Leaderboard

Popular Content

Showing content with the highest reputation on 09/21/2020 in all areas

-

12 points

-

There actually is only the illusion of redundancy. You can cross check the 830 to your factory gauges (which you won't because you will just be looking at the 830) but if a factory gauge fails you have to replace/fix it to be airworthy. I put in an 830 three years ago because I couldn't justify the funds for the 900 at the time. Times are better and I just upgraded to the 900, love it, and am glad I did. I don't regret putting in the 830, it gave me three years of use and provided valuable diagnostic information on more than one occasion. The 830 is better than no engine monitor, but if you have the funds for the 900 I would put it in.4 points

-

That’s not even 1 AMU, spreading iPad cost over a life expectancy of 5 years about $225/year. Not everything is about money. If you really want to save big money...sell the Mooney.3 points

-

Here's why the 900 is actually cheaper... You can install the 830 now and then pay to remove it and install the 900 later. Or you can just skip the 830 and install the 900 now. Regardless, you're gonna install the 900. Probably when you get tired of spending to keep the old original factory gauges functioning.3 points

-

3 points

-

Don't make this complicated. The injectors aren't the issue -- it's the terrible induction system design of most Continentals that prevent running LOP without GAMI injectors. Radials run LOP easily with -gasp- carburetors. Lycoming's 4 bangers have pretty well tuned induction systems. Piper included a LOP procedure in the POH for the carbureted O-320 Warrior (I've posted it previously). If everything is working correctly, an M20J should run LOP without any modifications. You don't even need fancy instrumentation. Lean carefully until it gets rough and richen just until it gets smooth. That's usually around 20-40F LOP depending on the power setting. Skip3 points

-

2 points

-

It seems that it has to do with protecting the ILS critical area. When the tower is closed, there is no guarantee that there is no airplane or vehicle in the critical area.2 points

-

No experience in any, but I like the look of the Ercoupe. Plus the windows roll down . . . I've heard that Luscombes have narrow wheel base, making control on the ground difficult and crosswind landings extra hairy. Then again, some people have heard that Mooneys are hard to fly . . . . Good luck with it! Both of you!!2 points

-

Everyone in this thread who tells you they can consistently change their oil without spilling a drop is a liar. We've been doing our own oil changes 2-3x year for the last 14 years. I have all the contraptions for dealing with the filter: the v-shaped piece of angle iron, the diagonally cut oil bottle, the rags, the bags, all of it. I've tried all the gimmicks, too: waiting two days after draining the oil to pull the filter, punching a hole in the filter, etc. And with dozens of oil change iterations under my belt I've finally reached the point where I only make a gargantuan mess pulling the filter every 2nd or 3rd time. It's just the way it is. Expect and plan for a mess. You won't feel disappointed or rushed when it happens, and you'll feel great on those occasions when it doesn't.2 points

-

2 points

-

Mark I have a PMA450B so I should have Flightmate. I have the PMA450A setup guide because of a question that I asked you at one of the AOPA fly-ins in the fall of 2018 (I think). I wanted to change my squelch setting and you provided that manual so that I could make the adjustment. I assumed (probably shouldn't do that) it was the latest that was available and applied to the B version. Sounds like the information I was using was out of date. @Tahir K will need to pick the PMA450B input that works for his Sonalert or will need some simple external conditioning to invert the signal. Thanks for the clarification. Jim2 points

-

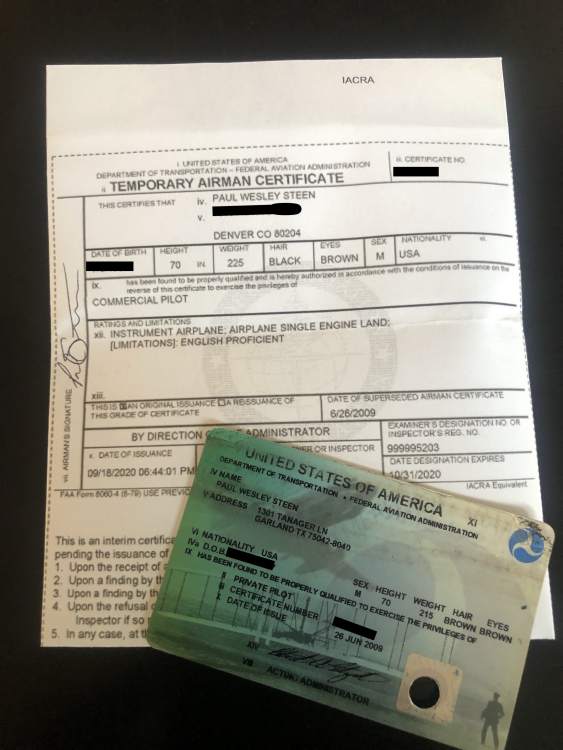

Fantastic! Congratulations! And now you too can give up your day job to pursue a career in banner towing.2 points

-

It looks to me like your engine is higher than it ought to be. I wouldn't worry about the left/right very much, when you get the spinner pointed down a little, it'll look just fine. Don Maxwell had a good article about shims, but I can't get it up on the internet. I saved a copy, he says the 1/8" shim will move the spinner about 1/2". I'd use a shim on each of the upper mounts. In 100-200 hours or so, when your brand new engine mounts are broken in a bit, you'll probably need to remove them. About 500 hours later, you'll probably install them on the lowers. Perfect!2 points

-

Great question,IP! Select a well qualified CFII... you have both the plane and you that want the good Break-in experience... Check @mike_elliott’s schedule... Mike is well known for his CFII skills and organizing the Mooney Summit... he also has a ton of engine skills too. Transition Training in a Mooney is a blast! Brake-in flights are even more cool than ordinary LOP or ROP flights... high power, high speed, high FF... Best regards, -a-2 points

-

Our truly amazing Ovation is now sold. Over the last 7 years, she has taken our family and friends from Yellowknife to Newfoundland, the Bahamas out islands to Oklahoma City, Boston to Kansas and more points in between than I can honestly remember...what an aircraft. Thanks to Clarence (M20Doc) and the gang at TriCity for keeping her in such great shape. Be well everybody.2 points

-

No question the best $1 AMU I've spent on aviation. And it's paid for itself many times over in increased engine longevity and reduced shop time troubleshooting the occasional problem.2 points

-

I just spent five days doing touch and goes in my 252. I logged at least 8 and sometimes 12 each day. I was working on the Commercial maneuvers which include several types of landings. It was a lot of touch and goes. Anyway, everything worked out, no problems.2 points

-

Dunno. But FWIW, I've used the method in airplanes with constant speed props too. Engine mechanics is not my strong suit, but as far as I can tell, starving the engine still produces roughness, whether it be a substantial RPM drop or something less but still detectable. Most of the time, it's an airplane with an old fashioned single EGT but I've done a comparison out of curiosity in a few which have more extensive instrumentation, including G1000s with lean assist. Hardly a scientific sample but I haven't seen a huge difference. Similar EGT, similar fuel flow, and similar cool CHTs. Obviously not the same accuracy as nailing 20 degrees LOP on the last cylinder to peak, of course.2 points

-

I tend to fly the Diamond DA62 or the Bonanza but every so often i'll pull out the non g1000 172, really wish there was a Mooney 8). realism is on high, graphics are mostly high but i only run at a 2560 x 1440 resolution. Framerates tend to run between 20 and 35 fps. Hoping to build a new rig soon, would really like 2560x1440 at a consistent 40 or 50 fps What also really helped, I hacked together some software which allows the msfs2020 to work with Garmin Pilot, allowing me to simulate most of what happens in the real plane.2 points

-

2 points

-

Here's a picture of my house! First hints of autumn color. Well I can see it and you can to if you know where to look - I better not point out where my house is exactly on the internet but I will say it is one of those very lovely houses on the river with a beautiful view. This picture was taken yesterday during the last 90 seconds of my flight - I am lined up and landing on RWY 24 at Potsdam, so as you can tell I see all the traffic coming and going which I enjoy and I have a hand held radio and sometimes I listen to the traffic although its a quiet rural airport so even on a weekend often an hour or two go by and no traffic.2 points

-

Lower cost should not dictate here. There is no comparison really. Despite it displaying much of the same data as the 830, the 900 is a completely different instrument in so many ways...many have been stated here. Start fresh, do it the right way, lose the ship’s factory gauges, and put the 900 primary in. Steve2 points

-

From our friend Bob Kromer, who was Exec VP and Engineer and Test pilot on the Sabre project... Thanks for sharing this great photo. This is the engineering and development team posing with 0001. We called it “Saber”. My estimate is this photo was taken in 1989 or ‘90. Later, after certification, marketing called it the TLS. The airplane has just been completed at the paint shop and first flight is imminent. I’m not in this photo, but I remember the day very well. Hopefully Mooney can find a way to return to this level of capability regarding new product development. As a company, we felt like there was nothing we couldn’t do. Takes vision, planning, money and a little time. I am grateful for the tech group you see in this photo. That was a fine R&D team. The shark’s teeth paint scheme was their idea. I said go ahead, have some fun with it. Those were good days. The best of my career. Bob Sent from my iPhone Bob Kromer SVP, Engineering - Blackhawk Aerospace2 points

-

Losing control of the J-bar seemed to be a once per year kind of event... around here. It has been lessening since somebody took a pic of a worn out down lock block... DMax documented the thumbnail test... David produced some new blocks both up and down lock when the Factory was unable... Learning the speeds which make sense for releasing the J-bar from the up lock block is amazing... It is a nugget of info usually discovered by a new Mooney pilot during transition training... Discovering on your own, may have a few holes, you might have to find in an odd sort of way... If the J-bar travels on its own during cruise... it can be considered like a bat traveling at full swing... the gear doors hanging out in the wind at 150mph can supply a lot of force... It has bent steel, it could easily bend a bone... Keep in mind airplanes built in the 60s didn’t have consumer protections like cars built in the new millennium... no seatbelts, but plenty of ash trays... PP thoughts only, not a CFI... Best regards, -a-2 points

-

It's not a common thing to do, so I suspect it is probably not worth doing. The bolts in the upper part are bit notorious for fitment and difficult accessibility behind the firewall, so the effort required to get them back in may not be worth the juice.1 point

-

If the rubber is still good, not flaking or breaking up it may be repairable until Mooney decides to order some more from their supplier. First check with your mechanic that it is OK to do a repair if he is the one reinstalling it. I used a light 1.5 oz fiberglass cloth (0.75 to 1.5 oz should work) You only need a few sq inches for the repair. I then got black high temp RTV from Amazon (comes in different colors, your choice). I cleaned the intake well with soap and water and let it dry, then wiped the area around the holes with solvent (90% rubbing alcohol). I cut several layers of patches each slightly smaller than the next, similar technique to fiberglass or carbon fiber repair. The first patch was about 2 inches in diameter. I thinned the RTV with a little Kingsford BBQ lighter fluid (naphtha) so it would flow enough to wet the cloth easier. Using a small brush, I put the RTV on the OUTSIDE of the intake around the holes just large enough for the largest patch cloth. Then stippled the cloth into the RTV and coated with a little more RTV for the next layer. I repeated the process for three layers of cloth and then let it dry in the sun to cure.1 point

-

1 point

-

1 point

-

1 point

-

If you swapped the antenna coaxes behind the panel at the racks, that all but eliminates the splitter. The antenna is in good enough shape because of the 155 working fine. Things to check are to see if one of the grounds on the Nav connector has come loose or is not making contact. Also, be sure the screws on the backplate are tightened because a loose connector can not fully seat correctly causing intermittent issues.1 point

-

I've done them in my E, no problem on my home field of 3,200' Usually will only do on request of a instructor, If I'm doing pattern work by myself, I like to taxi back to give myself time to reflect on the landing and the technique I used. More challenging in the Mooney is a go around initiated from the pre touchdown flare position. If you can master that, T&G's are no problem.1 point

-

For financing, I have had a very good experience with Dave Savoie with US Aircraft Finance co. I have financed two airplanes with them including my Mooney. https://www.usaircraftfinance.com/1 point

-

It would need installation... 1) The fuelP sensor for the O360 May be a different range than the IO360... But I don’t see FuelP on the list... FF is the more important piece of info... if you have FF, you have FuelP as well... PP thoughts only, not a mechanic... Best regards, -a-1 point

-

Dehydration can also cause problems and headaches are a frequent symptom. The oxygen is dry and cold air has very little capacity for water. Trying to manage bladders on long flights leads to starting a flight with minimal hydration. I know that after long flights in the flight levels I am dried out -- I always carry some water and try to remember to hydrate along the way.1 point

-

1 point

-

OK lets go down the road a little farther then as I do understand the Law of Motion If we have a 2 blade prop and a 3 blade prop (assume blade profiles are identical then we would have 50% more induced and parasite drag on the 3 bladder. How much HP would be lost in the additional drag that could be used for thrust OR does the disc density have a factor (also consider similar blade angles and RPMs) With the disc density I guess we change the blade angles to get the same RPMs and better climb because of the density? (Less slip?)1 point

-

I'm a CPA. Section 1031 needs to be planned and coordinated through an intermediary. But this only applies if the plane is in a corp. The issue with the IRS s the verbiage, " if the asset is used in a trade or business.." I would have to research prior cases on what precedent has been set.1 point

-

Now we got the primary vs other engine monitor out of the way... We have the 900 vs 930 depending on how large a screen you prefer... how much real estate you have, and how you like to scan your instruments... ... and, if for some reason you want a different supplier than JPI... there are two others in the primary category... EI and Big G... EI is known for being a great company when it comes to service... Big G is known for everything, nearly fully integrated... PP thoughts only, not a mechanic... A typical OilP sensor for the O is about $400 and about a four month wait... Best regards, -a-1 point

-

Yetti’s probably right for cheapest route. Easiest route is probably an iPad, foreflight, and a stratus or sentry. They both get you all your charts, approach plates, weight and balance, weather and planning. Also weather and traffic adsb in during flight. Foreflight is $125/year, sentry is about $400 one time purchase. It all just works. Bigger question, do you have ADSB out?1 point

-

Mike here’s a quick story, a buddy and I was going out to do some approaches, he asked if I had time for him to do an oil & filter change, sure I said, it won’t take all that long. He had changed his oil multiple times before and it wasn’t ever an issue, this time was different and he couldn’t have made a bigger mess if he had tried. Once he had the oil draining he moved to the oil filter, as a precaution he moved the bucket closer so filter (bent aluminum) would drain in the bucket, in doing so he partiality knocked the hose off the quick drain, while loosening the filter the drain came completely off (rocking the plane around) making a huge mess before he noticed. While putting the drain hose back on he knocked the aluminum chanel out from under the filter making mess #2. Next was dropping his last new filter which was partially pre-filled face down into 40~50 pounds of floor dry he had put down to help with the growing mess, so it was over to my hangar for a filter. New filter installed and safety wired, 7 qts in the sump he opted to leave the floor dry down until another day, at this point I was feeling bad so as I was putting the cowl on he went to empty the old oil from the bucket, as he walked back in the hangar I couldn’t help but notice he had oil from his hat to his shoes, to this day I couldn’t tell you what happened at the community waste oil dump but I can tell you this, there are those who have made a mess changing their oil and those that will eventually make a mess changing their oil.1 point

-

1 point

-

The difference between kinky and perverted? Kinky is using the feather. Perverted is using the whole chicken.1 point

-

It will also add a knot or two as you shift CG aft as an added bonus.1 point

-

I'm firmly in the pull the seat back and stretch out category. I ever find a huge need for rudder inputs in cruise flight.1 point

-

My 2 cents:. I'd go with the portable option. I did it for years and only stepped up to the 345 when I got my Aspen displays. IMO the 430/530 don't display adsb near as well as an ipad.1 point

-

Welcome aboard TV... If you have any difficulty finding one... We have two other resources to go with Mr. Loewen... @SheryLoewen Best regards, -a-1 point

-

Full flaps, half flaps or no flaps...these things are not that hard to land in any position. The procedure is the same, the sight picture just a bit different. I like steeper full flap approaches. It's quite alright with me if other's don't... I also think T and Gs are a piece of cake in my bird. I (parish the thought) raise the flaps to take off position on the roll (sacrilege) and then take off. It's ok if other's think I'll shoot my eye out. I've been doing them for more than 15 years with no drama. If T&Gs seem like a sketchy or dramatic operation to a pilot, that pilot probably shouldn't do them. If no regulations are violated I'm pretty libertarian on the operations and procedures of others. I do get a little preachy about short final speeds sometimes but only because I've seen several Mooneys needlessly end up in the weeds.1 point

-

Thank you Steven for your invitation. Regarding “Softmute”, PS Engineering Trade Marked the name in 1992 when we introduced the PM3000 intercom. The word “Softmute” actually was coined by Marc Cook, at that time, a writer for AOPA. it refers to the slow return of the music once it is muted. While we have legal rights to patent 4,941,187 (now expired) we wanted to give the pilot even more flexibility of music by being able to turn muting off completely. We call that the Karaoke Mode”. I often will place my tunes in the background with the aircraft radio in the foreground. This works perfectly for me, especially when I’m being bounced around in IMC, it helps to take the edge off. The GMA345 only allow the selection of music that everyone hears, this is accomplished by pressing the SEL button. Everyone can her Bluetooth, Music 1, or Music 2. There is a switch in the rear right side of the unit which, when switched, allows the passengers to always hear music 2. So in fact, it does not have music distribution, as far as I know. The PMA8000 series provides much more flexibility for music distribution while the PMA450B can do just about anything. IMHO, unless the pilot wants to use GARMIN’s Telligence with the GTN series, or doesn’t have room for stand alone audio panel, I personally can’t think of a single reason why to go with any other audio panel than one of ours. And I’m trying very hard to be objective! I’ll be happy to answer any questions you might have. Mark Scheuer PS Engineering1 point

-

Its my opinion that TnGo in a retract generally makes for an especially easy way to handle the gear lever wrong just once, retract at the wrong time or forget to deploy, and gear up. If I have the urge to touch and go, rather I touch, stop, reposition to the hold short, then go.1 point