Leaderboard

Popular Content

Showing content with the highest reputation on 01/24/2019 in all areas

-

Good evening all, Lurked around the site for a bit and thought I would make myself official. Very impressed with the wealth of knowledge and a willingness to help newbies on this site. You meet the best people at small airports I hold a commercial license, single engine and instrument rating. I have never flown a Mooney but always loved them, Total time around 400 hours, I have over 100 hours in an Arrow, similar time in a V-35, Citabria and a few in a Turbine Evolution and Citation 3 (thanks to a good friend). I have looked a few C models (budget under $60k ) Haven't had the guts to pull the trigger yet on any of them, the fantasy may be better for now, but stuff happens. Fly safe and thanks for a great site.4 points

-

3 points

-

3 points

-

We have carefully vetted the above dates for our Mooney Summit VII to avoid conflict with MAPA, the Caravan, MAPA safety foundation etc. We will have CAMI provide hypoxia training in the Prote reduce O chamber for us and we needed to confirm dates for their and our planning. Mark it on your calendar! We will open registration in late March once again.2 points

-

I think you are going to find various answers based on the plane involved. For my plane with a VFo/VFe of 109 KIAS and VLo/VLe of 104 KIAS, I find that extending the flaps to 15° and setting power at 16”/2400 before I reach the FAF stabilizes the plane for level flight at 100 KIAS. Dropping the gear at the FAF with a small power adjustment keeps me at the 100 KIAS while descending at 500 FPM. When I break out, I will decide whether to land at 15° or if needed, go to the full flap setting of 33°. Sent from my iPad using Tapatalk Pro2 points

-

But then how would you "circulate" fresh, warm oil to the prop hub? Any prudent pilot would do at least 3, mid-range, RPM pulls just to ensure the prop is purged of all that nasty cold stuff and replaced with that extra fresh, warm elixir. 9 out of 10 mechanics agree...unless of course they work for a prop shop and know better.2 points

-

I flew her this morning and the throttle and gear horn are spot on! Oh, the little things in life! Now, the 345 doesn’t seem to be picking up a tower. It’s always something.2 points

-

Reading this thread made me get out my notebook. I’ve had my Debonair for 7 years now and have many notes on airspeed and fuel flow. I also have done a 3 way gps true airspeed calc and compared it to my airspeed indicator. The gps calculated out to 156knts true, the airspeed came out at 154 knots true. I’d call that a wash as I was flying, and writing at the same time. I have the lower compression 225hp engine that is not as efficient as the higher hp v tails. i generally cruise at 150 knots at slightly under 12gph. That’s just slightly lop. I can do 160, but that’s pretty much down low and very rich. But I can burn Mogas. Currently 90 octain cost $2.66 vs $3.69 for 100ll. So to cruise at 150 Knt. 12 gph 100ll cost $44.28 per hour. Mogas cost $31.92 per hour. 8.7 gal of 100ll cost $32. So my Debonair using Mogas is also pretty efficient cost wise. Granted on longer trips it’s not available. And come overhaul time it will be hard not to opt for a 260hp plus engine for the extra speed.2 points

-

Indeed! As well they haven’t seen your panel in a while. Come to think of it, mine either. [emoji1787] Sent from my iPad using Tapatalk Pro2 points

-

If there is a big EGT difference, and since you've already checked your magneto, to me that suggests a mixture issue. If you had a plugged injector or other fuel delivery issue, I would think you would still have a big difference at cruise power settings. You said you don't. If you only have a big difference at idle, to me that suggests an intake air leak. At full power there is very little difference in air pressure between the inside of the intake and the outside of the intake so very little air gets sucked in and the mixture is about the same as the other cylinders. However, at idle the pressure inside the intake is a lot lower than outside, maybe 20" of MP? That would be conducive to sucking a lot of air into any cylinder that had an intake air leak. That would cause that cylinder to be much leaner than the others. If you have all the other cylinders running brutally lean, then the cylinder with an air leak will be even leaner. It may be so lean that it occasionally does not burn well. If that is the case, if you enrichen the mixture while at idle, does the stumbling go away? Then the question becomes, how much do you want to spend to fix it? If it only affects the engine at idle I'm not sure I'd be willing to spend a lot of money. I'll be curious to see what LASAR says.2 points

-

Man, that is very interesting! Yet another way for me to "invest" in my airplane. Last night, my wife and I were watching TV as I leafed through a flying mag. I stumbled on an ad for a single engine very light jet. I wistfully mentioned that if we suddenly come into LOTS of money, I'd like to trade up. Then, in a flash, I corrected myself and said, "no, I'd just like to have lots of time and money to fly my Mooney and install upgrades." I'm so prudent sometimes I surprise even myself.2 points

-

Even in the summertime, I close my cowl flaps on decent. I keep them closed until I am under control after flap retraction during a normal landing. During a go-around, they are on my list to open but I make sure I am positive rate climbing (and indicating) after I retract the gear before I worry about the cowl flaps.2 points

-

Hello everyone, My latest article has been published on Air Facts Journal. It's about my Sport Air Race League event from last year. Here's the link: https://airfactsjournal.com/2019/01/going-mach-0-3-with-your-hair-on-fire/ I only wish there were more events in the Southeast that I could participate in. Last season was hampered by poor weather luck, and I think racer participation was down. So if you have any interest, I would encourage you to check out the races for the upcoming season and dive in. They are really fun. The main league website is http://www.sportairrace.org. Cheers!2 points

-

2 points

-

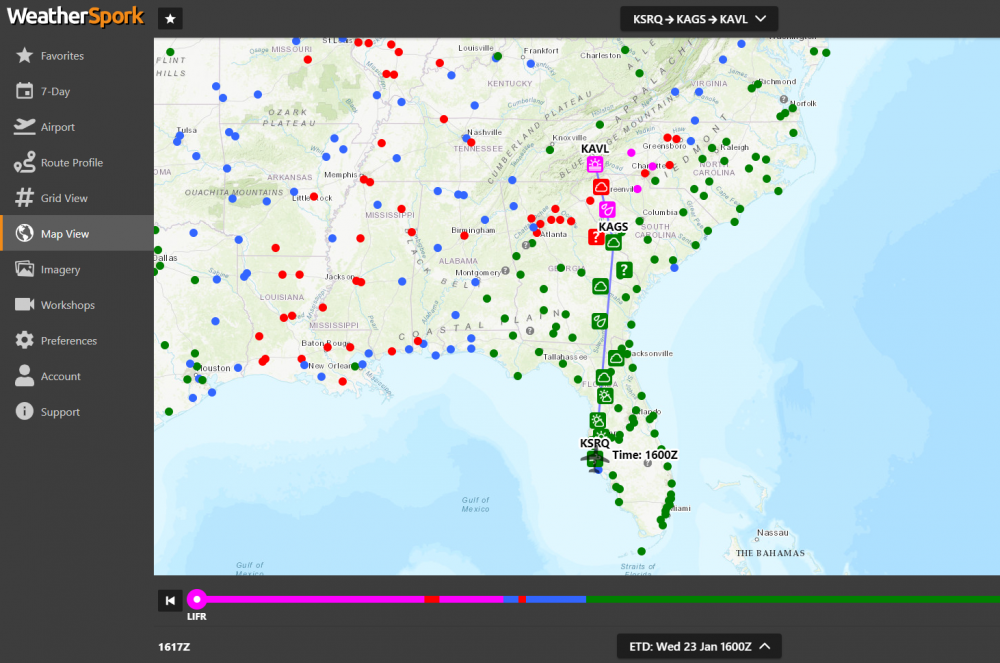

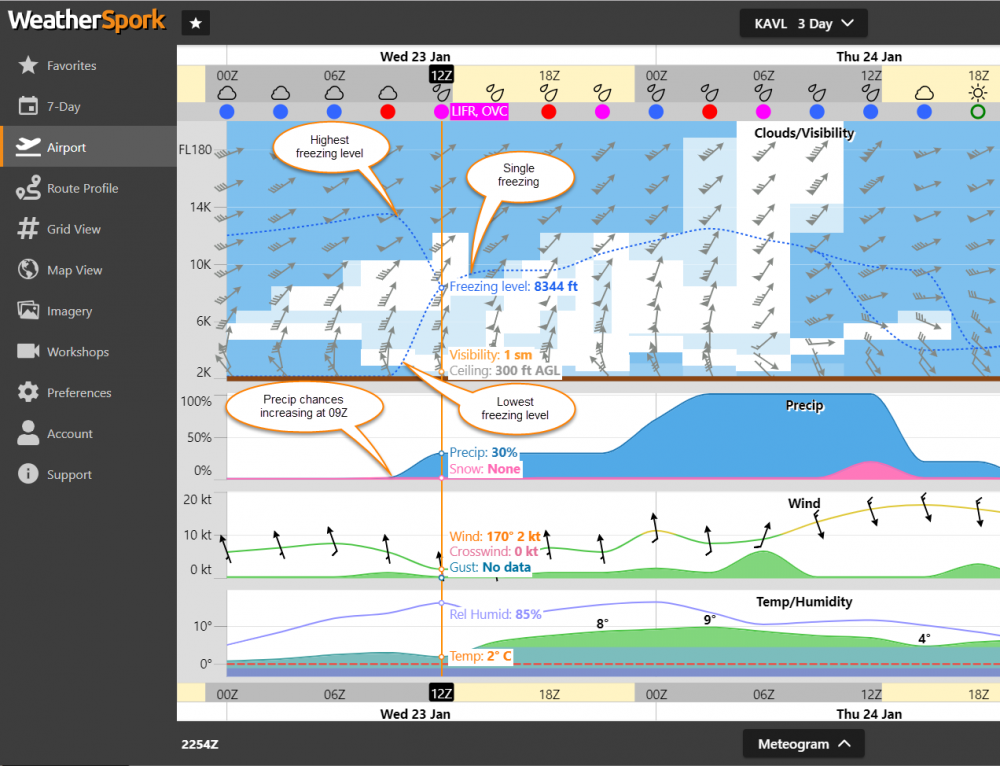

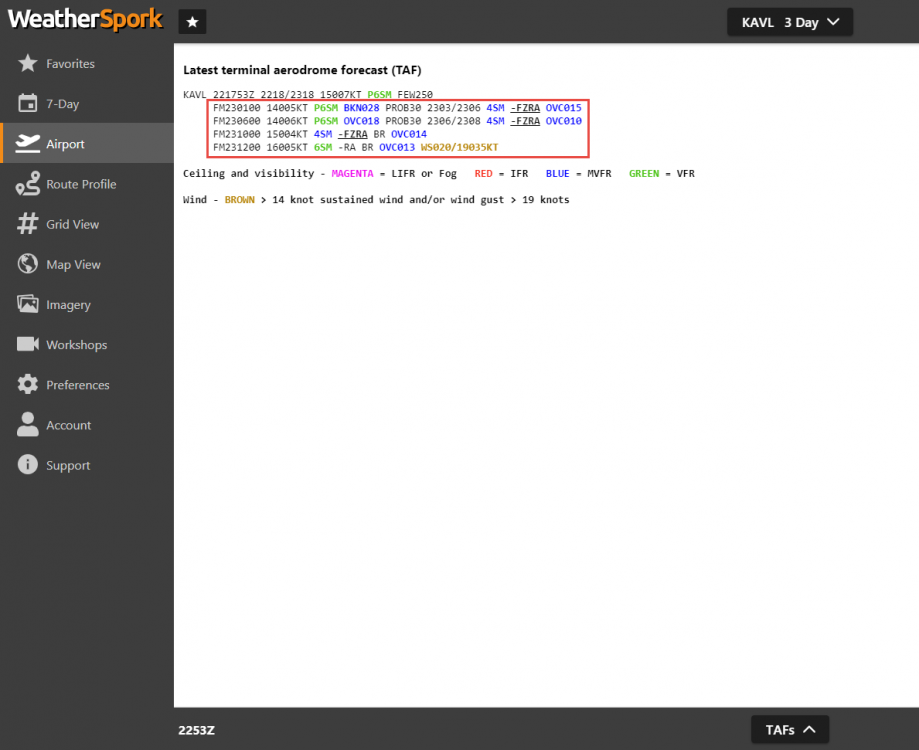

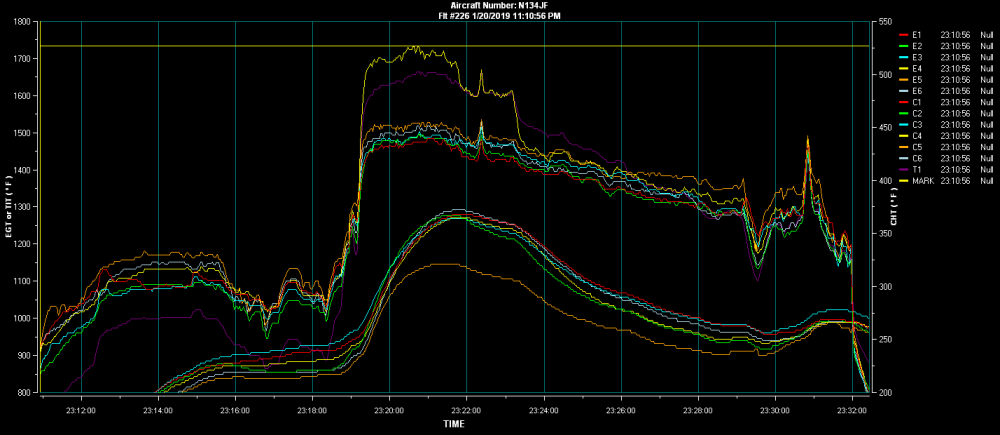

Was doing a one-on-one session with a customer yesterday who was planning a flight from Florida northbound to Asheville, NC (KAVL). His plan was to depart this morning around 9 am for a 2.5 hour flight. Mostly VFR conditions (green) expected along this route until reaching the Georgia where IFR (red) and low IFR (magenta) could be possible. The flight was planned well ahead of a major weather system moving in from the west, so no issues there. However, with cold air in place near the surface over the Piedmont of NC and SC, the chances of some freezing precipitation were expected ahead of the primary weather system as warm air from the south was overrunning the cold air at the surface. This was expected to give rise to a temperature inversion and multiple freezing levels as shown below (screenshot taken yesterday during the online session). Notice above that about 09Z, multiple freezing levels exist in this meteogram view for Asheville and then by 12Z, the warm air takes over aloft and creates a single freezing level after 12Z. The precipitation chances are shown as ramping up around 09Z as well with low IFR conditions (300 ft, 1SM) at Asheville at 12Z. This sets the stage for a freezing rain (or freezing drizzle) event with LIFR conditions at Asheville. So this certainly solidified the plan to wait a couple hours after 12Z to arrive in Asheville. Note this aircraft has a TKS certified ice protection system. Below, the Asheville TAF, on the other hand, has some freezing rain probabilities from 01Z through 12Z with MVFR ceilings and vis through the period. So, the forecasts above and the TAF agree that the freezing rain is expected to end at 12Z which is nicely represented in the route profile view above. Now that we can look at the observations, let's see how well the forecast above did versus the TAF. Here are the surface observations for KAVL from 01Z (at the bottom) onward. I've removed some of the remarks to keep the coded observations short.KAVL 231454Z 17003KT 3/4SM BR OVC003 01/M01 A3028 KAVL 231449Z 17003KT 3/4SM BR OVC003 01/M01 A3028 KAVL 231419Z 00000KT 1 1/4SM BR OVC004 01/M01 A3028 KAVL 231354Z 00000KT 1 1/2SM BR OVC004 01/M01 A3029 KAVL 231349Z 00000KT 1 1/2SM BR OVC003 00/M01 A3028 RKAVL 231341Z 00000KT 1 1/4SM -FZRA BR OVC003 00/M01 A3028 KAVL 231331Z 00000KT 1 1/4SM -FZRA BR OVC002 00/M01 A3028 KAVL 231305Z 00000KT 1 1/4SM -FZRA BR OVC003 00/M01 A3028 KAVL 231254Z 16003KT 2SM -FZRA BR OVC003 00/M01 A3028 RMK AO2 UPE40FZRAB40 KAVL 231246Z 18003KT 2 1/2SM -FZRA BR OVC004 00/M01 A3029 RMK AO2 UPE40FZRAB40 CIG 002V007 KAVL 231239Z 18003KT 2SM UP BR OVC004 M01/M01 A3029 RMK AO2 CIG 002V008 KAVL 231224Z 18004KT 1 3/4SM UP BR BKN003 OVC007 M01/M01 A3029 RMK AO2 CIG 002V005 KAVL 231220Z 18004KT 2SM UP BR OVC005 M01/M02 A3029 RMK AO2 CIG 002V008 KAVL 231154Z 00000KT 3SM UP BR OVC008 M01/M02 A3029 RMK AO2 CIG 003V009 KAVL 231054Z AUTO 22003KT 3SM UP BR OVC007 M01/M02 A3032 KAVL 231020Z AUTO 00000KT 3SM UP BR OVC009 M01/M02 A3032 RMK AO2 CIG 004V010 KAVL 230954Z AUTO 00000KT 5SM UP BR OVC010 M01/M02 A3034 KAVL 230943Z AUTO 00000KT 4SM UP BR OVC009 M01/M03 A3035 KAVL 230854Z AUTO 00000KT 9SM OVC010 M01/M03 A3036 RMK AO2 UPB08E44 KAVL 230754Z AUTO 11003KT 10SM OVC014 M01/M06 A3040 RMK AO2 UPE42 KAVL 230654Z AUTO 14004KT 10SM UP OVC016 M01/M09 A3041 RMK AO2 UPB20 KAVL 230554Z AUTO 14004KT 10SM OVC018 00/M12 A3043 KAVL 230454Z AUTO 16004KT 10SM OVC021 01/M13 A3046 KAVL 230354Z AUTO 14007KT 10SM OVC023 01/M13 A3047 KAVL 230254Z 14004KT 10SM OVC026 01/M14 A3048 KAVL 230208Z VRB03KT 10SM OVC029 01/M14 A3048 KAVL 230154Z 16004KT 10SM OVC030 01/M14 A3048 KAVL 230112Z 14003KT 10SM OVC031 01/M13 A3048 KAVL 230054Z 16004KT 10SM OVC029 01/M14 A3048 Using the observations, the first indication of any precipitation wasn't until 07Z with UP (unknown precipitation type). Likely freezing drizzle occurring (an ASOS can't automatically report freezing drizzle and likely reports it as UP). Then at 0943Z, more UP. The TAF only showed a 30% probability of freezing rain through 08Z whereas the forecast we used above showed a 0% chance up to 09Z. Then, notice the freezing rain actually was first reported at 1246Z and last reported at 1341Z as the temperature warmed to above freezing by the 14Z observation. The biggest difference was in the ceiling forecast. The forecast we used above had the flight category in the IFR range by 09Z and then LIFR at 12Z. The actual ceilings dropped from VFR at 01Z to IFR by 0945Z. Then by 1224Z, KAVL reported a ceiling of 300 ft. The forecast we used picked up on this trend really well and was much better overall guidance than the TAF. At this point in time KAVL is reporting very LIFR conditions and the pilot smartly diverted to Greenville Downtown (GMU) which was an expected outcome due to the potential of LIFR when we looked at alternates yesterday. KAVL 231601Z 16008KT 1/2SM FG VV002 01/00 A3022Overall, the tools we used did a pretty nice job showing the overall adverse weather hazard trends and allowed the pilot to plan a solid alternate accordingly.2 points

-

Flew to Hartford Brainard - KHFD today - to drop my wife off to spend a few days with her mom. Then I flew home. Beautiful clear day. But a little bit chilly - "crisp". It was -23F this morning as the sun rose so we delayed a bit and got underway around 1030 when the temps rose had risen to about -5F. It was still -10F in the hangar but the turbo-reiff heater (oil and cylinder bands) + full bruces insulated wrap still had the oil at 91F before I even turned on the key. But interestingly, at 1000rpm and lean for taxi - the oil cooled off to 85F so it took a little while to get the oil to heat up to 101F for the mag check. Home tarmac was all white but in that very cold snow, its very rough and has a lot of traction almost like sand. But on arriving at KHFD the atis warned ice runway with breaking action poor - and wow they were not kidding. It was plowed wide and 4400 ft but it was literally a slick ice rink - just the slightest tap of breaks and slide - so I just let it roll out on its own. With a long runway our airplanes are basically airships as if an airboat on water. The tarmac was so slick it took that slow short step "hockey coach" walk to keep safe. I found a small patch of clear though to park so when I restarted I did my runup before I even moved since run up would have been impossible on any other piece of ice. I took this picture on the way home. I don't usually fly so low so I was enjoying the view! There were some very cool wind turbines right in front when I took the picture. Wind energy - plus my flight was enjoying wind energy - I went out at 11500 with some nice tail winds and and ground speeds like 220 kts at very low power settings and then returned at 4500 (but later 6500 to keep safe in the Adironack mountains) with ground speeds from 135-160 on much higher power settings. It was a much more balmy 5F when I got home. Tomorrow they forecast 38F and ice rain! I think I'll leave N314EB safely in the hangar for that!2 points

-

1 point

-

1 point

-

Good point - made me chuckle. All that prop cycling has always mystified me. I think it's a holdover from old military manuals since the hydramatic props sometimes required cycling several times to get reasonable response in cold weather (been there, seen that). I have no idea what's magic about three cycles, but that procedure even made it into my M20J POH! To Clarence's point about skipping run up: I've flown for two Part 135 seaplane operators, and the FAA-approved SOP at both was run up on the first flight of the day only. Airplanes are meant to fly. Engines don't cool so well on the ground, and there's sand and gravel and whatnot in the run up areas to erode your prop. Do we wear our airplanes out ground checking stuff too much? Something to think about. Skip1 point

-

Fred, An important point to cover when discussing pumps and flap angles... The first pump pressurized the system...no movement... 2, 3, and 4 moves the flaps 1/3 of the total travel... each. Then there is 4.3 the last amount that isn’t a full pump. That will adjust how people are answering your question... Best regards, -a-1 point

-

Hank It goes like this As are appealing Bs are the best Cs are cool Ds are dynamite Es are excellent F are fabulous Gs are good Js are joyous Ks are killer Os are outstanding Rs are remarkable ........ well you get the picture1 point

-

For $1.50 worth of hardware, why bother? For a 500 hour inspection, they'd most likely be reused. For an overhaul, usually not for a reputable shop.1 point

-

But we have so much fun teasing people who ask stupid questions. Give us something to work with.1 point

-

I don't see why not, but I've never used one. They would just run a lot longer. Realize that these things are not going to make ABO. You are on your own as far as using it. The regulations are a little vague about this. I think you would be OK if you documented what you were doing and proved you were getting enough oxygen.1 point

-

Oh right - no it won't. But honestly I don't know if moisture free is a problem for our GA use. As I understand it the reason for moisture free is so that the lines don't freeze in certain aviation environments that we do not encounter. Consider a large O2 tank in the belly of a jet flying at 45,000 ft where it is -50C...then even a little moisture is a problem as the lines could freeze and you won't get O2 flow when you need it most during an emergency. But in our small time small airplane use, where the O2 bottles sit in the cabin with us...I am hoping I am not flying when it is that cold. So I wonder if the one-size fits all aviation standard of moisture free is important for us.1 point

-

Why are you concerned with moisture? With a built in bottle the regulator is in the tail cone and can freeze if there is moisture in the O2. These systems would most likely be used with portable bottles. The portable bottles usually live in the cockpit where it is rarely freezing. I realize there is a temperature drop at the regulator orifice that could lower the temperature, but if the bulk of the regulator is warmer than freezing, any ice would rapidly melt.1 point

-

Nice!! Well made, heavy duty and John Deere green!1 point

-

I pulled the grinder one time before I went with the strobe version. You can pull the entire unit from below. Just remove the mounting screws and the unit should be free. My comments are based on the 1975 version of rotating beacon. 60 models may be different. Once out, you can remove the cover screws and get to the gears inside. I can’t recall what lightweight grease I used but you want something that has a wide temperature range. Sent from my iPad using Tapatalk Pro1 point

-

yep, that way there tail strobe works for everybody whether they needed the white position light with the strobe or not; and probably most do.1 point

-

Bob, some day you're gong to have an opportunity to show a photo of that gorgeous airplane of yours...and you're not going to do it. At that point in time I may fall over forma heart attack from the surprise.1 point

-

First of all, EGT's at idle power and especially full rich, are meaningless. Even doing a run up on the ground full rich, is also meaningless other than to check for a fouled plug. If you want to check the ignition system, go fly and do an in-flight lean mag check. Check the SavvyAnalysis website for their Test Profile for detailed instructions. And at your earliest convenience, pull that JPI and send it in for the upgrade it needs to download data. Next, create an account on SavvyAnalysis where you can upload and analyze the data. The account is free. You can even share a link to data from a specific flight and let us all take a look at it. This service is also free :-) Report back after doing the above. In the mean time, don't worry about it and go fly.1 point

-

5/8”... do watch the video. Expect a little blood... Our royal highnesses are sometimes hateful but love them anyway [emoji846] Perhaps I should get Lynn and Nathan to do another video talking about metal contaminants [emoji38] Sent from my iPhone using Tapatalk Pro1 point

-

1 point

-

Seriously? Quoting/reposting these pictures more than 2 years later? Most of us were still trying to forget the first time!1 point

-

1 point

-

Wow..that’s the girl for me!1 point

-

It dose to a point, however a little weight on the tail is a Good thing with a Rocket....lol1 point

-

Don’t have regrets! There are plenty of good planes out there. Just be ready to pull the trigger (with cash, if possible). I lost out on several deals becuase I wouldn’t make a decision fast enough. I showed up to the plane two days after the ad appeared (I called and made the appointment the evening the ad showed up). The seller had emailed the logs which I had reviewed before I showed up to look at the plane. Having looked at countless planes over more time than I care to admit, I knew this was one worthy of an offer. I made a cash offer contingent on a pre-buy at a nearby MSC; he had 4 other buyers in the wings, but “bird in hand cash offer’ won the day. (Deal was made with a handshake and no deposit. Others may freak-out at “no contract” but it worked for us) The seller flew the plane to the MSC, plane checked out OK, and a week later I wired the money and escrow closed1 point

-

1 point

-

1 point

-

Okay! I removed the nose bowl and found the lower throttle linkage shaft hitting the oil pan. Under the supervision of and inspection by my A&P I moved the bottom lever one tooth and now have proper throttle operation and the switch is actuating abou 1/4” before throttle is full rearward. It is in the range of the switch, so I might have to tweak the switch slightly. I am very pleased with the whole thing and I now feel confident about the nose bowl removal and replacement procedure. Thanks for the help!1 point

-

Supercop- the Service Manual shows 2 different parking brake valves, the 4200 and 4500. You'll need to put your eyes on whatever is installed in your plane to see which one you have. If you have the 4200, life is good- simple o-rings to replace. The 4500 is a different animal, and then it depends where and how it's leaking. If it's dripping on your carpet, it's not too bad. If it's no longer holding your brakes, it's probably the seat assembly from the parts list- and those are pricy, if you can find someone to sell you one.1 point

-

My wife took the pic..blame her...The name of the place we stayed is the Tantalus hut...crude hostil type sleeping with large kitchen.They had just rebuilt dock and have a couple boats they lend.It primarily caters to mountain climbers and charged 20 per night in 2010.When we went,we cleared customs at abbordsford BC Than stocked up on groceries and beer and ice in the float compartments.Vancouver complained about our rate of climb (we were heavy).Charters available out of Vancouver or whistler...also there is a helicopter operator down in the Valley below.1 point

-

I'm not going to argue with you about how to do a go around- please remember that I fly the exact same airplane type as you. The point I'm trying to get across is that "quickly" is one thing, but it should never be frantic. (Unless you're doing a go around in a box canyon in the Idaho back country. Pretty sure that doesn't apply to either of us.) You should never get the "mother of all pitch up motions" from adding full power smoothly. A steady, smooth application of power that takes about 2-3 seconds is easily counteracted by elevator pressure to maintain about 75-80 mph. Roll in a few (about 2 or 3) spins on the trim and you're ready to retract the gear. Retract the flaps and the airspeed will come up nicely as the nose pitches down upon flap retraction. Now you have plenty of time to go to 25/25 if you desire, turn off the fuel pump, and open the cowl flaps. And this is the one time I will invoke my decades and thousands of hours- if it feels frantic, then it needs to be practiced more. Doing 4 or 5 practice go arounds at 3,000 AGL will do wonders. And "firewalling the throttle" should be smooth, steady, and gradual- not split-second and frantic.1 point

-

I have a Johnson bar Mooney, Michael. The "after take off checklist" I'm referring to would be completed as you're climbing through 1,000-1,500 feet or so leaving the traffic pattern or joining downwind. Having more than a year and a half of my life off the ground, I can't think of anything that is particularly "frantic". I have found that with that many hours, I make mistakes with much more confidence than I used to.1 point

-

It was less than a year after finishing IFR, call it Jan 2010 or 11. Lots of paper still around.1 point

-

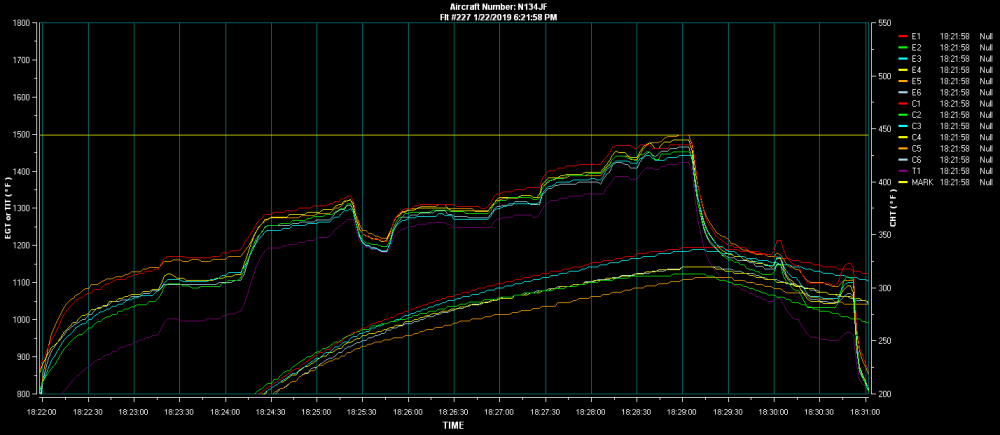

Reviving an old thread. Sunday I went up and less than a minute after take off my TIT was very high at full rich and my #4 cylinder was high - definitely caught my attention so I landed. @kortopates looked at my JPI data and it looked like a clogged injector but the data looked like it might possibly have cleared itself out after I landed. but I wasn't completely convinced that it had cleared itself since I couldn't get the TIT below 1100 before shutdown, when it's usually in the high 800's. This morning after reading @FlyDave 's post. I pulled the line away from each injector and with red straw that comes with the carb cleaner got a couple of good shots in each of the 6 injectors. I torqued the lines back on the injectors and let it sit for over an hour. I went out and ran it up and all the temps look great and it runs very smoothly now. The TIT at shutdown was back down where it normally is at 870. Thanks @kortopates and @FlyDave.1 point

-

Well, the Saga is over. I got my plane back today. I did the engine break-in this morning and all is well. The airplane is in better shape than when it went into Annual last September. I'm waiting on the last insurance payment to put this whole episode behind me. In the end it probably couldn't have gone any better than it did. Now down to LA tomorrow to work with another student; and in my plane and not Commercially. Edit: I got the final insurance payment a couple of days ago. The ordeal is finally over.1 point

-

The reskin and paint/balance was done by Dawson Aircraft in Clinton, Ark. The hold-up was getting the skin from Mooney. In their defense there was at least one hurricane that interfered and drained the supply of skins. Will Dawson had his son fly in and pick it up, my adjuster flew it back when he picked up his 210 from annual. The work is top notch, it looks great and of the highest quality.1 point

-

1 point