Leaderboard

Popular Content

Showing content with the highest reputation on 08/09/2020 in all areas

-

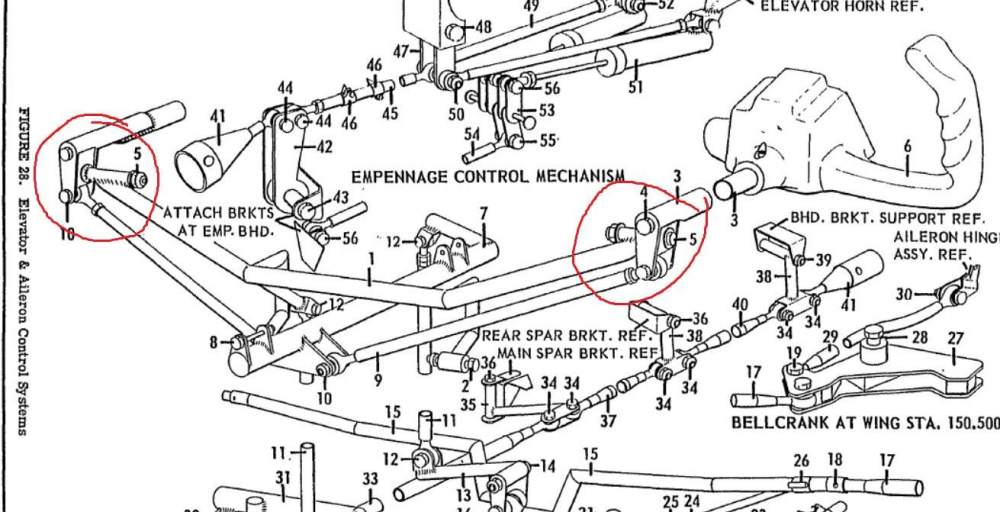

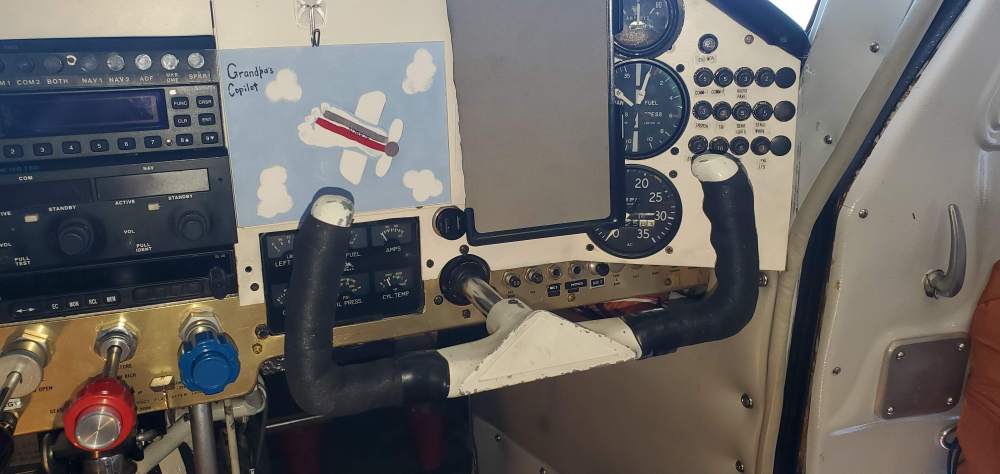

If you have a vintage Mooney you know about AD 77-17-04 which requires removing the control wheels every 500 hours and inspecting the shafts for cracks with dye penetrant. All M20 control shafts are the same outside diameter. People talk about the newer planes having a thicker shaft, the difference is in the thickness of the wall of the shafts, with the older M20's at 0.04 and the newer M20's at 0.06. The difference in the thickness of the shafts obviously results in a smaller inside diameter. The AD does not apply to the thicker shafts. Every now and then a set of control wheels comes up for sale, offering the opportunity to upgrade your old control wheels and remove the AD. I recently was able to buy a set of control wheels, shafts, and the yoke from a 1996 M20R to put in my M20D. If you have a chance to acquire a set, I highly recommend doing so. I did not think there was much of a difference, and mine actually feel pretty good with the bike tape on them, but once I wrapped my hand around the newer style wrapped in leather I wish I had done it a few hundred hours of flying ago. I want to share a few things that you will need to know if making the swap. The new control wheels mount to the shafts with a bolt going horizontally from 9 o'clock to 3 o'clock. The old control wheels mount to the shafts with a bolt going vertically from 12 o'clock to 6 o'clock. To replace the control wheels and use your old shafts would require drilling horizontal holes in the shafts. Even if you could find an IA willing to sign off on it I feel it would be extremely foolish to add a hole to a shaft that already has an AD to inspect for cracks... Depending on the shafts that you are buying you will likely have to also replace the yoke. The control shafts have a half circle piece on the end where they attach to the yoke. This piece is what allows the shaft to rotate and provides the stops so that it can't rotate too far. The ones coming off my plane have this half-circle piece on top, centered at the 12 o'clock position. On some models Mooney has the shafts that still had this on top of the shaft, and at one point offered these shafts for sale when upgrading control wheels. I do not believe it is possible to get them from Mooney anymore, and it is likely you will have to replace the yoke. On the ones that I got off the M20R these are rotated 90 degrees with the LH side centered at 9 o'clock and the RH side centered at 3 o'clock. If your new shafts are like that you will have to replace the yoke. In this drawing that Mooney put out for replacing the control wheels and shafts you can see circled in red the end of the shaft and circled in blue the piece on the end of the yoke that mounts vertically into the shaft. You can also see it in the parts catalog drawing circled here in red. I had hopes that I would be able to just remove the ends off my yoke and replace them with the ends off the new yoke, that will not work. The ends are held to the old yoke with a bolt through the end, then through the yoke, and a lock nut on the end of the bolt. The new ends have the bolt integrated into them and are held on with a castle nut and cotter pin. The diameter of the bolt on the new ones is too big to fit in the old yoke. You can see the differences in this video. Having established the requirement to replace the yoke, here are a few tips for the rest of the project. Remove the front seats, you are going to be spending a lot of time on your back under the panel, it's much easier without the front seats in the plane. There is not much to replacing the yoke (aside from contorting yourself and laying on your back under the panel) You will have already removed the control wheels and shafts so there are only the two bolts holding the yoke to the tubular frame and the one holding the push rod going to the elevators. Once you remove those you can remove the yoke and put the new one in. (The one off the M20R has a big bob-weight on it. The M20D does not need it so I removed the weight.) You do not have to replace the pheonolic blocks that the shafts go through. In fact in my case the new ones won't even mount to my panel. On my plane they are held in place with two screws at the bottom (about 4 and 7 o'clock) and one at the top (at 12 o'clock). The new blocks only have two at the bottom that don't line up with the holes. I had removed mine and had to reinstall which was a waste of time. Take a look at yours in your plane and the new ones before removing them. After you have the shafts in, the wheels on, and the shafts attached to the yoke you need to connect the push-rods that go to the ailerons. You will most likely have to adjust the length of them by turning the end to make them shorter so that the wheels are level. You will need to take the slack out of the ailerons before doing this. We used the plane jacks with a piece of wood on them under the ailerons to lift them (lightly) so that they sit even with the flaps. After that you can place a straight edge or level across the shafts and line up the wheels with it. Simply slide the bolt through the shaft and the aileron push-rod (no need to put the nut on yet) and then climb back out from under the panel and see where they are at. Go slow, a half turn at a time of the rod end, put the bolt back through and take another look. Continue to do this until you have them level. Once they are level put the lock nut on and snug them down. Make sure you work the new wheels and shafts through their full range of travel to ensure that they do not get caught up on or rub any wiring or the ducts for your vent/heat and defrost. I did this while laying on my back under the panel to make sure nothing was rubbing or binding. Because they are M20 parts your IA "should" sign it off as a minor change in your log book. Mine listed the part numbers that were replaced in the log book entry. (Disclaimer - I am not an AP nor an IA but I did work with mine on this project and this is the process we went through) I am looking forward to now having a push to talk on the RH control wheel and flying with the new control wheels. There really is no comparing the way they feel in your hand compared to the old ones. Old control wheel (wrapped with bike tape to make the summers less sweaty and winters less cold...) New control wheels (Need to make a plate to cover the top of the left side of the right weel)9 points

-

I used to have an engineer working for me that was a skydiver. Whenever we would go on a business trip, he'd scout out the nearest drop zone and bring his rig which he didn't want to check as baggage, so he would carry it on. Got lots of interesting comments as he walked down the isle during boarding carrying a parachute. He always replied that there was no way he would fly on (insert whatever airline we were flying) without a parachute. Skip5 points

-

When my son passed his PPL check ride my wife and I gifted him a Bose headset and a nice handheld radio. One was to save his ears and the other was to save his @ss. He was out with his instructor working on his IR this week in our C172 when the #1 radio stopped working. While diagnosing this small problem the #2 went dead followed by everything else in the airplane equalling a total loss of electric. They diverted to another airport and he reached back into his bag and pulled out his nifty new handheld only to find the battery was totally dead with no spares in the airplane. They made a uneventful nordo landing at a uncontrolled airport and sorted out the issue. What was the first thing he did after regaling us with his exploits of peril? Yup, you guessed it. Changed the batteries in his handheld and put some spares in his bag. I gave him the dad speech and let him know they don't help if they don't work and then I quietly went and changed the batteries in my handheld...3 points

-

If you don’t yet have access to an external antenna connection consider adding a splitter. A relatively inexpensive upgrade that can give your handheld the range of a panel com.3 points

-

The new lights are working flawlessly. While doing the install, I accidentally broke one of the wingtip covers - but that's nothing to do with my approach, it was just pure stupidity. You can try with the files and instructions I posted above. Let us know if it worked.3 points

-

Or do what I did, and get the dog to fit the Mooney! Sent from my Pixel 3a using Tapatalk3 points

-

I don’t know about you but for that price I’m bringing a big suitcase to keep the bath robe towels and soaps.3 points

-

2 points

-

My experience is the same as Paul’s (Kortopates). I have a 231 that I have flown a fair amount in the flight levels in cold temps. The coldest I recall was -54 F on a trip from Williston to Flying Cloud. It was so cold the heater and defroster could not keep up inside the aircraft, and I logged IMC time even though the weather was CAVU, because there was no way to see out the windows. I have used IPA from time to time, but have never found it necessary in cold climate flying. That said, if Mike B. says it can actually be a problem, I take that seriously. I buy it in pints at an autosupply store and keep some in the aircraft, I don’t think I would want a whole gallon sitting in the plane. Usually the problem is self-solving. If it occurs when warm fuel is loaded and then taken to cold temps, that is not a common scenario. Up here in the frozen north we fly from one cold airport to another cold airport. On occasion I fly from a cold airport (such as KFCM) to a warm airport (such as KGAD enroute to the Bahamas) in the flight levels. However the winds aloft virtually never allowing flying back up high where it is cold. The 70 knot tailwind you had going south does not help in the other direction. Usually the warm-loaded fuel is long gone by the time I get home, and what is in the aircraft was loaded somewhere cold. That said, I put a pint in each tank when conditions warrant. The water-in-fuel scenario that Paul talked about is a somewhat different issue. Because Mooney fuel caps are recessed, they sit in a well that funnels rainwater towards the tanks. The only thing stopping the water from getting in is good O rings. I have found as much as a pint of brownish water when sumping a Mooney tank, not my aircraft but a J I used to fly years ago. I keep my own seals in good shape, they are checked at annual every year, and I have never seen water in my tanks. For that matter there is a small O ring around the stem for the cap lock, if that goes you can get water in or fuel siphoning out. The fuel siphoning out can be fairly dramatic looking, it comes spraying out of the cap because of negative pressure. If you don’t think the curved upper surface of the wing creates low pressure contributing to lift you should try that some time. The 231 has antisiphon valves for this exact reason, they are a pain when fueling but the spraying, the one time it happened to me, is shortlived, just the cup or so of fuel above the anti-siphon plate. Nevertheless, Mooney gas caps are configured to favor water going in, so I always, and I mean always, sump the tanks after every re-fueling or if the aircraft has not been refueled but has sat for a period, especially outdoors. The only time I might skip it is if the plane was filled yesterday, I flew it and know the fuel is good, and then it went into the hangar overnight. It took some work to sump that gunk out of that J tank, and then it happened again the next time I flew it. Ugh.2 points

-

If it's that cold, that you think you need IPA in your fuel, stay home and have a pint of IPA next to a warm fireplace... https://www.totalwine.com/shop/best-india-pale-ales2 points

-

I've seen a lot of good King KCS55 system parts come on the market from glass panel upgrades. For those who don't have the budget for glass right now, you should consider keeping some parts on your shelf if you can find good ones at a good price. Look for low time components first. A lot of these will have thousands of hours on them, since the KCS55 is often used in commercial service planes. I just bought some parts for two clients, who will now have good spares and not need to have expensive overhauls to keep their systems going. Most times, when you need a replacement gyro or HSI, you're stuck paying a premium for an overhauled one when you're on the road and don't have many options. Barnstomers and Ebay often have listings if you want to put a spare on your own shelf. There is a low time KG102a remote gyro, and a KI-525a HSI (with harder to find bootstrap output) ending tomorrow on eBay. These would be good spares to keep. https://www.ebay.com/itm/133482586652?ssPageName=STRK:MESELX:IT&_trksid=p3984.m1555.l2649 https://www.ebay.com/itm/133482591388?ssPageName=STRK:MESELX:IT&_trksid=p3984.m1555.l2649 Gyros fail fairly often, with little warning. The warning they do give is "stuttering" during traffic pattern turns. HSI's mostly suffer from sticking flags or ratchety needle movement. The KMT 112 flux valve rarely fails outright. Unless a goober has used a power screwdriver in close proximity (less than 12") lately.2 points

-

This reminded me of a joke I heard a few years ago... What does Golf and sky diving have in common? In golf, you hear, “Whack, dammit!” In sky diving you hear, “Dammit, whack!”2 points

-

100hr inspection procedure on our flight school Piper Warrior III which uses the same style Klixon breakers calls for pulling and resetting all breakers with power off, maybe it helps clean the contacts without arcing which may happen with power on?2 points

-

2 points

-

@neilpilot I owe you a retraction and an apology. You really encouraged me to dig deeper since I was going by mostly my own experience here yet I know what you said is true, I just didn't believe it was that much of a threat. So I checked in with Mike B, since he's got 50 years flying experience, mostly Turbo, and has probably heard it all. He told me there is a real risk of dissolved (undrainable) water coming out of solution at low temperatures and freezing into ice crystals that can cause engine stoppage. He knows of several emergencies that occurred because of this, although it's definitely not common. Mike says these incidents don't occur in the wintertime as far as he knows. He says the major risk is taking off from a low altitude airport where the temperature and humidity are high and the fuel has become heat-soaked because the aircraft has been sitting in the sun for some hours, then climbing up to the Flight Levels where the OAT is very cold. It takes very hot fuel that can hold a lot more water in a dissolved state (as you pointed out before). The conditions leading to this issue have always been summertime conditions though, not winter. Mike B though has also never added IPA or even the low flow Prist (EGME) to his engine, but stated if he really thought he needed some, it would be his preference to use the Prist rather than IPA because it only takes very little Prist to do the job. I'll add Mooney says to use IPA, they started out saying 3% was okay in the K's, but later with the Bravo they dropped it to say a max of 1%. Even that is much more than what should be needed for a little water. Thanks for encouraging me to look into this further.2 points

-

Roger, Haven’t seen you around lately... Your SMM and IPC look funny... cross linked with your prior references... I was going to read what you were reading to find out if I could do any better. Might be my iPad... +1 for ziploc bags, WD40 for cleaning the old screws, and A sharpie for writing on the bag... their last known address... Best regards, -a-2 points

-

I don't have the IPC for your airplane but 53-30-00 for my J lists all the screws. Some are PK (sheet metal) and some are various sizes of machine screws -- you just have to figure out which ones go where as the IPC is not very clear on this. There is a theoretical corrosion issue with stainless steel, but there is so much more area in the aluminum (anode) than the stainless (cathode) that it's not really a problem. https://www.bssa.org.uk/topics.php?article=89. I use stainless steel screws and when I remove them I put them in a zip lock bag with some WD-40 (or LPS3 or Corrosion X -- it doesn't really matter). They go in easily and come back out easily. A common mistake that makes them difficult to remove is over torquing them. Skip2 points

-

It only takes enough to absorb the bit of water you may have in your wing(s). A pint should be much more than enough! It’s not good for internal seals so I would avoid using it prophylactically, and would wait till you really have reason to need it. I have never found water in my tanks and only rarely used it the last couple decades flying high in the winter. That said a Mooney went down last winter from water in their tanks after it sat out in the rain with cracked o-rings. The bigger problem was the pilot departed without sumping the tanks after the rains. A 3% solution probably wouldn’t have made any difference there. But my only real point is our first defense should be to keep our tanks dry and then IPA should not be necessary except on rare occasions. Sent from my iPhone using Tapatalk2 points

-

No time to press the Enter button, the video is in real time not compressed. The unit and audio panel was pulled by the avionics shop tech when he stopped by and is at his shop now. He has been trying to reformat with Avidyne's email support. He has told me that Avidyne is not answering their phone and that is why the email back and forth. I called Avidyne yesterday and got right through. Avidyne says it is covered under warranty and wants me to return the hardware to them for repair. I will be going to FWA tomorrow to pick it all up and send to Avidyne. -mark2 points

-

Jerry, Again thanks for the advice. It does go back to when I had an Electronics International CGR-30 installed. Found the GNS530 Nav and Com antenna cables switched. The GPS and G/S cables are ok. The Nav antenna cable was reconnected correctly. The Com1 Coax is open from the cable to the Antenna. The Com antenna SWR check was good. Suspect bad cable or loose connection behind the panel. A new cable was fabricated from the back of the 530 to the pigtail. Works as it should now. Sorry for the delay in the follow up.2 points

-

Pay no attention to @PTK and his negativity. He has offended almost all of Mooneyspace and is working on the rest. Thanks for coming on here Andy, please keep us posted on the exciting news down the pike.2 points

-

2005 Mooney Ovation 2 GX. 1,750 TTSN, Platinum engine, 310 hp upgrade, oil changed every 30 hours, regular Blackstone Labs oil analysis, TKS deice FIKI certified, G1000, WAAS upgraded, S-tec 55X (all servos and AP computer factory refurbished 2019), Speed brakes, 102 gallon tanks, GDL69 Satellite Datalink radio / WX, Flight stream 210, GTS800 active traffic, GTX345R (ADSB in / out), Stormscope, 4 place Am-safe seat belts (inflators replaced 2018), 4 place Bose, Factory oxygen (15 year tank replacement 2020), co-pilot brakes, Alphabeam LED landing and taxi lights, Maxpulse landing light controller. Mooney Service Center (MSC) maintained since import to Canada, 2012 @ 273 hrs, last annual January 2020 including IFR static and instrument re-cert. Flown year round from dedicated heated hanger.1 point

-

1 point

-

1 point

-

So, suppose you didn't have the IPC. You can always take a screw to the local hardware store and match it up to determine that it is, say, an flat head Phillips 10-32, 3/8" long. Now that you know what it is, you can order some aircraft equivalents from your favorite supplier. Skip1 point

-

It's pretty hard to bend the tab since it is heat treated (I know - I seem to catch a rag on it every time I clean bugs off the wing). The Maintenance Manual has an admonition not to try to adjust it by bending it or it will break due to the increased hardness from heat treating. Skip1 point

-

Tp OP There are a lot of 231's available right now for some reason. They would fit your bill pretty nicely if you don't have to have the dog in a kennel. That being said....It is a lot of aircraft for your experience level. Any turbocharged aircraft will be. Keep in mind, if you go with a turbo aircraft you are stepping into something much much more complex that it appears at first glance. Not only will you be dealing with the constant speed prop, retractable gear, speed brakes (possibly), autopilot usage (an art its self)... but you now have an aircraft that will go high enough that you need Oxygen and will put you in the icing levels quite often. You will HAVE to run the heater and so you SHOULD get a CO detector and monitor that as well. And you have to manage all of that while dealing with passengers and making sure they too are getting oxygen, all while potentially in IMC conditions flying on instruments and talking to ATC. Being a new pilot, I am sure you know what it feels like to have too many "balls in the air". As you did your training, you no doubt experienced times where there were a lot of things going on that resulted in mistakes or less than ideal situations. It took time/experience to build your skills up to the point of being able to handle the load. Getting in a turbo moonie will be no different. Point being, you should be very methodical and conservative in how fast you hop into one with family and head off. Get loads of training in it and do a few XC trips solo first. I tell people that I am more task saturated in my Rocket than I am when I fly a G650 and I am not kidding. The 231 has less power than the Rocket, but all of the elements that make the rocket "busy" are still there in the 231. I'm not the best pilot on the planet, but I am a professional pilot with about 5000 hours worth of experience and I can tell you, a turbo mooney will keep you busy and get you into trouble pretty fast. I am not trying to discourage you. I think it is great that you are getting your tickets and you plan to be a part of GA. I just get the feeling that you don't really know what you will be stepping into and I wanted to give you a better Idea. The trouble is it sounds like you will be flying at high DA airports... this sort of puts you in a catch 22 as far as NA vs Turbo goes. If you were flying out of Florida, Id be recommending a Normally aspirated model. But operating at higher field elevations and in mountains can be demanding as well, though in a different respect. Have you factored in insurance into your budget? I recommend that you call and get a quote for what it will cost to insure you. I don't know what it will cost, but I bet it will be a bit steep if you buy one while having less than 100 hours Total time. Maybe someone else will be able to chime in on that. FWIW, I pay about 2400 a year for the rocket with an ATP rating and 5000 hours.1 point

-

1 point

-

1 point

-

1 point

-

It tells me that the market is sooo small that without government subsidies or forced regulation there is zero reason for industry to invest in a solution. Frankly, the fact that it is such a small market tells me it's a REALLY REALLY insignificant environmental problem, too. This is a political issue. I'm hoping someone in the government figured this out and decided the status quo is just fine.1 point

-

Hello all! I apologize for not responding sooner. I’m not the greatest at handling all this stuff and the past few days have been tough on my nerves. Watching the Mooney being sold is like seeing Chris leave all over again since it was his greatest pride and joy to own and to fly. As far as the auction went, yes, it sold. I’m assuming the buyer had the required cash (not even sure what it sold for). I will be checking in with the auction company today to get details. If I should hear anything about a problem getting payment or anything like that (I don’t anticipate this being the case), I will of course let you know here. Chris bought it fair and square (I think bill of sale is somewhere in the attached papers), but he never registered it in his own name. Maybe tax avoidance? I don’t know...I never knew he hadn’t registered it until recently. This is strange to me because he was always so good about being sure our other taxes were paid. Perhaps it was more complicated than that? I would have advertised the auction on this page had I known it existed, but up until the day before the auction, I was completely unaware. Which is sad because, as I mentioned in a prior post, I would have loved for a true Mooney lover to end up with it. Thanks for being so kind and supportive everyone! From better days:1 point

-

Unless there is something obviously loose and recognizable, ie. the hardware at one end is loose, the outercable has slipped; here is nothing in the throttle cable assembly which should stretch or change. The control, cables need to be 100% reliable, without exception. There is also a useful life. How long have they been in there? Too many owners try to push things out and save some money, only to find that they have suddenly (and they think unexpectedly) lost control of their airplane when they had plenty of warning. Flying is not an endeavor where one should allow unexplained events go un-noticed, particularly in systems with no room for error. Noting what you did, and not finding a clear reason is allowing the problem to go un-noticed. The explanation your mechanic gave, cable may have stretched, or it is OK, u=is not giving you and answer as to why the event has occurred. There are all sorts of mindsets and abilities in A&P mechanics out there. Many of them i would not let near my airplane. You want someone with high standards and a high level of suspicion. You said your mechanic thought the cable had stretched; control cables do not stretch, they are not under sufficient load. They do bind, fray and break, all are un-welcomed. I would want to inspect the cable, but you can not since it is quite a bit of work to get it out. It is simply easier and safer to replace it. You do not want it coming apart in your hand at 10,000 leaving you unable to control power or be left with only a mixture control to do so. Not worth the $500 bucks you might "save" only to cost you more in the end, or worse. It is much easier to troubleshoot and work on an airplane when it is on the ground instead of in the air. John Breda1 point

-

Well, as is often the case, the problem wasn't the hardware. It was the software. And by software, I mean my dumb ass. I called garmin, went through everything, they decided it must be a corrupt data card. So they had me take the cards home, format them and manually load the databases. Did that. Went back to the Hangar. Put them in. GTN works fine, G500 still didn't work. I was pulling my hair out. I was flipping through aux pages on the G500 and saw the system ID. It was at that point I realized what the problem was. When I set up my account, I entered the serial number for the G500. Not the system ID. Doh. It wouldn't authorize because the DB cards were looking for the wrong system ID. Called garmin again this morning and they got me squared away. Everything is now operational!!1 point

-

I flew my Rocket to 2100 hours TBO (1600 TBO engine, TSIO520NB, same as the C414). I bought it with 300 hours on the engine. I replaced/rebuilt the turbo twice, each time at +/- 1,000 hours. If you are flying a turbo airplane, I would really be watching any turbos over 1,000 hours pretty closely. As Erik @aviatoreb and I have well documented here in the past, an in flight turbo failure will give you a very exciting (and stressful) flight experience. A 1300 hour turbo is running on borrowed time. On the Rocket, with a Bracket air filter, you can remove the filter and stick a thin magnet through the mesh at the back of the filter housing and grip it to the turbo shaft. I would guess the most common failure on older (high time) turbos is the bearings (was for me). You could prevent an in flight failure by finding play on the shaft from worn (but not yet failed) bearings. Tom1 point

-

Got the radio back from mikes avionics out of AZ. He couldn't pin point a problem necessarily but he realigned the radio to specs and all is well now. I recommend for older king and narco problems. Clear as a bell now.1 point

-

How about an led battery powered closet light from amazon? Portable and no paperwork required. And no risk of running down the ship battery and killing your new Concorde battery.1 point

-

1 point

-

On dark days think- "The longer you go without a bite the closer you are to the next one" A Confident Angler Just remember- You chose your position in life today by what YOU did yesterday!1 point

-

Mike, I like your approach... 1) After selling machines for a few years... I always wrote a purchase agreement... 2) It was a simple summary... 3) It basically covered everything we discussed... in a familiar numbered format... 4) What was included... 5) What was excluded... 6) The price... 7) The PPI details... 8) The timeline.... 9) The final details... that changed back and forth in the last few minutes.... 10) a pair of signatures... mine and theirs... Why? My memory was never that good... and theirs will be about the same a week or two later. Did I include the cover or not? Hmmmmm.... dunno.... time to check what we wrote down... Before delivering the keys... check the agreement to see if I have delivered everything I promised.... Its not so much a trust thing... it’s a CRS thing... No lawyer required... PP thoughts only, Not a sales guy... Best regards, -a-1 point

-

SureFly installed! David has it internally timed and worked on setting up the Garmin GTX 327 and GDL 82 (ADS-B) SureFly is a nice looking unit! -Don1 point

-

1 point

-

If it were me I would replace the breaker and be done with it. I don’t mind fixing a problem once. But I don’t want to deal with it over and over again. Odds are it will fail for good when you are far away from home and no mechanic is on the field.1 point

-

It is absolutely worth it. I fly often in the mountains (moderately high alt) in the south (high density alt) And out of shorter airfields. Let me repeat ~ It is absolutely worth it!1 point

-

The perks and luxury of having 4 cylinders Mooneys Yes bounces on grass tend to slowdown and more forgiving than bouncing on hard runway ! I think RedSky got his technique for grass landing with 6 cylinders polished in previous legs to two grass places: Charlton Park & Andrewsfield before the bag door saga happens? although the grass at Charlton Park is well cut and way smoother than load of tarmac runways1 point

-

you didn't use a checklist. . . . . . . . . . . . . . . . . . . . . I'm KIDDING, chill! nice job! I think I would have been much more concerned with that PIO that at that point you couldn't do too much about. just along for the ride waiting to see what happens.1 point

-

I have been on a mission to figure out how to operate my 231 in all the parts of its envelope. The certified ceiling is 24,000. We tried FL230 last year and had some excitement with "high altitude miss" where improper pressurization of the magneto leads to arcing across the cap in the thin air in the flight levels. Got that fixed at annual over the winter, but just have not had the right circumstances to go that high again. This weekend my copilot and I went to Kalispell from Flying Cloud in Minneapolis. We had the usual share of adventures. The vacuum pump pooped out on the first leg of our trip to KGPI, fortunately in VMC. I made the mistake of leaving the plane on autopilot for a little bit while we decided what to do and then told ATC we needed to divert to KBIS (Bismarck). As the AI wound down, the plane started bucking and gained a little altitude, which concerned ATC (because they knew our circumstances by then), but I disconnected the AP and made an uneventful landing. Lots of flooding at Bismarck and throughout ND. Bismarck Aero found a mechanic and the pump was changed in short order, but it was too late to continue so we stayed the night in the FBO at BIS. For future information, they have a sleeping room with two single beds, worked out really well. The trip out was at FL220, the winds aloft were not too bad, but another 2,000 feet to the service ceiling and they were screaming and in the wrong direction, so we did not have a chance to try FL240. On the way back we got our chance. ATC gave us FL240 for the leg from KGPI to our refueling stop at BIS. As those of you know who have been on this site for awhile, my 231 has the Merlyn wastegate and Turboplus intercooler. The Merlyn increases the critical altitude (the altitude at which the aircraft can no longer generate 100% HP), but I had never tested out where this happened with the Merlyn. The critical altitude on the 231 as it came from the factory with the fixed wastegate was 15,000 +/- 500. We found it at 22,500 with the Merlyn, using the numbers generated by the JPI's %HP algorithm. It was quite a bit warmer than a standard day, -24C at FL240 which is around 10 deg. warm, so I suspect we would get better on a standard day or a cold winter one. It was not until the last 1,000 that the climb rate reduced from my standard 500 fpm cruise climb. We hit about 300 fpm from 23,000 to 24,000. At altitude the plane quickly accelerated to about 182 TAS before I pulled it back to cruise. We cruised at 27.4 MP and 13.7 gph. The 13.7 seems to be the magic figure for my aircraft in a cruise range of 75-80%. I am at the point where it does not seem worth it to go through the lean procedure with the JPI, I just pull it back to 13.7 and all the cylinder temps fall in line in the 370' and 380's at altitude. Bear in mind that in the high thin air, cooling is not as good as lower down, so those are good working temps. We made the trip from KGPI to KBIS in a flight time of 3:00. We hit a ground speed at one point at cruise of 234 knots. My copilot got a picture of a 233 or maybe the 234 that I will post when I get it. Not too shabby for a fuel mileage of close to 20 mpg. I have a couple of goals to work on with the plane's envelope this summer. One is to run a tank dry, or nearly dry. At landing, if my gauges show zero on one tank or the other, there is still somewhere around 6-10 gallons in the tank. Normally we land nowhere near dry in either tank, even for a long trip, but I would like to know how far my plane really will go on full fuel. I have done some testing on the fuel flow meter with the JPI, and it is very accurate, much more so than the tanks. I know within a tenth of a gallon what I have used. Just need the right circumstances, I don't want to try this at FL240. If I blow it and the engine stops, so does the turbo, and it will be quite awhile and several thousand feet before the engine will want to start again. The other is to try LOP. I flew some LOP last year, and have taken the Advanced Pilot Seminar, but the plane really did not like LOP, just ran rough. I had it tweaked some at annual, so am anxious to try that again. Wouldn't it be great if I could cruise at FL240 and 225 GS, at 11 or so gph? Only a couple of other notes on the trip. I filed for FL240 leaving BIS to FCM and they wanted me at an odd altitude. The controller offered me FL210 and 230 and I took 210, but he questioned that altitude. His exact statement was, "We don't see many Mooneys at that altitude." So I don't know, maybe we need to organized a turbo Mooney group and buzz Salt Lake Center's facility at FL240 so they understand turbo Mooneys better. The other was the departure from KGPI. For those who don't know the place, there are Rockies on both sides, and the ridge on the east is around 10,000. Normally, we have plenty of time to climb over it, but this time my friendly winds aloft were pushing us pretty good. I had to go Vx at 9,000 and at that, had to fly through a "notch" in the crest ridge. Made for a pretty view though. Copilot noted the "TERRAIN ADVISORY" on the GPS. At least now she knows what that is for. She got some spectacular pictures.1 point

.thumb.jpg.ae084ff98f2eda1b3f595ed45b9592c9.jpg)