Leaderboard

Popular Content

Showing content with the highest reputation on 05/02/2019 in all areas

-

I'd check the usual items mentioned above, but it sounds like classic carburetor icing to me. Harder to feel the onset with a constant speed until it really flares up. The conditions were good for it based on what you're describing and being at the altitude you were.4 points

-

3 points

-

Remember carb icing is still possible without visible moisture outside.2 points

-

I had this happen just the other day. It hiccuped fast enough it didn’t even show up on the engine monitor. After it happened, I decided to do an in-flight mag check and found that one of the plugs was fouled. With the engine monitor watching it was very easy to pick out the bottom number six plug. When I did this check, it would stop running on that cylinder then it would clear out and would run again. After doing a clean and gap on the plug, no problem. Sent from my iPad using Tapatalk2 points

-

If we aren't willing to stand up for our rights sooner or later we won't have any.2 points

-

Another satisfied customer report, like the OP. I have the same setup of G5 for the HSI and KAP 150 for about a year. It has worked well, much better than the original HSI. In my case it also showed me that what I thought was a flaky AP turned out to be flaky signal from the old HSI. Installed about $6k including the G5, Magnetometer, the D to A interface to connect to the AP, and the labor.2 points

-

Glad to hear it worked out. Component level repair is becoming a dying art. But it is very possible even today in the age of surface mount components. Certainly some custom chips are not available, and some designs are hard to troubleshoot without documentation. But many are also very repairable. Today we have people replacing $1000 flap relay boards when the only thing wrong is a simple and available $10 relay.2 points

-

2 points

-

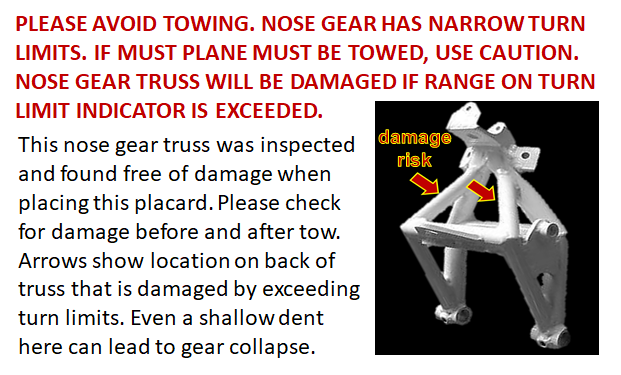

This hit a cord with me but here is the finished working repair. To those who thought it was silly, a waste of time, or dam near impossible here is the finished job. 7 minutes of total time. It took a month to find the parts and get the parts but the repair was easy. I understand that most people on this forum or any other forum for that matter really don't know the capabilities of the others on the site. But I am really tired of hearing negativity towards everything. If you feel so compelled to shoot down an idea just to add content do me a favor record yourself and play it back repeatedly. See if it gives you pleasure. Aviation is a rewarding field. So are many others, but non of the fields including rocket science is out of the grasp of anyone with the willingness to learn, read and TRY. I believe if it has been built by man it can be fixed my man. It might not be cost effective and that is a good argument to have, especially if other better options are available but in some cases that is not the case and that is when people like myself find it a challenge to resurrect the broken. AS FOR THOSE THAT HELPED ME THANK YOU A MILLION TIMES!!! This website is absolutely the best!2 points

-

2 points

-

Flew to Vegas last Friday and back on Saturday. On the flight back I started to get a fine mist of oil on the windscreen. Kept an eye on the oil pressure, lost about 1/2 a quart over the 90 minute flight. Emailed some pics to my mechanic and he stopped by the hangar to take a look, put some dye in the oil, cleaned the engine up, and told me to take it around the pattern once. I did that Tuesday after work and he went by today to see if he could see where it was coming from. I was worried about the #2 cylinder that has shown some very slight oil seepage for quite some time. He said there was no dye/leaks showing at the #2 cylinder, but the quick drain was spitting oil out and it was getting blown around. I guess on that longer flight (higher speeds) there was enough blowing around that it was coming up out the front of the cowling and back onto the windscreen. Small trail of oil across the top of the cowling after that 90 minute flight. #2 that I was worried was the problem, apparently just a bunch of oil from the quick drain that was swirling and blowing around. After the trip around the pattern with the dye, here's the problem... He gave me the part number that Spruce uses and told me I could have it sent to him and he will put it in. I told him I could just have my wife pick it up today and I'll stop by the hangar tonight to drain the oil and leave the part so he can swap it out tomorrow. Have I mentioned before that I think I have the best wife in the world? She encouraged me to get my license, buy the plane, and she picks up parts! Funny thing, she walked into Aircraft Spruce and the guy behind the counter recognized her and said "Pick up for Mr. Brown?"1 point

-

1 point

-

I suspect they were hoping since an equivalent volume of CO2 weighs 60% more than N2, that it could absorb or transfer 60% more heat. Totally bunk science if you ask me, but hopefully there are some more engineering types who could answer this. I get the moisture explanation, and that at least makes sense, but again, it's hard to imagine this being an issue except in racing where the tire temps are routinely near or above boiling temp.1 point

-

The best explanations I've heard from people I had the most confidence might actually have some idea were that it's mostly just that it's drier, and that if there *is* moisture from whatever source (tire mounting lube, whatever), that it will be less likely to affect pressure changes with pure N2 than air. I think the affect is a small one regardless. Many years ago there was a scandal in F1 where one of the race teams was accused of using espionage to find out that a competitor was using CO2 instead of N2 and that it gave them an advantage of some kind. I never did hear anything definitive on it, but some of the scuttlebutt is still around: https://www.apexspeed.com/forums/showthread.php?25913-CO2-tire-gas-re-McLaren1 point

-

While I love ADSB and the situational awareness it brings, I've never worried as much as you guys about mid air collisions. They've always been rare as hens teeth, just a few a year. I worry more about weather, about which ADSB gives mea great deal of awareness.1 point

-

1 point

-

I love them over a populated area. It really does feel like you are floating.1 point

-

The tire shop I patronize fills my truck tires with "nitrogen." At home, I top off when needed with standard 78% Nitrogen from my garage compressor. My Mooney tires always are 78% Nitrogen. I really don't care which is used, as long as there is no additional charge . . . .1 point

-

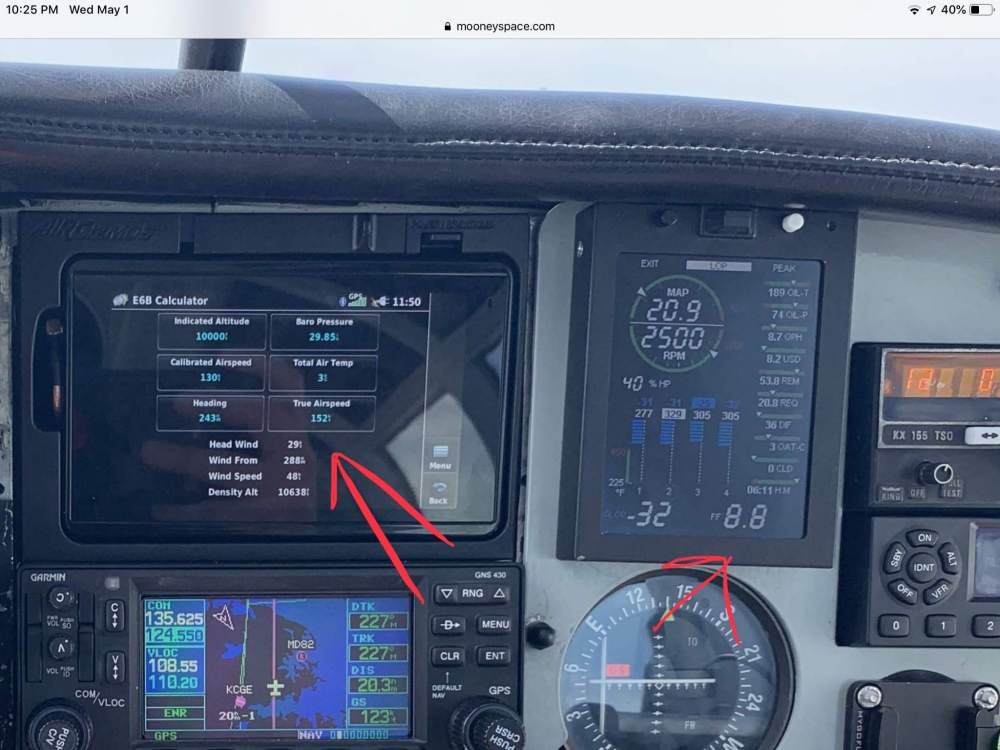

While it's true that NA engines loose HP with altitude, there is still a sweet spot where the ratio is optimal. My understanding is that that is somewhere around 8000 ft for the J? I've never been to FL280 to try for 252 mph in my K but I've seen 238 mph at FL260. *all figures in TAS1 point

-

Somewhere on that site there is a link how to get round the download limit (requires you have a google drive account) Well, I did have it working ok! Having downloaded and imported the Mooney files, then set about modifying them to a Bravo, and have succeeded in making the app repeatedly lock up, and can't find the options suggested in the documentation for mount/dismount an engine. Will reset the model and retry, but it's just moved down the list of things to do... I like Bryson too, but cant say if I've read that one1 point

-

I would check the plugs, but I am +1 on the carb ice. A chunk of ice ingested would have the effect you describe. Sounds like you were in the correct temperature range to produce ice.1 point

-

Ok, I have had morning sickness,but had this happen on descent to landing, since I already knew that I had a cam going bad, it was a easy decision to send engine off to be overhauled: In my case, my push rods were fine. Tom1 point

-

It all depends on when the engine fails. On take-off the records show that losing an engine on a twin is a handful, not that it's a good thing on a single either. However, losing one engine on a twin at cruise over mountains or water should be close to a non-event, other than damage to the checkbook.1 point

-

Quality paint job needs to be judged after years of flying and not soon after leaving paint shop. Most of the planes look great after completed job. Try to see their work done few years ago. When I painted my plane (2007) Corona was considered premium place to go and get a quality job. I remember their proposal was vey detailed and came by mail.1 point

-

What I have seen in situations like this is when the valve should be closing and pushing the push rod back down against the tappet, the valve sticks open, the push rod slips out of the rocker arm at the top of the cylinder, and the next rotation pushes the push rod against whatever it happens to be lodged against. Since the push rods are on top of the Lycoming engines, gravity should have the push rod dropping down onto the rocker arm. At 2000+ RPM, it only takes an instant to get it lodged somewhere it cannot move and bend it. Even in this case where the piston appears to have "freed" the valve without destroying itself, once the push rod is out of the rocker arm, bad things happen quickly.1 point

-

I turned carb heat on after the event for a bit. My carb temp gauge was in the yellow (close 0-5C) at the time of incident, OAT was about 45-50F, but I was above clouds in clear air at time of incident.1 point

-

If someone had offered one of the MS24693-C2 for $10 it would have been an easy fix. But what to do with the other 99 .. .lol?1 point

-

It’s at least 0.010 amu worth of humor... Good luck with the cut and reorganizing the threads. Whelen is in CT if you want to call them... to enact Plan Bravo... Best regards, -a-1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

All the new autopilots are capable of flying an approach. However, currently only the Garmin AP can legally do so. Not only can it fly LPV and ILS approaches, it can also do VNAV descents (think descent via clearances), capture altitudes, fly the missed approach, fly holding patterns, do IAS or VS climbs/descents, and return to straight and level with the push of a button. In short, other than running the throttle for me, it can do more than the AP in my DC9 could do, and do almost everything the AP in my 757 could do.1 point

-

And if you were at my home field the landlord would require you to carry at least liability insurance. (Suppose a fire that starts with your plane damages the hangar(s)?)1 point

-

1 point

-

Just pressed out the wrist pin so now the piston is free. Picture below. It's easy to see the point where it impacted the exhaust valve now. I also inspected the bent rod a bit more carefully and it has numbers stamped on it. I hope this enough to find a replacement. 15F19957-57 ON972 31-97 This seems to be it! http://www.aircraftspecialties.aero/push-rod-assy-15f19957-57/1 point

-

Don't forget about the Bogert Bar. I'm thinking about buying one as the $139 + $19 shipping from the Spruce may be cheaper than engineering my own.1 point

-

"Made available upon request" can mean a lot of things, including faxing or E-mailing a facsimile to said official after you get home. It does rankle just a bit, given my old man took a bullet fighting against guys known to say "Your paperz pleaze".1 point

-

I had this exact setup I had before the GFC500. The GPSS emulation alone made a huge difference for enroute and approach maneuvering. The 7 pounds of useful load increase didn’t hurt either!1 point

-

1 point

-

Check the useful load of the planes you are looking at compared to yours and then consider how big the 6 & 7 year old will get and how much fuel you need to make the flights you want to make. I like a Mooney as much as the next guy on here, but if I had a plane with the kinks worked out already that was a known quantity, 4 gph would not convince me to sell it and switch to something else. Now, if you want to switch because a Mooney is way cooler and more fun than a Cessna - welcome to the club. You've found the right place.1 point

-

1 point

-

That is an idea, but my day job involves working in a native linux environment. I've gotten used to being antiquated. That's why I fly a 1967 airplane!!!1 point

-

I replied to Jimmy when I got his listing email. If it had fiki I’d write you a check no questions asked. Sent from my iPad using Tapatalk1 point

-

1 point

-

We're not supposed to discuss politics here. Likewise, Yankees fans are supposed to keep those feelings to themselves as well.1 point

-

1 point

-

I have the man door, in the full width bifold door... It is a bit goofy entering and exiting when you just open the main door a bit to allow air flow in... Of course... my door barely allows the Mooney wings to pass... Room for two planes....? See how many Lancair boxes you can fit in the extra space.... +1 for the printed scale drawings of plane, doors, floor space, and people... called the paper doll method for machine floor layouts... Don’t forget your emergency exits, and fire extinguisher locations... PP thoughts only... Best regards, -a-1 point

-

Joe: I am an EE. The thing with simple power electronics is that any part that meets or exceeds the specs will work fine. And we can guess at the specs from the application. You said this diode is the protection diode for a relay. Any diode > 50V and 2A should be fine. So what I would do is measure the size of the good component with a caliper. Then go on the Mouser site, link below, and filter on the package size. Just find an in-stock diode with the greatest electrical specs that fits in the board footprint. May as well buy 10 while you are at it. If you post the size here I can make a part recommendation for you. Note that if the board was used after the diode blew the transistor driving the glow plug relay could also have been damaged since the protection diode is now missing. If you can identify that part it might be good to buy a few of them at the same time. The driving transistor would work for a few cycles after the diode was damaged but it eventually would be damaged from the inductive kickback from the relay. A relay drive transistor is similar to the diode. Any part that fits the footprint, has the same pinout, has a current rating > 2A, voltage > 50V, and the same type (NPN) will work. https://www.mouser.com/Semiconductors/Discrete-Semiconductors/Diodes-Rectifiers/Diodes-General-Purpose-Power-Switching/_/N-ax1mp?Keyword=diode&FS=True1 point