Leaderboard

Popular Content

Showing content with the highest reputation on 11/16/2018 in all areas

-

I replaced all 3 tires and tubes, because they were worn out. Other than that, the only part we replaced was gascolator gaskets. My last annual was $7,000. I did all the labor on this one, the IA just followed up and inspected my work. I spent under $1500 total for the whole shebang. And, stuff actually got done. The folks who did my $7,000 annual did not do about half of the things they were supposed to.6 points

-

What’s with all the negativity? Attacking another MSer? Attacking a product that other MSers use and support? Then follow it up with an opinion that isn’t in line with the people that have bought it... Some people feel a bitterness when something they want costs more than they can afford... I get this feeling all the time... leaving the the bitterness at home helps keep things interesting... Continuing the bitterness has people clicking the ignore button... Be a part of the community. Best regards, -a-5 points

-

You could add a small annunciator light labeled 'Fuel Pump On'. A lot easier than moving the switch. Checklist usage also helps. When do you retract the flaps? That would be a good reminder- flaps up, pump off, flaps down, pump on.5 points

-

The first annual after I bought my plane was owner assisted. I thought that all the panel screws that had to be zizzed off were just part of the annual. Now I realize that most of those panels hadn't been removed in many years by the professionals that had maintained the plane. An owner has the luxury of working without the time pressure of a shop clock. All the time consumming little jobs can be done and done right by an owner. The IA can spend his time doing what he does best: inspecting. I'm presently doing my 20th owner assisted annual.4 points

-

I think Fred probably forgets it more during tank swaps than immediately after take off. I like Andy’s suggestion of an indicator lamp. In my F the lo/hi vacuum annunciator is no longer used since I pulled the vacuum system. I also like his checklist recommendation. When I swap tanks, my flow is pump on, switch tanks, pump off, check pressure. I should probably add an in flight checklist for tank swaps but the flow has worked fine for 28 years. As has switching to the Weldon continuous duty pump for when I do the knucklehead thing and get distracted. Sent from my iPhone using Tapatalk Pro3 points

-

When I got the plane the entire inside of the cowl and everything in there was wiped down. There is absolutely no way I would pay someone to do that, but I was happy to spend my time. Same with scraping the rocker cover gaskets off. I got them way cleaner than any mechanic, but would never pay someone to do that.2 points

-

Like Anthony said, it flips to the off position. I had it happen with my landing light. Had some work done on the plane and when they buttoned it back up they had left the wire for the landing light too loose and it melted to the exhaust and flipped the switch. Tried turning it back on and it flipped back off, left it that way and investigated once on the ground. I don't turn it on for switching tanks in my plane either, switch tanks, watch fuel flow on the EDM, and fly on.2 points

-

I do not use the fuel pump when switching tanks in my C. I simply bend down, grab the switch in the middle and turn it 180°. There may or may not be a momentary pause at the OFF detent halfway there. Except the couple of times I have purposely run the tank dry first, there has not been even a gurgle, burp or wiggle of the FP needle. My switch is high and to the right, next to the radio stack and is a circuit breaker switch, just like the rest of the row. I use it mainly to build fuel pressure for starting the engine when cold.2 points

-

The problem with the GPS (Garmin) type of logging is that they don't work until you get to a certain speed. You're cheating yourself. On Tuesday I clicked off about 30 minutes at SJC San Jose just getting moved from runway to runway while ATC tried to figure out how to work a single engine IFR departure in with their 121 traffic. -Robert2 points

-

Yeah, my shop is 10 minutes from the field. The working part of the annual took me about a week after work and a Saturday. After it was all apart and the servicing done, the IA came by yesterday and spent about 6 hours inspecting everything and helping me put it back together. And paper work. He took the logs with him a couple days ago and went through all the ADs. I was down 2 weeks all together, but mostly due to me not being in a hurry. If you don't count all the tires tubes, grease, disposables, etc- the annual cost me $405.97, and that includes what I paid the IA.2 points

-

Campbell Field is a licensed, uncharted grass strip that's been in use since the 60's. Well maintained 1,700ish ft strip with obstacles both ends, and Campbell Field Restaurant is through the pasture gate and across the road. Great food and prices; we usually have 3 to 10 planes meet for breakfast on fair weather Sundays. It's about 21 miles NNW of the Birmingham, AL airport (KBHM). Coordinates are 33.844, -86.898. Don't just practice short fields, use it! Overhead view: Breakfast run parking:2 points

-

After a few flights in my M20C... i found my procedures needed adjustment... @1k’ AGL verify... gear up, flaps up, fuel pump off... When switching tanks... I didn’t use the fuel pump, flop the valve, verify the fuel pressure... done... Following the procedure is always a good idea... pump on, valve flop, pump off.... at the moment something gets in the way of this 10sec procedure, the pump will be left on until landing... All the switches on the lower edge of the panel are CB switches. You can put your head under there to see them... or check the wiring diagrams and parts catalog for the cryptic notes that indicate the CB... PP thoughts only, not a mechanic or CFI... Best regards, -a-2 points

-

Keep in mind that the existing switch doubles as a circuit breaker, so you would need to add a circuit breaker if using a regular switch.2 points

-

You also have to look at the specific engines. You can overhaul two IO-470 engines for about the same as one TSIO-540. Most people will change oil on a turbo at about half the hours as they do a normally aspirated engine (25 versus 50 hours), I know I do. Then you're down to just an extra prop to maintain. There's no question that a twin costs more to run than a single but the differential is much less than many think. I don't fly much at night either and never really have. A few years ago when I was prepping for my multi-ATP check ride, the night requirement of 100 hours was my nemesis. Without this sentence I wouldn't have qualified: "A person who has performed at least 20 night takeoffs and landings to a full stop may substitute each additional night takeoff and landing to a full stop for 1 hour of night flight time to satisfy the requirements of paragraph (a)(2) of this section; however, not more than 25 hours of night flight time may be credited in this manner." Today, after flying 24 years and 2,100 hours my logbook (I didn't really fly for the first 8 years after I got my license, family, work etc.) shows 83.5 hours of night. I do cross the Sea of Cortez regularly, but with a few minutes detour I could stay within gliding range of land. And I do fly over mountains pretty much daily but again, with slight deviations to my flight plan I could minimize that risk. All airplanes are good and all airplanes are compromises. We each pick which options we can live with and which we can't.2 points

-

There is some validity to that. If I was doing a lot of over water, mountain or night flying I would have a twin for sure. I am sensitive to risk management and for that reason don’t fly at night anymore because if something happens to your one engine in a single your options have the potential of being greatly reduced if out of range of an airport. But the twin comes with significantly more maintenance expense and the potential of not one but two overhauls.2 points

-

I just completed a current pilot record for insurance renewal on my Baron. I flew 175 (actually 177.5) hours in the last 12 months, 38 hours in the last 90 days. Of that, 150 was in the Baron and 25 hours in single engine, mostly teaching and exercising a friend's P210. In the last 90 days, 36 of the 38 hours were in the Baron with two flight reviews in single engine, each an hour flight time thrown in. I was expecting about 150 hours last year so 175 hours is a nice surprise. I do have a non-equity partner in the Baron and his time will determine the insurance premium, unfortunately. He has about 25% of the hours I do and flies about 25% as much as I do. But . . . he pays half of the expenses. Oh, and my first flight in the Baron was January 15, 2018 so that 150 hours in the Baron is for a 10 month period, not a full year2 points

-

Sailors love improving their hullspeeds... and a good strong wind to max things out! For modern day sailors... Here’s to hull speeds over 200kts and a good tail wind, cheers! Best regards, -a-2 points

-

I had a flight this weekend where I saw some really serious winds; on my tail outbound and on my nose coming home. What was exciting about this one was my best ground speed (yes, I know, it's all in the wind......but when you see a nice number you can't help but like it) prior to this flight was 395 knots. I saw 410 Knots on this flight, so clipped my best by 15 knots. Just wish I could see those more often on our Florida trips (well, on the way down anyway). .https://flightaware.com/live/flight/N994PT/history/20181110/1415Z/KIMT/KAGC https://flightaware.com/live/flight/N994PT/history/20181110/1945Z/KAGC/KIMT One screen shot showing 409 Knots GS and some FL240 shots over central Michigan during the snail pace trip back home. Tom2 points

-

Tom, I went through something similar early this year after a top: MP would lapse in the climb. Things we tried in order to identify the problem: Take the pop-off valve out of the equation Take the wastegate controller our of the equation; run it like a stock 231 overhaul the controller vacuum and pressure test the intake system visually inspect the turbos Since I was able to fly the plane, I was able to identify the MP lapsing. In your case, they've probably done all these things, but make sure 1 and 2 are good. If the plane makes compression and has fuel flow, something is either not allowing the turbo to put out sufficiently compressed air, or that compressed air is leaking somewhere before the intake valve. In my case, it was the rubber hose going from the intake manifold (front of engine) to the G1000 MP sensor/sender (firewall). That hose sits behind a wire bundle, and when the shop's mechanic snipped the tie-wrap, he or she nicked the hose in such a way that it was next to impossible to see. So let's add (6) to the list: check MP gauge plumbing for leaks! -dan2 points

-

Anyone have any pics of their MooneyMite they can share. I am looking to start a thread for the 300 members of the MooneyMite site that went into hibernation... Pictures would be an interesting way to get things started... Best regards, -a-1 point

-

1 point

-

Well as posted above it's my 65C that has a single indicator light for 3 items (fuel pump, landing light and pitot heat). I can see there might be an issue for a pilot that leaves the light and/or pitot heat on with some frequency. I do not, and that single indicator light has worked well as a reminder to switch off any or all of those 3 items.1 point

-

Absolutely! Actually, I'd really be pissed if I caught an A&P on the clock doing some of the laborious stuff I find time to do. Today, I spent a half hour cleaning the insides of inspection panels. (Is that OCD?). A shop half hour is one thing, but my time is essentially free. @gsxrpilot, you need to get your SWA brother involved. He's got lots of time off!1 point

-

Maybe not for you, but it sure works for me. I rarely forget to switch the pump off, and typically will notice higher fuel pressure first, but the indicator light has been effective as well. I also only use it on engine start.1 point

-

Some of the early C and D models had Facet pumps. You can buy a Facet pump for less than $100. The exact same pump with an FAA/PMA sticker costs $500.1 point

-

I matriculated through those certificates in the early ‘60’s but I won’t try to recite the details without digging out the old flight test guides. Basically 40 hrs for private, 200 hrs for commercial and CFI. No night required for private. Cross country requirement a bit different for private.1 point

-

15% more oxygen should result in 15% more fuel burned, which should result in 15% more horsepower...that would easily be worth the premium if true.Of course if the 20% is the amount of air (exhaust gases) left when piston has completed it’s exhaust stroke, and the volume is 1/15th of cylinder volume, so on in intake you get 14/15ths fresh air and 80% vs 95%...the difference would only be about 1%. And if you run LOP, there is some leftover oxygen in those exhaust gases, would make it less of difference. I would like to an independent test. Edit: I did find a test done in a Mooney by : https://www.planeandpilotmag.com/article/accelerating-a-mooney/ Upshot is to maximize gain, fly at 11,500’...5 knot gain, at 7500’ it was 3 knot gain.1 point

-

Fred, When overloaded, The switch toggle moves to the off position, via a spring. Reset is by turning it back on. Do it once, by the CB rule... A simple LED would make a great addition... for things that should be temporary. And cost a lot when over used. One light attached to a few switches won’t be enough of a reminder to turn the pump off... PP thoughts only, -a-1 point

-

Our 65C has a yellow indicator lamp in the toggle switch row that lights when the fuel pump, pitot heat and/or landing light are energized. Not sure how it was installed, and what breaker it might have replaced.1 point

-

That is an interesting announcement... The list is updated... but the associated low res graphic depiction has a 11/17 date on it... I was trying to quickly see if my favorite airports got an update... Best regards, -a-1 point

-

Owner assisted annual is a lot easier when you and the IA both live with the planes. You can wander out for a couple of hours "whenever". The annual is really just a compilation of many small tasks.1 point

-

Could you please post a link to our site where JPI was bashed? To my knowledge, we have never done that. Quite the opposite if you review previous advertising from our competitors. In regard to reliability, I suggest you read the posts from your peers and decide for yourself. If you visit any number of forums, I think you will find that our customer service is second to none. As an example, we are here on this forum, happy to answer any questions on our products, even assisting in troubleshooting our competitor's products.1 point

-

The switch should also be the circuit breaker, I would check voltage and resistance at both the switch and pump1 point

-

My governor failed this year. I agree with @N201MKTurbo you should take the governor to a prop shop and have it tested. Overspeed is a bad thing. Lycoming says overspeed for more than a certain number of RPMs for more than a certain number of seconds, you should tear down the engine. Don't remember the exact numbers, but they are very concerned about overspeed.1 point

-

26. He's just finishing school in the next few weeks, so will have the time and money to fly now.1 point

-

Anything that burns Jet-A is above my pay grade. I previously had a Colemill Baron (B55 with the 520s) and prefer the 470s. Either I'll keep the Baron or trade down to something that I can teach my son to fly in. We'll see.1 point

-

1 point

-

Cody should chime in. That shouldn’t happen. There is something wrong with your prop or governor.1 point

-

Actually, it still kind of works. The number of molecules of oxygen is dependent on V x D. So at 0" of MP you get (0/30) x (anything/27) = 0% power. Same thing before you start. (0/27) x (30/30) = 0% power. At low altitude using the magic number of 47 for 65%: (24/27) x (23/30) = 68% or (26/27) x (21/30) = 67%. Using 50 for 75%: (26/27) x (24/30) = 77%. I doubt it is quite right, but at idle with the throttle essentially closed and guessing MP is about 10": (10/27) x (10/30) = 12% power.1 point

-

1 point

-

In my airplane I see: 8 GPH per side = 160 KTAS 9 GPH per side = 170 KTAS 10 GPH per sie = 180 KTAS 11 GPH per side = 185 KTAS 12 GPH per side = 190 KTAS 15 GPH per side = 200 KTAS1 point

-

1 point

-

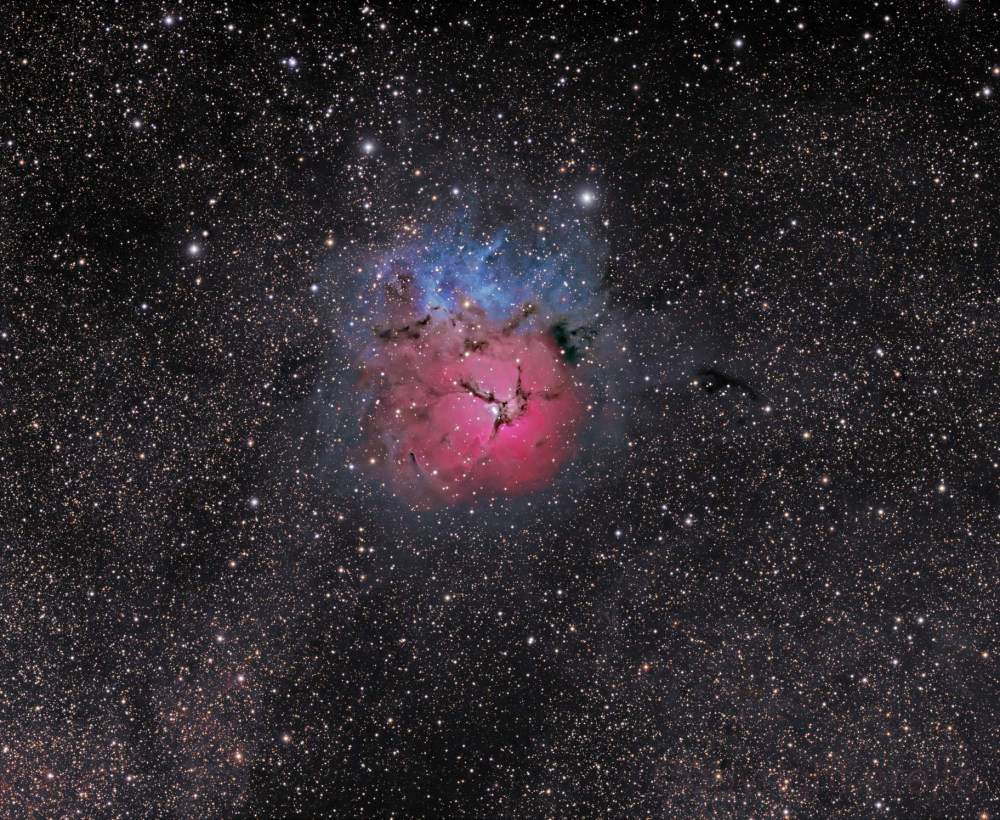

Since Anthony will probably welcome you Peter, Ill fill in some of his questions for you. Peter is a world class cellist who instructs at the Sydney Conservatory whos hobbies not only include flying, but astrophotography. He has his own telescope at the Sydney Observatory and produced this masterpiece. His son Nicholas is following in his fathers footsteps and already is one of the best classical guitarist i have heard at 16. Did I mention his wife is a world class pianist? If anyone gets to Sydney, do look Peter up. A finer family cannot be found.1 point

-

Great airplanes. It is a stock B55 so the IO-470-L. I was talking to a guy about a 182. He says he gets 130 KTAS on 13GPH. In "take your time mode", 80% or more of my flights, I fly at 2300RPM, 20" MP and 8 GPH per side in the Baron. That gives me 160 KTAS. The NMPG with the Baron or a 182 is identical, but I get there faster, have an extra 700 lb useful load, air conditioning and a second engine for those flights over the mountains or over water. It does cost a bit extra in maintenance for that capability but it isn't a bad price to pay.1 point

-

One of those options you might consider is shipping the prop to Wynn Arkansas where Cody's shop is located. Absolutely no worries that what needs to be done will be done and nothing not needed will be charged for! Ron1 point

-

It is often one of the four screws at the end of the support brackets. They don't have quite as much sealing surface as the cover screws. You can usually do a quick fix by removing the screw, coating it with tank sealer or Permatex, and put it back in. Just be careful when taking the screw out and back in, so you don't push the nut plate down breaking the sealant between the support and the top of the tank.1 point

-

Cody Like Clarence, I was originally trained to pump until grease came out the opposite fitting. Then, Hartzell said don’t do that with aluminum hub props, pump only a few ounces, not to exceed some number of pumps (the number escapes me at the moment). This is because pumping more might force grease into the dry cavity in the prop and this can affect normal operation. I assume purging is similar...pump until old grease is out. Do you find grease in props where it should not be? I paid the price doing an annual years ago where I pumped until it came out the cross port and the owner checked with Hartzell who said the prop needed tear down....so the annual became a freebie. I’ve been really cautious about following the manual ever since. Also, my understanding was the aero shell 5 can be mixed with 6, as long as you follow the temperature restriction. So, the ultimate question is....is it better to purge all the grease and risk the grease going in the wrong part of the prop or better to fly with a mix of aero shell 5 and 6? By the way, thank you for taking the time to educate us. These props are expensive and small missteps can cost us. I too understood that the overhaul requires grinding, which eats into blade life. Rob1 point

-

I have heard the Above Statement for Years. “Dont grease your Prop, an it won’t Leak” If care is taken when lubricating a Hartzell Propeller, you will have no Problems. The Hartzell uses a Quad-Seal that Ride on a Teflon strip on the blade for a sealing surface. One or Both have been Compromised with this Propeller. It happens over time. With the Above Propeller there is an Option to use a different type of seal vs the Quad Seal as it is very hard on the Teflon. That seal is the C3317-340-8. Be sure an ask for that seal when your Propeller is being repaired, Iys the Same Oring used in the TurboProps, an it works very well. I would opt for the reseal on this Propeller vs the O/H. There is about a $1500-$1800 dollar difference between the two.1 point

-

At that price you ought to sell it as a cheap timer.1 point

-

Not a good or bad comment, but it's Interesting that with - guessing 100k of panel work - you still find a portable useful on your yoke. To me that says Garmin has really missed something .1 point