Leaderboard

Popular Content

Showing content with the highest reputation on 11/13/2018 in all areas

-

Just a quick note to let everyone know Dr. Ron Dubin, @rocketmanMooney Summit cofounder, underwent back surgery today at UK. He is fine, and I’m sure he is recovering well without opioids. His slurred speech is normal....Get well my friend8 points

-

5 points

-

3 points

-

I've had my eye on these since the first time I saw someone post a link to them. I actually like that it keeps the traditional look of the panel, not that the big glass panels aren't nice, but these bring functionality while keeping the nostalgia of the classic panel.3 points

-

What's going on? There are a ton of long bodies on the market right now. My my count there are 32 US based ovations on the market compared to only 13 US based J models. I'm looking at Controller so I"m sure there are other planes advertised on other sites, but wow- looks like a fantastic time to upgrade a J to an R. J model prices are up, and competition should push some pricing on ovations down, particularly if an owner wants to get something done by the end of the year.2 points

-

The CFI almost got hit when he did the distract and pulled the gear breaker. I did scowl at him. I sit pretty far back from the panel and see everything. I can hit isolate on the audio panel and make you go away. :-)2 points

-

2 points

-

It's east Texas just look for the beat up shack with BBQ hand painted on the side on any road. Hint look for the smoke coming out of the stack, otherwise it has been converted to cooking meth. It is east texas ya know.2 points

-

2 points

-

If anyone likes living dangerously... my right seat is open. Come ride along and show me how to do it right :-) But seriously, always happy to have company.2 points

-

The crack, as posted by the OP and a second one that I posted, may just be the tip of the iceberg. In my case the flame tubes were also gone. Now, this is an even more controversial discussion. Is a muffler airworthy once the flame tubes are gone? I am told that the flame tubes are there to control inconsistent heating of the case which causes warping and cracking. So, while the crack could rather easily be welded, the question becomes how soon the next one starts? Do you knowingly put the muffler back on with burned flame tubes? I’ve been trying to get a reasonable answer on this for a while, but not much luck. I even thought that one shop was building a muffler without the tube, but could not find them. Another consideration is that the back of the weld can not be cleaned prior to welding. This leads to potential contamination which leaves a poor weld that can then just cause the crack to reopen or migrate. I think it amounts to a judgement call on the overall condition of the exhaust. If it is low time and most components look good, including the flame tubes, it is likely worth welding. If you have over 500 hours....or 1000 hours, you may be on borrowed time. If you are paying to have the exhaust removed and installed, consider the overall cost of pulling it again in a few hundred hours. Unfortunately, when you send the system out, the sandblasting also thins the metal and usually reveals issues with the risers and tailpipe as well. With the number of CO incidents each year, I can understand why IAs take the more cautious route and push for an overhaul. I feel better about my exhaust, knowing I don’t have to worry about the next crack for a few years...or so I hope. In the meantime....I’m going to research the damned flame tubes some more.2 points

-

Hi there, I'm in a similar situation: I also didn't fly for 12 - 13 years and started flying again last year. I got my BFR and went shopping for a J model. Prior to my hiatus I used to own an E model. Great performance for the $$, but limited utility once I got my instrument ticket due to the outdated panel. Usual advice about what your flying mission is obviously applies (that was my first airplane purchase and I didn't know what I was doing). By the way, if shopping for an older model if you find one with an alternator conversion that's a bonus. I was left stranded once when the generator failed. The E had about 1,400 hours on the engine when I got it and I was only able to put 280 hours on it before it needed an overhaul. Mike Busch has a persuasive argument for buying an airplane with a run-out engine vs mid time / high time; I'd recommend looking it up on Youtube. One other thing I learned with airplane purchase no. 3, is the tremendous value in being able to 'interview' the seller, which helped put me in a comfort zone with the purchase. Anyway, best of luck with your search!2 points

-

I usually get a couple of hours. I figure 1.5 hours is a sure thing but I might get over 2 hours. The key is to have the wifi/bluetooth/etc disabled. Also use a lower frame rate unless you need slo-motion. But I find I'm typically speeding up video rather than slowing it down when flying. Those things will maximize battery run time.1 point

-

I did get an email asking for an appraisal. Haven't heard back yet. One step at a time on the app... Working on history, methods and data now. Just getting started though. Once done, I will think about delivery.1 point

-

Just ordered one with expedite shipping. For whatever reason this post freaked me out because yesterday I was talking to my mechanic to check the cabin heat. I have never used it since I got the Mooney...part of the good news is the CO2 sensor (the cheap $10 one...) has not indicated any leaks. Now I need the second part confirming the no-leak after actually pulling the cabin heat knob! I think I will ground check it first with the Sensorcon ON...;-)1 point

-

It really is interesting how the brain works. Cognitive overload is an interesting experience that I have not had very often. In fact it really caught me by surprise when I was first working on my PPL. The first time it was the radio call that I couldn't make. I knew what I wanted to say but couldn't get the words to come out right. It got a chuckle out of my CFI who proceeded to make the radio calls for me. More time and experience and the radio calls come naturally now. On a recent flight as we were descending into the Sacramento area landing at Davis they gave me 5 frequency changes/handoffs in the last 16 minutes of the flight and I didn't think anything of it. Visiting my folks last week my dad said "Did I ever tell you about the formation touch and goes we did in training?" He then told the story of how he and another trainee were flying formation in T-38's. Their instructor pilots, a couple of guys that flew F-4's in Vietnam, asked if they wanted to do some formation touch and goes. It sound fun, they said sure. They flew the first one with my dad as wing-man and then switched and my dad was lead for the second one. It was uneventful and they didn't really think anything of it but after they landed they were called in and asked who had authorized it. They said their instructors had suggested it but to their knowledge there weren't any regulations against it. (There really wasn't, yet). The next day the instructors had to meet with the officer (can't remember his rank) over the training wing and they were read the riot act. Turns out he had been out at the runway watching at the time they did the formation touch and goes and was not pleased. By the end of the day there was a regulation in place for the training wing that there were to be no formation touch and goes.1 point

-

Reminds me of an old joke: The game warden caught a poacher who was eating a spotted owl. The game warden, after writing the ticket, said, "you know, I really have to ask, what does it taste like?" The poacher responds, "kind of like bald eagle."1 point

-

I've done quite a bit of filming from cameras mounted on the outside of the plane. I've generally always used GoPros and really like the Session model for external mounting because of their size. I've recently purchased a Rylo 360° camera. I really like it for the ability to change the view while watching the footage. I always use the GoPro or Rylo sticky mounts. Sometimes they are called helmet mounts. You might be afraid of them falling off, but I assure you they won't. I've never noticed any aerodynamic effects from using the cameras. I'm not a test pilot, but I've not wrecked any Mooneys while filming either. The mounts sold by Nflightcam and others are just overkill.1 point

-

I've always avoided Copeland's because it's a chain. I'll have to rethink that now that it's been recommended by a Louisianan!1 point

-

Just goes to show there are different versions of airworthy and just because you are paying someone to say it is, That don't mean it is.1 point

-

No, but Don Maxwell will. I know there's good BBQ in Longview.1 point

-

Hey Paul I’m staying in Shreveport while Don’s fixing my door, do you know of any good Barbecue restaurants near or between DMax and Shreveport.1 point

-

I was talking to Paul M yesterday about that same question he had a nice modern J in the shop abused like the dickens. Buy a nice Mooney then don’t care for it, what a damn shame.1 point

-

Yes we did meet. Patrick is an awesome mate! Sent from my Pixel 2 XL using Tapatalk1 point

-

1 point

-

A reasonable aeromedical concern. I myself rarely drink anything before a flight, especially one where I might have these sorts of concerns. And of course that last thing before I spool up is always a trip to the loo. Of course, if you take all these precautions and still have the need to relieve yourself before you get to your destination, either you need to plan shorter legs or go see your doctor for that fun little bit of intimacy.1 point

-

That Tanis note is terrible... Written by the same guy that said cam corrosion doesn’t happen... They should have given another few sentences regarding venting, and insulation and surrounding temps... the MS topics found in this thread... They went with electric heat doesn’t create moisture... no kidding? If it did, Einstein would have been all wrong. Its a technical device. It is OK to supply the technical reasons a customer needs to buy the device... They selected technical non-sense as a sales technique... I would be inclined to buy from their competitor instead... because matter can neither be created or destroyed... Sorry if this makes your choice more difficult... find a technical friend at the airport near you... see what they are using. Best regards, -a-1 point

-

No, I only get data reception down low, below 3-4000' or so. I was talking about streaming stuff saved on my phone to my headset via Bluetooth1 point

-

Everybody has their own list, and some people would rather buy a lot of oil instead of parts, labor and STC to add a filter / remote filter to an engine without one? Personally, I can't imagine an engine without an oil filter, even my weedeater has one!1 point

-

1 point

-

I think this could be a great deal of it all checks out. I’d be curious to know how much it is flying but at least it is in the dry desert of not very much. It has older avionics but still good equipment. I am in AZ this week on business and I might like to check it out myself, Encore to Encore.1 point

-

I wouldn’t suggest just welding the crack if the rest of the muffler was falling apart. But the origional poster didn’t indicate that there was anything else wrong with the muffler. You need to remove the muffler to weld it. When it is off it is easy to look down the flame tubes and see if thery are falling apart. Also the crack shown didn’t indicate there was any unusual stress on the muffler that would require it to be jigged when welded.1 point

-

I don't think the PFS has flame tubes. If I am correct in that it is a significant factor in the life of a muffler.1 point

-

1 point

-

1 point

-

Just a quick update... The Garmin GFC500 is not STC's for any Mooney's prior to a J. So for a C, E, or F... either get one that already has an autopilot... or wait for the Trio, TrueTrak or Dynon coming out soon or not so soon???1 point

-

I would suggest that there might be a few sitting around, with the number of people installing the 201 windshield mod, all it would require is a repaint.1 point

-

With stiff headwinds I worry more about if I'm going to make it to my destination before I have to pee...1 point

-

Awesome! That's great news! Glad you got it taken care of. I hope the information helped.1 point

-

getting actual sales price would be great. All I have access to are asking prices which may or may not be realistic.1 point

-

An A&P can weld a muffler if they are qualified to do so. An owner can provide an A&P with an owner produced part as long as it meets the specs of the original part (and is documented as such). I spent some time in my youth trading flight time for work at a repair station in the mid-west. Owner produced parts were more common than you might think. In that part of the country almost every male born before about 1985 had some exposure to Ag work and if they had a public school education, had used an arc welder, an Oxyacetylene weld/cutting torch and done some basic sand casting of simple parts in metal shop. This certainly did not make them capable of producing aircraft parts but it seems to have made them comfortable and competent at finding folks that could assist them in doing so. A good and fairly recent read: https://www.aopa.org/news-and-media/all-news/2016/june/pilot/is-repair-a-lost-art Sending a perfectly repairable muffler out for overhaul is about passing the liability on to someone else, not ensuring a safe, reliable and legal repair. I don't judge an A&P/IA for doing so, the world is a tough place and liability plaintiff lawyers are not concerned with finding truth, they're concerned with assigning and attaching blame to the deepest pockets they can.1 point

-

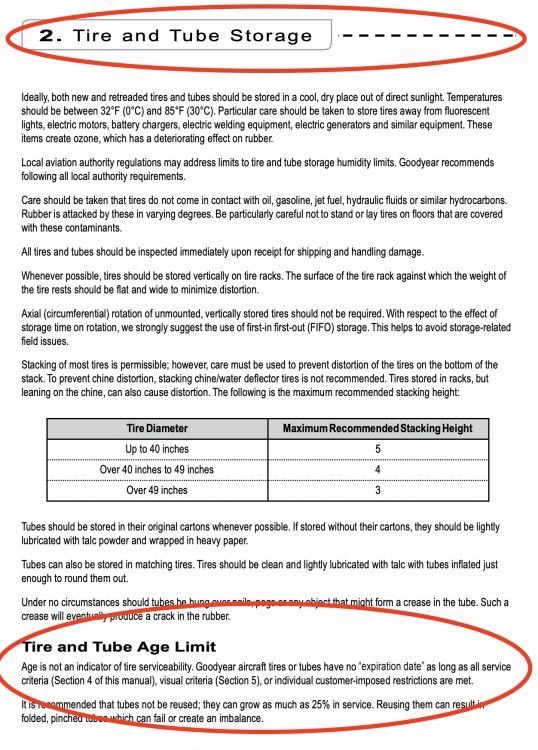

The above link is under the heading Tire and Tube Storage. It mentions temperatures and other conditions appropriate for storage. Having them on the airplane obviously puts them in a much more harsh environment. After taking my tires off there was some noticeable minor cracking and I was planning on changing the tubes soon because of the frequent loss of air pressure. So, for me, it just made sense to start with a known quantity: new tubes, new tires, new brake linings, o-rings, brake lines and fluid.1 point

-

Once during IFR training my brain was overloaded and I forgot and left the flaps in takeoff position. After leveling off I noticed the airspeed was low. No icing was forecast and we had flown thru about a 2000 foot layer in actual IMC with temps below freezing and that was my first thought. When I looked at the leading edge it was clean, but the flaps were in takeoff position. Uuggghhhh !!! Anyway I figure we flew about 10 minutes with flaps in takeoff position and after retraction everything was back to normal. I told the IA after we landed and it was annual time anyway and he said he found no issues. That's my data point FWIW and that was nearly 10 years ago. I'm sure I am neither the first or last.1 point

-

The heat shroud around the muffler should be removed every annual and the muffler should be inspected. Preferably under low pressure and soap and water looking for bubbles. No need for cutting. A Sensorcon or other similar low level detector is a good tool to catch an impending muffler failure. I test the heater for CO on every flight by holding the Sensorcon in front of the heat vent and look for changes with it on and off. @Frozen Flying I'm glad my little field trip encourage you to get a detector and saved you from a similar (or worse) fate. Thanks for sharing! Cheers, Dan1 point

-

@Frozen Flying, I'm so glad you made it down safely! Another save from a CO detector. This is a good time to plug the detectors that are offering discounts. Guardian has offered a 20% discount on all their CO products. It's very generous and may not last much longer. Code: coaware Sensorcon makes an excellent portable and they still have the 20% discount code active. Code: aircraft2017 I like redundancy so I have a Guardian, and 2 Sensorcons Cheers, Dan1 point

-

“Big deal” is subjective. Mooney’s climb just fine full flaps under most circumstances. I have never come anywhere close to a departure stall in my F model during a touch and go...whether I raise flaps or climb with full flaps. I do touch and gos regularly because I think it sharpens my skill set. I also practice aborted takeoffs, go arounds, power off 180 returns to base and more. Many on this board would see it as cowboy behavior but I have gotten to know my airplane quite well. I’m not saying it’s for everyone, but I don’t think flying an auto pilot cross country every month or so and a flight review every two years is a recipe for currency or stick and rudder competence.1 point

-

re: TIT IMHO there are three factors to consider here; 1) we should all agree TIT matters, and we should all agree that EGT absolute temps don’t “really” matter. 2) We should agree that there is much more incorrect (folklore) vs factual information out there as to why TIT matters and why EGT doesn’t “really”, and 3) we should agree that a Mooney airplane / engine combination is generally no different from that of any other like-type airplane / engine combination. No one will successfully argue against the fact that the hotter you make steel and aluminum the more they will fatigue and eventually fail. So given that, my comments below are driven by a cooler is better premise, however, I am not afraid of recommended heat ratings or running my engine at those temperatures. I recently had a long discussion at KOSH with a design engineer at Hartzell and we talked extensively about turbochargers from the manufacturers' perspective. I’ll abbreviate the convo here but I would love to discuss any of this in more detail. I asked specifically about the M20M’s dual max POH TIT (1750 max lower altitudes to 1650 max at higher altitude) I just couldn’t wrap my head around why the diff in max temps? The turbo has no idea it’s higher up in the air and temp is temp as fast as the materials are concerned - so why the diff and why don’t we see that on most “other” turbocharged piston airplanes? His answer surprised me and immediately made complete sense. Paraphrasing: Hartzell rates that particular turbocharger for a max *continuous* TIT of 1750dF, and that turbo will run all day long and with expected longevity at that TIT. He went on to say that Mooney (not Hartzell) lowered the max TIT to 1650dF at altitude to increase detonation margin due to the higher and unmonitored compressor discharge temps at altitude. Ah ha! I get that! So I said that I monitor CDT and Inlet Air Temp and at higher altitudes I can see little difference than in the mid teens so I suspect my detonation margin is not changing based on CDT, right? To which he replied: because you monitor those parameters you will know if your intercooler is working properly or not, you (me) should be able to safely ignore that lower TIT limitation as long as the CDT remain low and reasonable. Interesting - so what about metal fatigue? His answer was simple - we design the turbo to withstand and tolerate that max TIT of 1750 and there is a adequate safety margin there for metal fatigue and blade stretch. We don’t want these units coming back for repair, so we set the max operating parameters with care. So the take away is, if you trust the manufacturer, then our collective arguments of running TIT lower than allowable to “protect the turbo” is largely flawed. So what about the rest of the exhaust system? Some argue that this is the weakest part of the mooney’s engine and by running TiT less than max you will preserve the exhaust components. Maybe - likely - but no one can really say for how long or in what consistency owner-to-owner. But more importantly, TiT is not directly representative of the “rest of the exhaust system”. TiT is higher than individual EGT’s because it represents the additive effects of the pulses of heat collecting at one point AND under increased pressure at the entrance to the turbine hot side. Before that inlet, the individual EGTs are cooler (some can be 100dF cooler ) and after the turbo, the aggregate exhaust is at least 100dF cooler. On my Bravo I have a second TIT probe (TOT actually) at the exit of the turbo just past the V-clamp. I added that to monitor for a (unlikely) sudden failure of that section and it's always 125dF lower than real TIT. What this says to me is that if you are running the max TIT of 1750, you will be likely be 1650 or less in the main exhaust system. If you run 1650 max TIT then the math works out to be 1550 or less EGT and that is where we find most non-turbo systems running at decent power levels. Happily I might add. Some may argue that you’ll burn probes out faster at higher temps. Probably, but again how much faster? I think Mooney recommendation is to replace the TIT probe at 200 hours regardless, but I think that’s overdone as well. Thermocouple probes have gotten way batter in just the last decade, so they are lasting longer and staying accurate for a longer period of time. All that said - we agree that cooler is better, so run your engine where you want. But I would suggest that we should not be afraid to run the power up and go fast while not exceeding the limits, and also not being shy of approaching them. OK, let me have it! :-)1 point

-

I would test Rain X in the refrigerator first to confirm no ice adhesion to surface. Just simply spray Rain X on a metal spoon and then put a couple of water droplets on the spoon. Put the spoon in the freezer for a couple of hours. Take the spoon out and flip it upside down. If the ice comes off it is good for de icing. I did this with WD-40 and the ice came off. José1 point