Leaderboard

Popular Content

Showing content with the highest reputation on 07/18/2020 in all areas

-

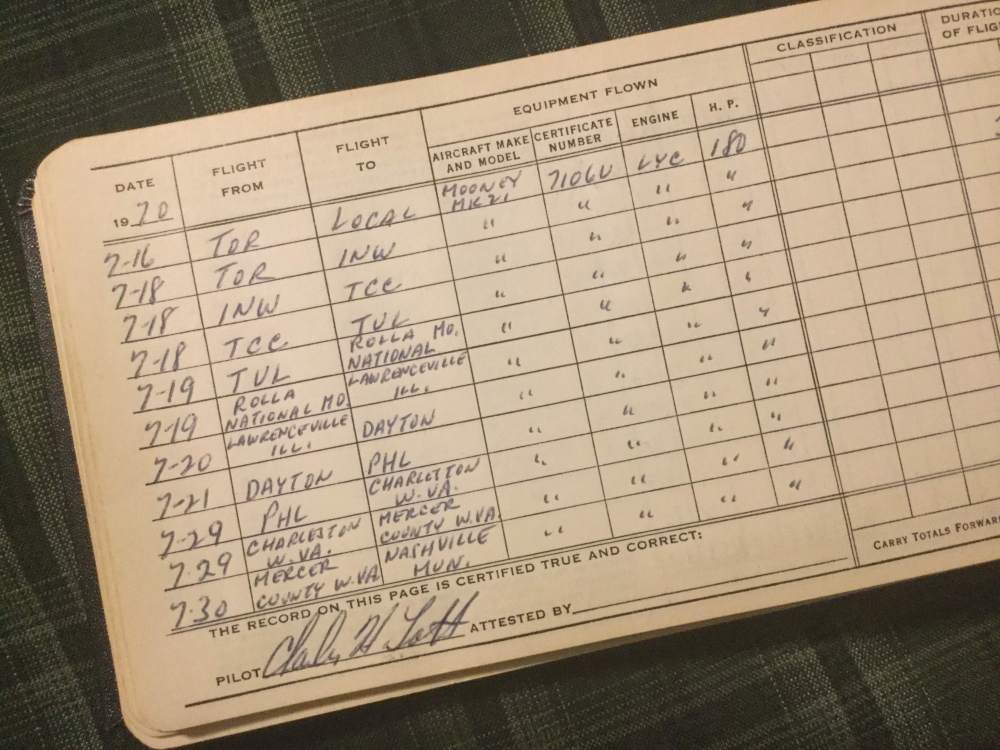

If someone were to ask you “what were you doing fifty years ago today?”, most of us would probably have a hard time answering that question. Unless it happened to be the day you got married or the day one of your kids was born. Sometimes other events become so meaningful in our lives that they too, stand out, as special moments, even turning points that forever change our life experience. I knew that the 50th Anniversary of one such event was approaching but I needed to look into my Dad’s logbook to confirm the date. That date is tomorrow, Saturday July 18, 1970. It was the day that my Mom, Dad and I climbed aboard Dad’s 1964 C model Mooney, N7106U to not only begin our summer vacation, our first family flying vacation, but to be part of Dad realizing his boyhood dream of one day flying across the country in his very own airplane. This was only the second time since my Dad’s passing that I have looked in his logbooks and I was not prepared for the flood of emotion that would follow. You need to understand that this was more than just a vacation flight. It was more than a trip from California back home to Pennsylvania to attend a family reunion. It was the culmination of nearly four years of constant searching for the right airplane to make his dreams come true. It was also going to be the opportunity for Dad and me to find some of his flying buddies from the 1940s and 1950s and to see if we could find his 1946 J-3 that he ordered brand new from the factory in 1946. And, to make it even more challenging, we had to do all this in just two weeks time, because that is all the vacation time that Dad had. So over the next two weeks, I would like to invite all of you to climb aboard 06U and ride along with my family as we relive that special event from my childhood, just as it occurred so very long ago. I promise there will be adventure, an accident, a pretty girl and a celebrity along the way. Like all true stories there will be some tears and death as well.15 points

-

Your newly overhauled engine is far more likely to fail than your engine that seems to be running well with a minor leak. From a purely safety risk perspective, you’re currently flying the safer engine.4 points

-

4 points

-

It’s in Sarasota Fl right now. Landed a week ago! somebody still loves it.4 points

-

Saturday, July 18, 1970. First leg. Torrance, CA. (TOA) to Winslow, AZ. (INW) We got up early and piled into our green 1966 Pontiac LeMans and headed down Hawthorne Blvd to Torrance Airport. Unexpected was the solid gray overcast which blanketed the Los Angeles basin. It was high enough that we could at least get started. We made a right downwind departure from Torrance, heading East. When Dad contacted Flight Service to activate our VFR Flight Plan, he learned there were Pilot Reports of a good sized hole further on. Two other planes were ahead of us heading in that direction so we followed them. As we approached the area of lightness, the first plane pulled up and disappeared. Then the second plane did the same thing. We did too. It wasn’t a huge break in the overcast but it was big enough. We were on our way. Our first stop was Winslow, Arizona, long before it achieved fame in the song by Glen Frey and the Eagles. Winslow was about 442 statute miles straight line distance from Torrance. Of course there was no GPS or magenta lines to follow in those days. We were navigating by VORs along the Victor Airways. Our actual flying distance was farther. Dad handled the flying while I watched for traffic and learned about folding, unfolding and refolding Sectional Charts. While we were busy up front, Mom was busy in the back seat as well. This is where the brilliance of my Dad’s preflight planning really shined. Dad had skillfully obtained and strategically placed a supply of motion sickness bags in the pockets behind the front seats. Mom was vigorously putting these bags to work. We were in serious jeopardy of running out of bags before we even arrived at Winslow. This reminded me of an old black and white photo that I saw in one of my parents old photo albums. It is a picture of a Navion with the canopy slid open. Sitting on the wing is a bucket with a rag hanging over it’s side. On the back of the photo Dad wrote these words: “Ruth’s first plane ride. Note the bucket and rags.” We managed to make it to Winslow in 3 hours and 10 minutes of flying time without a bag crisis, although I do think some additional contributions had been made to previously used bags. Because of the time zone change, the fact that Mom could use a break and there was a restaurant on the field, Dad thought it would be a good idea to take a lunch break while the Mooney was getting topped off. The best part of our lunch at Winslow was the pretty blonde waitress, who had her hair in a pony-tail, that waited on us. Being a thirteen year old twerp who lived some four hundred miles away, I knew my chances of ever seeing her again were pretty slim. Seven years later I would meet another pretty blonde and that one, I married. The second one was worth waiting for. Second leg. Winslow, AZ (INW) to Tucumcari, NM (TCC) Between Winslow and Tucumcari we had to dodge some isolated rain showers along the way. I remember thinking that even though the altimeter showed that we were flying higher than I had ever been before, the ground didn’t seem that far away. After barfing her guts out on the first leg, Mom had settled down and we covered the 402 statute mile distance in just 2 hours and 45 minutes of flying time. I think my memories of this leg must have been obscured by a blonde cloud. Third leg. Tucumcari, NM (TCC) to Tulsa, Ok (TUL) Our final leg for this first day of flying was a 438 mile run up to Tulsa, Oklahoma. We covered this distance in 3 hours and 10 minutes of flying time, bringing our first day total to 9 hours and 5 minutes while covering a distance in excess of 1,282 statute miles. Tulsa was a busy International Airport. We parked the Mooney next to some big brick buildings and hangars. I am guessing that the FBO was probably Tulsair. It was sunny, breezy and loud. What was making it so loud was the 747 that was practicing takeoffs and landings. Boeing had a factory there and we had never even seen a 747 before that. We were awestruck by how big it was and how slow it would appear to fly. It was an amazing sight back then. Aside from the deficit of motion sickness bags in the Mooney, our first day of flying was a great success. We were halfway across the country in just one day. Reaching Philadelphia should be a cinch tomorrow but the weather had other plans for us.3 points

-

3 points

-

Totally agree with you prof EB. Those two risk curves intersect. I think the fact is that an old engine will probably tell you it wants to be overhauled before it goes quietly into the night... if you’re listening. A new engine might suddenly shout stomp and scream like the toddler it is. It probably most depends on whether you have the tools to listen and you know what you’re listening to.3 points

-

3 points

-

3 points

-

Okay...this isn't a tasteless joke...or maybe it is...but it made us chuckle. We recently opened a restaurant and unfortunately we've had issues with transients and drunks sleeping and pissing on our patio at night. The property owner won't let us enclose it, so we bring the cushions inside every night...and the furniture is chained down. That doesn't help with the trash and piss clean-up though...so I added a wifi water valve and a 1/2-inch water pipe cap with holes drilled into it, to narrowly aim pretty aggressive water jets...for washing the furniture at night, of course. This was last night's video. Patio Watering.mp43 points

-

2 points

-

I have a WX-900 and it works great. I fly in/around a lot of terrible weather. It doesn’t paint much because for the most part we don’t fly in weather as bad as we think we do (minus a select few). You also need to use a skin mapper to determine where to mount it so electrical activity on the plane doesn’t interfere with it. Check with a real deal avionics shop.2 points

-

So how did the 2500hr engine look upon disassembly? I’m guessing pretty good if you’re questioning it’s removal from service. I think people tend towards anthropomorphizing engines as though they age like humans. Even though we (I’m guilty as well) know better, we use terms like tired, run out, past its prime, long in the tooth...etc. We know they don’t really age that way. Components that are operated at moderate temperatures while receiving proper lubrication (clean oil, preheated if needed) in environments that don’t foster corrosion should perform consistently for a long time. Performance should not peak and decrease gradually as it does with humans. If compression is good and the valves are opening to spec, an engine will run as strong at 1800hrs as it did 300hrs yet many will suggest it is ready for overhaul just because the numbers fall close to an arbitrary recommended age limit. I get that we need a proxy for powerplant value but I’m speaking strictly about operations. Aircooled, internal combustion engines (in almost any application) can be built to a remarkably consistent standard. However, anecdotally speaking, I sometimes run into one that just seems better than its siblings. It is nuanced but still noticeable. I’ve ridden many of the same make and model motorcycles but one might pull just a touch harder or feel a touch smoother than the others. When I have a powerplant of any kind that is performing optimally, I really try to avoid messing with it.2 points

-

Skip, when I originally installed the led nav lights on my J, my “gear safe” light became dim all the time. The grounding backfeed through the un-powered LEds was not sufficient to give the daytime brightness required. as someone on Mooneyspace recommended, I installed a grounding relay...now it work perfect like original function2 points

-

There is a data- and experience-backed point of view that is an alternative to this. https://blog.aopa.org/aopa/2014/02/11/roots-of-rcm2 points

-

No altitude but you can create a location alert (the destination will be filled in when you create a flight plan).2 points

-

2 points

-

That’s a cylinder issue. Which is an engine accessory. Many cylinders don’t make it to 1000 hrs let alone 3000 hrs. Cylinders should be considered separately. Ask any IO-5X0 owner.2 points

-

Al Mooney’s plane from before that was the culver cadet. It had a cool mechanical device that prevented the throttle from being moved below about 1/3rd with the gear up. When the gear was lowered, the throttle could be pulled to idle. The first one, legend has it, was delivered to orangeburg SC. The factory delivery pilot had some problem with the throttle and couldn’t land. But he figured it out, he pulled the mixture on final. And landed gear up.2 points

-

FWIW, my engine did something similar. Oil analysis showed metal the same time the magnet did, and the local Lycoming rep as well as the guys at AES that had done a recent tear-down on the engine (within the previous two years) both said to just monitor it. It kept running fine and compressions stayed good, and every oil change there was less metal and the oil analysis said things were improving as well. It's been doing that for two years and more than 200 hours, and the last oil analysis said things are back to normal now, and there's not much metal on the magnet to speak of. If you have an engine monitor keep an eye on temps and oil pressure, and just keep an eye on oil analysis and what comes out of the oil filter. If it gets worse, start consulting the Lycoming SI (which quantifies allowable metal in the filter in teaspoons) and qualified engine experts. If it gets better, just keep monitoring. At least, that was the advice I got when mine started doing that.2 points

-

‘94 Annunciators and newer are pretty complex devices... the wiring diagram in the MM looks complicated... +1 for having lights on all the time... -1 for not being able to see the green gear down light on short final... when nav lights are on... and it’s daylight out... and the annunciator panel is far enough to the right.... Best regards, -a-2 points

-

Brave wasn’t exactly what I was thinking, but you’re right, it’s his airplane. Just don’t plant it in a subdivision and give us all a black eye.2 points

-

1/2” to 3/4” seems reasonable if the governor is limiting to 2700 when full in. Some of it depends on the rigging. When the blue knob is in, it may have about a 1/16” to 1/4” gap from the nut (all the knobs are best set with a small gap). This insures that the stop at the governor is setting the limit. Some will rig it different, yielding different movement. What kind of gap do you have full forward? The age of the governor, oil type and temp will also make a difference. I know you weren’t asking, but you have mentioned speed a few times in the thread. As others have suggested, you may want to try 2500RPM cruise and 100ROP if you are trying to maximize speed. (Even at 100ROP you will be More efficient than anything Certified out there for the speed).2 points

-

2 points

-

2 points

-

From Deloitte's website (an example of other website's as well): One of the most important questions that must be addressed is when the cost of private aviation is considered an ordinary and necessary business expense. If business is typically conducted locally, or business travel is between major cities that are regularly served by the major airlines, it may be difficult to justify the cost of private air travel as an ordinary and necessary expense of the business. A better argument exists when the business requires flights to out-of-the-way locations without ready commercial air service, the timing and duration of business flights are unpredictable, or personal security is a significant concern. One of the sometimes (apparently) difficult things to substantiate to the IRS for the use of personal aircraft for business travel was the key phrase "Ordinary and Necessary". With Covid-19, I wonder if it is now "more ordinary" to want to use a personal plane for business travel instead of being so close to other passengers in the closed air system of commercial airplanes? Covid-19 also makes me wonder about the phrase "personal security" as it relates to the risk of being infected by other members of the traveling public - from the large airports and huge amount of personal interaction to sitting on a flight. Any thoughts?1 point

-

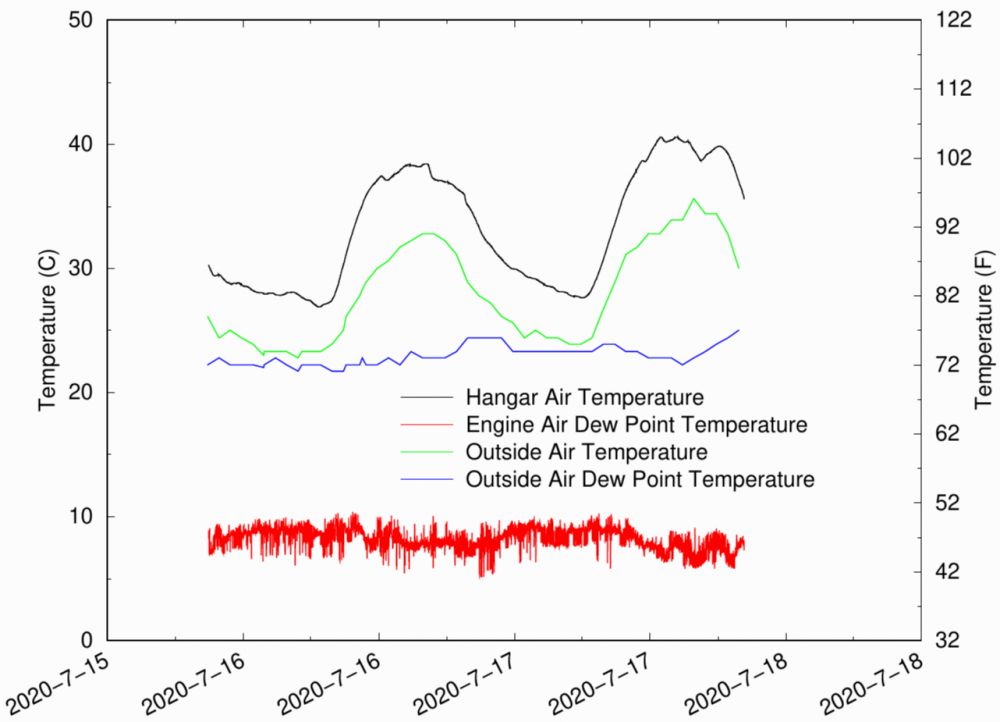

I write to share what I think are results of a pretty cool experiment aimed at preventing engine corrosion in our grounded M20C. Our beloved C is grounded pending piston pin plug replacement on one cylinder. Since buying this aircraft in 2017 I've always flown her for at least an hour every two weeks or so, especially during the steamy parts of the year to keep the oil film on the engine parts and help prevent internal corrosion. Earlier this year increasing amounts of aluminum in the oil filter suggested a possible loose piston pin plug, which was confirmed by endoscopic examination, so we stopped flying in June. Since it is the steamy part of the year here in the deep south U.S., I immediately became concerned about preventing engine corrosion. Searching the internet turned up the most common solution of pumping air through a desiccant and feeding that air into the breather tube. My experience with desiccants in humid environments is that their effectiveness is pretty short lived. And of course there is Camguard(TM) and the like, but I've never been too trusting of magic potions. Call me skeptical. I also see that there is a commercial electric engine air dehumidifier but I have the parts and expertise to design/test a frostless dehumidifier system and have confidence in how it works. My engineer brain kicked in, and I prototyped a closed dehumidifier using a Peltier effect device as an aftercooler. After experimenting with a few configurations, I found a set up that works really well. It consists of a Peltier cooler in a sealed chamber that also contains a piezoelectric positive displacement aquarium air pump that is ridiculously simple and rated at about 10 l/h (~3 gph) flow rate. The intake air to this chamber is filtered using a Fram G-2 just like the one used on Brittain PC vacuum systems. I put an el-cheapo digital temp/r.h. indicator in the cooling chamber just to indicate what's happening in there. I epoxied a type-K thermocouple to the fins of heat sink on the cool side of the Peltier to monitor its temperature. The dehumidified air then passes from the air pump through a hose barb bulkhead fitting and flows into a second measurement chamber that contains a research-grade (Vaisala HMP50) temperature/relative humidity sensor. I also put another el-cheapo digital temp/r.h. sensor in there as an independent check. Testing revealed that the el-cheapo R.H. sensors are qualitatively correct, but not particularly accurate. If they indicate <40% r.h. the dew point is less than 10C at hangar air temps. The air leaves the measurement chamber through a 3/4" hose and flows into the engine breather tube on the aircraft. I sealed off the "ice hole" on the breather tube and unscrewed the dipstick. The slickest part of this system is the programmable controller/data logger. It cycles the Peltier on/off to keep the thermocouple temperature in a range of 11-13C. This prevents icing. I wrote an iterative solver to calculate the dew point temperature from the research-grade r.h. sensor data. If the Peltier temperature exceeds 15C, or if the dew point temperature of the system output air exceeds 15C, the system shuts off the air pump and Peltier, and switches on a red LED on the panel. This puts the system in a safe condition and prevents a failed component from leading to pumping humid air through the engine. That system is now pumping dehumidified air through the engine on a continuous basis, waiting for our date with the repair shop to get 'er fixed. The temperature of the output air is actually a bit warmer than the hangar air because the Peltier doesn't remove much sensible heat, mostly latent heat. Here is a photo of the system in operation, and a data plot showing: (1) horrendous high dew point (humidity) of the ambient air this time of year in Alabama (from ASOS), (2) ridiculous high mid-day hangar air temperatures, (3) nightly low ambient air temperature approaching the ambient air dew point, and (from ASOS), (4) the greatly reduced dew point of the air going into the engine, reduced from 22-24C to below 10C! I over-instrumented the heck out of this thing. The total cost of this system if all parts were bought new would be ridiculous, but I used all surplus measurement/control gear and re-purposed a computer case to serve as a chassis. Oh, and it uses only about 30W of electrical power. A sniff of the air coming out of the dipstick tube confirms flow through the system. A rag around the dipstick opening keeps the bugs out. These things should be common in hyper-humid climates. Engineering rulez.1 point

-

Stormscope picks up the gear motor starting or stopping, or maybe switches making or breaking contact. Same thing with a Bonanza I had and the Stormscope worked great in that.1 point

-

120MPH and then slower (the actual STC I want to say says climb at 135, I find 120 works fine because I am a rebel). All the RayJay really does is give you what you have at 1000’ at FL190. The challenge is the air is much thinner so heat becomes a problem and you have to pitch down to cool down.1 point

-

It does seem odd, but the Lycoming SI criteria for allowable metal in the filter is a lot more than one might think. The Lycoming rep and the local (reputable) engine shop that had torn down my engine not long before I bought it, both had the same advice of, "don't panic, just run it normally and monitor it." These engines are pretty simple, have pretty large clearances, and decent filtering systems, so the accumulated wisdom from experience seems to be that if you keep an eye on it you're likely to either see it sort itself out or let you know well in advance if you need to do something else. I think the key thing is to do a good job of monitoring it.1 point

-

This all sounds like the right calculus. I overhauled an engine at 2500 hours that was running absolutely perfectly. The thinking was that it couldn't keep going forever, and since the plan was to keep flying it for the foreseeable future, an overhaul was the best way to ensure long-term reliability. That said, oil burn and compression have been consistently worse since the overhaul (about 1000 hours ago) and I've wondered many times whether it was the right decision.1 point

-

I am a retired engineer. The vast majority of my career involved controls and automation. In the course of this experience I learned that no matter how many safeguards are put in place, NOTHING substitutes for the human brain. All these bullet proof interlocks, alarms, warnings and safeguards can not substitute for the human brain. Don’t expect all this automation to be a 100% substitute for your own noggin. If you develop a good habit pattern it will go farther than all the automation you can hang on the airplane. Since you’re discussing such automation, I assume that it’s not a Johnson Bar plane. My first Mooney was a Johnson Bar and I would still have it had I not injured my right shoulder. My current plane is electric gear and I felt more confident of not having a gear up in the Johnson Bar plane. I developed a habit of giving the bar several tugs after GUMPS. In the pattern I would tug after turning base again when turning final and still again on short final. When I had to go to the electric gear plane I converted that habit to looking at the light and if possible looking at the gear window. One of the biggest shortcomings of automated systems is lack of need for operator knowledge of the system, but more significantly is complacency developed from dependency on the automated controls. In the case of the gear, there’s is no problem having full understanding of the gear system. The danger is dependency development. I sincerely believe that good habit development will give you a much better chance of escaping a gear up than all the automation you could employ. If you will simply develop the habit of multiple glances after GUMPS and have this burned into your brain it will be better assurance than all the sensors, horns, lights, bells and whistles that you can install without causing the plane to be over gross. My $0.02,1 point

-

What a paint job! Looks like it become an Acclaim as a grown up1 point

-

1 point

-

Howard only had a Masters’ degree from MIT. The rest were PhD’s. My sister and brother in law are both PhD grads from Caltech in the mid 90’s. Her being Canadian, and the brother in law a Princeton undergrad, it was fate that they met at grad school. My sister is very outgoing and more “Street smart”. My brother in law is the book worm, questioning and by the book. to this day, I still swear that Sheldon and Leonard were modelled after my Sis and Bro in Law.1 point

-

1 point

-

Considering how many Boeings are sitting idle these days, it will probably be quite some time before anyone notices they are missing. ;-)1 point

-

26. My mother taught me what an emergency is: "You'll shoot your eye out"1 point

-

Good news! - Mooney's web site is back up. If someone mentioned it earlier I missed it in all the other topics going on here. They might only have a couple guys that can turn wrenches left, but the website looks good Put in your internet orders now.1 point

-

SureFly and harness are on the way to David! Hope to hear in the next couple of weeks she’s purring again... Still doing some IFR training in 3535X for a bit... getting more excited ;o) -Don1 point

-

I'm not sure I'm ready to ride in a quadcopter. They autorotate like a sack of cement.1 point

-

Yes, they have the 870 medical valves. I'll grab some extras for you. As far as regulators go, this is the best deal I found. I wanted a second regulator and found these - this is a quality regulator and the seller has a bunch...it seems like he/she bought out a vendor or something. At the price, I got 2 and they're very nice...especially for $22.50 each. These particular regulators are the 0-15 L/min version https://www.ebay.com/itm/Precision-Medical-Oxygen-Regulator-Hi-Flo-168715D/153933666020?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2057872.m2749.l2649 EDIT - I just picked up 9 cylinders at my local place. I got some Ds, for myself and EricJ, a couple of shorter C (M9), and one tiny B (M6) as an extremely portable back-up. All were $10 each. They must have 100 left, so if anyone else needs me to pick up a few just let me know.1 point

-

Yeah, I understand and can't argue with the logic there. To fully get on-board with the -500, I'll have to get past - in my head - the GPS limitation that isn't present on the -600, as well as a couple other things. On the lighter side, I'm convinced I'll eventually blame you entirely for every upgrade in my cockpit... :-)1 point

-

Airline traffic is coming back slowly, with a bit of a plateau now due to the latest covid news, total domestic passenger counts are now at 25-28% of pre-covid for this time of year. Many airliners have been brought out of storage and are flying again, but many are still parked. Many still flying with empty space but its not as dismal as April.1 point

-

I think I've shared this story before. A couple years ago when I was at the AME for my 3rd Class we were discussing different things. The talk turned to how expensive it is to not only live in Southern California but to do business here. He said that he was talking to his wife about moving someplace with lower taxes, less regulation, etc... Her response to moving was "The hell we are, you make enough money, just pay the taxes."1 point

-

1 point

-

Blue line as mentioned is Best Rate of Climb SE. Vmc (Velocity minimum control) is the airspeed where a twin engine airplane can still "fly" but with full control input to stay in straight ahead flight. No climb, not much control but barely fly. Vmc is lower than Blue line All twins will actually lift off the ground at a speed much less than Vmc If such is done and an engine quits there is not enough rudder power and/or aileron power to prevent the airplane from rolling toward the dead engine clear over on its back and doing a high dive into a smoking hole. Such is the demise of many twins flown by non-current or low trained pilots. It happens all the time. Twins are safe if flown within their performance parameters by competent pilots. Doesn't matter if its a Twin Comanche, MU-2 or 767. They all will fly on one engine WITHIN their design parameters. Some can climb to the mid teens on one engine and some quit at 4000' density altitude. The pilot HAS to know the capability of any twin on one engine to be safe. Blue line gives enough control authority and airspeed to be able to handle any engine failure and continue in controlled flight to go around and complete a safe landing IF below the service ceiling of the one engine performance capability. I was taught and i have taught many to never lift off at Vmc or lower and have no climb until you reach blue line. Anytime you T/O at an airport where you need to lift off and climb below blue line it is a calculated risk that you won't lose and engine until you can accelerate to blue line and above. In the case of lifting off at a slow speed (below Vmc) your ONLY chance if an engine fails is to bring the good engine to idle and land straight ahead PERIOD. There is NO other option when down below Vmc speed. Between Vmc and Blue Line you MIGHT be able to make it if you're real good. Probably not1 point

-

Very true. It's not absolute protection, but it gives you some advantage in litigation to defend it. We got a ® registered trademark on our business logo, but I've seen it copied exactly on some motorcycle gear, on some guy's plasma cutting website, and on some clothing. But who could blame them...it's fun.1 point

-

Bob's daughter Sharon here. My son is the grandson who flew with him to KOSH and the rest of the country in July-August 2019. Thank you for all your kind words -- the "Mooney Family" sure is special! The obituary is posted. We haven't planned the memorial service he deserves due to the covid situation, but wanted to share the obit with you. Hard to condense a life lived to the full. http://www.sossomanfh.com/obituary/9346-robert-cairnes-bob-belville1 point

-

Your original tach was never an approved source for setting the RPM limits either. We're required to use a much more accurate source such as an approved optical tach so that RPM can be set accurately not to exceed redline. You really want to ignore it now because you couldn't tell it was overspeeding before? How much error becomes important? As an example, I just flew with a client who's OEM RPM was reading 120 RPM higher than actual (opposite issue). He wondered why is performance was so far below book. A 50 year old instrument can be pretty far off without getting re-calibrated. Modern engine analyzers give us accurate data, generally at the same accuracy test gauges do. Its a shame not to make use of it.1 point