Leaderboard

Popular Content

Showing content with the highest reputation on 10/15/2019 in all areas

-

5 points

-

5 points

-

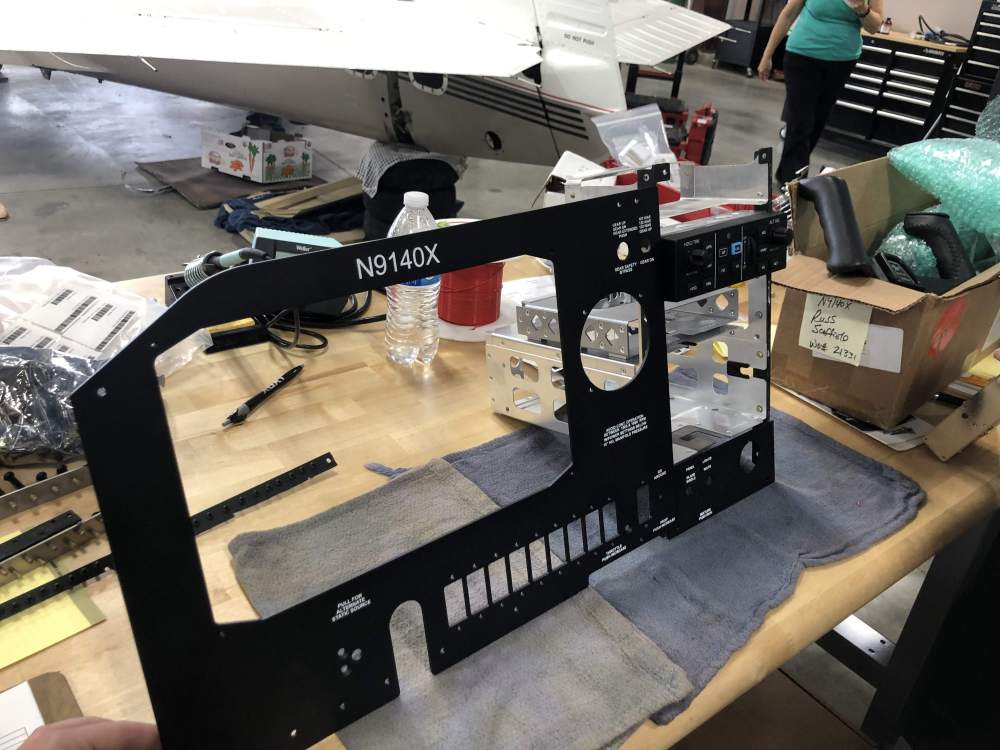

Nothing gets by this crowd There are a couple of velcro strips attached to that ring that I can use to depress and hold the button on my vernier throttle, effectively making it a push/pull throttle. I use that configuration during formation flying. I like the vernier for most operations but when flying formation there is constant throttle adjustment needed to stay in position and the thumb gets tired holding the button down.4 points

-

By Mooney is the best way to get to Kerrville, isn't it???4 points

-

Jonathan, I'm glad everything went well! Please let me know if you need anything else4 points

-

Yeah, I need to buy one of those. This Nissan Altima ain't cutting it.3 points

-

for me, the differences in flying to Aspen in a C or M model is this: owning a C model, I can afford to have a good time in Aspen owning an M model, I sleep in my plane at the airport.2 points

-

2 points

-

+1 for Triad. Solid, experienced engine shop that stands behind their work. I have about 500 hours on the IO360 they “overhauled” and I’m very satisfied. @AGL Aviation sends them a lot of work. Sent from my iPad using Tapatalk2 points

-

If an Exocet hits your Mooney I doubt the Stainless Steel firewall will be of much help.2 points

-

Seth, I met you at Oshkosh. I’m Chucks tall friend. I had Carlus Gann overhaul the engine on the Baron. He will tell you what it costs upfront and how much more it will be if your parts are not useable. He was $28500 for O/H to new limits with new CMI cylinders. Gann Aviation2 points

-

Nice follow-up J0nathan... Nice follow through PearceBK... Best regards, -a-2 points

-

Talk to Poplar Grove Airmotive in Poplar Grove Illinois. C77. VERY knowledgeable and esteemed engine shop. Sent from my Pixel 2 XL using Tapatalk2 points

-

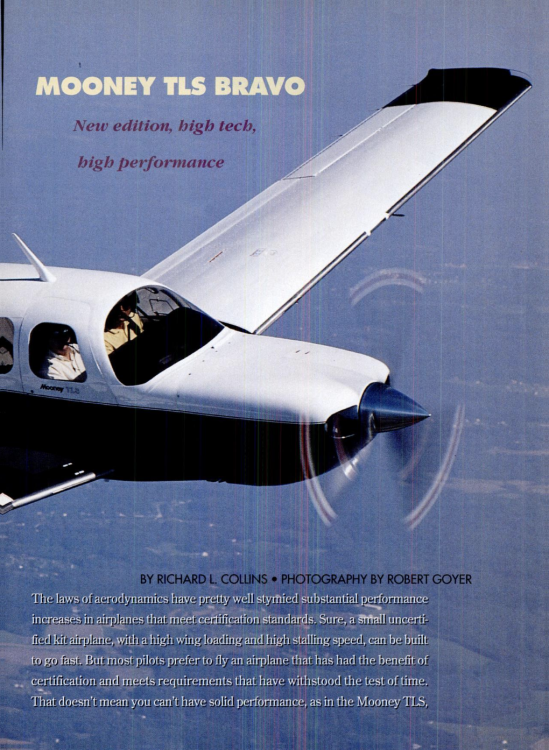

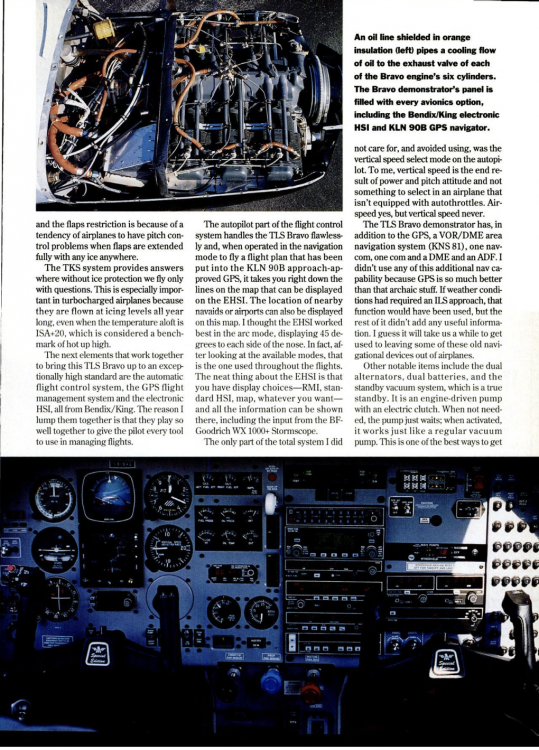

It might be compared to the difference between driving a VW bug and driving a Lincoln Continental. The C grosses out at 2575 while the Bravo grosses out at 3368; a nearly 800 pound difference. The C is light on the controls and can be landed short like a Cessna 150. The Bravo is a lot heavier on the controls, and with experience can be landed short, but not as short as the C. For longer trips over various terrain the Bravo brings more capability and options. Much more can be said, but this is a good start. The above statements come from having done trainings with students in both airplanes and having owned a Bravo for the past 27 years.2 points

-

From what I can gather firesleeve is good to 500F continuous, and SCAT is similar. Even the lowest temp aluminum alloys don't melt until about 900F, and some alloys and pure aluminum are as high as ~1220F. Given that there's some decent mass to that part (i.e., it's not foil or thin material) and it's plugged into a stainless heatsink, I'm having difficulty seeing why the part in question would be an issue, given the general number of other holes in the firewall and the stuff that's usually connected to them. As others have mentioned, I think if you get to the point where that thing melts and creates an issue it's unlikely to add significantly to your problems at hand. But if you really don't like the aluminum one, you can use a plain Bowden clamp: https://www.aircraftspruce.com/catalog/appages/bowdenclamp.php Or put some red rtv on it, supposedly good to 600F, better than firesleeve! Just my dos centavos, ymmv.2 points

-

Generators must be disconnected from the battery when they aren't generating any power. If they didn't have this feature it would rapidly discharge the battery with the engine off. A generator regulator has a contact called the cutout relay that connects the generator to the battery. The adjustment of this contact determines what RPM the generator comes on line at as much as the generator. The cut in is determined by the voltage output of the generator and the spring pressure of the relay. The cut out is determined by a current reversal in the charging circuit. The regulator should be adjusted to come online at the specified voltage. I just did all these adjustments along with the voltage regulator relay and current limit relay on a 1951 Willys jeep. It works way better now! http://www.ruiter.ca/mc/info/PDFs/1R-116.pdf2 points

-

When I purchased my M20C I bought it with the intention to own it temporarily to learn about complex aircraft and ownership in general. I always planned on selling towards the end of summer 2019, and since flying in the winter in the northeast sucks, purchase another aircraft in the spring of 2020. I must say that my family and I had a blast in the Mooney. It was always reliable, stable and fun. We've traveled thousands of miles and visited multiple states. Our plan now, though, is to purchase an aircraft to fit and last our family for at least 15 years. I really want to stick with Lycoming for the engine and will be looking at Piper Comanche's and Cessna R182's. I recently went through the selling process of aircraft ownership and much prefer the purchasing side of things. Some airworthy items came up during the sale and without the help of @orionflt and @Alan Fox would not have been sold. By selling an airplane I have learned more about buying one then when you buy one. Again, I want to give a big thanks to Brian Nelson for his help and professionalism and to Alan Fox for his recommendations and ideas. Here is the kids last flight in the Mooney...1 point

-

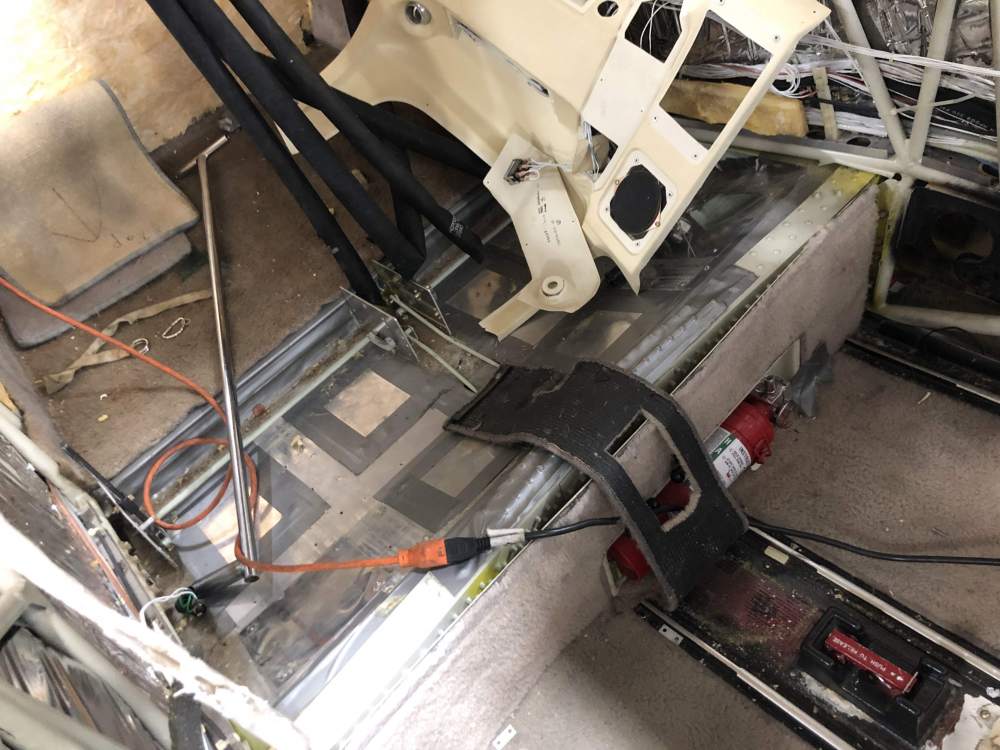

When I bought my plane, I took it to a place with what I thought had a good reputation. I told them "leave no stone unturned". Basically gave them an open checkbook. I've detailed here before the shoddy work done (if it was done at all). Today, I found more. They logged in my books (and charged me for) shimming the engine up. I've noticed recently that it seemed to be sagging more. I looked through the logs and couldn't find that new engine mounts had been installed since overhaul in 1989. Sorta surprised they didn't change them when they had the engine off for what was basically an IRAN in 2012, but whatever. They did note it was shimmed when reinstalled. Since it was shimmed in 2012 and ostensibly again in September 2017, I figured it was time to go ahead and replace the mounts. Well, I seriously have my doubts that they were shimmed in 2017. Why? Well, first of all, there was only one 1/16" shim on each lower mount. Further they were full shims, only able to be installed by completely removing the engine mounts. If you've ever done the lower mounts on a Mooney C model, you know how much work it is. If 2 years ago they removed the mounts entirely, when they had an open checkbook, why would they reinstall mounts with a cure date of 5/1988..... 31 years old. And, in my estimation, there's not a chance in heck they looked fine then and look like this now....... Both lower mounts looked like that. At any rate, I'm really happy it's done, and my spinner lines up great now!1 point

-

And this is one of those "never thought about it" things for me. Thanks!1 point

-

Yes, but many folks don't believe they're getting a good quality product unless they pay top dollar. Some think that only the factory knows how to overhaul their engines. The scope, details, and instructions for an engine overhaul are all dictated by the manufacturer. Any shop that has a repair station certificate or that does enough overhauls to warrant oversight by the FAA will be following the manufacturer's instructions to the letter. Extras such as "blue printing" or "port and polishing" or stuff like that might be shop dependent. I would ask your installer who they recommend. They'll know which engine shops are decent, responsive, and have good customer service. They'll also know how to keep shipping costs under control because they've worked with them before.1 point

-

Just out of curiosity, I was wondering if you considered Penn Yan or Zephyr? I have a Penn Yan overhaul on my Saratoga that was done for the previous owner back in 2001, and the thing runs like a top after 1700 hrs. I know from when I was looking at potentially overhauling the engine in my bravo ( went with a factory reman for a number of reasons that were unique to my situation) that Penn Yan has a better than most warranty which is three years versus two. I know numerous people that have had excellent experiences with Zephyr, and as I write this I cannot think of any folks that I know that had work done by Zephyr that had a bad experience. I understand they really stand behind their work no matter what.1 point

-

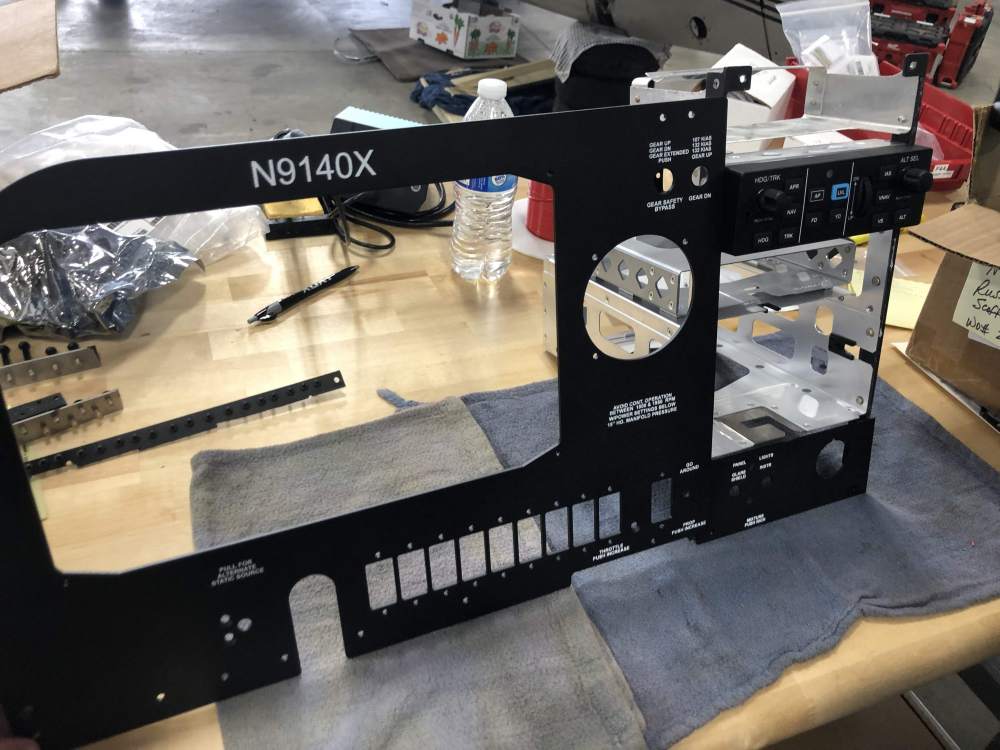

The JPI and the G5 are almost the same size, the only difference the G5 being square and the JPI being rectangular. By nipping off one side of the JPI bracket, it holds the G5 securely with mounting screws on three sides. It was easier than making a bracket in the shop as Garmin didn't offer a flush mount kit when I installed mine. They do now. Both instruments also have a 3" round section on the back which is how the bracket holds the instrument. Those are exactly the same. I think Crystal Avionics did a great job on my panel and the flush mount instruments look so much better than surface mount.1 point

-

There is a remarkable about of downplaying the seriousness of a firewall and the penetrations through it. For starters, check your sources, a TSO C53a hose, the kind that carries fuel, must withstand a 5 minute direct application of a 2000F flame 5 inches away for 5 minutes. The firewall and all fittings are rated for 20 minutes of something similar. Now, like I said, older airplanes are what they are, copper tubing or TSO hoses behind the panel for fuel and oil, no shoulder harnesses, single vacuum pump with a lazy turn and bank indicator for the backup. You upograde them to newer standards when you can. But the justification for adding an uncertified fitting in a safety-related function becuause its "easy" or "looks spiff" is inexcusable. The rules are there for safety, and once you know about it, you know. A grommet with some Permatex red silicone will burn through in less than a minute. This fitting is good for a couple minutes longer. Usually you are more than one minute away from a suitable landing site. Its your plane, but your passengers donrt get to make the same deliberate decision to, or not to, compromise their airplane. from: https://www.aopa.org/news-and-media/all-news/2006/january/01/airframe-and-powerplant What's the difference between fire-resistant and non-fire-resistant hoses? A fire sleeve. There are two types of fire sleeves — the slip-on and the molded-on, or integral. The minute a woven fiberglass slip-on fire sleeve is properly installed over a rubber tube or Teflon tube hose, that assembly becomes fire resistant. Slip-on fire sleeving has a bright-orange exterior while the integral sleeving is colored a rust brown. TSO C53a requires that fire-resistant hose assemblies be able to withstand a 2,000-degree Fahrenheit flame applied from one-quarter inch away for 5 minutes.1 point

-

Same here. I tried one of those on my A3B6D and couldn't find a way to make it work. Now I just use the "let it sit overnight" method before removing the filter, and it's empty when I take it off. I find that much easier.1 point

-

Nice work BK, we’re paying attention to this kind of customer service!1 point

-

1 point

-

You can believe whatever you would like, but I lived about 40 miles from the factory back in those years (20 miles from it now) and was completely aware of what was and was not available. Had you owned an M20M back then you would know that you could not do anything regarding an AF1B before January 31, 1996 when the service letter came out. This engine was modified for one model airplane on the planet, an M20M. The reasons are explained in the article below. The Chronology pdf, which was written by Mooney Mod Squad in Sarasota FL, which is no longer in business, shows an optional AF1B on 1994 an on models, but plain and simply it is wrong. It may list it that way because those owners had theirs converted to a Bravo from '96 on. You can believe whatever you'd like, but on my life I swear it was not available then. Serial number 209 was the first one converted in early 1996. From that point on all new production had the AF1B engine. Since the price to convert was relatively cheap ($5500 including parts and 6 new cylinders and Lycoming covered 42 hours of labor) almost all TLS owners went back and converted their TLS to a Bravo.1 point

-

Piper Cherokee 140. They are super cheap and easy trainers. The flight schools haven't driven the values up like on the 172's/182's. The last thing they should do is buy a plane for the long haul. Get one cheap to train in and then sell it to get something better... maybe a Mooney.1 point

-

You must not have read the emails that say all Florida Mooney's are junk....1 point

-

I love flying at night, but I won't fly over the open desert here at night, no visual references. Maybe @Raptor05121 can chime in. If I recall Alex did a lot of night flying as that was about the only time he could get in because of his work schedule.1 point

-

You are correct, it can be a Pandora’s box. Owners/sellers of geared up planes will of course tell you it’s a non issue, it has been repaired and documented properly, bla bla bla. The decision has to be made by you the buyer and the question boils down to this: do you really want to pay for an airplane that has DH? Irrespective of the price. It will always be in your mind every time you fly the thing. It is also the one thing that negatively affects its value and you can do nothing about. Like location location location in real estate. My personal opinion: I’d never even look at a geared up plane. There are plenty of NDH candidates. No matter what anyone wants you to believe.1 point

-

My wife and I decided on Sevierville TN, and are building a hangar on the airport there (KGKT). Lots of housing choices within 5-10 minutes of the airport to suit just about every budget. Moderate climate in the Smokey Mountains, although possibly a bit on the warm/moist side in summer. As long as you don't need an ocean beach at hand and you're not a big city person its a pretty good choice. Bonus is all of our kids already like to vacation there so they will have a free place to stay and we'll get to see the grandkids regularly! Cheers, Rick1 point

-

My point exactly. There are definitely real short fields where conditions mean doing a real short field landing, including dumping flaps to remove the last vestige of lift to increase breaking power. Landing on 26 at your home airport, I'd probably do the same to be sure I avoided the nasty overrun. I doubt that's typical of light piston pilots generally. This group might be unusual, but I know a lot of pilots who think anything less than 3,000' at sea level requires a short field landing with all the trimmings. Kind of reminds me of the time I wanted to take a rental into a grass strip. It was the only rental FBO in my area which permitted it and it required a ground checkout by the chief instructor. It would be my first time landing on grass. Asked for description of how I would land, I innocently said, I would use my best soft-field landing technique. His response was priceless, "If you need to do a soft field landing, we don't want you flying there."1 point

-

I never argue with anyone who wants to do it, unless I am in the airplane giving instruction. Your flight, your risk, your choice. My only view on the subject is that, while the risk of inadvertently raising the gear may be minimal, retracting flaps on rollout is unnecessary. So I don't. BTW, one of those three I know personally where the squat switch didn't help. There's a 4th on a touch & go. Not the Mooney vertical separation, but also where the separation of gear and flaps has convinced many that there's "no danger" of inadvertently raising the gear instead of the flaps (similar to,"Ill never forget to put the gear down because...)1 point

-

All flood batteries also have internal resistance. They will go dead if let to sit on their own. -Robert1 point

-

Quick update to this, on a recommendation of a paint shop (and others here) I went to Finishmasters and had them match the color. The store down here also carries Axalta AF-400 which is a very common aviation grade paint (not cheap unfortunately). I need to mix it with an activator that paint shop was kind enough to provide free of charge since Finishmasters only sells it in gallons for $325. I’m going to get a small sprayer and hopefully paint the leading edge soon.1 point

-

on my 75 the codes were in the manual. The paint shop I took the codes to gave me a deer in the headlights look. i even asked to check their books. Nada nothing. no cross match that I could find. Realizing the interior was done in antique moss.... a color that should never had seen the light of day.1 point

-

Ok guys - here's the re-installation of the screen - minus the R-rated segment of re-safetying where we hear some unknown and colorful phrases. Just fyi, the screen came out clean. 34399758_585924511794568_5701013011729219584_n.mp41 point

.thumb.jpg.dd6f0dd6af1fd870a32b41f8f62b2916.jpg)