Leaderboard

Popular Content

Showing content with the highest reputation on 04/17/2019 in all areas

-

Hi. I'm new to the forum. Been lurking while I sort of fell into a 64 m20e basket case. I have spent the last few weeks inspecting the aircraft before purchase. I am A&P , very little experience in GA, been at American airlines for most of my career. This aircraft was fairly well maintained up until several years ago when prev owner got tired of costly thorough annuals.after nearly a decade of short cut annuals, The owner got what he paid for. Now he had a basket case on his hands and I got it for a bargain.....I think. It is currently 4 yrs out of annual. Plan on going through the whole aircraft and bring it up to a safe condition. I visited the Mooney center in New Jersey. The guys there were great, gave me tips and a lot of confidence to move fwd with this plane. I dont have a pilots license, I'm 10 hrs into my training in a 172. I'm in the Chicago area, aircraft is currently at KLOT Louis univ airport. It's parked under the canopy is out there, feel free to stop by and chat I will be out there a lot trying to resurrect this aircraft. Glenn Villa park, IL5 points

-

My hangar is 50x50x14. I love the stack doors. I can open mine quicker than my neighbor can open his bi-fold. And they let in a lot of light and its easy to open a panel or two to regulate temperature. I used Cooper Hibay led fixtures and have 50 fc on the floor. I have running water but no toilet since it’s not too far to the house. The 50x50 is big enough for my Mooney and Citabria, my sons boat trailer and my workshop. Lee5 points

-

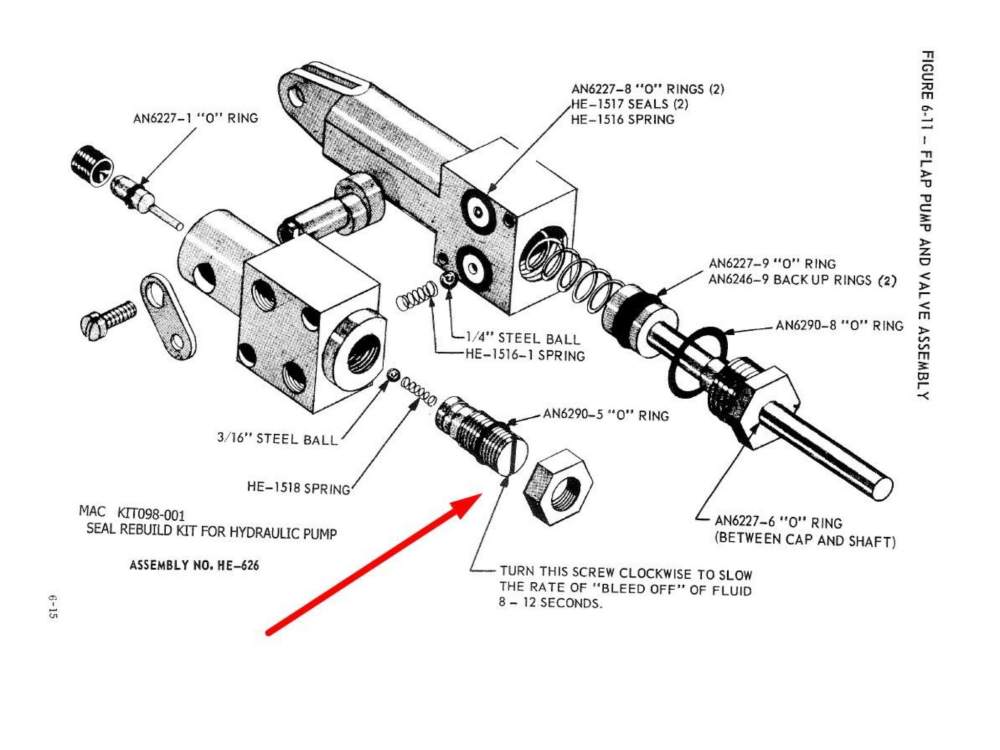

I think a lot of folks overcomplicate this procedure. An F model will climb just fine under most circumstances with full flaps and the gear out. Raise the gear after positive rate is established, then raise flaps after the plane has accelerated to ~80mph. It’s pretty easy. Getting your flaps properly adjusted will make things smoother. A 10 sec retraction on the ground will work out to about 4 in the air.4 points

-

Hi, I wanted to chime in on the conversation. Buying used the equipment and having it recertified is not a cost-effective bargain. I would ask that you contact your local dealer for the charges to purchase the STC paperwork, install kit and to certify and install the used equipment. We have 26 Pre -STC purchase orders now and the Genesys Aerosystems Mooney 3100 STC start date is July 1st. Genesys Aerosystems S-TEC 3100 is a fully featured, attitude-based autopilot that gives you a list of workload-reducing and safety-enhancing capabilities that were previously unavailable on aftermarket autopilots. The S-TEC 3100 has this feature packed into the system. Automatic Trim included Envelope Protection/Alerting Straight and Level Recovery Precision Approaches/Missed Approaches Indicated Airspeed Hold Altitude Preselect The 55X is a rate base system verse the 3100 attitude-based autopilots. The 3100 has built-in MEMS technology that is capable of working with the basic 6-Pack panel. The 3100 is compatible with advanced digital sources & EFIS displays from Garmin, Aspen, and others. The most significant benefit to submitting a purchase order (early) is that we will extend the 2-year warranty to 3 years for all new parts from the factory (new installs and new controllers/servos). Also, we are offering a 2-year warranty on any currently installed S-TEC servos. No matter how old they are. The extended warranty offer is only valid until we gain the STC. Once that occurs, the regular warranty period will be offered. Importantly, the POs are non-binding (until the STC is issued and we start building the system) so if your circumstances change, you are not obligated to purchase. Please Visit our website: Product Link - http://genesys-aerosystems.com/products/s-tec-3100-digital-flight-control-system Pilots guide link - https://genesys-aerosystems.com/sites/default/files/87325.PDF Brochure link - http://genesys-aerosystems.com/sites/default/files/files/GenesysAerosystems_S-TEC_3100__Digital_Autopilot_Brochure_2017 (002).pdf Please contact me directly at: Barry LeBlanc Genesys Aerosystems Regional Sales Manager PH: 940.327.0707 Email: Barry.LeBlanc@genesys-aerosystems.com4 points

-

The airframe needs a bit of work, but Shane gave me the confidence that I could manage it myself. Focus for now is cleaning it up(nests and poop in the tail), accessing the airframe, going over the rods and rod ends. Lubricate everything, acf50 I don't know when I'm going to have time to do my flight training. Very excited about working on this bird. Glenn3 points

-

2 points

-

I've gone from KICT to KVNY (1400 sm) with just 1 com/vor , a pencil and plotter and a Sectional, just by looking out the window. What could be simpler? iPads? iPads? We don't need no stinkin' iPads! :-)2 points

-

Be careful thinking the old pucks are still good. Much of the landing force will be transferred to the forward and aft trunion fittings. You may be causing yourself a very expensive repair by wearing out the aft landing gear fitting and the landing gear leg itself. My airplane has a ton of landings to go along with the 7600 hours of flight time and I have changed the landing gear leg with a used serviceable unit and am putting in a new aft bearing block. These are not cheap. David2 points

-

Depending on where you live, now may be the time to start thinking about density altitude again. My home airport (57AZ) is reporting a DA above 5,000 ft right now. It is 2940 MSL. Today the high is forecast to be 93ºF with a high of 95º tomorrow. Summer's coming.1 point

-

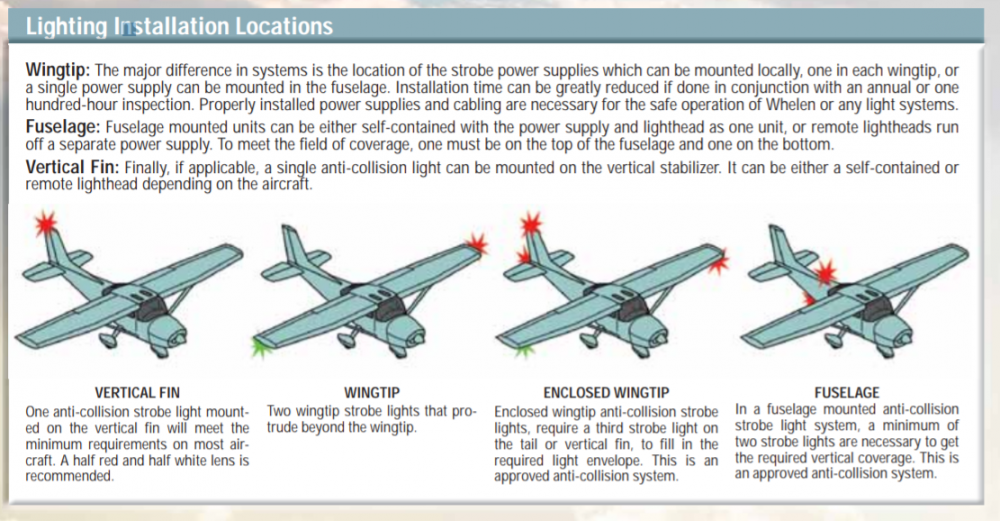

1) These are what I used for the same job. Only difference is that you want OR6501G, OR6501R if you don't have enclosed wingtips like I do. 2) Unlike me I think you're good to go with just the wing tip lights unless you have enclosed tips. If you're going with LED strobes though, it's tempting to go all the way at once and never have to replace a bulb again. 3) No it's mainly a style point. I think your installer has to run a wire from wingtip to wingtip. It added minimal extra labor for me when the plane was already opened up at annual so I did this. So do it at annual if you're cheap like me. 4) My A&P had to fabricate and install a cover for the hole (I just had the belly beacon). Looks like you will need two of these these. The top one merits being sealed very carefully to prevent future water leaks. 5) It's no biggie. You will gain at least ten knots, and women will find you even more attractive than they already do when you pull up on the ramp .1 point

-

Agreed, but don't forget, this area can not be viewed through any inspection panel. It is on the very tip of the wing and is only visible/accessible through the nav light hole. I took off the four outermost inspection panels and there was nothing like this in any of those compartments. Kind of makes me wonder how long it's been there. When I get it out, I'll report back on what it is (assuming I can figure that out once it's removed). I'll also spray some corrosion-X in there and try to get it covered well. My other wing had a bucking bar in it from the previous wing repair. I let the mechanic keep it for his tool set.1 point

-

That's better than the empty Coke bottle that was in a door of my grandparents' new Buick . . .1 point

-

This would be easily won, as it will be a silent auction item if Barry decides to have Genesys run with the other big dogs that donate to the Mooney Summit's silent auction. I certainly hope he can make it happen for Genesys, they would be well served. Ill let you know what Hank and him come up with Sent from my Pixel 2 XL using Tapatalk1 point

-

My folks live in Pine Mountain. I fly in regularly to visit, but can't make it for lunch due to work responsibilites. I told my mom about the lunch and she is talking about stopping by the airport to see all the Mooneys. If you see a lady in a red Rav 4 wandering about looking at the planes, say "Hi, Debra!" or "Hi, Mimi!" That will make her day.1 point

-

A lot of people do the screaming eagle upgrade when they overhaul the engine. Makes it easier cause the prop is coming off anyway. So just throw one the mt and have the gov and fuel flow adjusted while the overhaul is happening.1 point

-

Ouch, that's a big swing in the SS/FS price. At my home it is a 10 cent difference so I just have the truck come by the hangar, but at a couple dollars a gallon I'm going to pump my own fuel all day long. If it's a poll towards the CB in all of us, I think you need a lower bracket of $5-10. Under $5 I'll grab the FS, more than that and I'm probably pumping it myself.1 point

-

I spoke with both last week on this, as an Aspen is in our future as well. If installed before the integration is complete, both the TT and Aspen will need a firmware upgrade. The TT going back to the factory, the Aspen can be flashed by any dealer.. Planned for next winter, unless our DG goes south.. (getting noisy) Looks like Garmin is really serious about NOT integrating with other products.... FWIW!1 point

-

Boy, this is a tough, suspicious group! I think the poster just wanted to put in a good word for an excellent app. I, too, am going to speak up for FlashPass and will add a funny story. Last summer I flew from California to Alaska via British Columbia and the Yukon. While in the Yukon I ran across an elderly gentleman in his Cessna 120 who had saved for his trip from Wisconsin to Alaska for, he said, a decade. But there he was, stuck in Watson Lake for 2 days because he couldn’t figure out how the heck to complete the standard eApis form to be able to cross into the US at Northway, Alaska. He had spent, without exaggeration, 48 hours trying to get it to work and by the time I met him he was genuinely considering turning around, giving up on his decade-long dream. Well, I was then using FlashPass so I set him up on that app and 10 minutes later he accomplished what he earlier found impossible. To see his joy you would have thought I blessed him with eternal youth.1 point

-

No, I overhauled both at same time, engine was on condition, prop and governor was just because it’s been 10 years and it was already off the plane. Tom1 point

-

Its great to see qualified folks taking on these challenging projects. You’ve already gone to the right folks in Robbinsville for advice. There are a few folks here with similar expertise who are generous with their knowledge (eg Clarence @M20Cdoc) to help you along. Many of us can’t help much but will enjoy learning from your growing Mooney experience if you keep posting. Now go get that PPL!!1 point

-

One of the many advantages of life in flatistan. We really don't fret about it that much.1 point

-

Pics or it never happened . Good luck and you will find that there is a plethora of information and many individuals willing to step up and give someone some help around here. Look forward to seeing updates on this1 point

-

The standard bar won’t slip if you bend the shaft slightly so that the part that slips into the nose gear is at a slight acute angle to the shaft. Piper has nice clips on the Cherokees - you could get those, unless Piper parts prices are as bad as Mooney parts prices1 point

-

We will do, Barry. This is a very very inexpensive way to really reach the Mooney owners, prove Genesys' commitment to the Mooney Community and buy a huge amount of priceless good PR. Far cheaper than any trade show and we would invite you to also present on airport day with a display. @Hank, can I ask you to reach out to Barry in his personal email as I will be doing my training thing for the next couple of weeks.1 point

-

1 point

-

1 point

-

Nope. EE, programmer and developer for more than thirty years, and Apple shareholder since Jobs went back to work there, which is partly how I'm retired and paying for airplane stuff now. Just not a user. Thank you all for your financial support, though.1 point

-

1 point

-

As a seller I would not agree to such an invasive inspection as taking off a cylinder. Way too much risk of a maintenance induced problem that I would own if the buyer did not purchase in the end. As a buyer, I would realize that taking a cylinder off would cost 10 hours labor and probably $1200. Put that towards the engine fund. You can get a good idea of risk based on oil changes, oil filter, and hours flown. All of these engines are a risk no matter how good the inspection. One thing I think would be valuable in a pre-buy is downloading the engine monitor data and reviewing that. When I bought the Encore I asked the mechanic to do this, and it was like they had never done it before. They did not have the cables and/or software for the JPI 700. I would have done it myself except I was buying it long-distance. In the end they did, but it didn't matter because the monitor was old and was not set to record data. So nothing there to review.1 point

-

If you are open to options I bought an old riding mower without a deck on it for cheap and built a tow bar in about 3 hrs with $25 worth of metal now I can move my plane around easily1 point

-

People first... Then machines... Does the same MSer operate all three vehicles? (Extra multi-talented) What is the work vehicle that goes with all this? B737? Oops, back on topic.... I vote big bi-fold door.... electric powered, with lots of solar panels on the roof.... Though, The big roll-up door in the background really works for this bus in the background! I also really like the hangar home that one MSer had his Mooney in.... (that may have been TX as well) Somebody did post their business of hangars around here somewhat recently... some interesting ideas were also included.... Take good notes on all the different hangars you see... no two will be alike. It is going to cost a huge amount, so get everything included from the beginning.... post some progress pics and layouts when able. Have no fear... somebody will add some good ideas. Somebody else will make an off color remark, accidentally... it will be a growing experience the whole way! Where is @WorldWiseTrade? Hmmmm..... wide screen TV, surround sound stereo, a couple of comfy couches, a refrigerator, A wall of Mooney tools.... Best regards, -a-1 point

-

Bathroom in your hangar definitely a plus. However, if your house and or garage is right there then maybe not so much. Just so long at there is one handy. I have to walk up to the club house for bathroom but the rent is real cheap. Trade-offs1 point

-

Redo all your antenna cables if you have not. run some extra coax for GPS antennas if you have not already1 point

-

I finally fixed my switch...these are the before pics. Re- installing the base with the wound spring and plate was an interesting challenge. After cleaning and lubricating with Luberex, the switch feels like new and checks out great.1 point

-

Pretty much this. You can minimize it but hard to check things like metallurgy. I think this sums it up. Just like the asking price, the depth of the pre-buy is whatever the buyer and seller negotiate and this will vary according to each party's perceived risk and risk tolerance. In my case, I found a 94 J with less than 1200 hours on it that had been well maintained and had some nice avionics upgrades. On the down side, it was burning about 1/2 qt per hour and hadn't been flown much the last few years. I had a thorough pre-buy done by Don Maxwell who personally borescoped the cylinders. No metal in the filter, compressions in the mid-70s, oil analysis was good and trends OK compared to previous several. The engine started and ran well. The airplane seemed a little slower than I recalled my last one, but that was many years ago, with less instrumentation and fewer antennas. I didn't even consider pulling a cylinder. I negotiated a fair price based on known condition (the rest of the pre-buy showed only very minor issues). Twenty five hours after purchase, the oil ring in #4 broke taking out part of the piston skirt and scoring the cylinder. When we pulled the jug (low compression, metal in the filter) we found the cam spalled. So, now I have a rebuilt A3B6. Cost some money, but I ditched the dual mag, and got roller lifters and a zero-time logbook. Maybe the ring was broken before I bought it. Maybe we could have figured it out if we had pulled the #4 jug. Maybe we should have pulled them all. Maybe we should have disassembled the entire engine. I think at some point you just have to accept that buying a 25-year-old piece of complicated machinery is a risky proposition. The point is: I'm fine with my decision based on what I knew at the time; others might have wanted to probe further. Skip1 point

-

The guy at the Powerflow booth at Sun N Fun showed me a chart of a J model before and after and said LASAR can back up the claims of performance gains... I was skeptical since I’d heard from multiple sources it was not too much of an improvement on the IO-360 vs the O-360. I didn’t talk to LASAR since I wasn’t really interested, just trying to escape from the PFS sales pitch.1 point

-

Welcome to the world of engineering. Might I suggest you design the systems first then design the envelop to fit the systems? Then you can begin the "value" engineering1 point

-

I've built a few industrial buildings so I can suggest something on the sky lights. I've installed windows high on the walls. They'll let light in, no leaks, less expensive than skylights so you can instal more and depending on which way your hangar faces, more windows on the east and west sides will provide natural light longer. It's also cheaper to build a bigger hangar first than find out later you need a bigger hangar. I'd also ask other owners about door size. Maybe you'll want a king air next or want to sell later to someone that has a larger plane. Check out Beechtalk also. Lots of guys there have built hangars and I believe there's a few threads on it.1 point

-

people are getting their transport vs data protocol interchanged. Time to get out the 7 layer OSI model.1 point

-

Couple notes: The HP% on engine monitors is generally not too useful. I don't know about the 900, but I think on mine it's calculated using MP and RPM. I agree with everyone else and suspect your GAMI spread is wide. It tends to cause that broad, flat TIT over a wide range of FF due to different cylinders peaking at different times and would account for your inability to run much leaner than 10 GPH. Until you get this sorted, since you're likely running one or two cylinders close to peak, you might want to consider just running a lower power setting to keep TIT lower. Pulling back to something 55-60% (say, ~9.0 GPH, with MP also pulled back to 26-27") will drop your TIT down to something a little farther from the continuous limit.1 point

-

No, that sounds exactly right. A coordinated turn is a pitching and yawing maneuver. (A flat turn would be all yaw, a 90 deg banked turn would be all pitch. A coordinated turn is a combination of both). The g in the turn comes from the pitch rate. Rolling into a turn to counteract a pitch up is the counterpoise to leveling the wings to stop a spiral. 737 MAX guys would have to roll inverted first though.1 point

-

Get out the IPC and make a list of the parts you'll need to do the conversion. Call Corrine at LASAR and get a price quote. When you get off the floor, I think you'll decide to figure out how to adjust/lubricate/live with your present cowl flaps.1 point

-

I’d like to know as well what the benefit has been across the fleet. I wonder if we created a poll for those who have the PF exhaust and allow them to vote what speed increase if any they saw might help. We would need to know the model it was installed on. Then again, like all Mooney speed mod topics, my F model does 210 KTAS on 2 tablespoons per hour at FL250. Sent from my iPad using Tapatalk Pro1 point

-

You might call the folks at Lasar with this question. When I needed a new exhaust system about two years ago my intention was to go with power flow. I happened to mention that to the then GM of Lasar who said they provided the test aircraft and found no performance difference. That’s surprising to me (which is why you ought to call them to be sure I wasn’t talking to someone who just had an unreasonable gripe with them) but his comment was enough to discourage me from purchase. It doesn’t make much sense to me, though, why a system that demonstrably works on other aircraft wouldn’t on ours.1 point

-

But it's powerful compared to my C . . . . But with my Hartzell 3-blade, I'll probably outclimb most of them.1 point

-

Waaaaay back, Bill Kershner was a leader in authoring aviation training manuals. He was able to write and illustrate concepts that made it enjoyable. I believe ASA has bought out the rights for them and publish them now. I'd look at those. The Student Pilot's Flight Manual is the title of the primary one. Brian1 point

-

Yes, they did my seats and yokes. They did a fantastic job, with a quick turnaround1 point

-

And the day we understand this, the Earth will stop rotating. I particularly never liked how one FSDO thought something was fine and another didn’t. I know a couple years back I read that they were trying standardize this. Not sure it went anywhere. Sent from my iPhone using Tapatalk Pro1 point

-

1 point