Leaderboard

Popular Content

Showing content with the highest reputation on 12/15/2018 in all areas

-

One of the things I teach when I do complex transition training is that you never want to hear the gear horn in normal flight operations. I tell my students tongue in cheek it's because their boyfriend, girlfriend, life partner, spouse etc will hate the sound no matter how you explain it and won't fly with you again. But the real reason is two-fold. It means you have not planned the descent to the pattern adequately. And hearing a "warning" regularly diminishes its effectiveness as a warning.3 points

-

GUMPS is my routine but my primary gear down tool is my ASI I should re name it the gear down instrument as I'm always working to get it to 120 on approach its my number for OK to drop the gear. As I'm trying to get it slowed down I have only one thing on my mind get it to 120 so l can drop the gear then it's at least twice I say gear is down green light is on accompanied with a check on the J bar to make sure it's locked in place in the block. I know none of us is infallible but if your primary thought is slowing down to achieve gear speed and having an airplane that is hard to slow down it really makes you focus on that all important step.3 points

-

Don, Chris, Paul, and several others here are promoters of putting an EDM 900 in front of the pilot. I’ll be the contrarian and suggest there are good reasons to put the larger 930 off to the right of the fly-the-airplane space. Playing flight engineer is mostly a tertiary activity below aviate and navigate (and communicate for that matter) in the pecking order. Sent from my iPad using Tapatalk2 points

-

2 points

-

My primary and instrument instructor taught the same thing. He said never to sit and listen to the gear horn. When it comes off, stop what you're doing and turn it back off. Turning the gear horn off involves either extending the gear or increasing power. Either is fine, just don't sit there and let it ring. The last thing you want is to get used to hearing it ring.2 points

-

With where your G500 TXi is placed on your panel, I would not like the PFD on the right side either; it would have to be on the left side to look balanced. And then I would definitely want a GCU 485. My G500 TXi has the PFD centered over my yoke, or when in split mode, the split is directly over my yoke. This makes the screens looked visually balanced regardless of whether you are on full screen PFD or split mode with PFD on the left or the right. This is the only configuration where I think the PFD on the right side is not offputting. And is currently only really possible when you are using the engine EIS as the split occurs at the same place the full screen PFD is centered on. See photos. Without the EIS, the split is offset either to the left or the right on a 40/60 split so it can never lined up directly on the same centerline as the full screen PFD. If Garmin allowed for a full screen 50/50 PFD/MFD split instead of a 40/60 split without the EIS, one could center everything over the yoke without the EIS. Maybe a future software feature? Currently the only way to get a 50/50 split like I have is with the EIS. In my opinion, having the centerline of the PFD and the split over the yoke with the PFD on the right this is the only un-clumsy way to do it without a GCU 485. I originally was going to get a GCU 485 when I did my upgrade, but there was no place for me to fit it and have the G500 TXi centered over my yoke. So I chose to have the centered PFD and have the PFD on the right when in split mode. This allows me to use my right hand for all of the altitude settings and changes, which is what you want instead of having to cross your hand over the yoke or switch hands.2 points

-

Agree that consistency is important. GUMPS out loud abeam numbers, base and final or at IAF and final. I grab the J bar and pull down at least 1 time to insure the thumb lack is engaged. I also installed the P2 warning system a yer ago. It is a good back-up to the afore mentioned. If gear is down, a male voice says, "Gear is down for landing." If gear is not down, a female voice says repeatedly "Gear! Gear! Gear!" until you fix the problem. The P2 unit talks to me at 85 kts airspeed. Well worth the $2000. John Breda2 points

-

If you’ve ever forgot to do something in an airplane on a checklist then it’s possible dropping the gear will be one of them. I’m sure 99% of the people that forgot said they never would. I’ve had this conversation before but I believe there have been people that don’t put their gear up on purpose to get out from under their loan. Or not wanting the ex to get it in the divorce. FYI, I’m not married and my plane is paid for. So if I land gear up it’s because I had a brain fart..... Sent from my iPhone using Tapatalk2 points

-

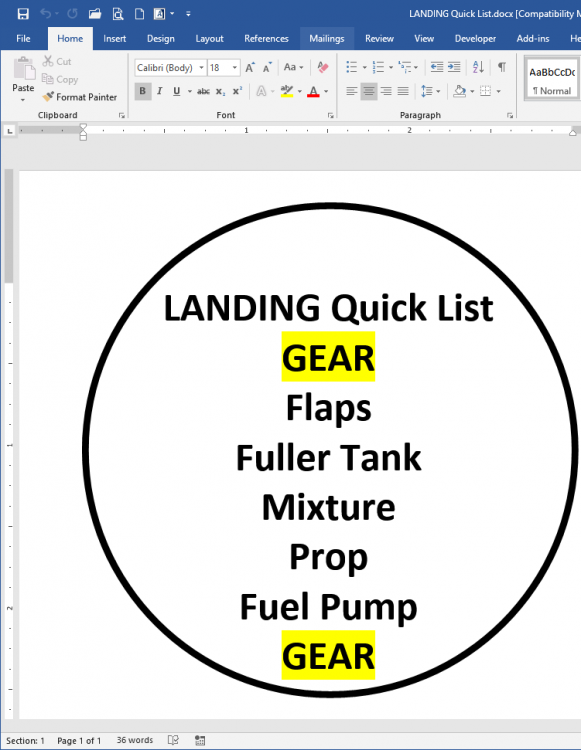

G- Gear Down U- Undercarriage Down M- Make sure the gear is down P- Put the gear down S- Sure the gear is down? Got tired of forgetting the gear so I had my A&P safety wire them down. It’s the first E to D conversion I’m aware of. Seriously though it is always a threat when something else nonstandard is happening... traffic, birds, weather, unrelated system failure, drying the plane off after a washing. That’s when you have to slow everything down and make time to go over the basics.2 points

-

2 points

-

Good luck! I would guess that 90% or more of the people on this site would say you have a good list. However, 90% or more of us are flying a plane that wouldn't meet your requirements. If you do find one, jump on it QUICK or it will be gone.2 points

-

Come on folks... two M20K's landed without gear in the last week. The insurance renewal next year is gonna be ugly for all of us.1 point

-

Agreed, by the same token Nancy could fly the plane through the famous 95% boredom phase of the flight but you and I get the big bucks to deal with the 5% sheer terror. IMNSHO, during the cruise portion of the flight it really doesn’t make much difference where anything is in the panel.1 point

-

You are of course, correct sir. But I find that with my KFC150 handling the aviating, the IFD540 handling the navigating, communication only happening every 20 minutes or so when changing Center controllers, I'm left with plenty of time on my hands to play flight engineer. It's certainly not wasted time either as close management of the power plant can easily double my range on the current flight and extend the life of my turbo engine to TBO or beyond. YMMV but on my flights of over an hour in length, I find myself playing flight engineer about 80% of the time and the aviate/navigate/communicate about 20% of the time.1 point

-

If I need to pull power to slow to gear speed and it makes the gear horn go off I always put my hand on the gear switch and don't take it off until I put it down. It is usually lapses in power planning, but sometimes ATC induced. Never say never, but it is to be avoided.1 point

-

Based on 20 years flying and 12 of them teaching in Colorado, I guess I'll disagree with you on that. Those closer in descents were a reason for me to start slowing and putting the gear down earlier to take advantage of the increased drag.1 point

-

It's been a while since I've flown missions down to Baja for Mother load chapter of Flying Samaritans.Last month ,a group flew down to SAN Quintin ,Baja Mexico Sur.Flights consisted of all volunteers,Dentists,Nurse Practioners ,pilots doubling as equipment repair specialists,MDs ,specialists etc.Here is their report....patients are treated free of charge in a 15 x30 cinder block Ranch structure ,dispensing eye glasses,basic medical and dental services to underserved areas of Baja California.1 point

-

I'm attending our clinic in February but not March, in case you want to join us. http://www.flyingsamaritansaz.org/Tucson/2018-2019_Schedule.pdf1 point

-

@DanM20C is close-ish in Minnesota. He knows the C very well and he met me in Florida for my transition in to my K. His maintenance knowledge even saved us a wasted trip. He also has some amazing stories.1 point

-

If your carb heat doesn't close tight, warm air leaks in. Warm air is less dense, sonless oxygen is present to burn fuel, therefore each throttle setting creates less power than it should.1 point

-

Not sure how close you are looking for, but we did ours at Southwest Texas Aviation and were very pleased. Sent from my SM-G930V using Tapatalk1 point

-

The check of the floor indicator on final has saved me twice; hopefully checking the light over the runway will remain just a habit . . . At least there is only one light, unlike other brands with three gear motors, three lights and the opportunity to land with one or two wheels reetracted. Mooneys always land with all three wheels in the same position, up or down, except for the unfortunate few who have actually broken rods in the gear system. There is no possibility of "missing" one green light because we only have one. I will say this: with the gear up on a long, curved, descending GPS approach in the clouds, you can be on speed or on glideslope, but even cranking in more than normal flaps will not let you do both. Even VFR, if Tower sends you 15 miles out before turning you inbound, descending goes much better when you finally remember to drop the gear (at idle, full flaps, ~150 agl over the numbers and Tower blathering about expediting off the runway). Putting the wheels down will salvage the approach, make a normal landing and not block the runway and upset the many planes descending behind you.1 point

-

I haven’t been excited about a small piece of kit like this in a long time but this thing looks really coolI haven’t been excited about a small piece of kit like this in a long time but this thing looks really cool1 point

-

The controller has 4 buttons on the front of it. Pull on it. Should slide out of tray. On top of controller you'll see the pots that can adjust the gains on your autopilot. The manual has lots of info on tests and trouble shooting.1 point

-

1 point

-

1 point

-

I"m with you on this one. 120 and is goes down. Primarily so I can slow it to 100 on downwind. I also like what my CFI taught me to add more flaps flaps on Downwind, Base and final. I use this to also check that the Gear is down on each leg.1 point

-

Pretty sure I saw the Modified GUMPS check on here before: G - Is the gear down U- U sure the gear is down M- Make sure the gear is down P- Positive the gear is down? S- Surely you put the gear down.1 point

-

I placed the manual in a .zip folder in the Downloads/Avionics section.1 point

-

1 point

-

Yep, a higher airspeed than expected for the same or lesser power setting on base/final or on a straight in approach should alert you to check that your gear is down. As always, if something seems out of the norm, make sure you didn’t forget something. Flows, checklists, GUMPS checks should be used consistently. I like to check gear down 3 times including a Final panic check.1 point

-

Always do a final "centerline check" for gear down. I'm probably to the point of being obsessive about checking gear down. Verbalize your GUMPS every time and it helps ensure you don't forget.1 point

-

1 point

-

1 point

-

Aargh! The real problem is that humans can get distracted quite easily. Says me lower the gear and do your flaps a couple miles out. That way they're less likely to be forgotten during your distractions the landing pattern.1 point

-

That had been done previously. There can still be water sitting behind ribs that doesn't get drained, and that eventually (and apparently sometimes gradually) can work it's way down to the pickup/sump area. I think maybe if they'd shaken the wings when they were draining it it would have helped.1 point

-

My problem is the only border I'm near is the Canadian one, and I think they've got better health care than I do.1 point

-

1 point

-

Huge congrats! You're the beneficiary of extreme over-investing by the previous owner. Hopefully it is as mechanically sound as it is gorgeous, and will serve you well in retirement. I can't wait to see it in person some day. Sent from my LG-US996 using Tapatalk1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

PT20J, Everyone giving you numbers about the time it takes to change the oil, generally have been talking about theoretical or maybe ideal conditions. Her is a real account. (I am not making this up). I arrived at the hangar a little after 11:00 this morning to change the oil. Taking the cowl off, I found that someone had put additional washers on the lower two camlocks on the lower cowl, to help with wallowed out camlock holes. One of them made the camlock so tight, it would not come loose. After trying three screwdrivers, I had to use a Dremel tool abrasive wheel to cut the washer before it would come off. Then I put the hose on the quick drain and attempted to push it up and latch it "open". No luck; no oil cam out. I cut its safety wire and discovered my open end/box end wrench set skips from 3/4 inch to 7/8ths inch, and the quick drain is 13/16ths. Trip to Lowes to get a 13/16ths wrench. Removed the quick drain, draining the oil into a plastic pan. (I usually drain directly into empty milk jugs). I cleaned out the quick drain and it was open. Cleaned it up, replaced it and re-safety wired it. I still have no idea why it would not drain. Attempted to remove the oil filter, finding someone had used gorilla strength torque installing it. Too tight to remove with the usual box end wrench. Hooked up a 1 inch socket with a long break-over bar and a 2 inch extension, since the cowl flap linkage prevents reaching it without the extension. Loosened the filter and while putting the plastic zip lock bag around the filter to keep it from leaking too much oil, a friend showed up in front of my hangar to chat. I didn't time our chat, but it was probably 45 minutes or so. It was actually kind of nice, as it gave the oil time to run down into the zip lock bag, and created less of a mess. Uneventfully installed and re-safety wired the new filter. Poured in the fresh oil and set out the empty oil containers to drain, since I don't like waiting for the length of time it takes to completely drain the quart containers, and I'm too much of a CB to toss them with a tablespoonful or so of oil remaining in each one. Emptied the plastic drain pan into my container to take to the oil disposal place, and set the filter to drain. I will go back tomorrow to cut the filter and replace the cowling. I left the hangar at 2:45. Re-cowling, filter cutting, inspecting, oil disposal and logbook entry, yet to go.1 point

-

The renovation on the house is now scheduled to be completed this Friday. Assuming it is, that will be 32 days later than initially promised (about 50% more) but less than 1% over budget.1 point

-

I’ve never flown a 182. How fast do they fly on 8 gallons an hour? My F does about 165 mph at that fuel flow.1 point

-

There is no doubt in my mind how Mooney tanks work... And I’m pretty sure I understand what is described by José... How most Mooney tanks are built... 1) The drain is near the bottom of the tank. Close, but Not at the bottom of the tank... (took me a few years to recognize this) 2) The volume below the drain is about a gallon. Alex has a really nice pic of a stained area where water had probably been there a while... (before he re-sealed his ship’s tanks... 3) Further up from the bottom is the fuel pick-up 4) from the top of the pick-up to the top of the tank is useable fuel... In a different way... there are three regions in the tank caused by the location and type of fuel drain used... Level 1) un-drain-able fuel... that includes water, and foreign objects like dirt and collected insects... alcohol fuel additive is needed to remove water here, physical clean out to remove everything.... Level 2) drainable, But unuseable fuel... allows for a safety distance of good fuel that doesn’t normally enter the fuel pick-up... unless the turns are unusually uncoordinated whith the nose pointed down... water that collects above this level gets drained when the sump opens... Level 3) Good quality fuel, fully useable in flight... My applause for the guys discussing this topic and not losing typing control. Is this un-drain-able fuel idea new to anyone? I think that it may be... On the topic of changing the drain’s height... The added aluminum block in Jose’s design pics is indicating a higher level of this un-drain-able location... 1) as long as the drain is below the fuel pick-up, it will operate in a similar fashion. Under most conditions... 2) the operation doesn’t change, very much... 3) Things can change if more un-drain-able water is retained in the tanks... during uncoordinated and nose down flight... 4) It would be advisable if you know you have had water enter the tanks... to take the effort to have the water removed... just for those uncoordinated events... Like I said I’m unsure about Jose’s additional tanks with inter-connect tubes and all. I am Just familiar with the part about Mooney tanks and getting the water out... Let me know what I missed. It is probably something big. PP thoughts only, not a mechanic... Best regards, -a-1 point

-

I like it. “Hon, you don’t mine that I look at some panel porn, do ya?” Sent from my iPhone using Tapatalk Pro1 point

-

I got some glamour shots over Thanksgiving weekend... Here is one in case it inspires you to do something similar! Sent from my LG-US996 using Tapatalk1 point

-

Just wanted to add some feedback about AGL Aviation in Morganton, NC. They are simply the best, nicest people and Lyn knows Mooneys quite well but on my last visit they truly were beyond amazing. I had a new Garmin G5 attitude indicator installed and had to go back to AGL for an over voltage light that we did not have time to address at my last visit. While Lyn was fixing a broken connector in my alternator he discovered a crack in my #2 exhaust manifold (just because he always looks for anything wrong whenever he's looking at an airplane). As it turned out, the manifold was in fact broken and Lynn offered me the manifold off his airplane because I was departing on a long trip! Unfortunately his manifold did not fit (C model versus F model) so he called a guy that flew in on his helicopter, took my manifold to his shop, repaired it and returned in an hour and had me on my way. He only charged me what the repair was which was $45! Amazing, just good people running a great company. No matter where you are, I suggest you take for plane to AGL for your annual. If you have any questions, please feel free to contact me anytime.1 point

.thumb.png.7c67574d7b28f67b0b4a17760919b1ac.png)