Leaderboard

Popular Content

Showing content with the highest reputation on 12/22/2018 in all areas

-

8 points

-

Fresh out of paint, our new to us Mooney Rocket. Mechanically she is sound but she will need some love getting the little bugs out. Flew her a couple of days ago at 12,500 doing 206KTAS. Got to love the speed. Anyway, new to the forum and wanted to introduce myself. Gavin Woodman CFI/MEI/ATP AEROCOR.com FlightData.com7 points

-

FWIW, in 26 years, I've had 3 issues with the KFC 150, not including replacing some lights in the KC 192 computer. One was a pitch servo in 2001 (repaired), the trim servo in 2003 (repaired), and finally the trim servo in 2014 (exchanged) that I didn't know wasn't operating up to par. On landing I always manually set the trim back to takeoff trim so as not to work the servo and it seems to have paid off. Also, since I can fly the airplane smoother than an autopilot when turbulence gets to a certain level, clicking the AP off at that time also saves on overworking the serves. If the KFC 230 becomes real next year, I would seriously consider it as an economical and less time consuming install option (especially since my plane has been out of commission for 3 months this year). As the above shows, the KFC 150 had been pretty bullet proof over 26 years, and with everything staying the same except the computer and another interface part, looks to be a promising, reliable alternative to the GFC500. The 2 year warranty on the servos would be a bonus.4 points

-

Test it on the ground with someone putting some pressure on the cowl flap with their hand. The motor on my 252 is super slow and very powerful. Something like 1 RPM. Check to see if the shaft is turning at the motor but not moving the arm. The roll pins might be sheared off. In my case recently, the roll pins were a bit short and had mashed the ends over just enough that on the ground with no pressure, it would move the flap, but if you put your hand on it, the shaft would slip. New roll pins solved the problem.3 points

-

It’s a $15,000 project. The $800 spent on planning is well worth it, and the difference between a professionally designed scheme and a mediocre layout guy with a roll of green tape is huge. The first thing you notice is the proportions and the flow of the scheme. Then you look at the rest. This matters especially when the owner wants a long body scheme on a shorter airplane or the reverse. They don’t scale well.3 points

-

Agree with this statement, I am on my third Mooney in 24 months. Most people hear that and freak a little: it’s not because of bent metal. I started with an (NA) M20F, but without my IFR and pricing avionics, I decided it would be better to upgrade airframes to an GPS WAAS capable bird to get my IR. So, I bought a well oiled mid/high time 231 with a proper autopilot and avionics. Great bird. Got my IR in the 231 and flew the pants off of it. I think in 12 months I logged over 350hrs. Then, I found (for me) the holy grail. A true 252 Encore with 1150 of useful load with a low time engine: my forever bird. I jumped on it as there were only like 37 produced, and not looked back. My advise is to find the nicest, most expensive bird you can afford and don’t look back. I was lucky in that the transitions did not cost me a lot (loss) to move up because I bought the very best I could afford at the time and when I sold, they brought near what I paid.3 points

-

It will never happen to me. #1, I am much too good as a pilot,. And #2, I use a checklist. This worked for almost 38 years. Unfortunately, I won't make 39 years. In September, I was flying to get a $100 hamburger. I almost always do a standard pattern, but on this day, there was a low cloud layer directly over the downwind path, and the runway was clear dead ahead. I decided to do a straight in and stay out of the clouds. I was close and fast, so I pulled power and pulled the nose up to bleed off airspeed. Once I got to 120 mph indicated I dropped the gear. Slowing under 100 I put full flaps. Something did not feel right, but I did not listen to the little voice. Short final,, 70 kts. I reached over and verified the gear handle was down, a habit I always do (usually 3 times). I came in for my greaser landing and then "womp" - I was sliding down the runway on my belly. After stopping, I wondered what the heck. Looking around, I saw the gear breaker had tripped, and the gear only came down about. An inch. I did not verify the gear down light, nor check the floor window. I assure you, that is on my checklist now. Hope you.guys can benefit from my boo boo.3 points

-

Hi All. It’s been a few years and I got around 500 hours on the engine. Not a single issue. Speed is within margin of error, best I can tell exactly the same as when the motor was just broken in. I still don’t know if the extra steam under the cowl came from the power flow exhaust or jewel, but it runs great and oil consumption is a quart in 10hours or better. Jewel is one of the best kept secrets! Sent from my iPhone using Tapatalk Pro2 points

-

No doubt Bendix King abandoned small GA for a number of years. But farther up the food chain their AeroVue in the Honeywell Primus is pretty nice and they are bringing the AeroVue Touch & XVue Touch down to small GA . If they are serious about competing again in small GA the AeroCruze 230 is a smart way to get back in since they have so many King Autopilots that are ripe for upgrades.2 points

-

Sure, but it could be the thing that would make me select the King over the Garmin if the king doesn’t have that issue. Sent from my iPhone using Tapatalk2 points

-

Tie down rings... They are on the remove before flight list... No, they don’t fall out either. Lasar has some fancy alternatives for aero dynamic ones... They get removed to jack the plane up at annual.... Tensile strength is important, don’t get ones that just look right... The tail tie-down is more sensitive to weight and length. It can hit on the ground... Best regards, -a-2 points

-

Mike- Thanks for your input and effort. I didn't know the problem had made it this far yet. I tossed the question out as I had never seen anything close to 10 oz. needed between one paint job and another. It doesn't pass the smell test to me. As to the bondo, If it was removed and not replaced that would make the balance weight lighter not heavier, I would think, as the bondo would be behind the hinge line. I asked how the other surfaces came out but have not heard back yet. If they had no issue with rebalance on them then I told Russ that I'm still skeptical of the procedure and not the surface. I suggested that they really review the manual to make sure they were using the correct one and not from another model Mooney as the balance limits change from model and production block number quiet often even in the same model. Can't use a J model balance limit on a K model. I think Pieter Mol is pretty sharp but I also think something is being missed. Its all coming to Pieter from the pint shop. They, not him, are doing the balance. I don't know anything about the paint shop or their experience with Mooneys. I've asked for the torque figures the paint shop has come up with. I'm thinking they are going for perfect balance and not the underbalance called for in the manual. I'd like to see the torque figures. I'd prefer to see a picture of the balance rig with the elevator in it. Don't know if they have the control horn on or off during the weigh either. I have seen 1 -3 ozs on other airplanes at times but not 10 oz. Some people have actually used slugs of depleated uranium to balance as its heavier than lead. Thanks again. Story to continue after the holidays as the factory is closed.2 points

-

Clock is not just used for timing approaches. It is also used for clearance void times, EFC and position reports. Sent from my iPhone using Tapatalk Pro2 points

-

The same thread I linked to before included a post where someone mentions that the KFC 230 installation requires Bendix King to test the servos. The bendix rep didn’t respond to the post. I don’t have a clue if that’s correct or not. The GFC600 install I just had completed was pretty straight forward according to the tech that did the install. New brackets with new servos in the old locations. I don’t have a breakdown of the time to install just the autopilot, but I’m sure it was a time consuming process. Autopilot worked perfectly on the first flight.2 points

-

2 points

-

And my own runway on Island on the Caribbean ,Secluded cabin on Alaskan Lake,Turbo beaver on amphibs,TBM ....that's not to much is it Santa?.....oops wrong website......2 points

-

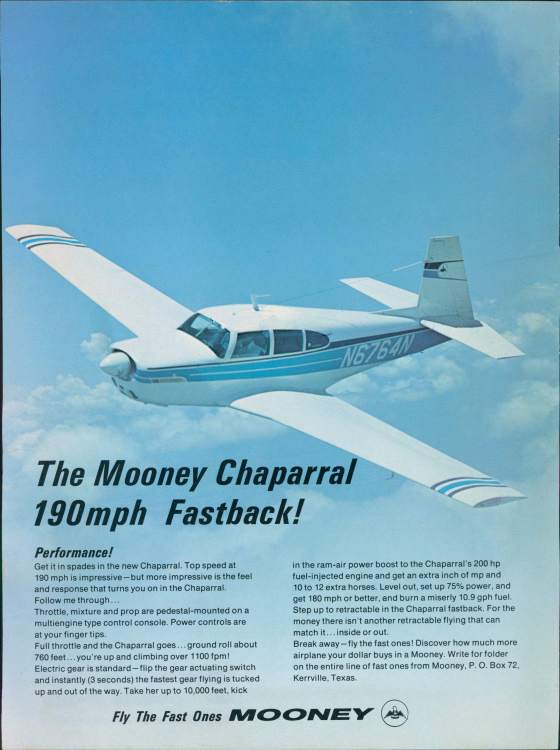

mooney chaparral 1969 m20e serial #690069. 1578 ttaf, 242tte. recent annual 8/18. low time original mooney. this plane could be the finest near original mooney chaparral in existence. electric landing gear and electric flaps. take a close look at these pictures to see how magnificent this plane is inside and out. 90% original paint and interior. always hangered, very well i repeat very well maintained. logbooks are very complete and in excellent order. lasar mods, no damage history, and a new hartzell scimitar propeller. 1578 ttaf, 115 ttpsn, 242 tte, io 360aia lycoming serial # l6640-51a, kx155 nav/com, garmin gnc 300xl gps, kma 24 audio panel, narco at150 transponder, sigtronics spa 400 four place intercom, king vor glidscope. a must see. call anytime: john 727-470-11411 point

-

I concur, mine has been very reliable. Of the autopilots I fly at work, the king is also my favorite, except for the lack of roll steering. It performs better than the S-TECs and Cessna autopilots. That said the Garmin is excellent too. Sent from my iPhone using Tapatalk1 point

-

I’m not disagreeing that the software should be updated in the future for the gfc500. They could easily put a warning symbol on the g5 and keep the AP connected. I think combining the data is a great idea and will provide unparalleled precision (in small aircraft) during ILS approaches. I know one of the top rebuilders of BK equipment will not allow AP usage in their own aircraft (BK 150 AP) under 700 agl. This was after multiple failures that resulted in full pitch deviation malfunctions. Im not upgrading to the 230...with a touch screen etc the maintenance will eat you alive. Currently THREE THOUSAND DOLLARS to just bench test a AP head unit. If you think the BK unit will save you money in the long run you’re crazy.1 point

-

Welcome aboard, Gavin. https://flightdata.com/ Best regards, -a-1 point

-

Including Mooneys of all shapes would be nice including your Rocket which I’m sure rocks.1 point

-

Again my current 25 year old king does it just fine. Not like the sloppy S-TEC. It’s a reduction in capability and if you fly hard single pilot IFR its an unacceptable one. Sent from my iPhone using Tapatalk1 point

-

Condition of the leads coming off of the mag. The spark plug leads shouldn’t have breaks in the shielding and make sure the they are attached completely. Think it is 35 in.lb on the spark plug side (one of the IAs can confirm the torque or tell me that “just snug” is fine). Sent from my iPad using Tapatalk Pro1 point

-

Sorry to get political. Those folks still have to pay their bills. Goncourt IOUs don’t pay for groceries or impress your banker.1 point

-

Read the service manual carefully. These elevators are often under balanced, IE, the trailing edge weighs 10-14oz when sitting on the jig and level.1 point

-

So what's your procedure to lower the gear when tower sends you 14 nm beyond the field still almost 7000agl before turning you inbound to land? That's what almost got me, but the short final check caught the error and my landing was nice, complete with the expedited exit Tower asked for while still 7-8 nm out. Two things typically catch people: distractions and non-standard approaches.1 point

-

I used to fly a Liberty XL light sport plane. It had dual electric ignition and dual FADEC which depends on 28vdc with a battery back up. It had a master caution and master warning system and it had a two battery system. If the alternator failed, it would be on ships battery down to a certain voltage, then switch over to the back up battery, run it down to a certain voltage then tie them together and at that point you’re not guaranteed to have a functioning engine after that. But the manual clearly stated this, in case of alternator failure you have 30 minutes of demonstrated time to get it on the ground. This also assumes a battery capacity test every year. If the master caution illuminated you continue your flight carefully but if the master warning illuminated the manual said to get the aircraft on the ground as soon as possible and it does not have to be limited to an airport. The engine could fail at any minute. It’s the only plane I had stumble and misfire a bit after shutting down briefly because I pulled the alternator circuit breaker simulating an alternator failure. Anyways be careful with that stuff.1 point

-

1 point

-

1 point

-

Yes they are still for sale. However I’m out on travel until Jan 2. If I can wait I’ll ship promptly.1 point

-

Is the cowl flap motor getting weak and not able to overcome the resistance in the air?1 point

-

I had occasion to be in contact with Joe for several months he does respond to phone best. I hate to call a guy who might be in the spray booth so I texted him and he usually called me immediately.1 point

-

1 point

-

I was having just higher oil temps than I liked, often near the top of the green arc and sometimes approaching exceeding it during climb. It wasn't very consistent and the cowl flaps still made a difference. Changing the vernatherm fixed it. Maybe it was stuck partially open or something. I think this is one of those things that can be hard to pin down without just attacking it. I thought the vernatherm would be an easier and less risky change than poking at the oil cooler, so we took that approach and fortunately it worked out in my case.1 point

-

IIRC, the AIM suggests that the segment between the IF and the FAF is generally designed and intended to be as straight as practical to give you time before the FAF to make final preparations for the approach. I imagine that is not always true, but it's a reasonable argument to do your primary landing checklists in that segment (or comparable segment if there is no IF or FAF)1 point

-

My reading is it won't fly any needles without GPS. It will display pretty green needles to fly either by manual commands(hdg bug, etc) or by hand. From what I've seen that's only if you have an existing digital attitude source(KI-300, G500, Aspen) otherwise you'll have to add one of those. Similarly it doesn't include an HSI, but it can use the existing one. I thought I saw a vapor announcement for King doing a digital HSI, but I can't find it now.1 point

-

I think vis a vis flying in Europe, if you have to ask you really can't afford it. I'm surprised anyone can.1 point

-

https://www.iaopa.eu/fuelprices https://www.you-fly.com/airport/ there are others1 point

-

I've searched my PC over and over and just can't seem to find the ALT HOLD button. I guess I'll just have to stick to my dual installed Mark 1 Eyeballs for monitoring and 5 digit control manipulators for the actuation.1 point

-

^^^ This. It might be annoying to have just bought a Mooney and then train in something else, but if you are rusty, you need ANY stick time, not necessarily Mooney time. The transition could come later, and who knows, if you find a local instructor that works out, he/she may become more comfortable with training you in the Mooney once they judge your skill level. Sorry, @DanM20C, I wasn't trying to ruin your opportunity to get out of the snow and ice1 point

-

1 point

-

Adam, I highly recommend Dan Bass. He will get you so ready for your checkride it will be a total non event. Dan is a pleasant, humble fellow you enjoy completely.1 point

-

1 point

-

For some reason, I'm more concerned with getting OUT of that runway, than getting in. My 252 tends to eat up runway and doesn't exactly climb away quickly.1 point

-

What is the number of your current (Champion massive) plugs? My plugs are UREM38S U: Tempest (blank: Champion) R: resistor E: 5/8" 24 thread (H: 3/4" 20 thread) M: 18mm mounting thread; 1/2" reach; 7/8" hex 38: the higher the number the hotter. Range is - 26-50 S: fine wire (E: massive)1 point