Leaderboard

Popular Content

Showing content with the highest reputation on 09/24/2018 in all areas

-

LASAR review As many of you know Lake Aero Styling and Repair has been bought and is now operating under new management. I couldn’t find much in the way of a review of LASAR with the new owners, so I wanted to share my story. I have owned a 74 F for the past 5+ years. I wanted to take the plane to an MSC for an annual this year. I also wanted to explore the option of doing an owner-assisted annual. The folks at LASAR were accommodating to the idea and eager to work on my plane. They came in on the high range of quotes at “$2,700-3,200”, but it was not significantly higher than the other MSC in the region that quoted me a $2,500 flat rate. LASAR also had a banner on their homepage advertising 10% off of service if the plane is dropped off by the end of the month(August). So, accounting for the discount, it was a wash in airplane dollars. The other MSC was also quite busy and not open to the owner-assisted annual. My schedule snowballed, so the option of doing an owner assist was out this year. I called LASAR back and asked what the revised estimate would be. They explained that they charge the same whether its an owner assist or not. So it was a done deal. We made arrangements and my wife and I flew the plane to Lakeport on a Wednesday evening with the intent of dropping the plane off after hours. A friend was going to be there in a couple hours out to pick us up in a 210, so we had some time to kill. We noticed a few guys were hanging around the ramp area, so I decided to go introduce myself. It turned out that we had inadvertently run into the new CEO of LASAR and a few of the other new folks that worked there. They were exceptionally friendly and talked about their hopes and goals with LASAR in both continuing the legacy and expanding the business. Sometimes when you chat with people who work in aviation, especially in maintenance, there can, unfortunately, be an air of burn out in the conversation. It was rather refreshing to be met with enthusiasm. My wife and I went off into town to grab some dinner at a place they had recommended while we waiting for our ride home. After a nice meal, we came back to LASAR and were somewhat surprised to find the LASAR group sitting in a circle of chairs in front of the hangar doors. They graciously invited us over and we ended up sitting around with them for a while, chatting about Mooneys, the recent fires, who was who, where they came from and their business goals. They wanted a grow a business that already had a good reputation into more, they wanted to have a good relationship with customers and avoid the “surprise bill at the end.” I was ready to be a lifetime customer based on that interaction alone. We were picked around 10 PM and to my surprise, they had stuck around. I had to travel for business on Thursday and when I settled in to check my email Friday morning, I had this email(names and sensitive figures removed, I will refer to myself as “customer”): “Good afternoon (customer). (Name removed) here, I need to get some information from you so that I can get it all into my system. 1) I need your address. 2) Contact number. Also I need to collect a down payment for your annual so can you provide me with a card? Feel free to call me…” ——————- A deposit for an annual? That seemed a bit odd. So I replied and intentionally omitted the CCV code until I knew what exactly was being asked: —————————- “Hi (name removed), Sorry yesterday was a travel day Sure thing. (Requested information removed) For my accounting, how much are you planning on running for a deposit? Thanks” ————————— “Good morning (customer), Thank you very much for that info. I am going to get all that info where I need it and as far as the deposit goes. Is it ok if I run your card for $3,220.00 which is the cost of the Annual.” ——————— I was busy with work and missed several calls and a voicemail stating they were going to go ahead and run the payment but needed the CCV code. I was… flabbergasted. There was no discussion about requiring full payment in advance for a service. Mind you, they hadn’t touched the plane yet. So how did we end up at the high end of the quoted range? I had a few quick sanity check conversations to make sure I wasn’t imagining things, so I replied to the service manager and CC’d the owner. ——————— (Name removed), I finished up at work for the day and saw the email and missed calls. I am not sure if you have me mixed up with someone else? I just dropped off (Tail number removed) Wednesday night. To be honest I am not OK with the idea of you running the card for $3220 as a "deposit." I was not told ahead of time that's how you guys do business. I also have a few issues 1.) You told me that an annual with your shop is $2,700+ over the phone. I understand that's a baseline estimate. But, if this is a deposit, that means that the work is yet to be completed? How did it get straight to $3220? It's not the cost, its the concept of this happening after you guys telling me that is not how you do things. 2.) Paying a deposit for a service of this nature is not typical and again it was not stated as a condition. I was so-so on the idea of a deposit when you brought it up, but I was assuming that you guys wanted money up front for consumables or a small amount of insurance in addition to already possessing the airplane, the logs and the keys. 3.) We haven't talked about the work required on the airplane. 4.) You have a banner on the front page of the website advertising 10% off of service if the plane is scheduled and brought in by August 31st? I hope you understand my reaction. When I met you guys the other night, I thought it was flat out incredible that everyone was spending time together late after hours, with an electric air of invigorated, enthusiasm about the company. That is the kind of endorsement you can't get anywhere else. You pretty much had me as a customer for life, based on that alone. So I am hoping that this is a mix-up. ———————— The service manager replied. ———————— Hello (customer), So first of all let me apologize for not having mentioned anything to you about a down payment prior you dropping off you’re A/C. I know that it is not standard practice in the aviation industry to make down payments on work, however it is our practice here at LASAR. So for not having mentioned that to your prior, we will waive the down payment for you’re A/C. So that I don’t make that mistake again let me go ahead and inform you that, if we do any work outside of the annual we do generally get progressive payments on work that is performed. With that being said we will not do any work on your aircraft outside of the annual without your approval. As to the 10% discount on labor for the Annual, you are correct. It slipped my mind this morning when I gave you that number. The cost of the Annual will be between $2,990 and $3220 minus a 10% discount on the annual labor. There is still an electric air of invigorated, enthusiasm about the company. We are still the same group of guys you got to hang out with the other night. I do sincerely apologize for the lack of communication about any deposit. Thank you very much for your time in expressing your concerns, please have a wonderful evening and I look forward to making you a very happy and satisfied customer! —————- This didn’t really smooth things over. It was backpedaling, and excuses. If I had been in town, I very well may have asked them to not work on the plane and made arrangements to pick it up. But I was committed at this point. In the end, it would have cost me more time and money to go get the plane on principal. —————- “(Name removed), I spent the weekend wrestling with this. No matter how I look at it, that was a very disappointing opening to doing business with you guys. Ethically speaking, you were ready to overcharge me for work that from my vantage point has not been started yet. What am I to think? So here is where I am at. Despite what this looks like and sounds like, I am going to give you the benefit of the doubt. I understand your policy and I will play along. This is because I effectively do not really have a choice at this point. We are going to have a long talk when all of this is done. Moving forward, I am going to ask you to provide me with detailed quotes for additional work required. Once we have that discussion and come to a written number, I will provide you with payment information.” ———————————- They began the work on the plane and had the annual completed at the end of the following week with the unsurprising list of squawks. I provided CCV information for the completion of the annual and discussed the items they found. My tentative plans were to pick the plane up the following Friday provided they had everything completed. I got a call from them that following Friday that they had just begun doing the post annual flight testing and were going to need more time to finish and were working on the issues that I wanted them to address form the get-go. This wasn’t a big deal, but at the same time they had the plane for 2.5 weeks at this point. I wasn’t able to get to the plane until Monday anyway after some travel complications but had a tight schedule with vacation plans. Monday they called and still weren’t ready, I explained that was fine if they were ok holding into the plane until the following week when we returned. They were accommodating, finished up the work and held onto the plane. I ended up deciding to pay them to ferry the plane to me as I was getting a little uncomfortable repeatedly imposing and canceling with pilot friends who were gracious enough to offer me a ride. Review Quality of work (Great) I will say the quality of work they did was top notch. They found several things that the previous shop had missed or done incorrectly. I have since flown the plane for about 16 hours without any issues, and I am thrilled that they were able to get the PC system working again without much fuss. Time management (OK) I dropped the plane off the evening of August 22nd and the plane was technically ready for pick up around September 19th. Work done was the annual and a handful of basic squawks. I wasn’t in a rush to get the plane back and explained that to them. I was not clear why they waited so long to start working on a few squawks I had told them about in the beginning. Communication (Marginal) Policies (Poor) The billing interaction was just plain bad. The annual ended up running just under $2,700 in labor with the discount and about $500 in parts.(oddly convenient) As for the conversation I wanted to have, I was able to talk with the production manager after flying the ferry pilot back and provided some constructive feedback. I completely understand asking for a deposit on a capital intensive project like say, a panel upgrade. But for a regular service that is predominantly labor ? That's simply not necessary, especially when they have the aircraft in their possession. They have legal protections from deadbeat customers, which I hope there are few and far between. I also prefer to do business like this with cashiers checks, not credit cards. I greatly prefer to closed transaction nature they provide. I am also not thrilled about my credit card information potentially floating around on someone's desk. My intent here is not to rake these guys over the coals, I genuinely like the group, I believe they have the talent and are headed in the right direction. The production manager was apologetic and receptive. So hopefully they will move their policies into a more normalized platform. They believe in the company and are infectiously enthusiastic about the potential. Of equal importance, they are stewards of one of the great resources in the Mooney community, they need our support and constructive feedback for it to carry on and grow.5 points

-

15 people have taken advantage of the Hampton inn Beachfront Mooney Summit rates so far. While the Mooney Summit doesnt get a "vig" from them, it is always nice to support the companies and vendors that provide us a service. If you haven't made your reservations, please consider the Hampton Inn, our host hotel. And while I am on this soapbox, consider purchasing fuel from Sheltair, who always goes way overboard to make our group welcome, providing lunch, drinks, a hangar to hang in on Friday, and many other fantastic touches that make the Mooney Summit so nice. Yea, even with the Mooney Summit discount you can find fuel cheaper, but you have to pump it yourself and by doing so are not doing anything to help motivate Sheltair to continue to support us going forward. Not only does this have to be a good deal for the Mooney Summit attendee's, it should be for our vendors and sponsors also. See you guys Friday!! /soapbox off5 points

-

And we're done . . . But NC's problems are far from over yet. ****************** Flight ops in North Carolina by us are ended as of yesterday. Some local folks are continuing on a smaller scale on their own, but we decided that Sunday was a good stopping point for us. We are, after all, a week one disaster response organization. There are jobs better done by trucks, and jobs that a Blackhawk needs to do instead of a civilian airplane. North Carolina is largely into those phases now. We shattered all previous metrics that we used to measure our success on this one. Number of flights, number of volunteers both pilot and non, number of tons delivered; all are records in terms of this organization. Thank you all for making that happen. 517 flights 280,000 pounds of cargo 468 volunteer pilots All of those numbers reached in less time than we spent on Houston last year. Until next time,5 points

-

Thought I'd share this with the group, just finished this morning and was one I set aside to do the promo painting of LucasC m20c. As always the photo doesn't do it justice. I sure am enjoying retirement.4 points

-

Nice successor to the Acclaim Type S. Here are my comments as a former Acclaim owner: I'm disappointed they didn't bump the engine to 310hp. I had that mod on my Acclaim and it made an incredible difference in takeoff and climb performance. Not to mention it would give them another box to tick against Cirrus. I chafe a little bit at the useful load criticism this plane always gets. I had 102 gallon tanks and never had a useful load problem. Why? Because these planes are so fuel efficient in the flight levels, especially LOP, that you rarely need to haul 102 or even 90 gallons of gas. I was able to get safely and comfortably from Napa to Orange County with just 60 gallons on board, and I'd still have an hour of fuel in the tanks when I landed. This allowed me to carry more people or more stuff if I wanted. The only times I topped off were for flights to/from Denver and the West Coast, or to/from Denver and Cabo. Even then I could still bring my wife and two carry-on sized rollie bags. The lack of a pilot's side door never bothered me. It made the business side of the cockpit much quieter and less drafty than the passenger side when cruising high and fast in cold air. However, adding the door allowed them to add the FMS keypad, which is a big plus. No need to trim the nose up in the flare - it's already there! The Acclaim is so nose-heavy at approach speeds that the elevator trim is nearly full aft at touchdown. This means you'd better be very careful in a go-around, or you'll enter a departure stall with the nose WAY up. My technique was to dial throttle in gradually until positive rate of climb was achieved, then raise the gear, slowly add more throttle and crank the trim wheel forward like a mad man until the plane is properly set up for climb-out. The trim wheel motor isn't nearly fast enough to keep up. I've never owned a turbo Mooney without TKS, and after some of the icing encounters I've had over the Western US and mainland Mexico over the years, I never would. It adds tremendous dispatch flexibility and safety margin to the airplane. I sometimes miss my Acclaim, but I'm grateful for the 7 fantastic years I got to fly it.4 points

-

After what they went through this summer with fires and everything and just buying a business I'm sure things are tight for them. Since the annual has to be paid for anyway I wouldn't have had any problem with them putting the flat fee on my credit card, less the agreed upon discount. Granted, it's not standard practice but I have empathy for small businesses. They have payroll to meet every week and overhead every month. I agree that the communication should have been better. Since it turned out to be a great annual, they fixed the PC without charging much at all and they ferried the plane back to you, I don't see the need for the negative review. When I hear about nightmares that people sometimes have with annuals at other shops it sounds like they did a great job.4 points

-

Here's what I tried today: BRASSO metal polish. The oxidized brass connector was quite dark. Brasso worked great! Very gentle too- I was afraid that the steel wool might score the surface too much. The metal polish contains micro-abrasives that worked with very little mechanical effort. Applied with a micro-fiber cloth, polished for maybe 20-30 seconds, then wiped off. Plugged everything back in, turned on the avionics, and no more scratchy connection. Should work for quite a while by appearance.4 points

-

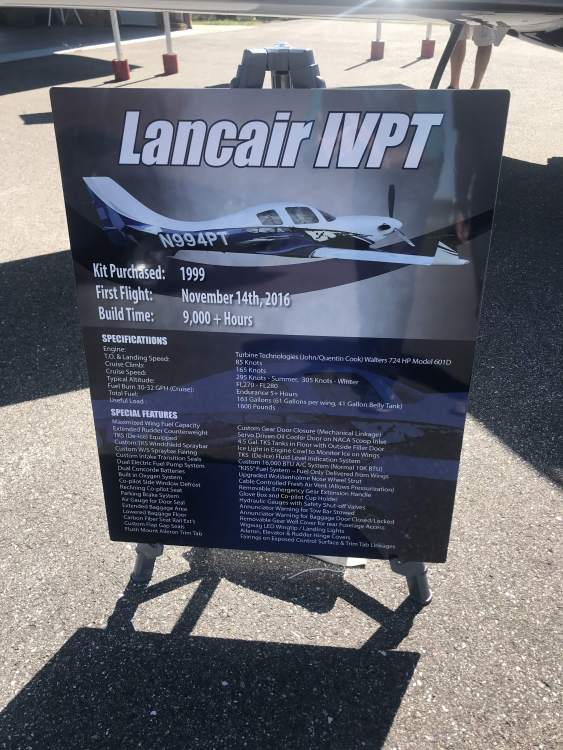

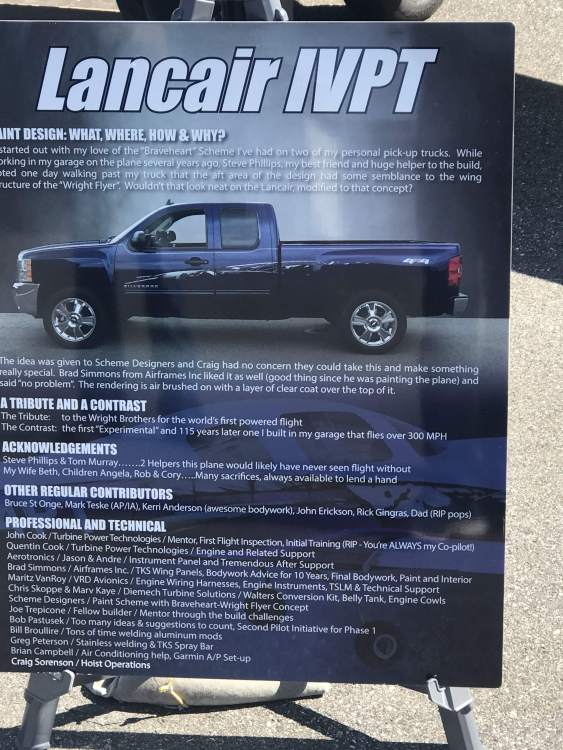

The Lancair IV, IVP, and IVPT do not have the best safety record (ok...it sucks). 90% of the accidents happen in the first 100 hours, usually attributed to new owners NOT getting transition training. Of course, being a very complex high performance plane, those accidents have a higher than normal fatality rate as well. Knowing this, when my initial transition trainer said I was ready at 9 hours, I refused to fly alone until I was at 15 hours with him. Then he said I needed to fly OFTEN, not let the plane be a hangar queen. I racked up 190 hours in it the first 14 months (November 2016 to January 2018), with 3-4 of those months down for maintenance, upgrades and bodywork. I also severely limited myself from doing any hard IFR, approaches to low minimums, and any night flying. I lost 4 months from January to May this year for paint and interior, and got less than desired flight time going up to Air Adventure, rebuilding my complete A/C drive and prepping the plane for the show. One of my goals for late summer or this fall was re-current flight training. There are only two LOBO (Lancair Owner and Builder Organization) "Approved" flight instructors for the IVPT Prop-jet. I met up with one of them about 10 days ago, Chris Rust, an A-10 pilot in the Air Force. We did 4 hours of structured ground school (another hour during lunch) and then I flew with him the better part of 5 hours. By the time I flew home, my brain was a wet noodle. But.....the training was awesome. I flew my first approach in a while in the Lancair, and after being taught a very structured approach sequence from Chris, it was comfortable (maybe even easy) and I nailed it like I was flying the plane on rails. I will be doing 6 month re-current training with a local prop-jet ace and doing the annual training with Chris. I'm well north of 200 hours in the plane now too. Here's a couple flight tracks of the training. Not looking forward to seeing my fuel bill for that (prop-jets drink fuel pretty seriously down low). Tom https://flightaware.com/live/flight/N994PT/history/20180912/1757Z/KEZS/KPCZ https://flightaware.com/live/flight/N994PT/history/20180912/2215Z/KPCZ/L 45.67670 -88.169104 points

-

Thought I would share some of my before and during interior renovations on my M20k summer project! I Just purchased 922PT several months ago with the complete understanding the interior was SHOT (as you can see below). The plastics were rotten; brittle and crumbling so I purchased all New interior from Plane Plastics. I have spoken to several whom have installed the product on 172's and other Cessna models but no one from the Mooney world. All Cessna owners swear by it, I however never what the hear the words "trimmable" again and will reserve final judgment until I'm done!! I have had to climb in and out of my Mooney 2,000 times it feels like, as to work all the "Trimmable" pieces and I'm not exactly a pilot size person LOL! In my renovations I thought it would be nice to wrap all the plastics with Leather with exception of the headliner and baggage compartment. I researched a fella from Great Britain that seems to specialize in high end leathers with modern design and off they went. I have added a few pictures he sent back of the door panels done thus far and the headliner work I've completed to date. Also adding the best sound proofing and insulation everywhere! ENJOY !!!3 points

-

Bought a 2x4 basics kit (the legs and shelf brackets) for about $70. Could have done it just fine with wood, but this is very quick to build and you're basically guaranteed it's square and level. I bought 1 sheet of plywood (3/4" finished - it's already sanded and sealed) and had home Depot rip it in 2 pieces, one 23" and one 25". Bottom shelf is 23, the top overhangs the front by 2". I like a lip on the top to clamp things to. Used 6 2x4's to build the bottom, 6 for the shelf. Used a piece of scrap I had to add a 2nd shelf. Added pegboard to the back wall. Also picked up a really neat LED under cabinet light. It has built in Bluetooth speakers! The whole project cost me around $225, with the lighting. It was too dark to take a good pic of it all set up, but I'd give a thumbs up to the 2x4 basics kit!3 points

-

@bonal Yup, I bought N335BB from @Bennett at the end of July. It was sitting in LASAR's hangar for the duration of the fires, and it wasn't until the end of August that I was finally able to take her up. I've been averaging around an hour of flight time a day since then, and am enjoying the heck out of that aircraft. Bennett did a wonderful job on the upgrades and equipment selection.3 points

-

Went to Ithaca yesterday with our youngest son Adam (17) to see his brother Scott, (20) our middle son at Cornell. Fun day. First time my son showed interest in the airplane. He had me explain every instrument on the panel and what I was thinking as I touched each button and switch. This is a big change for a kid who generally didn't like flying until recently! Meanwhile - on roll out at KITH tower said to me - WOW they like my paint job!3 points

-

I have this special technique where I spill oil everywhere and then clean it up. I am interested in @Ah-1 Cobra Pilot's tool.3 points

-

2 points

-

WOW - CONGRATULATIONS bdash! I have sat in that airplane, in Bennett's hangar once when I visited him. That is a STUNNING example of an M20J. Maybe the nicest M20J on the planet - well I haven't seen all of them but its the nicest I have seen with some special mods, special paint, special interior and clean...and I am sure there are none nicer. Congratulations and enjoy!!!!!2 points

-

2 points

-

The demonstration of the engine mounts and the movement of the engine was interesting. I did not realize this about this airplane. Is that style of engine mount just for the Ultra's (Ovation and Acclaim) or did it come before in the Type S and prior Acclaims and Ovations?2 points

-

Of course you’re right. It’s all in the details: Buzz Aldrin claims he was the first man named Buzz to walk on the moon.2 points

-

Well it was this. During the flight I kept on thinking it was the engine because I had done the oil change about an hour of flying before my flight to big bear. on the flight to bear, I did indeed have a back seat passenger and he must of hit the emergency gear latch. I couldn't sleep tonight, so about 30 minutes ago I decided to go check if it was the latch, and to my surprise when I got to the plane, the latch is unlocked and the CB for the gear actuator is out. Somewhat irritated and disappointed that I missed that because I kept on looking at the engine gauges instead of the whole picture. very happy though that the gear got stuck down and not up. Also happy that I went and checked it at 3am because If I wouldn't have, the plane was jumping on jacks tomorrow morning, and that would have been a wonderful couple hundred dollar bill from my mechanic, for something as little as an emergency latch. And as usual, this forum never disappoints. sorry for wasting your guys' time for something so minor. Nik2 points

-

More research is not what you need.... A good visit is what you need! Sitting in front of the new glass panel displays is a comforting feeling... Watching a known MSer speed through the various pages was a blast. The normally aspirated 310hp O1 is pretty spectacular. If I were to move up the food chain, the 310hp Acclaim would be on the top of my list... have no fear about the wind drag related to small things hanging in the wind... when you fly in the flight levels, the air density is less than half of what it is at C172 levels... Lee Drumheller has been great about combining MSers with the factory owned planes... 1fr, The Acclaim power plant is called Turbo-normalized... it has a higher CR than the usual turbocharged Mooneys, But is slightly lower than the IO550 in the Ovation. It is an efficient airplane with an engine that will still run with a turbo challenge at altitude... and it has two turbos.... call Lee... If you want, I can call Lee for you... (calling Mooney about buying an Acclaim would be great). Lance Phillips can be pretty helpful as well. Will you be wanting FIKI ice protection with your Acclaim, sir? We could go from completely confused, to completely enamored, in about an hour... 15minutes from being on the ground to being in the FLs... PP thoughts only, still not a plane salesguy... Best regards, -a-2 points

-

I had the same exact issue possibly. My number three probe was attached to the top spark plug. #3 always ran 50 degrees or so hotter than the rest. We simply pulled the factory probe and put a JPI prob in the hole for "testing purposes." After determining it was a prob issue I bought a probe that piggybacks off of the factory probe. The piggyback probe led to a lower reading than the others. Long story short, a couple of years later I have a JPI900 with all the old factory stuff removed and temps read fairly close on all cylinders. The weak link for me was how the JPI doesn't work effectively with the spark plug probe or the factory piggyback probe, only through the mounting like the other three.2 points

-

...Passed. Took the written last November, started flight training this July. ‘Bout time.2 points

-

Well here is a solution since this year's registration is closed. Come Next year! With over a year of planning, see what you can do about taking Monday off. The Mooney Summit will be held Sept 27-29th, 2019 in KECP. Registration will open in late March. Go ahead and sign up for this years wait list anyway, as it will give us an email address to notify you when Registration is open for Mooney Summit VII.2 points

-

Pic 3 looks like one of the terminals is loose. Make sure they are all tight.2 points

-

The plane performance can be found in the POH. As we say in shooting, the gun is more accurate that the shooter will ever be. Can you do it is the question.2 points

-

mines' about 10 percent of the cost 1100 miles on 64 gallons. Mooney F for the win2 points

-

Lucas C with his picture of his C parked in front of the rocky desert background. I chose this because I was really excited about the challenges of painting the very low angle of the sun and how the light played on the subject. Believe me it was not an easy choice as there were so many that I really wanted to do. Thank you all for your entries.1 point

-

Stumbled on this today on the Web version of foreflight: https://blog.foreflight.com/2018/09/12/foreflight-trip-assistant-door-to-door-flight-and-fuel-stop-planner/ Plan trip legs based on available fuel load, time, or $. This is very useful to those of us that fly useful load constrained planes like FIKI Acclaim. Fltplan has had a fuel stop finder for a while, but it is not really well implemented. Bravo foreflight1 point

-

Fly it down and let them do the removal and re-install. Take Greyhound back . . lol1 point

-

1 point

-

Please dont get me wrong. When landing, i knew where the gear was. I checked 3 times. One on downwind, on base, and on final. On takoff though, i was paying attention to the annunciator panel for gear safe and it just crossed my head completely, that the gear never went unsafe. As when i retract the gear, it jumps from safe to unsafe, back to safe. I should have looked down, and that was my mistake. Also ive made a checklist over the time as had the aircraft, and didnt include the gear latch because i thought it was just an analog lever. That will definetely be added to the checklist. My mistake and thanks for the help. Nik Also yaw was me. Ive never climbed at 90 knots. I usually do at 130. So with the same power settings, considerably more rudder is going to be required to center the plane than at higher speeds.1 point

-

+1 for shared experience... +1 for Adding this to the checklist... People (big and small) scrambling to get in or out of the back seat, have been known to accidently release the E-release... they don’t know it’s a sensitive and important switch... Things to know about the gear transition.... 1) Hard to know it has gone up without checking, both places the light and mechanical indicators... 2) Going down, is much easier to know it is happening. You can feel it locking in, going over-center... 3) Follow-up with light and mechanical sensor... Some luck was involved... the gear moved enough to load up the CB to make it pop... Then the plane landed on the gear in a less than known position... Some MSers have not fared as well under the same circumstances... Follow-up with what Andy mentioned above... the yaw is indicating something is not balanced from left to right... something has probably changed. You want to know what that is... Best regards, -a-1 point

-

Twenty plus years ago I had to fly a Mooney M20M that I owned back from Ft. Worth to San Antonio with the gear down because of this very thing. The next day when I called Lone Star Aero to get it in to have it looked at Dennis Bernhard the owner of the shop asked about the latch. I drove out to the airport and sure enough , , ,1 point

-

Sounds like your landing gear is not retracting. On my Mooney, green means that the gear is down. I would taxi it to a maintenance facility and get it up on jacks and swing the gear to see what's going on. (You might first check that the latch covering the emergency gear extension is not popped up - that will keep the gear from retracting. If you've had rear seats passengers that's a definite possibility.) The rest is intended just for your safety, not to preach. Feel free to read on if you like, if not, no problem . . . . On another note if it is yawing to the left, don't strap a go pro on it and go fly it. What if the one of the control surfaces is binding? I wouldn't fly it at all that way. I wouldn't want to try to sort that out in the air, especially in SoCal. On yet another note, the Maintenance Manual on the M20R, same engine as the M20S, says in section 79-00-01 that the oil filter should be replaced at every oil change. Elsewhere in the manual they also recommend cutting the filter open at every oil change. Your life and the lives of your passengers is worth following the Maintenance Manual to a tee. There are pictures of what people have found in their filters. The bad news was they weren't going flying today. The good news was they didn't go flying that day. Although some owner maintenance is allowed under the FARS, most owners don't necessarily do it to save money, they do it to get to know their airplanes better. If you haven't learned how to safety wire an oil filter yet, and that's the trickiest part of the oil change, that's ok. Get someone to help you with that part of it. That goes with removing and re-installing the lower cowl also. But don't leave steps out. You might look at each oil change as a "quarterly inspection". If you have an exhaust crack develop three months after annual, you don't wanna fly around nine months with it that way. It will destroy your cowl, but could cause an engine fire or much worse a cabin fire. Hitting the exhaust slip joints with mouse milk at every oil change gives you a chance to put some eyes on those areas. Shortcuts on automotive maintenance might mean you are stranded by the side of the road someplace. Shortcuts on aircraft maintenance has many times led to engine failure on take-off and resulted in stall/spin fatalities where the pilot tries to get it back to the airport. Follow up: Just remembered - one more reason to cut your filter open on the IO-550 engine . . if you find tiny orange rubber slivers in your filter it means that the alternator drive clutch is going bad on you. The rubber slivers probably aren't gonna hurt too much, but not having an alternator soon would be nice to know,1 point

-

1 point

-

When buying the plane in December I knew she needed attention. Don Maxwell did a great job with the needed/requested upgrades including new flaps, new brakes, new pucks, new oil lines, new tires, new wheels, new visors, new yokes (leather wrapped). I’ve also recently had new flap seals, vernier prop controller, new voltage regulator and alternator installed as well. Since that photo above was taken I’ve also upgraded the panel with a Garmin set up. GTX 345 Transponder ADSB OUT/ IN GMA 350 C Audio Panel with Bluetooth and Connectivity Voice Commands. GTN 650 Nav/Com GPS GI 106 B Heading Indicator. EDM 700 Engine Monitor- Upgraded and New Display I’m done with the upgrades for a while. She’s ready to fly on with confidence. Now if only I could get my hours in her to match the dollars I spent getting her in shape. Love my plane! [ Sent from my iPhone using Tapatalk1 point

-

Thanks everyone. A lot of good advise. The best was a M20J flew in today and was off in about 800’. Dry hard short grass, 65 deg, DA ~300’. From the poh @1740 it should take ~1,100. No matter what I get there will be days I have to go light or even not at all.1 point

-

Thanks Anthony. Well, I have a sister in Florida and it's just starting to get colder up here... I've done that flight a few times VFR and the weather has been cooperative. Be good to route and fly it IFR, though. Always wanted to try KNEW / New Orleans. Been by motorcycle, car and airline. Personal airline should be next. Oh, and definitely Eastern Newfoundland, maybe via PEI. Could have gone VFR but better with Instrument capabilities. Almost forgot. I've got my annual due in October so will be paying AGL in N.C. a visit at the end of Oct. There's another one.1 point

-

Yetti I flew over Kingston to New Bern low, I saw a huge beautiful lake, as I got closer home roofs were showing through. SAD. All we can do is help and pray, saw 5-6 Mooneys On another note a 2018 new Cirrus left behind me out of EWN and the controller gave me a vector so he wouldn’t run over me, after five he said sorry 3ps direct RDU, your 20+ knots faster. Talked to the nice guy in RDU he asked are all Mooneys that fast, I smiled and said yep, I was dialed back for fuel savings, I didn’t have the heart to tell him that.1 point

-

1 point

-

Peter might be hitting the refresh button too many times checking on the ki300 ???1 point

-

Its been a while since I posted an update. I think I've finally hit a point where stuff stopped breaking (knock on wood). I've done nothing but contribute to the Shell stock price in the past few months, and I think I'm at about 350 hours in my plane since I purchased it 3 years ago. In other news, I've officially started my IFR training. I have the written scheduled for next week and today was lesson #3. A couple of approaches- the VOR's seem quite easy. The ILS was fun and my nephew took a time lapse of me coming down into Valdosta today (if the link works). I've accumulated 18 hours hood time and am looking forward to learning more. Stuff is starting to click and I can't say I've been excited about flying in a while but this is really lighting a fire under my butt.1 point

-

I haven't posted for a while on the Lancair, well actually haven't posted much at all lately (been pretty busy). I saw quite a few of you at Oshkosh, with some of you stopping by to look at my bird on display. We had a real good show, got some attention and it was the first Oshkosh I attended from opening day until closing day. I had painted the prop, as one of my last "to do" items before the show, the day before we flew out. When we landed on Sunday afternoon (I was lucky enough to be approved for the war bird approach, so didn't see the delays some of you had) and after getting out of the plane, found my two 2" white stripes on the tips of my three blades had ran right off the wing tip. Clearly there was something wrong with the paint, as it had over 24 hours to dry before we launched. It was a mad scramble to get that fixed before judging began. I elected to just sand the crap off and paint it gray like the rest of the prop. We set up a pop-up tent which made the sun so much easier to deal with, dropping it down and pulling the top cover off each night. We also set up some signs describing the different aspects of the plane like the builder details, plane performance numbers, acknowledgements to those that helped me, and some detail on how the paint design was determined. My wife even attended the show for 4 days and my daughter and family plus my oldest son attended on Saturday. During my long build I had a hot rod friend invite me to a garage open house after he completed a restoration of an old 1950's Ford. I thought it was pretty neat, getting to visit with old hot rod friends and told my wife when the plane was done, we were doing the same thing. Two weeks ago we had a hangar open house. We had sent out about 120 invites and were totally blown away when a good 150 friends and relatives stopped by to see the plane. So many of MY friends had heard (ad nausea) about me building this over the last 19 years; it was time to show them I had actually finished it. I was also concerned my wife's friends were being told she was flying in this "homebuilt/experimental airplane" to Florida, so I wanted to quell concerns about what I was "forcing" my poor wife to fly in. Some of the comments were interesting. It was not what they were expecting. One of my snowmobile buddies asked Beth and me to stand by the plane for a picture. She hates getting her picture taken, but on the day of the hangar open house she was really enjoying herself. The smile on her face was priceless (actually, mine wasn't too bad either). We really enjoyed the day. @tigers2007 showed too. Tom1 point

-

Build as you go. Paint stirrer and sharpie. Draw line. Fuel and then subtract from 321 point

-

1 point

-

Lucky it didn't run his ass over..... should have pulled the chute1 point

-

1 point

-

I can’t believe no one was hurt. It put a knot in my stomach when he danced in front of the prop.1 point

-

Damn. If I didn't have this job thing I'd be down there with you guys. You dudes rock!1 point

-

@AGL Aviationannuals several long bodies - Bravos, Ovations - and Mimi's Screaming Eagle this month. You might be able to get a ride home if you need it and are willing to fly in my lowly E.1 point