Leaderboard

Popular Content

Showing content with the highest reputation on 06/18/2018 in all areas

-

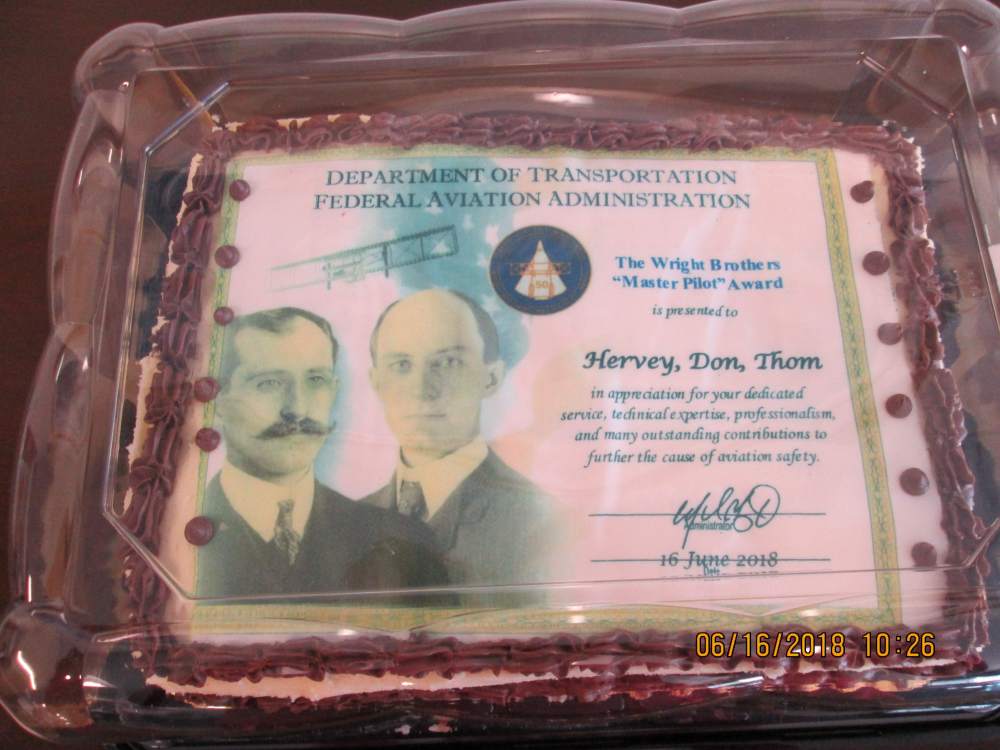

Time has a way of slipping by almost unnoticed---until it is. Yesterday I had the honor of participating in a Wright Brothers Master Pilot awards presentation. There were 3 of us getting the award. One of the requirements is having flown for 50 years. The time starts from the first solo flight. Not surprising all of us had first soloed in 1967. As I listened to the accomplishments of the other 2 participants given by Karen Arendt, the FAAST Team manager at the San Jose FISDO, I marveled at how unpretentious both were in our pre award conversations. You can do a lot in 50 years, as was demonstrated by these two individuals. Karen first showed a movie detailing the Wright Brothers step by step achievement towards attaining powered flight. Then she detailed the histories of each pilot with input from each as she went along. Photos from each of us went a long way in guiding those biographies. I remember Karen talking to me about receiving the "Blue Ribbon Package" which determines one's eligibility. That package was given to each of us and contained every document the FAA has ever had on us. Once home I reviewed it, and a lot of memories were brought back. It contained the results of every knowledge test, every flight test ever taken, every medical, and every renewal of the flight instructor certificate. Needless to say after 50 years it is pretty thick. And just think, the FAA has this record on each and every pilot in the United States. We were given a beautiful plaque, a letter acknowledging 50 years of our lifetime in aviation, and lapel pins for us and our spouses. The celebration finished wth distribution of pieces of cake that Karen brought and is shown below. All in all quite a day.9 points

-

Electric landing gear would always extend normally but intermittently would not retract. Troubleshooting confirmed motor needed overhauling (bump motor with fist when in failed mode or reverse leads and it started immediately). Overhaul shop found brushes were completely gone. Overhauled motor was reinstalled in plane. Same problem. Diagnosis found motor was again not working properly (same symptoms). Motor was returned to shop where a new armature and another set of new brushes were installed. Reinstalled motor in plane. Same problem, but troubleshooting confirmed motor was now working normally. But now when the DN relay was tapped lightly the motor started immediately. New down relay was installed. Same problem. Tapping the DN relay did not start the motor now but tapping the UP relay did! UP relay was also replaced. SUCCESS!! Moral of the story... if your Mooney has over 3,500 hours and/or is over 40 years old, you probably should have the gear motor overhauled. There is a 200-hour requirement to inspect the gears and coupler in a Dukes actuator, but the brushes (inspection not required) cannot be inspected without destroying the caps (which are epoxied in), so they need replacing anyway in order to inspect them. The motor overhaul was under $1,000. You might also consider replacing (or cleaning if you’re lucky enough to have Cutler-Hammer relays) the gear relays since they have had a good life and can start causing real problems when they get weak. If one relay is bad, chances are that the other one is not far behind. This happened in a '77 M20J with 4300 TT that has a Dukes 1057 gear motor with 40:1 gears but could happen in almost any Mooney. I don’t want to hear from you guys with Johnson bars though! Hope this saves someone the headaches and expense I had wrestling with this compound problem that was defying resolution. -Lee6 points

-

Great pics! of A3 (Andrew, Andrew, and Al...) I like the classic panel. I also like clean arteries! Highly recommended. Best regards, -a-4 points

-

One of several reasons I like to regularly run a tank dry at altitude. Switching tanks becomes the default quick reaction. I can recognize the very early initial symptoms of fuel starvation and instinctively reach for the fuel selector to switch tanks. Just performing an action, will get one past the initial "startle effect" and on to productive troubleshooting.4 points

-

We don't have the CRM that exists in the cockpit of a jet. Add to that that most of us are amateur/weekend pilots. We also don't have the automation or computers that most jets have. Attending the APS class in Ada, OK there was a discussion of how most private pilots over complicate fuel management, especially in low wing airplanes where we have to switch tanks. They put forward a very compelling argument that included simplifying the steps involved in fuel management (fewer tank switches) and the benefits of running a tank dry to ensure correct data on useable fuel and location of said fuel. I've taken it to heart and it works so well and is so simple. My range has increased significantly as a result of knowing fuel.3 points

-

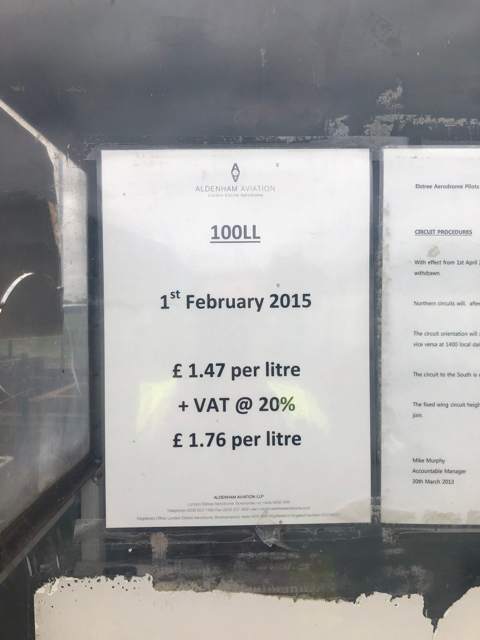

I got to see a famous Mooney today. We didn't actually fly, but I guess there was flying involved to get here. Andrew's @Hyett6420 beautiful M20J G-OBAL! With a largely original 1987 panel it is one of the nicest J's I've ever seen. The paint is absolutely perfect. Unfortunately there is some paperwork that is keeping it grounded at the moment. Thanks to Andrew and Andrew for a great day at the airport! I can imagine this is an amazing way to get the South of France for holidays or just across to Normandy for lunch. The interior designed by Andrew and created and shipped to England by Hector at AeroComfort in San Antonio is incredible. Here's how you keep the birds from roosting on the antennas. This is about $8.86 per gallon for 100LL and it's probably gone up since then. We spent some time in the Control tower as well learning the English way of controlling traffic. Cheers3 points

-

On my ATP checkride in that gawd awful Seneca. The examiner discreetly reached down between the seats and shut the fuel off to one of the engines. When it quite I reached down and switched tanks which turned the fuel back on. He was a bit mad and said he wanted to see how I would handle an engine failure. I said I did.3 points

-

I think it started with the first guy who stuck $30,000 of new avionics in a $30,000 Mooney. Sent from my iPad using Tapatalk Pro3 points

-

Nah, that looks just like the two doors on my also-1970 cowl, with flip-up latches. I would also recommend adding a doubler plate beneath it and riveting it down again.2 points

-

I suspect you are correct. Somehow the concept of single pilot CRM needs to be introduced into primary flight training. When CRM was first introduced (circa 1975?), there was huge resistance and lots of jokes. However it is now gospel bearing good fruit at all the airlines. Maybe, just maybe, we can get those genrral aviation non-planners on board to use all the resources out there?2 points

-

Clarence, I normally agree with you, but I really can't agree with you here. If a twin loses an engine, it's a handful, but if I lose the engine on my Mooney, it stays safely in my hangar until I find it.2 points

-

And in the mean time how many planes have crashed because of fuel exhaustion or mis-management. As other's have said, the proper design of our fuel tanks, regular sumping, etc. make this type of problem exceedingly rare. Whereas fuel exhaustion or mis-management issues continue to kill pilots. Periodically running a tank dry is a common and recommended practice by many experts including Deakin, Busch, Braly, and others. The other option is to tanker fuel everywhere just to account for your guestimation of how much fuel you actually have in each tank.2 points

-

Two men that were loved and respected perished while trying to help others. Noble are thee. PTK especially thinking of you as well as families and loved ones. This thread, as most, shows the best and absolutely worst of MooneySpace. All my thoughts have been clearly communicated by others so I will just say: Peace and Love.2 points

-

Tommy, I won't get into a long drawn out debate on a subject that we cannot solve here, specifically the existence of God, as you have a right to have, or not have faith as you wish. However, your statement " ... another thing to prove that god does not exist" proves nothing. Let me correct my own statement, you are correct, the god that guarantees that humans cannot kill themselves, regardless of their actions, does not exist. The god that says no human will ever get cancer, or any other serious illness, does not exist. The god that says, if you are doing a charitable action, you are free to defy the laws of gravity and still live, does not exist. The god that says you will live on this earth forever, does not exist. In other words, every one of us is going to die at some time. Some from an incurable disease, some from tragic accidents, some from the body giving out with old age, but we will all die. The fact that we will all die, for some reason, does not prove the existence or non-existence of God. Now, I am not telling you what to believe, or not believe, but your statement that this proves there is no God, is not correct, regardless of your belief.2 points

-

You guys are talented, and artistic writers.... Interesting points from all. I have worked.... in a McDonalds, at GeneralFoods/MaxwellHouse, a cup manufacturing site, a lid manufacturer, and sold million dollar cup printers to people that make coffee cups.... I am a big fan of coffee. I didn’t get any of the literary skills that you guys have... but, I did learn one thing... McDs and other restaurants do like to serve really hot coffee... Customers like to put cold milk and cream in their coffee... some experienced customers would order it with one or two ice cubes... really surprising to the young kid working at McDs... To keep all the customers happy, the hotter the coffee is, the more cold cream it can take, before customers complain about getting a cold fresh cup of coffee.... (yes, hotter water does extract more coffee out of the beans, faster...) If the end user doesn’t use all the additives, they just have to wait a little longer before enjoying that tasty cup o Joe. Some oddities I did notice... the cup manufacturer and the lid manufacturer can often be two separate companies... trying to match a written standard... expect a lot of mismatch happening when one styrene lid is used for both paper and styrofoam cups... The lawsuit changed the way I (as a consumer) Test things before relying on them to work correctly... it is easy to not get the lid on right. Just last week the lid was on right, but did not seal completely causing a drip on my shirt... What has changed since those days? Cup holders! No squeezing a cup between your legs... you can’t escape the tragedy fast enough. Disrobing in public isn’t a natural response, when seconds count... Now, call Mooney and order fancy cup holders to go with that pilot side door...! PP thoughts only. i like my coffee, dark roasted, black, columbian AAs... Best served in a SS mug acquired from the Mooney Summit Best regards, -a-2 points

-

During all of my transition trainings, at some appropriate time, I will simulate an engine failure. I have been emphasizing how to manipulate the controls and find a suitable field even if it is the airport. I have not been emphasizing the importance of immediately (and what should be a memory item to do when time is of the essence and there is no time to pull out the checklist) switching tanks. And as ridiculous and improbable as it may seem to accidentally end up with a tank dry when there is plenty of fuel in the other tank, there are unusual chain of events that can occur that can lead to that outcome. Don't let it happen to you. Always, and I mean always, pre brief before takeoff what you will do in the event of an engine failure on takeoff. It will save 4 to 5 seconds of "startle effect" along with possibly saving your life.1 point

-

Experience certainly helps but it really comes down to 3 things: 1) Incredibly accurate fuel planning. At my airline (yes, the one of Gimli Glider fame) the planned fuel burn calculated by our flight planning system is usually accurate to about 100kg on a 10 hour flight that will burn about 50,000 kg of fuel. 2) Extremely accurate fuel Totalizers. The "cost to carry" excess fuel is a big deal in the airline world, so we carry exactly what we need and no more. That translates to destination + alternate + legal reserves plus a statistically determined "contingency fuel" for unforeseen events. Then we add deviation fuel in minutes of additional burn for known weather or ATC delays. 3) SOPs. Airline pilots live and die by SOPs. You have an estimated and a minimum fuel quantity at every waypoint on your flight plan which you monitor throughout the flight. If your burn exceeds your plan, you spot it early and come up with a plan. You always have an out, and you exercise it when it is required. All of the above can be applied to my Mooney. The only difference is the somewhat lower degree of accuracy of items 1 & 2, which can be compensated for by adhering strictly to item 3. Most GA fuel exhaustion accidents I have read about were the result of either not having a fuel plan, or failing to follow it. Minor trivia note: Years ago I was instructing in the 767 simulator and we had to review the dual engine failure drill as part of the recurrent training scenario. I made some comment about it being good training but extremely unlikely that it would ever happen. "I mean, have any of you ever had a dual flameout?" I asked. The Captain was a quiet and very competent old guy, very close to retirement. He smiled and said, "Actually, yes I have." His name was Maurice Quintal. Everyone at Air Canada knows the name Bob Pearson, the famous Captain of the Gimli Glider, but few remembered the name of his FO. It was Maurice.1 point

-

1 point

-

1 point

-

I have the exact same access door. Looking at your picture, it looks like the door is sitting high and it also looks like the door may have popped open in flight at some point. I'll post a picture of mine when I get a chance.1 point

-

Our local small engine repair shop (lawnmower and weedeaters) charge more per hour than our shop. Ditch the yardwork and go flying. Sent from my iPhone using Tapatalk Pro1 point

-

Ok, disassemble old parts, cut new pieces, debur edges, drill, debur holes, dimple rivet holes if necessary, rivet parts together. 15 minutes? I don’t think so.1 point

-

Would you be willing to PM me his name or contact details? I'll invite him to join the local Mooney community of pilots, or maybe he already is.1 point

-

A local pilot here in Georgetown, TX who moved up from a short body. I don't believe he's on this forum and has only been a pilot for a couple of years.1 point

-

I agree with a doubler, just make sure it goes past the crank. How sloppy is the hinge? Might be a good time to replace it as well1 point

-

I think @rocketman may have had help from lycoming on that... (this is an invite to see If Dr. D. recognizes your situation. Maybe he has some input...?) It seems Lycoming may have created a situation that only they can fix. (Possibly?) There is a similar situation where a newly built IO360 generates too much oil pressure and causes the Mooney gauge to bust a redline... no technical issue other than the legal redline bust... it took a while, but I believe they came out with a solution here as well... PP thoughts only, not intending to bash an engine builder... Best regards, -a-1 point

-

Ok I’m raising the ante... I’ll buy beverages of choice whenever I get to meet you for the Bravo owner who can fill in this chart! PM ok if you don’t want to share! And if you could also let me know whether you have digital or analog gauges and if you’re on your original engine. Altitude Oil Pressure (psi) 12,000 ____________ 15,000 ___________ 18,000 ____________ 21,000 ___________ 25,000 ___________ Thanks hugely!1 point

-

I think a doubler repair that wraps around that corner where the crack originated will be adequate. Certainly would not replace the entire cowl for that. Sent from my iPad using Tapatalk1 point

-

I have a feeling that the people running out of fuel aren’t doing defective flight planning. They are doing no flight planning. Or forgetting to switch tanks.1 point

-

The pressure regulator balances engine oil pressure against the spring pressure and atmospheric pressure on the outside of the ball. The atmospheric pressure on the ball is about 15 PSIA at sea level and about 5 PSIA at 25000 ft. So there is about a 10 PSIA difference between sea level and 25000 ft. The bypass orifice has an area of about 1/2 sq in. So just because of atmospheric pressure changes you can expect about a 5 PSI difference in oil pressure. Oil temperature will also have negative affect on oil pressure. The oil cooler is less effective at higher altitudes. Have you tracked your oil temperature with altitude?1 point

-

That doesn’t look very original... Could be a different hinge... looks like the bend doesn’t match the cowl... The latches may be newer than 1970... Park next to another E if you can, to see what the finer details may be... it kind of looks like the door may have been replaced from something else... Whatever it is, may be causing the strain. 150mph causes some pretty large forces on things that stand out... Got any notes in the logs about it? My 65C had two doors on the cowl. One for the oil access, the other a battery access point. Both were 1/4 turn type of fasteners... PP thoughts only, not a mechanic... Best regards, -a-1 point

-

Probably better for the arteries than the fried chick, chips and apple pie with cream Andrewx2 treated us to I’m March. We had too little time to see Baby.1 point

-

As @carusoam says, you just pull the mixture right through. My POH says it's ok to exceed the 1650 TIT redline for up to a minute or so while moving from Rich to Lean of peak. In the 252 I never get to 1650 but then I never exceed 65% power when doing the mixture pull. But it doesn't hurt to pull the mixture all the way until the engine is running too rough to be comfortable, check your TIT, then push the mixture back in until smooth enough. Check TIT again to see if it's below red line. If it is, you're probably good to go. My first rule is never attempt this without a good engine monitor (I like the EDM900) and knowing how to use it and read it properly. But just in case I'm wrong or off just a bit, my second rule of never going LOP over 65% power gives me a margin of error and protects my very expensive (to me) engine. I'm at about 1400 hours on original cylinders which I think is good for a TSIO360.1 point

-

I find "ignore" works well . . . . Also, bad things happening do not disprove the existence of a benevolent God. Dust off your Bible and read the book of Job . . . Or most any of the books. Bad stuff happens. What's important is your response to what happens, be it good things or bad. I won't be flying my Mooney today, I'm in town for a wedding this evening.1 point

-

I bought my covers from airplane-covers back in 2010 when I purchased my Mooney. In fact, on their site, my M20E is still the «Cover girl»! My Mooney lives outside all year long, and the covers are still strong. I've redone 3 of the buckles and some stitchings 2 years ago, at the local shoemaker for $75 and should be good for another 10 yrs! Good stuff!1 point

-

1 point

-

I have a panel mounted GPS, the Avidyne 440 and it does not have any fingerprints at all. That's because I use the IFD 100 Ipad app for all entry except for the squawk code and I use the knobs for that. Bartman drops the mike and walks away....1 point

-

This is an STC and while all engines are different, the basic goal is 25hp increase. They do have a dyno test stand at the facility...and folks that send their engines in for overhauling will get a certain amount of break-in on the stand. I chose option b, so my overhauled engine went straight onto the firewall and a company test pilot did the honors for the first 1.5 hrs. Of course, everything went fine, but not sure I would trade jobs with that fella. In theory, this mod should increase hp output by 25hp + or -. I was there and watched the test flights... it’s in FlightAware. The break-in procedure is straight forward. Cht’s Under 400 and fly long legs over 2hrs at 60 to 65% power settings at or below 7,500’ for up to 50 hrs. As the cylinders seat, they will begin to transfer heat better to outer cooling surfaces so in essence, temperatures dictate power settings. Mines at 25hrs and break-in is almost complete. Soon i’ll Be able to stretch her legs (cool pun) and see what she’s hiding. But she’s already faster than before.1 point

-

I think you basically just did a homemade version of the 'commercial' low-wing jack. The reason they are so expensive is twofold: 1) low volume production and 2) liability. I have dreamed of a common application for a jack like this appearing and then running down to HF and buying a pair for $80 (with the coupon!). The other ridiculously overpriced aircraft toy is the electric towbar. You can get one of these at HF for 0.16 AMU, not much difference to a Sidewinder:1 point

-

A friend has an SR22 at a BFI hangar and is paying $980/month all in. This is more typical of what I've heard from others. $1500 seems high but perhaps there are some. Of course either is expensive. Tie downs range from $125-250 depending on location. Putting cost aside, I would give BFI consideration. It is hugely convenient if you are living in Seattle and don't forget that Seattle road traffic can really ruin your plans sometimes. I've been at BFI for about 10 years. I know some have the view that it is not GA friendly but I haven't experienced that. There is some GA training and it is certainly busy but I can't think of a single bad experience I've had with the controllers there. I live in North Seattle near the UW. If I wasn't at BFI, I would probably be at PAE. Less convenient but definitely cheaper. Let us know if there is anything else we can help with you settling into the PNW Aviation community. If you happen to be on FB, there is a huge GA group called FATPNW (Flights Above the Pacific North West) that is very social and organizes a lot of events. Trevor1 point

-

Hi Hector, I may have some of my baffling that I removed for my cowl mod. I'll check tomorrow. It's not in too bad of shape. What parts do you need? I might be able to make you new ones if mine are in marginal shape. E-mail is sabremech at gmail.com Thanks, David1 point

-

Diag, keep a good attitude and work with the docs. It's amazing what physical therapy can do (been there, got the t-shirts). Some of ghe things therapists have you do don't make sense, but they work. Give it time and do what they say. Joints, however, seem to heal slowly . . . . .1 point

-

Yeah but the jokes on them. I already stripped all the copper wires out of the jackets, and used used electrical take to re-insulate the steel wires . King cheap bastard here.... Sent from my iPhone using Tapatalk1 point

-

To remove stuck cover plate screws, get a drill that is slightly larger than the threads of the screw and drill straight into the head of the screw until the head falls off. After you get the cover off, grab the back of the screw by the threads with a pair of pliers and screw it out until you can grab the end of the screw where the head used to be and finishing screwing it out. It takes less than 1 minute per stuck screw.1 point

-

10-12 hours of flight time seems to be typical in my area nowadays. Plus a fair amount of ground. Of course weather is rarely an issue where I live. There are a lot of reasons those numbers vary, of course. The bottom line is, you train as much as you need. There is no "one size fits all".1 point

-

My grandmother who is a hundred said anyone who makes it to 80 better know coffee is hot. No it was not overheated. Straight from the percolator coffee is just under boiling. The fundamental problem is we now have a belief that someone else is to blame, and our civil system has enshrined the concept that someone else is responsible for our mistakes and for managing/elimination of our risks. Cap lawyer fees on these cases to a multiple of minimum wage, make all pain/suffering and enhancements go to charity. Then you will see how many rituous cases you have. Tim Sent from my LG-TP260 using Tapatalk1 point

-

And she likely got half the plane when he got tired of her...1 point

-

I just want to say one other thing. I am not a test pilot or an aerodynamic engineer, I am just a damn lawyer with a head for math. So don’t anyone go out now and think, that’s cool, I can run my aircraft up to +10% of Vne. For one thing, from what I understand from my friends who actually do know this stuff, the certification standards have built in tolerances for things like wear and tear. So your 35 year old Mooney may not have the same flutter tolerance it did when it came off the line. For another, you can’t necessarily infer from one airframe to another. Didn’t we just have a thread a couple of months ago where someone said that the Rockets, for example, had to have extra reinforcement added to the airfoils? Test pilots get things like quick exit doors and parachutes, and instrumentation to measure the onset of flutter, which, by the way, is a sudden onset event, a change of 3 or 4 knots is enough to tear your airfoil off. These are all good things to know, if I found myself with a fire and needed to get down from, say, 19k, I might fudge Vne a little given the other choices, but just please don’t let becoming smart about something make you stupid.1 point