Leaderboard

Popular Content

Showing content with the highest reputation on 10/22/2018 in all areas

-

Pickup day has finally arrived, and I couldn't be more pleased! After several years of saying "maybe I'll get it done this year..." I finally bit the bullet, and committed. It turned out even better than I had imagined. Sadly, the lighting wasn't the best today for pictures, the blue appears very dark in some of the photos, but, you guys will get the drift.... Before and after included....9 points

-

I was a Mooney nut about 40 years ago and I owned 2 Bonanza's, 2- 210's and a Super Viking but I kept coming back to Mooney's and im at an age that this will likely be my last aircraft and I figured what the hell, buy another Mooney. As long as the prebuy doesn't go sideways, which it likely won't as it's a real clean aircraft. Anyways this is a great site, I've learned lots going back on old threads and im looking forward to flying my favorite little speedster again. Cheers!6 points

-

I personally like to balance at two different RPM’s. Reason being, you can aquire a clock angle on the Prop at say 1300rpms then raise to 1800rpms an Check that the clock angle is in roughly the same place. Im most cases it will be, but the few times it swings 180 degrees, that means you have a blade tracking issue. When that happens you need to have that Repaired before you go any further. Also, when Balancing a propeller, you want to be aware an have the guy at the controls to do his part to make things as smooth as possible. That comes by way of the Mixture knob. Some folks are reluctant to lean when on the ground, but trust me an engine that says IO an has a Bendix RSA-5 servo will make you pull your hair out. They are extremely Rich an rough on the ground full rich. I have also had great success Balance Propellers not on the Governor. Just a spinning Propeller. After it’s balanced, running it up to say 2200-2300 to verify the balance doesn’t change is okay. If you Balance say at 2400 “ where it’s run at” an it’s rough at every other RPM, then there is an underlying problem. Little food for thought: What if I was to say your not really Balancing your Propeller, while your Balancing your Propeller...:)5 points

-

Took my baby girl up for her first flight yesterday. It was a short flight and shorter for her cuz she was out in the first four minutes. Sent from my iPhone using Tapatalk5 points

-

5 points

-

No intention is misdirecting this thread. However, I can't help but make an appreciative comment on this experience. All too often we believe that when we do something, like move a switch, the intended action occurs. In fact, I suspect many of us are lulled into complacency because what we expect to happen usually does. This is a perfect example and reminder of what we should all be doing...all the time. After initiating an action, like extending the landing gear, verify its completion. The same could be said about Flaps, frequency changes (nav and com), autopilot and oxygen to name just a few. There is nothing small about this incident. It was only a pilots vigilance to detail that converted this event into a successful landing. Thank you for the reminder.4 points

-

Funny you should say that... I once picked up my F at the FBO after they finished my ADSB upgrade and drug it over to the fuel pump to top off. While getting gas noticed a family looking through the fence with young kids. Asked if they’d like to check out the airplane. Showed them in /out. Said goodbye, hopped in and cranked for taxi to hangar. Saw the bright red Bruces plugs with flags and strap go flying across the ramp. Shut down, picked up plugs and pride off ramp, waved to kids still watching, got back in, crawled into my hole to hide.4 points

-

3 points

-

Another thing that's a real pity is these guys are actually doing their communities a disservice. I usually contribute to the local economy when I visit a locality. Lunch, perhaps bit of shopping, and I need hotel if I get weathered in. That all costs money that I'll happily spend, unless Signature runs the FBO. Then some other community will get my money.3 points

-

3 points

-

It truly is a concern. I didn't do anything with the gear, but did use painters tape, 2", to cover all the seams. On returning to civilization, I paid to have the plane detailed inside and out. I also had the oil changed and all filters changed. Even so, I'm hesitant to go again. It's a wonderful experience and a cool place to fly. But the dust is concerning.3 points

-

You or your A&P might get an answer from Hartzell with a phone call. Pretty savvy tech folks there.3 points

-

The title of this thread is a bit misleading... Sounds like an emergency... or tragedy... you might consider adjusting it with words like ... requesting ideas on... or looking for Otherwise, a pandering award can be given... Kind of like yelling fire in a crowded theater... Best regards, -a-3 points

-

Well the time has come, with our growing family I really needed something bigger so I jumped off the cliff and bought a Cessna 310R Colemill conversion, man she is sweet but really likes to drink 100LL. I was thinking it was going to take a while to sell 1YG so I would have more time with my Mooney however a local guy @jrothen4 snatched her up real quick. Its a great bird that I have upgraded throughout the years and it will serve him well. Also since he is local we are keeping the plans to do the first TruTrak install on 1YG. I will definitely still be around here frequently and in any if you guys come to Vegas shoot me a line!!!3 points

-

3 points

-

Nice Job! As you know I recently went through the same after having owned this airplane in its old paint job for quite a number of years. Somehow getting her painted is like moving in and deciding you are going to stay for a while - to keep her for a while longer, eh? Which is a lovely feeling. I was just in the hangar today doing a grounds op inspection of my tks running to make sure all panels are working. And admire the paint....3 points

-

3 points

-

I never turned wrenches on F-22s but I did on F-16s. Certain maintenance actions can only be done at the depo and require special tools, gigs and cradles. Removing wings is generally one of them. Tyndall is not a F-22 depo. Additionally, the storm grew and moved faster than a team could have been assembled, traveled to Tyndall and completed the work. You also risk additional personnel and aircraft being on the ground when the storm hit. Yes, the commanders are responsible for their equipment (planes), but they have a greater responsibility to their personnel. The potential is real that 2 Billion dollars in aircraft were lost, but zero lives were lost. It sucks to be a tax payer, but its better than attending funerals.3 points

-

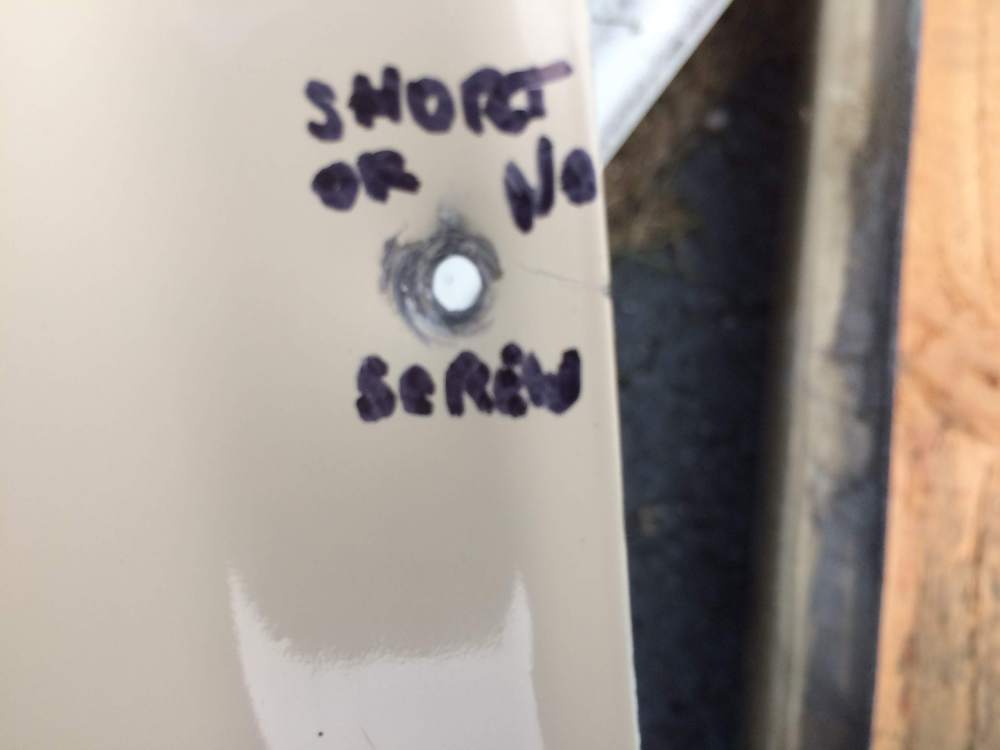

i Thought this might be something everyone here might want to check out? Yesterday, while playing around with my airplane, I noticed the aileron on the right side would not travel very far towards the up position when moving it at the wing by hand. It was obviously hitting a stop of some sort. I got in the plane and tried using the controls. I was able to get it to move but heard a loud pop and then things seemed ok except I could hear metal on metal under the wing near the fuselage. I had my cousin get in the plane and work the yoke right to left while I was under the plane. I quickly found the problem. One screw in the leading wing to fuselage filler panel was rubbing the aileron control rod. So much so that it had fatigue cracked the panel next to the screw. I removed that screw and no more rubbing noise. That screw had been replaced by a larger one (see photo) and I assume it needed replacing because the original smaller screw was also hitting the rod until that threaded hole was worn out. I then removed the filler panel to get a better look. There is a thick piece of felt that is probably supposed to keep the control rod away from the sheet metal and possibly if the screw is short enough the tip may not protrude through and touch the rod. Although in my case it did. Actually that screw is located in precisely the wrong spot. Moving it an inch either forward or back looks like it would have resolved the problem. I could see someone chasing the continual lose screw with a larger one and finally create a potential real problem. From what I could see from the underside with the filler removed, the control rod has a change in section or a weld joint that catches the screw. This may not be a problem on your plane but if you have a stripped or missing screw in this location I would think this might be the reason. I’m just going to leave that screw out for now. I did note it with a marker so next annual it doesn’t get replaced with a new even larger one. Pictures show original and replacement larger screw, location of screw in filler panel and crack in panel next to screw.2 points

-

Robert, there is one downside to owning a C which is particular to Mooneyspace. You need to be aware that you will not be able to participate in all the threads about how hard it is to start the IO-360. That darn C just starts and runs too easily to be of any interest.2 points

-

2 points

-

My wife and I made our first trip with her in the right seat. M72 to 1J0, 281 miles in 1.5 hours.riding the tail wind of a cold front between wide layers. Of corse today we have a direct headwind to make up for the ground speed we saw yesterda. 1J0 is in the panhandle of Florida. I didn’t get a picture of it but the wind sock is hanging in threads.2 points

-

I just spoke with Ole (sp?), one of the owners of Aeromotors. He spent a solid 20 mins on the phone with me detailing all of the upgrades that Aeromotors has made to the Dukes design. It's primarily materials changes but there are also a few design mods that improve reliability. The original duke's design utilizes a sleeve bearing on the rotor shaft that needs fuel for lubricant. This has been replaced with a sealed ball bearing that has been relocated outside of the rotor cavity (Dry). The shaft seals have been upgraded from O-Rings to Lip Seals (crankshaft seals are a type of Lip Seal) in addition to a host of other small changes and refinements. Ole told me that he personally ran one of their overhauled pumps dry for a continuous 10 hours with no sign of wear afterward. He then ran that same pump wet for 200hrs continuous with no wear. Aeromotors also overhauls Weldon pumps which he said are robust but have their own set of issues that Aeromotors has addressed. The impression that I was given is that any advantages to switching to Weldon have been mitigated by the minor changes Aeromotors has made to the Dukes. I came away from the conversation feeling that either pump should be far more reliable after being overhauled by Aeromotors. I'm hoping that's the case because I accepted his offer to build an exchange for me so that they'd have next day turn around when my core arrives. Ole seems a genuinely nice guy, if Aeromotors does what he says it does then this is a big win for folks that have been living with the fragility of the Dukes pump. Cost for OH is $450 before shipping.2 points

-

It seems you recalled correctly. As @jaylw314 pointed out, the Hartzell application guide states, "With IO-360-A1A, A1B engines: Avoid continuous operation between 2000 and 2350 RPM." The only difference between the A1A and the A1B is the impulse coupling magnetos. Starting with the A1B6, counterweights were added to the crankshaft. The same section of the Hartzell guide lists the HC-C2YK-1B(F) as acceptable for usage with the A1B6 and A1B6D, but does not list these as needing placards. As suggested above, I called Hartzell tech services and they did confirm that my engine/prop combination does NOT have any sub-2700 rpm limitations.2 points

-

Fred, this is the first I've heard that my landing gear is fragile . . . Ground clearance is 10", with very little lost due to nose gear compression, because those shock discs don't compress much [almost none compared to pneumatic struts]. I don't go off-roading in my C, but grass strips are not a problem. Look up "piperpainter" in his bright red M20-C on youtube, and you may learn something about the "fragility" of our landing gear and where our planes can be flown. But no, don't look for me in many of those places . . . . I ain't that good! The plane, however, is fine.2 points

-

My son still falls asleep seconds after takeoff. And he is 21! Sent from my iPad using Tapatalk Pro2 points

-

One more thing, and it's something that I hate. I have what I consider to be a somewhat well-tempered sense of justice. I get really pissed off at the injustices that we deal with in life, but as pissed as I am with FBO pricing, or having to hold for a long time on the phone with a call center, only to speak to someone who barely speaks English, et cetera, I don't shoot the messenger. The person working the front desk just works there and has about as little to do with the fucking that we're getting as the person answering the phone when you call customer service. Sometimes it's not even the FBO, it's the airport sponsor forcing the FBO through some corrupt channel to pay too much for fuel and those costs get passed on to us. And worse, they often are the buffer for the negatively that goes along with what their employers are doing in setting prices. I go out of my way to express in the kindest of manner how much I appreciate the individual's help and in the same tone of voice, I voice my complaint over the high fees and explicitly tell them that I know they have nothing to do with it personally. Oftentimes it results in a fuel discount or fees getting waived even though I never ask for that. Signature is the only operation on the field at KGSO. They have excellent service and relatively inexpensive self-serve fuel. A couple weeks ago I went to a crowded bar in Tampa with my girlfriend. We're navigating through the crowd and this guy is looking at her and sortof blocking our path. I guide her to the right of him as I'm following her from behind. The next thing you know, as we're passing him, his hand slides up and grabs my ass. I don't think he even realized that it wasn't her. I felt violated; the same way that I feel when I fly out of Asheville.2 points

-

If you're so inclined Burning Man Every year in the Nevada desert.2 points

-

2 points

-

2 points

-

2 points

-

Over a year ago. Their new design is just like Tempest with an integral resistor which should make it easy to tell what kind they are. Sent from my iPhone using Tapatalk2 points

-

Not sure what they are charging you for the v-clamps, but . . . The exhaust V-Band clamp part number is Lycoming 40D23255-340M which sells for $1060 (http://www.aircraftspruce.com/catalog/eppages/lycomingcouplings.php) . However the Mooney service bulletin (http://mooney.free.fr/Mooney SB SI/283a.pdf) says that the equivalent Aeroquip part number NH1009399-10 can be used. Aeroquip makes the above part for Lycoming - they are the exact same part (see picture below). Lycoming names them as their vendor on this part on this service instruction: https://www.lycoming.com/sites/default/files/Assembly and Torque Procedures for V-Band Couplings.pdf). The Aeroquip part is a lot less at Aircraft Spruce (http://www.aircraftspruce.com/catalog/eppages/engineclamps.php). Some shops are buying the Aeroquip clamp and selling it for the Lycoming price. $500 here and $500 there adds up. On another note, save your old exhaust system and send it off to get it "rebuilt" - you'll need it down the road.2 points

-

2 points

-

Nice update to your Missile!!! I love seeing these sorts of updates and improvements! -Seth2 points

-

Incorrect. They are appproved for our engines and have bags of clearance. We aren’t dealing with high compression pistons in a high performance engine.2 points

-

Wow! I love that paint scheme. Who designed it for you? Sent from my iPhone using Tapatalk Pro2 points

-

Bruce's makes good plugs that aren't overly expensive, and have the flags so that you can see when they're installed from the cockpit. https://www.aircraftcovers.com/ Click on Engine Inlet Plugs. I got a set for my J and they're quite nice and fit well.2 points

-

Our airport is attempting to have owner funded 60X60 hangars built. Although much larger than I would want, I sat in the meeting to listen to the cost estimates. For 6 of these hangars, the cost of the building, land improvement and systems (not sewers, heating or cooling - just the electric service to the building, water to the building) came in at $1.86M. The airport manager felt they could be built for less. I found that interesting since the airport built brand new hangars in 2016 for $1.7M and the cost of materials are already higher due to tariffs on the steel and aluminum. Even if he could get them built for 1.7M, that is $283k per hangar. The 60X50 hangars rent for $1200 per month. So it would be 20 years just to break even on the construction. Although the potential builders would be responsible for all land improvements and utilities, the airport would also charge $140 per month (with an inflation escalator) for the land lease on the 40 year contract. Renting is indeed cheaper... Sent from my iPad using Tapatalk Pro1 point

-

1 point

-

My plane is a 1978 J model. Has a ttaf of about 1200 hrs. Original paint and interior. Never on it’s belly or repaired. I really don’t think there were ever tinneman nuts behind the skin. I’d check it out tomorrow and verify but my wife and I are headed to Mexico for my son’s wedding. Tinnerman or no tinnerman, my intent was to inform that the screw no matter what size, can interfere with the aileron rod. The location just wasn’t ideal on my plane and probably on others. Probably not a particular hazard but a good thing to check out. Maybe mine was a freak?1 point

-

You didn’t mention the status of your gear. Was both the gear safe (light off) and the mechanical indicator showing gear was retracted? The only time I have ever heard it was when my donuts were frozen and it went off when I was trying to retract the gear. I have the squat switch. Sent from my iPad using Tapatalk Pro1 point

-

No, it's a shame. On more than one occasion, I've shot the RNAV to 3T5 and then done a "Circling Approach" to 84R. It really does need an instrument approach.1 point

-

My elves got the Maglite parabola reflectors and cut them down and then then paint the backs black. Then they installed the Crazed Pilot Bullet LEDs and they seem to work just fine. After I'm sure about them I might think about having the elves install new, unmelted lenses to replace the wingtip lenses . . or maybe I'll just forget about it and move on.1 point

-

You took these pictures before your mechanic had a chance to safety wire the v-band clamps, right? Nice shiny new exhaust! I've wondered what that looks like... LOL Cheers, Rick1 point

-

I’d view it as 2 1/2 types. For massives, there are also BY plugs with an extended nose designed originally for oil fouling on the bottom plugs. An additional advantage is the same price as other massives. Also the theoretical advantage of firing more within the cylinder fuel mixture rather sparking at the edge of the cylinder head which, again theoretically, should give the effect of more spark advance. Works for me.1 point

-

As all the experts have spoken , Lasar makes a shim that goes on top of the truss over the tube under the collar , it is 45 dollars , and will stop all shimmying.....But by all means spend 2000 dollars trying to do what everybody says ,1 point

-

Aside from all good advice you have gotten so far... For additional background there is a maintenance piece written by DMax called the eight second ride... it details the wear issues described in this thread. The title is a reference to riding a bull... How well is your 2200’ grass strip working out? Best regards, -a-1 point

-

It’s an early Sunday morning... And I have already lost control of the font for this post.... We are sitting in the front row... watching how market forces act... in a small and limited airplane market. Very similar to observing Schroedinger‘s cat in the trunk... Next steps... Hangars will be rented in preparation of airplane ownership. Similar to painting the baby’s room before he/she/they arrive... That step can cost an amu every two months... Its been about 11 years since the last time I heard somebody ‘snap up’ a 120amu plane... The broker’s fee has just become a drop in the bucket... Sort of... The price of doing business... The economy has been expanding for the last 11 years straight... unemployment is at the lowest in several decades... There has been no inflation in years... Some people are even getting pay raises... The financial markets are just off their all time highs... E-trade ads have gotten over the top goofy again... Job hopping is being advertised on television as a normal activity... An independent PPI is still the best protection for your wallet. In good times and in bad... An all-in-one (buyers agent, ppi, TT, etc...) service is starting to look more like a lot of convenience at a cost that isn’t readily obvious... maybe an ‘opportunity lost’ cost? Pretty hard to tell until after it is all over... I think we have unwrapped the buyer’s broker term...? At least maybe we have... We are talking about a buyer’s agent. A person that helps a buyer through this purchasing process... A broker is a person that helps sellers through the same process, just representing the other side... The more people involved in a transaction, the more expensive they usually become... Being out of the country doesn’t make anything easier... I never bought anything expensive without seeing it first... even if it required traveling thousands of miles to to do so... (often combining business trips with machine hunting exercises...) One thing...(possibly?) for sure... if you go through all this effort, and the paint color doesn’t quite match expectations or look as nice as the pictures indicated... you can always sell it...? What we learned from Schroedinger... the act of observation, can alter what is happening to what we are trying to observe... Jim over there... is now preparing the rocket nets... (Mutual of Omaha’s Wild Kingdom reference regarding Mooney acquisition) Let the good times roll... and all that Jazz... PP thoughts only, not a plane sales guy, and ... boy, @Jeev Jeev’s (now @jrothen4‘s) plane sure looks great..! Best regards, -a-1 point