you are in the field you can get your fingers around the edge sufficiently too compress the spring and extend the stud. No tool needed. They are not nice and "flush" as the 2700 but they look fine as the cowling is riddled with 4000 series exposed anyway. https://milspecproducts.com/c_spec_2000_series_general_purpose_fasteners__camloc__compatible_2 points

-

I keep a small piece of 2” closed cell foam in the AC. Weighs nothing and is easy in the knees.2 points

-

2 points

-

What part went missing? The hole or the core? There are tools for both... The core tool is a special pair of pliers... The hole tool is more of a punch... Either aren’t typical amu pricing for planes... but a pair of pliers for something you only use for five minutes... The core tool is good to have... because they like to jump overboard every now and then... Best regards, -a- https://www.aircraftspruce.com/catalog/hapages/camloctools3.php?gclid=Cj0KCQiAh4j-BRCsARIsAGeV12CLaUXzxKtWg7PNcv1PxsaT2UFZMuC0WKDeBiLXYi-8Fg6fbgFG838aAiW6EALw_wcB2 points

-

Actually there are "hub caps" there in the center. They actually call them that in the MEL. They also provide rpm input to the anti skid, so if they are off, the anti skid for that wheel is inop. Also they leave the thru bolts on the periphery exposed, because they are a preflight item along with cooling. They snap in half with some regularity. Many people are surprised that on a typical wide body you can have up to 7 thru bolts missing, not all adjacent of course. By the way, if the anti skid goes inop, you can cap that brake. However, you have to leave the wheels extended after takeoff for tire spin down. Not because of a spining tire in the well but because the gyro precession forces are very significant on the gear leg during retraction with wheels that size.2 points

-

Great information there. The noise is indeed what we would call conducted emission from the TC. The TC motor is getting noisy, maybe even arcing. Regarding the common grounds, the note from Ranier in the thread goes into more detail. Note how he lumps the systems into buckets. Basically you want to keep the noisy grounds away from the sensitive equipment.......but you typically want to keep common system grounds together to avoid the ground loop. So, Greg’s advice above was to minimize ground loops within the audio system. My advice was to minimize noise on said grounds or unintentional ground loops. Most airplanes are not assembled with the thought of electrical grounding. We electrical types compete with our airframe engineer friends who want to prevent corrosion. The coatings and wet assemblies are problematic for good ground planes. A well designed airframe will have very specific ground clusters and power busses, based on equipment types. This is one reason for an “avionics buss”. We go to great lengths to provide such power isolation, but not as much effort goes into the grounds. Now, schematically, the power buss and the grounds appear to be the same, but for the reason above and as mentioned in the Vans thread, they are not always optimal. Our Mooneys were designed when radios were an afterthought. I guess when all you had was a speaker and no headsets, this noise was the least of their worries. With today’s lower power and sensitive avionics, little things like ground and power placement, shielding, and even equipment qualification become critical. When you see things qualified to DO-160x, part of it is it’s tolerance to other equipment or it’s ability to keep its emissions to themselves. In the case of my TC, it likely would not pass today’s design standards....making it more important to improve my installation. Hope this helps. I work with folks who have Masters and PhDs just in these areas....so I am way over simplifying it.....mainly because that’s how I need to think about it...lol. I’m glad they are around, because some of this can feel like black magic.2 points

-

2 points

-

Something doesn’t sound right... Primary fuel pressure gauge....? Probably needs to use the same primary fuel pressure location... or expect to see different ranges of fuel pressure needing to be defined... including the green arcs and redlines... The Bravo has a vented fuel pressure sensor that is a challenge to install when they don’t know the tiny hole is a vent... This sounds like the installer wasn’t familiar with how the owner intends to fly his plane..? Why would they choose a different sensor, and put it in a different location..? In the end, it doesn’t sound like they handled the situation like it is primary flight instrumentation...(?) Great question! Ask the installer if it is a primary instrumentation compatible installation? PP thoughts only, not an instrument guru... all stuff I read around here... Best regards, -a-2 points

-

I went to the local Tractor Supply store and bought $3 worth of 3/8” washers (they sell them by the pound). Pressed those into every turn of the spring, then used duct tape where necessary to hold them in place. Unlocked the gear, swung it part way, and removal was easy.2 points

-

2 points

-

1 point

-

Flew a couple of quick hops to visit our daughter yesterday so we stayed low. I don't keep track except by "feel" but 180 KTAS at 6500 MSL feels about 5 knots faster than normal. Must be a sweet spot in some complex temperature/pressure/humidity curve. Whatever it is it makes me smile. 65%, 30", 2250 rpm, 18.5 gph, 1550 TIT. Genuinely curious: anyone know if an Ovation or Acclaim will do this on 65% power at this low altitude?1 point

-

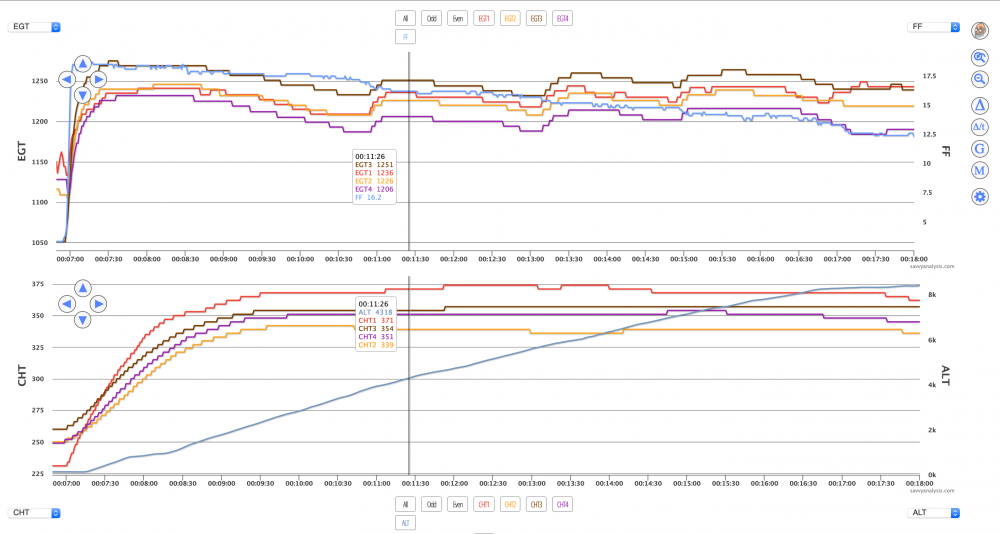

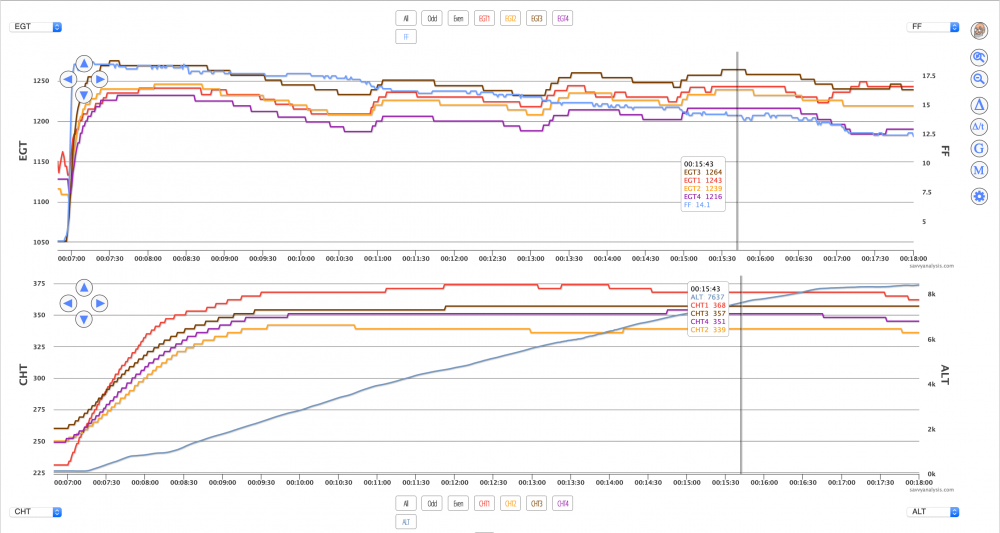

Hi everyone Here is a play back of an M20J Vz climb profile, starting at the POH initial climb speed with TO flaps of ~72 KIAS. I was a little fast and labeled the segment as 75 KIAS in the video, but the POH number is 72 KIAS. I also said 75 KIAS is the POH speed, it's actually 72. Turn up the sound for narration. [edit: I may re-do the voice over and cut out a couple of flubs with the visual overview display] Then the transition to the Vz profile [113 KCAS (115KIAS) -> 500 fpm -> Vy] is flown and shown in the video. I made another mistake in the voice over, Vz for this airplane is initially 115 KIAS or 113 KCAS. After that is graphs from the Savvy Maintenance analysis tool showing the Target EGT mixture management method during this same climb. Mooney M20J Vz Profile Video.mp4 The graph below shows the data after the first Target EGT mixture pull, from a little over 17 gph (the blue line) to 16 gph or so, EGTs pop back up nicely to near takeoff values, note the altitude and CHTs at the same time in the lower plot. A little later in the Vz climb, this is the third mixture pull, note the EGTs climb back to near the takeoff full rich values, CHTs stay nearly constant and we are at ~7600 feet now. About 115 KIAS or so most of the way up, cowl flaps in trail, CHTs tracking nicely.1 point

-

I’ve Been involved with GA since 1980. I’ve heard the mantra that if we would just use modern engine technology everything would be so much better. So here we are 40 years later and we are in the same place. It seems that there have been at least 40 years of failures to implement the new technology. Not for lack of trying. Is it possible that all who have tried are idiots? It is hard to imagine that is the case. I think the fact is that airplanes are not cars, or boats. And our engines are probably more suited to the job then most people give them credit for.1 point

-

See what Carenado has to offer... They support flight sims with different airplanes... For some reason, they focus on the latest planes... Not exactly what you are requesting, but may get you closer... https://www.carenado.com/sitecarenado/microsoft-flight-simulator-2020/ Best regards, -a-1 point

-

Tim, Not what you are missing... it’s what you have too many of.... looks like you got an extra space in the middle... aircraftpower Go MS! -a-1 point

-

Thanks for the tag, Anthony. Let me dig around internally at G and see what I can find out! @Davidv - please check your messages on here for my email address.1 point

-

I'm not trying to knock other pilots but it's always surprising when people don't know their own TAS. It's really the only measure of true performance. Before I had a fancy EFIS with a temperature gauge I would use my ASI to calculate TAS and sometimes pull out the e6b to verify. It was mostly from the natural Mooney paranoia that your airplane is slower than everyone else who has the same model .1 point

-

1 point

-

We had some folks from Tempest come and give a presentation at our EAA meeting. They basically took over the old Autolite facility, to start their company. They are very good folks who care deeply about the quality of their products. They are proud to go up against "Goliath" and build a better product and they have done just that. Their spark plugs have proven better and I buy their filters because I like to support small business, especially in aviation. We need more competition.1 point

-

If you have a brake "capped" (meaning the pressure line is removed) the entire brake for that wheel is inoperative. Tapping the brakes won't do anything because there is no brake pressure to that wheel. That said, in ops normal, brake pressure is applied to all wheels automatically when gear is selected up. The 737 has to take that a step further because if you shred a tire on T/O the spinning tire can cause damage to vital equipment in the wheel well. So it has a hydraulic "fuse" that sticks down just outside the circumference of the well which will break off from the spinning tire shreds and depressurize that gear from retraction mode.1 point

-

1 point

-

+1 for Mr. Wheat! Who probably was involved with placing the stall strips on this M20E in the first place... -a-1 point

-

Changing the contour of the leading edge would be a big deal with the FAA Not something to attempt without mucho FAA involvement and aero engineers Checking the correct placement of leading edge stall strips might be a better endeavor Adding VGs does work to lower stall speed and control at lower airspeeds. Pilot technique and practice is easy and pays big dividends, I try to do every 3rd landing as a short field landing every where. I easily get stopped in <1100' (far end of the 1.000 ft big white blocks). Of course Bill Wheat would bury any of us in this if he was still around!!!!!1 point

-

Thanks Anthony for calling in the reinforcements! For their info I'll just add that it's a 1992 TLS with a TIO540.1 point

-

+1 for following the instructions that match the new hardware... Let’s see if our new Garmin guy @KLudwick can give us a hand solving the mystery..? (G3X Fuel Pressure sensor and location for a Bravo...) Another resource for tech details and panel instrumentation is Greg @Baker Avionics K may be new, and might not know everyone yet, but he may be an excellent resource for finding the right answer or the person with the right answer... PP thoughts only, not a Garmin expert... Best regards, -a-1 point

-

Thanks Anthony. Apparently the Garmin STC doesn't include using the old transducer and must use the Garmin supplied unit. Since the Garmin one works differently it cant' be put in the same location as the old transducer. The old one was at the bottom right side of the engine next to the injector unit. The new transducer was placed near the firewall with a fuel hose routed all the way from the bottom of the engine. I'm not willing to blame the installer yet if this is normal when putting in a Garmin EIS... Picture below of new pressure transducer location.1 point

-

I was going to go white or blue, but the wife said that was boring, so I made them match the scat tube and fire sleeve. It is Chevy orange...1 point

-

100% agree with @Vance Harral. There are very few A&P out there these days that are specialize in any thing else other Cessna.1 point

-

Mine has them. Frankly, I don't think they are worth the trouble. And, I want the extra drag when slowing down . When I paint the plane, I may epoxy coat the wheels and leave them off. I'd drill holes in them, but don't want to go down the road of unintended consequences and violate the rules.1 point

-

I am not sure how to edit the title, but CONTRACT PENDING!1 point

-

The only one I've seen that allows you to check tire pressure with the covers on is the Hubba Hubba hub caps from Lopresti.1 point

-

That is an appropriate price range for a solid to very good M20J with moderately upgraded avionics and a mid-time engine (probably the two things that modify price the most, I think). You might find a low-time engine with mildly upgraded avionics or high-time engine with fancy avionics. Most of the J's I've seen for sale do not have major airframe modifications, so we'd be curious which one's you're seeing... Be prepared to spend an extra $5-10k with the buying process, including travel, pre-buy inspections, first-year insurance, and ferrying.1 point

-

1 point

-

I thought the round windows were 5kts faster. Minimum. Sent from my iPhone using Tapatalk1 point

-

I wrote it up a few years ago in this thread. Maybe it will help. Looks like I still needed the tool.1 point

-

Put lock wire around the end of the spring and then around a metal bar like a screwdriver held sideways about 6 inches from the end of the spring. Grab the screwdriver with the wire going between your fingers and pull to extend the spring enough to slide the bolt out.1 point

-

I hope to fly also recovering from back surgery three weeks ago so I’ll most likely bring a pilot or CFI along. Happy Thanksgiving to all!1 point

-

Meh. Millennials and post millennials are far more entertained by Instagram, tiktok, millions of other goofiness than flying, scuba diving, building anything, carpentry, machine shop, aquariums, and a million other pursuits requiring developing a skill. It’s too hard!!!! ...the “spectator” and “critic” generation. Some salaries have risen to ungodly amounts while many of the generation continue to live mom and dad comfortably into their 30’s...and mom and dad ain’t buying them no airplane. Short attention span, ADD, idealism and fear. Ugh. I don’t know that I agree that flying is inherently unaffordable. One can buy an Ercoupe for less than $20k, and other models are in the same range. Even an older 4 seat Piper can be had in the 30’s functional and airworthy. You don’t need a GTN and AP to fly. In LA you can park a plane at some airports for $35 a month. 7 gallons an hour isn’t expensive flying. Now many millennials and post wouldn’t be seen on anything less than a Cirrus, let alone something “like a G6” to coin a song... Growing up people used to have crass jokes about “spatially gifted” (read full-sized) women being like mopeds - a lot of fun, but do you want to be seen riding one? An Ercoupe or Piper just doesn’t fit the image of many who live the Instagram life... 40-50 flying hours for a license is just too long for some in the Twitter generation. Besides, flying from point a to b? Why not like, Uber or Lyft? Doesn’t grandpa fly one of those a“ little” Cessnas? They couldn’t tell the difference between a 150 and a P210/310/340/337. And it probably wouldn’t be worth explaining. Don’t those little airplanes like fall out of the sky? Children are our future - remember that. To me, that’s the state of GA. I don’t see GA new airplane numbers growing, let alone exponentially. Low cost new airplanes? Yeahno-remember the $170k sport pilot seaplane that took a zillion deposits? With trailer, the Icon A5 scratches a cool half a mill now for a 2 passenger sport pilot bird. Any cheap GA birds in the horizon? It’s not even a liability issue anymore, or recouping the cost of certification - marketing people see the anchored prices of single engine GA planes, rotax powered or otherwise, and while the engine may be cheap, or the cost of manufacturing, or even certification, no new airplanes means our little DINKs will preserve most of their value or appreciate.1 point

-

I check the pickup screen on my io-360 every year or so. It’s not that difficult. I think some are exaggerating it. Maybe if you’ve never worked on cars, boats, bikes etc before it may seem a big deal but stuff hard to access isn’t unusual for mechanics. Btw who built this engine? -Robert1 point

.thumb.png.7c67574d7b28f67b0b4a17760919b1ac.png)