Leaderboard

Popular Content

Showing content with the highest reputation on 09/03/2019 in all areas

-

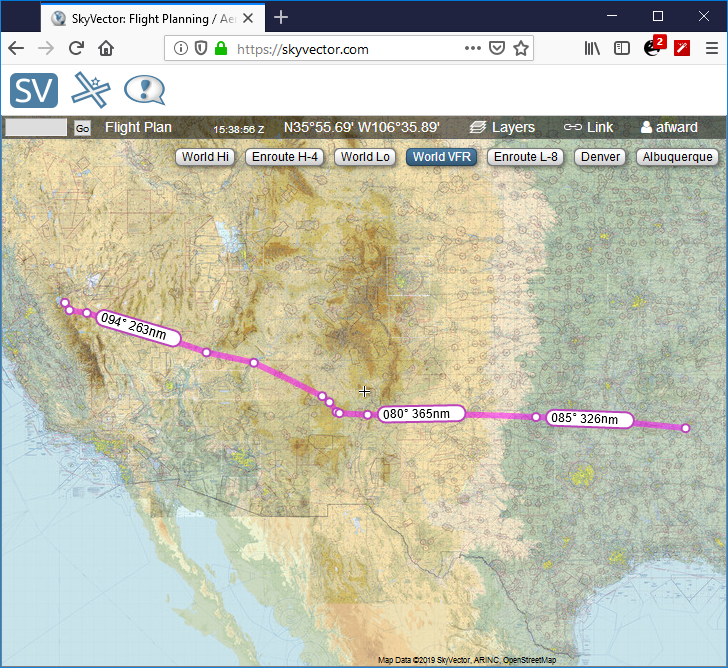

Can it be "Yesterday's Flight"? My CFI and I flew my new plane home yesterday: We stopped for fuel in KPGA and KHBR, deviated around buildups just west of ABQ, and spent a good bit of time riding the mid-day bumps over NM and TX. Wheels up in NV at 7am local, tied down in AR at 9:15pm local. It'll be quite some time before I fly that much in one day again... I got pictures en route to KPGA, but threw my phone in the back seat when we got ready to leave Page and I forgot to take any more pictures. Ah well, here are a couple I did get: And of course, the obligatory picture of the plane in Page:7 points

-

5 points

-

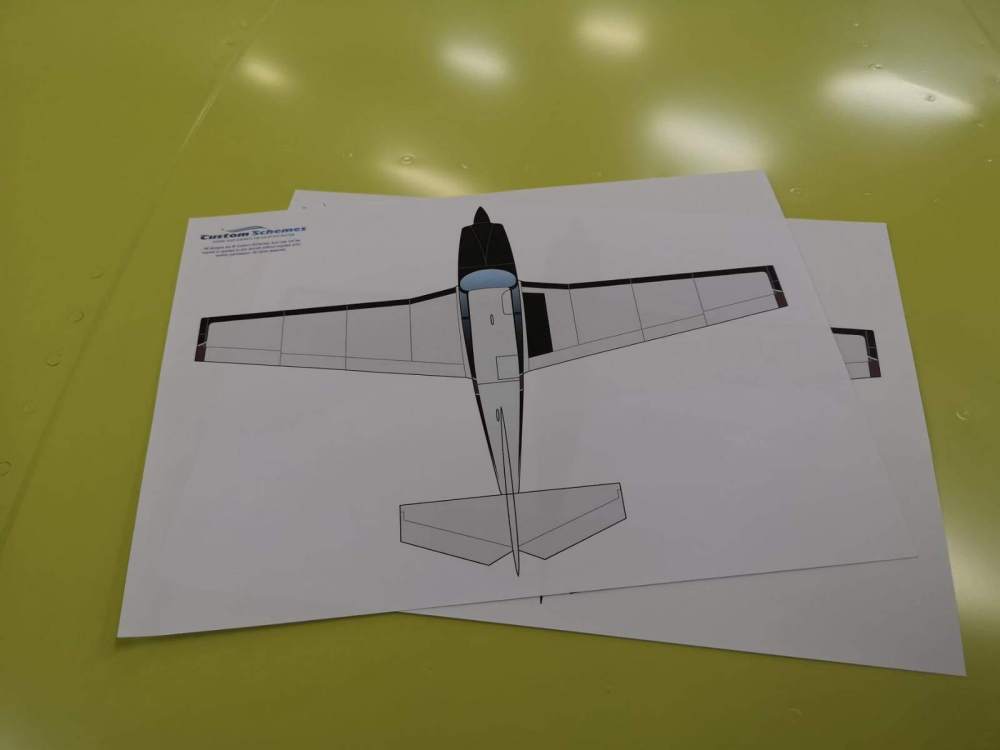

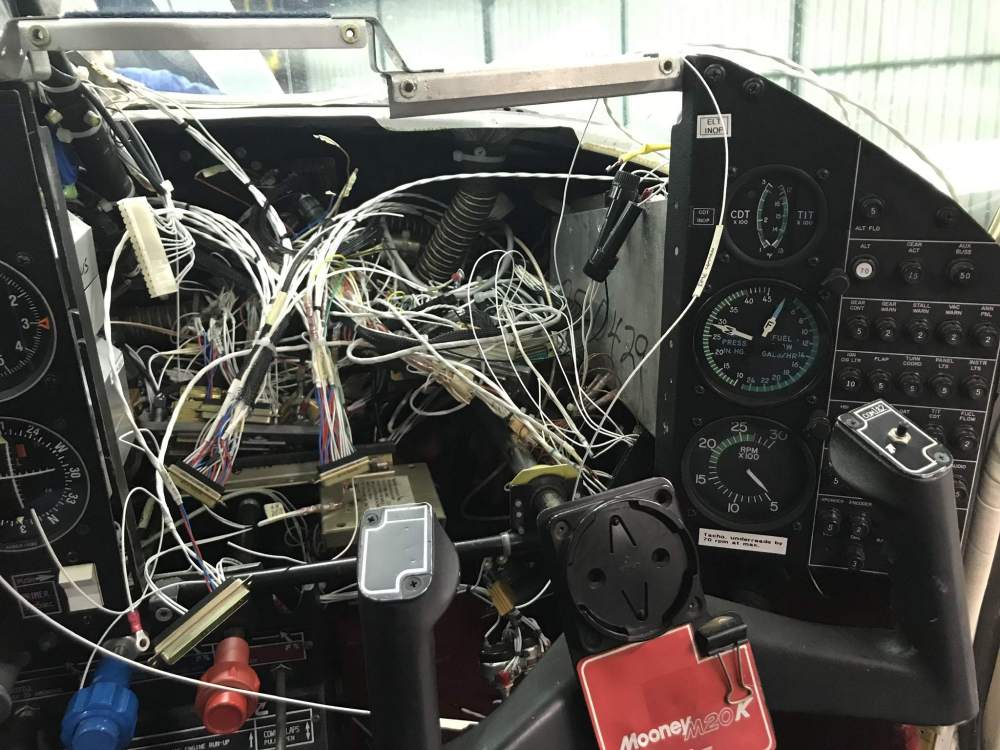

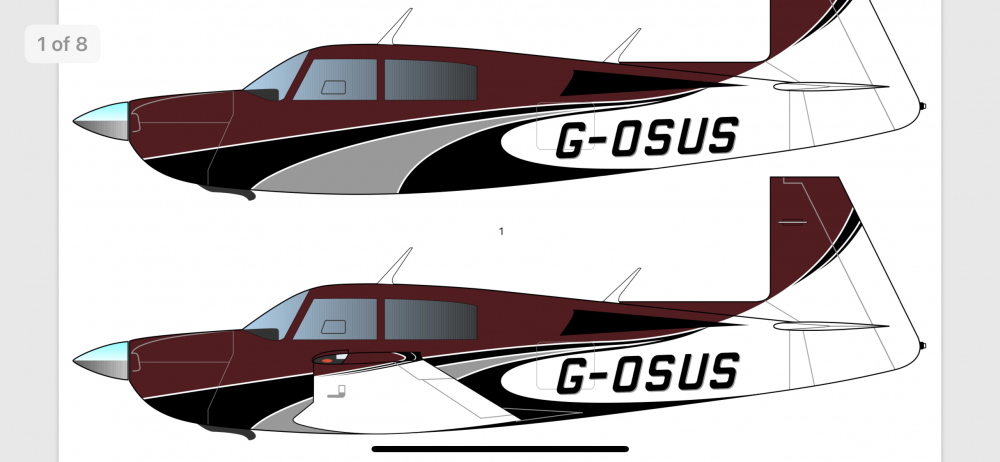

So much flying in the last month I haven’t been able to post on this thread. Oshkosh was a blast and look forward to next year! I went up this morning for a short flight to warm up the oil and decided to check out a close by short airport. I didn’t plan on landing but once I flew over it I figured it was doable. It’s now the shortest and narrowest airport in my log book. And probably as back country and tinny airport I’ll ever land at in the Mooney. My wing span being just over 6’ wider than the runway. Landing on 32 you are landing a little up hill but into rising no go around terrain. Another first for me in this plane. Exciting times, now to finish the dirty work.... Sent from my iPhone using Tapatalk4 points

-

After I made my first aircraft purchase this year I knew the first thing I wanted to install was a good engine analyzer. I installed an EDM 900 and it really is fantastic. To fantastic in fact. The old analog gauges did their job but now I get to see every little nuance that has probably been with the aircraft for years! My prop speed goes to about 2708-2712 on takeoff, my oil pressure is little low, my oil temp a little high, one cylinder's CHT is probably a little high and another is probably a little low, amps need to be adjusted a little so they don’t read -2 and start flashing at me, etc… I get to see it all in real time and then I get to review a recording of it! To make matters worse (or better depending on your point of view) I have paid a guy to nit-pick every parameter so he sends me an analysis of my engine data every once in a while to let me know how my engine is performing compared to others out there (or under-performing ) . Anyone else find this true after installing a digital analyzer? Note-to-self: quit obsessing over engine data and go fly the damn airplane! All of this is good and I would never go back, but sometimes more detail is not what I need in life…3 points

-

I flew a rather interesting SID and VOR DME approach the other day. Lots of arcs and a circle to land from 15 to 33.. Hope you enjoy.2 points

-

I have heard some discussion regarding the advantages or disadvantages of the retractable step. While most will agree it is cool, some disagree as to the advantages. In a recent Facebook post I saw that someone had their vacuum system removed and has the step hanging out without detrimental effect. Before the electric step conversion, I had left my step hanging (original crank equipped aircraft) by accident and recalled noticing because my speeds were lower and the ball was slightly out. Anyway, decided to do some testing on a short trip yesterday and verified that it does make a difference. In fact, it was quite notable when paying attention to the numbers. I’ll call it an average of about 3 knots. I repeated putting the step up and down a few times and it was consistent. I made a rather crude video for those who must see: https://youtu.be/zOD2mXwcOIk. There are two reasons for the significant speed change. One is obvious, it is that the retractable step has zero aerodynamic abilities. It is a large square tube with an equally blunt step. The second is less obvious, but it is the effect of asymmetric drag on the airframe. Those who have left the step out may note that the ball on your turn coordinator will be ever so slightly out of center, requiring a touch of left rudder to counter it. Just like slipping a plane on final induces drag and gets us slower and lower, this slight slip slows our aircraft down. What percent of the drag is due to the step drag vs slip I’m not sure, but it clearly adds up. Mooney’s are especially sensitive to good rigging, as noted by some wide variation in reported performance. Modern Mooney’s have a more aerodynamic step, so Mooney opted out of the retractable step business in the late 60s. I think it would still be cool to have it retract, but it might be somewhat invasive. Anyway, would love to hear from others with detailed side by side speed comparisons of step up or down or on or off. While I am on the taller side, I still appreciate the step and I know my pax do as well.2 points

-

A friend put an engine analyzer in his antique taildragger. Now he has all kinds of problems with the engine that's been running in that thing since the 1940's.2 points

-

2 points

-

In 2017: As a seller I was fine with moving my plane to a reputable Mooney specialist selected by the buyer—so long as a pro pilot flew the plane there and the buyer paid expenses if he didn’t buy. The plane was in Minnesota. I agreed to the move to Texas for the inspection. The deal closed ok. As a buyer I insisted on a pre-buy with a nationally recognized expert mechanic so the seller flew his plane from the east coast to Kansas. It would have been at my expense if the deal failed. It went through. So, yes, you can move the plane to your designated inspection site. Some sellers are comfortable with the idea. Others are not.2 points

-

Just to add a bit more info to the pile... I asked a few questions on Beechtalk and got some answers from a very knowledgeable person. Here is his bottom line: "If your flying in the US, there are a handful of SIDs that require RNP 1. SIDs that utilize RF legs are designated as requiring RNP 1. I only know of one such SID in the US at Atlanta (ZELAN4) and it is Turbojet only, but there may be more. If your aircraft is not approved for RF legs, you won't encounter a need for O2. I recommend coding B2, C2, and D2, but as a practical matter D2 would suffice. There is no use in the US for specifying S1, S2, or Z and NAV/SBAS. It won't do anything other than make your flight plan longer. ERAM will ignore SBAS and S1/S2. Also ERAM does not need to have any mode S designation for the transponder and C will work in all cases." I then posed the question about what I should file if my airplane WAS approved for RF legs (GTN650 + GFC500). Here is his response: "It is eligible for O2, as is my GTN750/G500TXi, but I don't waste my time adding it." By the way, I had to look up what ERAM is. It's The En Route Automation Modernization. That's the program that assigns your route of flight after you file your flightplan.2 points

-

Left mine out on one flight, I noticed I was a few miles an hour slow. Of course that's nothing compared to my flight yesterday where I left the gear down for a bit. Gee, I wonder why I'm only going 100 miles an hour? Not my proudest day yesterday.2 points

-

The best Article I've read on assertively interacting with ATC, by Mike Bush is below. After reading it, now what would you do again in the same circumstance? Let's Make a Deal.pdf2 points

-

Dev - I think there might be too much thinking going on about her intention. If you listen to the entire audio clip you provided, you hear her give a Trenton tower instruction to a plane she already gave the instruction to and then tries to give it again and even switches to a backup radio because she was convinced they didn’t get the instruction. I think what she intended to give you was a “intercept the final approach course” probably because she thought you were close to a direct course to PACKS. And instead of saying that, she told you to proceed direct to PACKS. What was your needle deflection when she issued the clearance? It’s hard to determine from your overly large airplane on the chart. The scaling of the GPS CDI will change depending on the segment. If you were within a half CDI deflection of the leg between KEHSO & PACKS, and given the “Direct to PACKS”, I would have considered myself “established” and begun descending to the 1400’ altitude for the leg to PACKS while maneuvering to stay close to the published leg. I’m sure that was her intention. Having flown into Philly satellite airports for years, I’ve learned to expect the unexpected. The radio is your friend... Sent from my iPad using Tapatalk Pro2 points

-

Hi Everyone, Mark had his autograft surgery this afternoon and it went well. They put it on his left torso to fill the gap where he needed it. They prioritized his surgery for today and postponed his esophagheal cardiac assessment to tomorrow. They want to make sure he doesn't have enough of concern such as a blood clot. Whatever the results, given his heart arrhythmia, they will do an ablation to address it. From here on out, Mark needs to heal, both the donor site where they took the autograft from, the autograft itself, and continued healing and growth of his CEAs and prior autografts. It takes CEAs 30 days to grow to join together to create an entire section of skin. The hope will be by Sept 12th, when a new batch of CEAs arrive, that his arms in particular will be mostly covered with new skin grown from CEAs. I've been reading Tina Fey's Bossypants book to Mark. There are some real laugh out loud sections that would make him chuckle. He's been looking relaxed most of today so we've been playing quieter music - classical and meditation tunes.2 points

-

1 point

-

I am, it looks like oil, it feels like oil, it smells like oil. I dump it in the engine and the engine keeps running! A lot of people think there is something mystical about engine oil, but in reality they knew 99% of what there is to know about engine oil in the 1920s. Most of the additives they put in these days were known then, but they choose additives that worked better, unfortunately some of the best additives are a bit toxic, so these days they have to use the second tier stuff because it is all they can get away with. The bottom line is making a good engine oil is old technology and anybody that wants to make a high quality product, can.1 point

-

Top of the yellow arc is pretty common for me on the ground at low idle. Having it drop out of the green at any other time would indeed be alarming, so I’d want the alarm to stay. This is where the flashing red warning of the digital instrument could be a lifesaver.1 point

-

When I spoke to them about their website a few weeks ago, the person on the phone snorted derisively and said they forgot to include the storefront on the first release. I love Agile projects....1 point

-

I went through the same frustration 4 years ago when I got my EDM900. The early obsession is a good thing and part of the learning process. Switching alarm settings in the device can help. The brain also automatically develops a filter for the TMI stuff it does, and it becomes less of a distraction over time - you simply readjust what you see as normal vs. concerning. It is worth poring over your downloaded data early on and understanding what it shows. Paying for analysis is one good way to learn the types of information that are inherent in the data and learning how to look at the data on your own. Also, if you look at paid analysis carefully and ask some questions, you will find that the data is easy to overinterpret - the service sometimes ascribes potential problems to features of the data that can have other, more benign interpretations. Thinking through these limitations is another part of the learning process. Despite this learning curve, the monitor really shines is in helping narrow down the problem when something is going wrong. At these moments, it is worth its weight in gold for safety and peace of mind. And the diagnostic efficiency it offers will ultimately offset the cost.1 point

-

I was able to remove my Ki256 with oversight from my local A&P. The glareshield will most likely need to be removed. The input and output of the vacuum will need to be removed and the electrical vacuum switch will need to be removed. Also, my Ki256 had a backing plate that will fall if you were able to disconnect everything and remove the insturment.1 point

-

I just got off the phone with Jeppesen. They said "Don't use the website, we are having issues"1 point

-

1 point

-

Interesting topic. When I first got my instrument rating I felt like what ATC told me to do was an order and it was my responsibility to follow it exactly. Over time, I’ve come to realize that ATC instructions are offers which you can accept or reject. In fact, as PIC you have not only the option but the responsibility to reject ATC instructions which jeopardize the safety of flight. Ive had several instances where doing what ATC told me to do would have potentially harmed myself or someone else. Realistically, I think about 99.5% of what ATC tells me to do I agree with, but part of your responsibility is to find that 0.5% that is unsafe and call them on it. From the comfort of my couch, here is what I might have done: ATC: Fly direct PACKS, maintain 3000 until established, clear RNAV (although they should have included a distance to the fix). ME: Unable. That would not put me in a position to make a stabilized approach and landing. I would like to vectors to the final approach course. Would it have worked? I don’t know. Bottom line is that if you don’t feel it’s safe, you don’t have to do it. I have found > 99% of air traffic controllers to be professional and reasonable so I think the odds are in your favor. We’re all human and make mistakes but fortunately we have the same goal when it comes to arriving safely so it should be rare that you can’t work something out. Thank you for sharing your experience.1 point

-

1 point

-

1 point

-

Actually I did see a huge improvement with the increased fuel flow. CHT's went down by 20 to 30 degrees. That allowed me to install a Electroair ignition without seeing an increase in CHTs.1 point

-

Hey, @M20Doc (and anyone else interested in the Lycoming Valve Guide "Wobble Test"... I read SB 388C, the Lycoming 400 hr "Wobble Test" service bulletin very closely as I was planning on buying the test rig when I discovered this statement: "400 hour intervals or earlier if valve sticking suspected until exhaust valve guides are replaced with guides made of improved material. (Refer to latest revision of Service Instruction No. 1485.)" I then looked up Service Instruction No. 1485. It says: "TIME OF COMPLIANCE: Half way to recommended TBO or at 1000 hours of operation, whichever occurs first or earlier at owner’s discretion or anytime valve sticking is suspected. \As a product improvement, Lycoming has introduced a new exhaust valve guide material with an increased chrome content for improved wear characteristics. The incorporation of this guide material has significantly reduced the amount of valve guide wear (bell-mouthing) seen by some operators of Lycoming engines. Improved exhaust valve guides were initially incorporated into some cylinder assemblies beginning in April 1996. Since March 1, 1998, all engines, cylinder kits and spare exhaust valve guides shipped from Lycoming contain the improved material. Cylinder assemblies which incorporated the improved “Hi-Chrome” exhaust valve guides when the engine was shipped from Lycoming are identifiable by the letter “C” stamped inside a circle on the boss for the drain back fitting. The individual guides made with the improved material can be identified by a 5° chamfer at the top of the guide (See Figure 1)." So, for those who are interested, it appears that if your cylinder assembly is newer than 1998 and the guides are therefore the improved ones, the "Wobble Test" is recommended every 1000 hrs instead of every 400 hrs.... Alex1 point

-

Shhhh... I was trying a new “strategy” as he said ... his slower airplane with bad leg room is clearly better. And history of any problems was the pilots’ fault. He’s better looking and smarter too. I’m selling my mooney to buy a beech.1 point

-

1 point

-

Myth: It’s the Pilot’s fault. All of these airframe failures were the fault of the Pilot who was invariably a Doctor. Reality: Error prone Pilots must have only flown the V-tail model and not the straight tail model. Again, the facts from the report: The Problem The statistics leave little doubt that the V-tail Bonanzas have a safety problem not shared by their straight-tail counterparts. Over the years there have been more than 200 fatal in-flight breakups in V-tails (as of 1978). There has been just one in a straight-tail Bonanza. The Aviation Consumer's 1979 study of in-flight breakups during the years 1964-77 showed the V-tail to have a rate of 0.65 breakups per 100,000 flight hours, compared to just 0.03 for the straight-tail 33 and 36 models combined. Early in 1979 the FAA released a study of aircraft dynamic characteris tics. This study (see The Aviation Con sumer, May 15, 1979) took particular interest in the in-flight failure rate of the Bonanza. Over a 10-year period the FAA report noted that “the Beech 35’s in-flight airframe failure accident rate, at 0.779 per 100,000 hours, is 20 times that of its straight-tailed compa nion and, in fact, is exceeded only by a few aircraft with substantially less exposure ... In May 1979 the NTSB released its own study of general aviation accidents (report No. NTSB-AAS-79-1). Even though they did not separate V-tail from straight-tail Bonanzas, they found their combined in-flight failure rate to be “considerably higher than the mean rate of the selected aircraft group” for the five-year period studied. NTSB then commented, “It is significant that all 40 of the in-flight airframe failures of the Beech 33/35/36 involved the V-tailed models (Beech 35). Obviously attention should be focused on this model.” Three studies—an NTSB study of five years of data, an FAA study of 10 years, and an Aviation Consumer study of 14 years of accident data—have all shown the same fact. Yet this is not the first time in the history of the Bonanza that this failure pattern has been observed. The evidence suggests that both Beech and the FAA have studied it extensively over the years and should have long been aware of the problem. Chinese Water Torture The first in-flight failure of a Bonanza occurred in 1946. During a dive test, an experimental prototype, serial number D-4, disintegrated. The observer parachuted to safety, but the pilot was killed. In the years since, there have been fatal in-flight airframe failures in every year for which data are available. As of 1978, the total of known in-flight failures of V-tail Bonanzas was 208. There was one straight-tail failure. We do not know how many people died in these 208 accidents. However, if a sample of recent data is represen tative, there have been about 2Vi deaths per in-flight failure. We estimate approximately 500 deaths in Bonanza in-flight breakups. Thus, probably twice as many people died in V-tail structural failures as in the worst U.S. air disaster in history, last year’s American DC-10 crash in Chicago. Like Chinese water torture, the bad news has trickled in over the years. Bad years, like 1953 with 14 accidents, were sometimes followed by relatively good years, such as 1954 with three ac cidents. Such swings must have en couraged apprehensive Beech designers. They were not idle. Beech made several significant structural changes to the Bonanza design as they tried to chase the gremlins out of the wing, the fuselage, the tail. The external posture Beech adopted (and to a large extent, their internal one also) was that these accidents were due to pilot error, pure and simple. Meanwhile, Beech kept beefing up the airplane, but they did little for Bonan zas already in the field as they strengthened subsequent models. My comments: There was a program to modify the original 35 with structural improvements to correct design issues that Beech discovered. These aircraft were re-designated as Model 35R. I believe that there were 13 of them. None of the improved aircraft experienced an inflight airframe failure. If the airplane is up to specification (something that needs to be regularly checked and maintained) and is operated within it’s limitations, it should be perfectly fine. The problem is that so many of the airplanes have been found to be out of spec over the years and that is where you are exposed to having an issue. Ruddervators that are out of balance or become out of balance, control and trim cable tensions that are not correct, fuselage rear bulkhead cracks, fuselage skin that is no longer as thick as it used to be or is supposed to be, etc. This is what you are dealing with. No, Beechcraft did not foresee the effects of twisting loads being placed on the tail spars and that is why the tail cuffs came into being. All the concerns about the center section and wing spar cracks were probably overblown because the wings typically failed outboard of the landing gear mounts and landing light location, WS 66, where there was no spar web until the later, beefed up models. I read somewhere that Ralph Harmon, who was involved in the design of the V-tail, was also responsible for metalizing the Mooney. He wanted to make sure that the Mooney was overbuilt (built right) and not something that JUST made Certification standards.1 point

-

I actually like the slotted ones. They are a nuisance to keep from scratching the paint, but I like to be able to look at the cowling and know that if all the slots are running the same direction, they are all latched.1 point

-

Remember, though, it's a dry heat...so, a gazillion only feels like a bazillion1 point

-

This is one pretty plane! I love the checker board tail and matching MT prop. Also, the TKS is a great addition.1 point

-

Seems EMB Joined November 8, 2010 and aviatoreb Joined March 14, 2011 I guess somehow you lost your cookie for aviatoreb on your desktop (browser upgrade? New/different browser? Cookie cleanup?) which forced a logon, and when you couldn't recall the password, the system created a new password and sent you a link for the first account it could find with that email address, which happened to be EMB. However, as your phone still had a valid cookie, that stayed logged on as aviatoreb I suppose the board could only allow one user per e-mail address, but there are cases when that is a valid situation, but in the case where there is more than one user name associated with an e-mail address, it should probably ask which one you want reset when requesting a new password. You might be able to delete your own EMB account, or you might have to drop Craig a note requesting deletion1 point

-

1 point

-

Just to follow up on the outcome, the shop installed the new pressure transducer (EI PT-100GA). Now the indicated fuel pressures are back up to 26-27 psi with the engine pump, and 29-30 psi with the electric pump. Total cost was $180 for the transducer and 1.5 hours of shop time. The mechanic thanked everyone on MS, he said he somehow got it in his head that the Lycoming pump normally put out 14 psi, so he was initially doubtful that was the problem. Getting feedback from everyone that the pressure should be higher prompted him to double-check the specs before doing anything else.1 point

-

The inspector and industrial are the ones to look at for in the cockpit use. The industrial pro has added features that we don't really need. The Industrial includes the vibratory alarm and the inspector doesn't. This is handy if you plan to wear it from airplane to airplane. If you are looking to Velcro to the panel someplace the inspector should be perfect. Sensorcon recommends calibration every 6 months to guaranty accuracy. Without calibration the accuracy could wander but by very little. If the actual ppm is 50 and we see 40 or 60 is no mater for us. If no calibration is done after 2 years you will either get an EOL warning at start up or Calibration Required warning. They will continue to work. Just last week I ferried a friends airplane and his gave the cal req at start up. During start up/taxi out it showed between 8-10ppm and mirrored the one I brought with me that I had just calibrated. I have calibration equipment as well as the Mooney Summit. If anyone not attending the Summit would like to send me theirs I can calibrate and send back. I would appreciate a small donation as I calculated each calibration costs me about $5 in test gas. Sensorcon gave me a new discount code to share that I don't have it handy right now. But as @Junkman shared above this labor day sale is a little better. I'll post the updated code next week. Cheers, Dan1 point

-

1 point

-

I had my transponder fail about 100 miles north of KCHD a couple of years ago. I was talking to Phoenix approach, which covers half of AZ these days. KCHD is south of town, under the class B, and inside of the mode c vail. They asked me what my intentions were and I said I wanted to fly to KCHD. The lady sounded annoyed and said “stand by”. She came back a few minutes later with a full clearance through the class B, over KPHX and to KCHD. She said to report any heading and altitude changes. They worked me as a primary target through the class B, I reported my position and altitude just like in the 80s before mode C. They seemed to enjoy the process. So, exceptions can be made.1 point

-

My home field is Class D under a Bravo shelf inside the Mode C ring. I had an alternator failure and did a precautionary landing at an uncontrolled field about 80 miles from home. After unsuccessfully trying to find an A&P that would work on it, I called the number for our tower. I told them I had my handheld but didn't know whether they'd be able to hear it, etc., and we figured out my ETA and that I might be flying back dark, no transponder, etc.. I showed up right on time, and the response to my first transmission was something like, "We can hear somebody transmitting, but can't understand it, if this is N201TS click twice." They cleared traffic, made somebody else go away for a while, and got me in with double mic clicks only. So, yeah, sometimes you just call 'em and it works out. Probably helps to not be on their sh*t list.1 point

-

Yes, I'm planning to go next year. And since there's a landing strip there, I'm damn sure not driving in But seriously, the plane does get dirty. And I'm sure for a lot of owners that would be a deal breaker. But as an owner, I'm sure I look after it a bit better than a couple of renters would. I've been there twice. The first time I came back and paid to have the plane detailed inside and out. I also had my shop, SWTA, clean the engine, change every filter in the entire plane, open up every inspection panel and clean everywhere. I spent close to an AMU post Burning Man to get the plane cleaned. That experience was overkill. We didn't find dust in most places we looked. And a lot of the filters, like instrument filters, were still clean. So the second time, I still had the plane detailed inside and out, but mostly just because it was dirty and needed it. I skipped changing all the filters, hoses, etc. We did spray down the engine and clean it good. A couple of things to note. The dust is not abrasive at all. It's like a talcum powder. You won't find any evidence of trips to Burning Man on any of my windows even though they were covered in dust even under the canopy cover. It's just not abrasive. Secondly, it's an alkaline powder and therefore is not corrosive to aluminum. It can be hard on exposed steel, but not aluminum. As you can see from the pictures, I covered the large openings just to keep the dust and dirt from filling those areas up. Maybe a few years from now with a new interior and paint job, I won't fly it to BurningMan. But for now, I'll fly the Mooney out there. I really don't believe it does any lasting damage to the plane.1 point

-

Paul, In 15 years, when you take custody of my Lancair, you'll see that problem a lot less (step climbs and level offs). Once they see 4,000' a minute, or 250 knots when they level you, you'll get moved up and out pretty quick. (grin). The most common challenge is getting an initial climb to 2,000' above the airport and not getting turned over to departure quick enough. Once they've seen me a few times, I get sent to departure while the gear is getting stowed. Tom1 point

-

1 point

-

Went up today with @Warren to get in some practice IFR approaches. I like to make sure I get them in and not let the currency lapse. We'd been talking about going flying since I moved to Denver, but this was the first time we actually got in the plane together. And it was a good day to have a second pilot in the cockpit. CRM was very welcome today. We arrived at BJC where we are both based and the METAR was reporting OVC008. The field is IFR. So we filed to LMO, a 5 min flight if that. It's so unusual to get flyable actual IMC here in Denver. But we had a very stable layer at 800 ft that was about 1000 ft thick. We got in four approaches and a hold, all in actual IMC. Add into that the very busy Denver Bravo, and it was nice to have a current and local, pilot, in the right seat. Approaches at KLMO, KFNL, KGXY, and KBJC.1 point

-

Best Go electric speed brakes... never look back... Also consider the second alternator mounted to the pad where the vac pump used to be... the second vac pump, motor, and frame weighs a few pounds(?) Don’t add up the costs... don’t calculate an ROI... Do calculate the weight and balance changes... before spending money... in case you need to add ballast... PP thoughts only, not a mechanic... Best regards, -a-1 point

-

Jeebuz, forgot I did this: http://ericjacobsen.org/Files/USB_Power_Supply_RF_analysis_2.pdf From the thread below a couple of years ago. FWIW, a two-year old analysis on stuff like this is essentially obsolete, because the implementations change so frequently. An adapter bought today will likely have significantly different guts than the ones I tested. I think the conclusion is still valid, though, that there's going to be a lot of variation in units, and if you get a noisy one just take it out and replace it with something else. Even another one from the same multi-blister-pack might be a night-and-day difference.1 point

-

I'm a EE and spent about 35 years doing R&D on wireless communications. I have a pretty well-equipped lab at home where I can do a lot of relevant testing and measurement. A few years ago while travelling in a buddy's Cherokee we sorted out that a USB plug that I'd brought along to run my tablet was the source of some interference we were experiencing. A cheaper, crappier one was used instead and it cleared up the noise and didn't bother anything. This got me curious so I tested a large variety of 12V USB power adapters, everything from ones I'd spent a fair amount of money on to spiff-free crap that had been handed out as swag to various friends. The idea was to see whether there was a trend or any kind of identifiable feature that would give away which ones were noisy and which weren't. First, it's easy to identify a noisy one with a spectrum analyzer. The DC-DC converters that are the guts of these things have oscillators that provide the chopping frequency to make the DC voltage change. Bad ones generate a lot of harmonics from the oscillators and those can get fed back into the 12V source via conduction, they don't even need to radiate it, it just goes back into the power system and old or cheap radios or audio panels that don't have good power conditioning send it straight into the receiver, or the transmitter, or whatever place will maximize the annoyance to you. The radiated energy can cause trouble, too, but this is one of those cases where a common path of the impairment is conducted, through the power supply or perhaps the ground. Anyway, my conclusion was that which ones are noisy and which ones aren't doesn't have anything to do with the manufacturing source or how much it cost, or anything like that. It may have more to do with whether it got dropped somewhere along the way and there's a solder crack on a capacitor or other filter element and now the thing is just noisy. The quietest one I tested, i.e., the least noisy, was a cheap unit that had been given given away as swag at a real-estate event. I went out and sorted out who made them and bought some more, and they're all pretty quiet, and since they're also nearly flush I use them in the jacks that feed my back seat outlets, so that they minimize the physical interference to the passengers, front seats, etc. My personal view is that the sorts of things that make one noisy or not can happen just as easily to a $500 in-panel unit, but when it craps out, what are you going to do? If you have a cheap unit plugged into a 12V outlet and it starts making noise, you take it out and grab another cheap one out of your flight bag and go on your way. So, just IMHO, using the cheap ones provides improved safety by giving you a quick way to solve the problem in-flight if needed. If an in-panel unit goes bad, you may need to pull a breaker to shut it up, and you'll also lose anything else wired to that breaker.1 point

-

Rope trick is a method of removing a valve from its guide, reaming the guide and reinstalling the valve with the cylinder still mounted to the engine. It is outlined in Lycoming Service Instruction 1425A. It SOP as the first step to solving a sticking valve. I’m curious why there was such a rush to pull the jug.1 point

-

Ill give you a MS gold today. [emoji471] Sent from my SM-G930V using Tapatalk1 point

-

1 point

.thumb.png.7c67574d7b28f67b0b4a17760919b1ac.png)