Leaderboard

Popular Content

Showing content with the highest reputation on 06/19/2019 in all areas

-

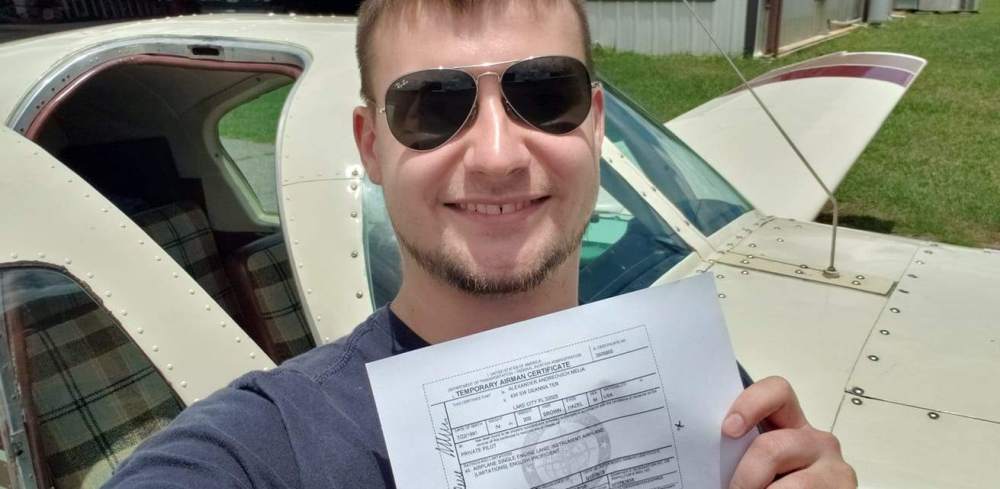

Hey friends, You didn't know we were friends yet, but here we are. We're all members of the "Owned by a Mooney" club. (Flaps hanging because I shot this picture from a J-3. It was my second-most-mismatched formation flight ever) My connection with this M20C goes back a while. I was a mechanically-inclined airport kid, well on the way to earning my A&P when I ran off and joined the circus. A flying circus, if you will. I crewed for Chris Smisson on the airshow circuit through high school and much of college, and in addition to his fast-movers, he had an M20C. Johnson Bar, hand pump flaps. All the latest and greatest gizmos that 1992 had to offer: A BF Goodrich strike finder, Apollo LORAN, even a widget that deciphered morse code to identify the VOR and the radial you were on. It was a great go-somewhere bird. He sold a small percentage of the Mooney to a friend, Kelly, so the insurance company would be a little more understanding. When Chris died in 2003, the friend bought the remaining share of the bird. Both of these men were like family. Without their patience and generosity, I'd probably be running a grader for the county road department. There weren't a lot of tickets out of my little hometown for kids without means, but they helped me chase a dream. Fast forward two decades. The friend wants to sell the Mooney and make room for other flying machines. He's spent years making ridiculous offers to me whenever he wanted to sell an airplane. He tried to sell me one airplane for $1 years ago but I was making chump change flying RJs for a day job. I couldn't afford insurance on it, much less any real maintenance. I had to say no. This time, the offer was reasonable, and I'm doing a little better flying A320s for my day job and spinning words into stories for some busywork on the side. I'm becoming the caretaker of a bird that's been in my family of flying friends since 1980. I took my bride for a flight, fully respecting her veto power. "If this just had a headrest, I'd be asleep in no time. Buy this airplane," she said. So, here we go. Hi Guys. My name is Jeremy, and I'm newly owned by a Mooney.19 points

-

11 points

-

Welcome to Mooney ownership! Usually @carusoam does my dirty work for me , but looks like he missed it. Your first upgrade should be a proper CO detector. Cheers, Dan5 points

-

5 points

-

Not a big fan of wheelies, but lane splitting has positive safety value.4 points

-

I started commercial ground today (I already have the flight requirements done) & calling a CFI with a Citabria tomorrow for tailwheel endorsement I am also looking at a local flight school with an Aztec for multi4 points

-

Aaaaaand on the flight home..... Irony? Luck? My plane is equipped with a Precise Flight backup which (with a power reduction) it pulled enough vacuum to erect the gyros. Good practice and interesting to see how the engine's intake system provides suction for these units. Back to Mooney-ing while a replacement is on the way. Looks like the old pump was installed in 2013, and was the last entry before I bought the plane. Lasted 428 hours. I'm also temporarily doubling my personal minimums for the first 15 hours of operation with the new pump until I'm comfortable with its use.4 points

-

I HAVE had a corrosion issue with my airplane but it was in a location that seems unlikely to be related to tks, which is in the fuel tank area. And I had not been using, or even been aware of, the anti-corrosion misting agents - but I am now! But - not doing TKS because of worrying about corrosion, is worrying about a chronic problem vs an acute problem. Sort of like deciding not to get an x-ray to examine your broken arm because you are worried about the possibility of the cancer causing properties of x-rays. If you find yourself in a situation wanting-needing-wishing for tks, because of an inadvertent (or fiki) ice encounter, I promise you, if you flick that tks on switch, you will not be thinking about corrosion at that moment.4 points

-

I've been rear-ended on a bike, it can be impossible to avoid in this kind of traffic. When I filter it's usually no more than 10 mph faster than the cars. If someone krons into the back of me I might not see them, if they change lanes or open their car door in front of me I will. Moreover, smacking into something at 10 mph isn't all that terribly painful. I usually filter to get past sticky spots in traffic, so it can save me a boatload of time. I don't allow dumb shit laws to keep me from doing what's safe. As far as being so dangerous, been riding like this for 30 years now. I doubt anyone arguing with me has ever ridden motorcycle. If you had you'd not be arguing.3 points

-

It is only specifically legal in California, but in several other states there are no laws against it. Further, studies have shown that it it much safer for the rider than staying in lanes. One of the most dangerous accidents for a motorcyclist is a rear end collision. When lane splitting, that risk diminishes significantly and, according to the study, enough to justify a possible side swipe from being in a blind spot.3 points

-

This bird has the LASAR cowl inlet, and most of their speed mods, other than the clean belly mod to move the antennae inside. 201 windshield and wingtips, gap seals, flap hinge seals. The airframe is about modded-out. There are a few things that need attention outside, but the panel is going to be "The Money Pit." I was considering dual Garmin G5s until a friend suggested the Aspen e5. One box to replace both the AI and DG. It talks to legacy nav/comms and GPS units. Over time, I'd love to modernize, but realistically one box at a time is a more realistic way to go. In time the LORAN boat anchor will give way to a GPS - Maybe an older Garmin 300XL or the new GPS175 if I can swing the expense. Anyone got a better suggestion that I've not seen yet?3 points

-

Always happy to meet an old friend. (Dang, that sounds like something a time-traveler would say). If you're ever down near Atlanta, let me know. I'm always glad to meet the friends I already knew.3 points

-

Driving is too... pedestrian. April in Florida can be really chilly... in NC, it was probably just above freezing... With a plane full of people, it is hard to carry along the fancy powered bikes, skate boards, or hover boards... Not enough UL to carry a spare case of beer. Given the choice... walk to get food and beer, or stay stationary... the usual American sedentary lifestyle has to take a back seat... With the LB, and only one other person, there is plenty of room for all that, a spare power source, and ice if you were to want your beer cooled... and all the sweatshirts you ever needed... When at first flight... there is only one rule posted... ‘No Camping’... Surprised we didn’t get arrested for possession of a tent or two. what can you do with that finely posted sign..? The whole visit is about celebrating defying important laws... namely the laws of physics, and that pesky law of gravity, and doing things that people called crazy... So when visiting FF... wait til the sun goes down... before setting up the tent! Be experienced before attempting setting up a tent in the dark, with 20kt chilly winds... and a nights worth of food and beer in your stomach. Not admitting any guilt... I may have seen somebody doing this... Best regards, -a-3 points

-

I’ve heard they spontaneously combust above 10k’. You should sell yours immediately.3 points

-

That's just not true. Sometimes when I park my car at the Walmart I need to walk all the way across the parking lot to find a nice motorized shopping cart.3 points

-

A real short flight from KOSH, Door County WI, a lot of very cool, quaint water side towns, B&B's up the wazoo, nice restaurants, etc. https://www.doorcounty.com/ http://map.co.door.wi.us/airport/ Also, Traverse City MI is nice to hang out for a few days. Have fun!2 points

-

2 points

-

2 points

-

Legal here in California because of the safety increase. There has been talk about congress recommending the DOT ask more states to allow it. Sitting behind a line of cars stopped at a light is about the most dangerous time of riding. https://newatlas.com/motorcycle-lane-splitting-filtering-safety-research/34425/ -Robert2 points

-

I use these, from wally world to hold pens: Like this on the right side; mine is on the pillar between windshield and window: There's two in the Mooney, one on each side; one on the dash of my truck; at home, one on my band saw and one on my wood lathe. Easy to find, inexpensive and very, very functional.2 points

-

I've cupholders in mine, but coffee is verboten in my aircraft. The coffee stains on the headliner are evidence enough of what a good idea that is. I'll try and post up photos. I didn't do the mod.2 points

-

Hey, Jeremy! I'm based at PDK but was based at Falcon for a long time. Sounds like you are somewhere around Mallards or Brooks Bridge. Good times down that way. Great looking plane and great writing skills. And man I miss Sammy's. That was a nice place to go and have a good lunch. William2 points

-

2 points

-

2 points

-

New canadian campaign slogan, "we built it, and the US is going to pay for it."?2 points

-

Cool story! That's awesome how you are able to keep flying this plane you have so much history with! My E just got the E5. I'll give a pirep once I get to fly her a few times. Sent from my SM-G930V using Tapatalk2 points

-

In the hours before signing the papers today, I did a few little housekeeping fixes I'd been putting off for (cough, cough) many years. Installed two new fuel gauges in the wing indicators. Those things are cheap, and LASAR was only too willing to sell me a new pair. Installed a new landing light circuit breaker switch, and cleaned out the pitot static system. Couple of bugs decided to try and defeat me with their pitot-static nest building skills.2 points

-

Yes Sir!! 3M sells it. It’s EC-776 an it is a must for all Mooney owners. Its a Bit pricey, but worth it2 points

-

2 points

-

Today at Udvar-Hazy at Dulles I “flew” the Wright Model B simulator. Jeez, three minutes seemed like FOREVER. Rotate st 35. Best climb 35. Best cruise 35. Stall 35 (seemingly) Wing warp to turn with hideous adverse yaw roll stick left = forward and right = aft. Thot I was going to die. And I have thousands of hours: the Wrights had to learn to fly in that beast.2 points

-

2 points

-

I'd try mineral spirits and then acetone if that didn't work. One of those should make easy work of it.2 points

-

I don't see any evidence of poor judgement. This isn't a VFR pilot who finds himself in IMC despite a mountain of evidence it was likely. This sounds more like a guy who cognitively accepted the risk for the thrill of it. Similarly few would say that the act of climbing mt Everest is poor judgement but the risk of death is very high. His calculus of risk/thrill was just different than ours. But it was his life to live on his terms and he didn't own anything to us. Don't forget that for 90% of the public climbing into a small airplane is in itself an act of lunacy. You could just drive a safe Volvo. Your risk calculus may vary. -Robert2 points

-

Forty years ago I flew our Cherokee to New Mexico to visit the in-laws. Got home, slammed the door, sold it and bought a Mooney.2 points

-

I disagree. I think poor judgement, irrationality and faulty decision-making are normal states of the human condition, and require no additional explanation. The goal is to find ways to mitigate those faults that everyone is capable of. Blaming the on unspecified "mental health issues" is another way of saying "it'll never happen to me."2 points

-

Discussing these quirky operational things... at least keeps it from happening accidentally... Things to consider... Prop strike at cruise speed... Black smoke seen after contact with the water... engine no longer with the plane... prop blades bent far back... Plane seen climbing rapidly before stall and plummet... Larry sure did leave us a lesson we can all abide by... The compliance of water is quite strong. Those hydrogen bonds really hold the water molecules close together. Density of water is pretty high. Conservation of momentum rules... Chance of survival after coming in contact with water at cruise speed, is proven to be quite limited... Controlling speed requires having control of the plane. It appears the plane may have had its WnB, or even center of lift, altered upon impact... So, things we learned from Larry’s flight... If your flight prep includes checking the wave height at the Jersey shore, add several hundred feet to your planned altitude. If required... Remember to slow to near stall speed before landing on the water. Water isn’t very friendly at high speeds. People aren’t going to be very friendly after you load up your risk level. Or place your loaded risk level onto somebody else. Broken planes are hard to control. Altitude above the plane still does nothing for the PIC... MSL has variations, in reality. I hadn’t ever considered flying over the surface like that. Actual height above the ground is hard to establish without continuously scanning... A simple controlled descent in a Mooney is accomplished at 500fpm... about 10’ per second... Avoiding a controlled descent to the surface takes a lot of talent when traveling 10’ agl... Changes in wind, changes in temperature, change in atmospheric pressure...lots of things that can cause a descent... That’s pretty eye opening. RIP, Larry. Best regards, -a-2 points

-

Bucket List Flight today Beautiful morning with maybe the best opportunity for flying while we're here in NC so we flew out to First Flight. Fairly smooth, hazy flight but the winds do swirl around a little coming in final over the beach to 21. Once you drop below the treeline it changes again, but wow, how cool to land there. I get emotional about some things but must say I was a little surprised at the level of emotion I felt being up there on top of the hill. There may or may not have been a few tears shed. We back taxied on 21 along with two other planes departing and my wife snapped a great picture as we lined on 21 and waited for the Cessna ahead of us to depart. If you look close you can see the monument in the background.2 points

-

2 points

-

Flying at single digits low level is stupid, especially in a single engine airplane. And the hours this guy had were too few to go about this. I have 1000s of hours low level and I've done some stupid things over the Pacific Ocean in a B-52G at 390 KIAS, but never 10 feet! Either act is stupid. But a Buff at 10 feet AGL going 390 KIAS would attract attention and make noise. A little bitty Mooney at 10 feet is 'meh'. Therefore, he gets no cool points from anywhere. RIP. This is my first post. I love flying my M20C. But I like cruising at 10,000 feet. More time to make decisions.2 points

-

Mine is very similar to yours but with a 3 blade speedbrake. I’m usually 142-148kts ROP between 7-10,000’ density altitude. Depending on density altitude and weight. If you’re cruising at 10,000’ in socal, what’s the da? You’re losing some speed up that high. Also, take the 5 minutes to do a 4 way gps test. You’re using your indicated airspeed to compute TAS and the IAS is likely off by a few knots.1 point

-

I didn't find it that bad for the OAT probe I put in for the JPI. Biggest help was having one of those cheap inspection/borescope cameras to play find the safety wire when I missed the hole so I could aim better. Also remembering that if I couldn't get one way to work I could use a new piece of safety wire from the other direction to hook onto the one ferrying the actual wire. Admittedly it would have been nice to have an inspection plate between every set of ribs and then it would have taken about 5 minutes. Then again I've had plenty of practice doing this in my attic which is too short for a human so all my electrical and network conduit runs are done by fishing from the attic opening, often involving magnets.1 point

-

Greenville is my home base. I alwasy admire the Mooney's sitting outside runway cafe when I'm at the airport. I guess I should start walking in and introducing myself and saying hello. Oh well.1 point

-

1 point

-

Come on, guys! Oxygen is toxic. Hypoxia is the new black. The single O2D2 used to be enough for us but my wife just realized that she feels much better after a flight when she uses oxygen so it’s time to expand. They are amazing little devices!1 point

-

Check to see if this isnt the proper part: https://lasar.com/flight-controls/flap-stop-block-210114-009?rq=flap block or https://lasar.com/flight-controls/hinge-block-240005-501?rq=block1 point

-

Amazing - isn't it. The wrights had to learn to fly that thing with no experienced CFI to teach them how to do it!1 point

-

You can't put the cover on when you fly through the rain. Just make sure the drain is good. -Robert1 point

-

1 point

-

This is an interesting point. For an ideal Otto cycle engine, the ignition occurs at TDC and the mixture burns instantaneously at constant volume and then expands adiabatically (without loss or gain of heat) as the piston moves down on the power stroke transferring work to the crankshaft. In a real spark ignition (SI) engine, the mixture takes a finite time to burn and there is a rise in pressure to a peak and then a decline. The peak pressure position (PPP) measured in crankshaft angle (degrees after TDC) is determined by mixture strength, rpm and spark timing. There exists a PPP for each engine (based on engine geometry) that will produce the maximum brake torque (MBT). Operation at MBT produces the greatest efficiency. In automobiles, the spark timing is viable allowing PPP to achieve MBT over a range of operating conditions. Our engines have fixed timing, and the rpm is variable only over a limited range due to propeller efficiency. Thus, our primary control to affect PPP is mixture. LOP mixtures operate nearer the ideal PPP which is why LOP mixtures have the lowest brake-specific fuel consumption (BSFC). This all is just the physics behind why LOP is more efficient than ROP. For the pilot, it means that if you can get the same power (meaning true airspeed since that is what the power is converted to in cruise) running LOP as you can ROP, then LOP will be the more efficient choice. This is clearly apropos to turbocharged engines. For normally aspirated engines, if you can accept the airspeed generated by operating LOP at a particular altitude, then LOP is again your most efficient option. If you need to go faster and the throttle is already wide open, you will have to run ROP and accept the lower miles per gallon. BTW, the loss in efficiency from operating off MBT by 5 degrees or so is small, which is another way of saying the optimum operating point is broad. This is why Lycoming could change the timing from 25 deg BTDC to 20 deg BTDC without claiming a power loss -- the loss was absorbed in the tolerances permitted by certification. But the engine will produce slightly more power with the 25 deg timing. Chapter 2 of the attached document has some interesting description as well as measured engine data. Skip Maximum Brake Torque Timing.pdf1 point

-

The 252 is easily the best "bang for the buck" if you factor in resale and maintenance. The MB engine along with the improved cooling and airflow of the 252 means less maintenance and an easier/longer running engine. 231's can match the reliability but only if flown very carefully. The value of an airplane is more accurately measured by the difference of purchase price and eventual sale price, minus maintenance costs. The 252 is the sweet spot for turbo Mooneys.1 point

.thumb.jpg.7bba7d617dfb8c35fc45bed8621dd98b.jpg)