Leaderboard

Popular Content

Showing content with the highest reputation on 06/08/2018 in all areas

-

I talked with DMAX after I bought her- he said I'm still allowed to come to longview as long as I park on the other side of the ramp. I'm sure he'll make sure KRS charges a Beech premium. I'll keep the photo for a while, but the new owner of my plane is here and I'm going to respect that change. You don't want mistress' ex constantly reminding everyone.. not fair to him. A couple photos attached. Bird wasn't cleaned up to show- plane is in better condition that the photos would indicate. She's a 1985 turbo normalized A36 with tip tanks, air conditioning, and oxygen. 1340 lbs of useful load, no damage history, 1950 hrs on the airframe but flying a lot recently. Same owner for the last 15 years in NJ.9 points

-

My bird is gone, but hangar wasn't empty for long. Mama is pregnant (our second) and she wants more room in an airplane. You know what they say- the best plane for any mission is the one your wife likes. The Tarbes Built Mooney (TBM) is still out of reach... 6 seat piston with some speed... pretty short list. Made the flight home in an A36 from NJ to Dallas in 6.5 hrs of flight time (one stop). I'll always be a Mooniac... I'm glad the new plane has air conditioning.7 points

-

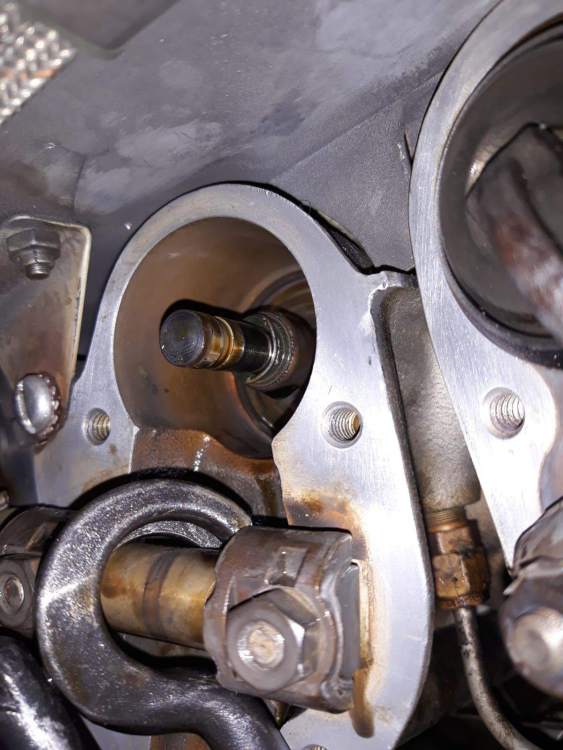

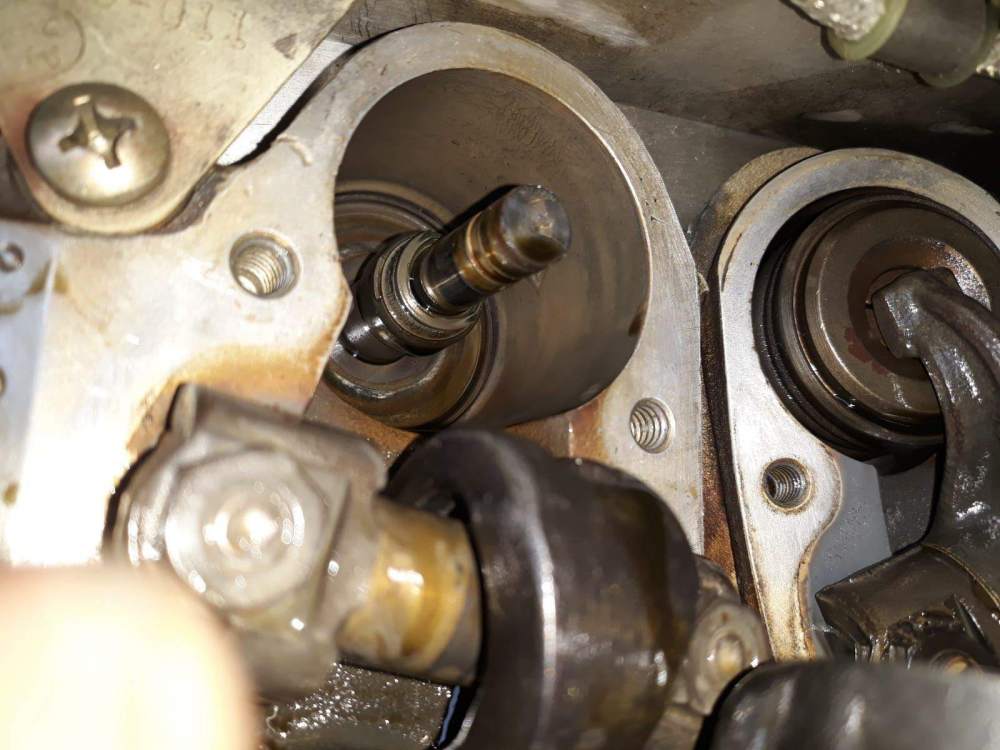

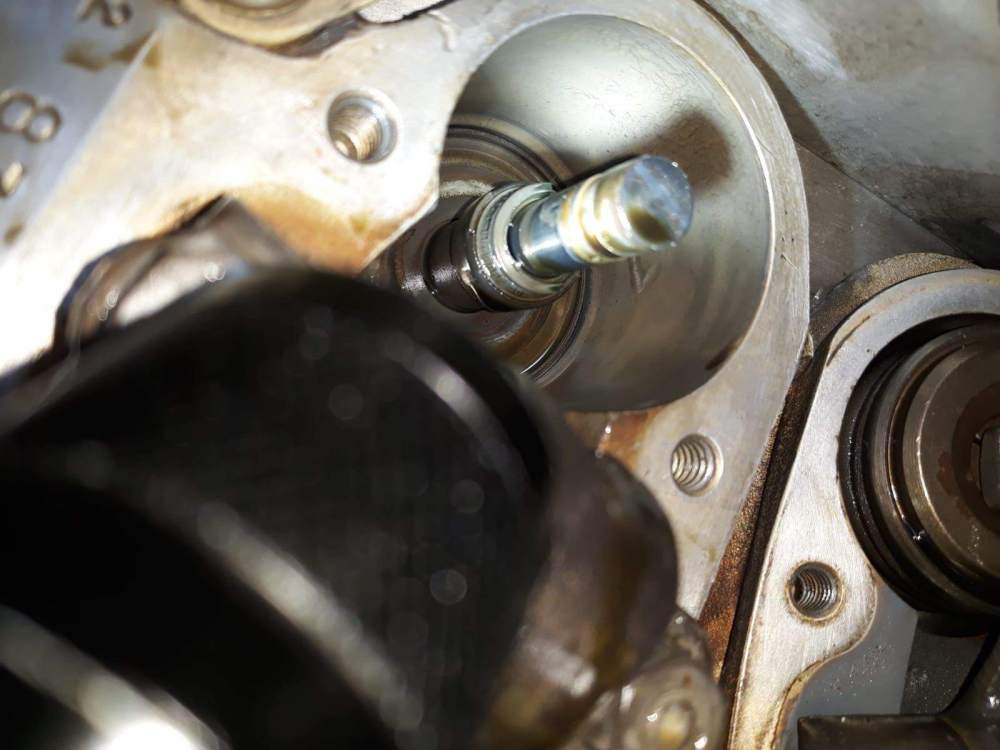

The e-mail my mechanic sent to Mooney and all other parties involved sorting my engine out. Maybe it can be of use for anyone else, so just putting it out there. Mind you, they checked the cilinders for oilleakage with an endoscope and had no reason to suspect the valvestem seals. ”Hi Guys, For a number of years we've been trying to solve the mystery of the oil coming from the exhaust tailpipe of a Mooney M20K with a TSIO360MB engine. (factory new 1989, 1168 TT, no major repairs been done to it apart from 1 cylinder change 2 years ago) Every time the aircraft was started up or flown the RH nose landing gear door and belly where wet of oil coming out of the tailpipe. At some point the turbocharger was changed. There was always about a cup of oil standing in the turbine housing. This didn't cure the problem. The one way valves in the oil system to/from the turbo where cleaned several times and eventually changed for new ones..... unfortunately no joy. We've checked the scavenge pump but it seemed OK. At some point the the starter clutch was broken and the complete housing was changed including the scavenge pump. We hoped that this would fix it..... No.... During a 100 hrs inspection some metal spring particles where found in the oil filter. Small bits like a lipseal spring. This gave me the idea to have a look at the intake valve guide seals since they have this kind of spring installed on the seals. I removed the valve springs and found 5 out of 6 seals being damaged. On 3 of them the springs where completely gone and on 2 others the seal was partially broken but the spring still in place. The only good seal was installed on a cylinder which I changed about 2 years ago. I guess that the one on the old cylinder was damaged too. I changed all 6 valve guide seals. Ran the engine and no more oil from the exhaust tail pipe. The aircraft has made several flights/starts since and so far good news. I thought this can be helpful to share. Greetings, Martijn”6 points

-

3 points

-

When I first arrived to fly with Jerry in his PA46, there was about 30 seconds of “Jerry I don’t think I’m going to fit up here” going through my head. Part of the issue was Jerry’s plane’s former owner had the co-pilot seat built up for his short wife. It is still is a snug cockpit. But certainly comfortable enough for a nap. Sent from my iPhone using Tapatalk Pro3 points

-

I have been working on radios, antennas, running new RG 400 and found radio noise was relieved when I did an in-flight mag check. The mag was sent out so I decided to use the power of Mooneyspace and fix my roof vent with the blessing of my IA. There are several threads recently about this so I researched and used all of the collective wisdom. I do have a couple of things to add, and some pictures too. Although I learned from many threads regarding the vent problems and repairs, I found these two threads most helpful with a link to original step by step content from @rogrbal and subsequently updated by @carolinaflying in the link below. https://mooneyspace.com/applications/core/interface/file/attachment.php?id=50929 I ordered the spring steel wire from McMaster-Carr and it was easy to find on their website and cheap too. Removal of the front and middle sections of the air plenum required drilling some rivets, and getting the control mechanism out was not fun, but I did not remove the rear section. Overall not complicated at all, just time consuming and a perfect project for a motivated owner/IA combo. The old wire was bent at the control arm and there was obviously a previous attempt to repair, but with less than optimal results. The wire loop at the post on the control arm was not a tight spiral, and the cable was not aligned properly setting it up for failure. After removal of the old wire I stuck the little nozzle tube for the Tri-Flow into the end of the cable housing and just sprayed intermittently until it came out the other end and let it soak in well. The key for me was making the loop that attaches to the control arm post SMALLER in diameter than the post itself. I used a 10d nail driven into the workbench all but about 3/8 inch. Use Vice Grips to wind around the 10d nail and keep pulling hard and it made a perfect spiral around the nail. Don't cut off the excess because it is used to "un-spring" it just enough to fit tightly around the post, then trim the excess. The cable housing was originally on the opposite side of the set screw as shown in the pics and I think it was out of alignment when in the vent open position and caused the wire to be prone to failure. I adjusted it several times for best result both open and closed, but it is never gonna be perfect. JB Weld came in handy to attach a washer on top of the post and I have my doubts as to whether it will stay, but the spiral is very tight on the post and I don't think it will come off. After attaching to the control arm then run the new wire from the inside and out the overhead vent. Had to use a small piece of the wire to make a little hook and pull the cable housing up where it is supposed to be because it slipped down out of alignment. I made the loop for the vent door wrapped around a very small screwdriver, but it does not have to be perfect like the control end. The attachment on the vent door is ferrous metal and riveted to the aluminum door and had rusted so I cleaned as best I could and put some zinc chromate on it, followed by some white rattle can paint as seen in the photo with the tape measure. As you can see in the pics below the door opens a full two inches. I'll be wearing a mask for the test flight, because I pulled out some of the 40 year old hog hair and damn it was nasty but again I didn't remove the rear section of plenum so I'm sure it is full of dirt and dust. I don't know how many feet were in that 1/4 pound of wire, but I got it right first try and have the rest left over.3 points

-

3 points

-

What I’m doing is: 1. Replacing fuel senders with CiES 2. Replacing G500 and JPI EDM 930 with Garmin G500 TXi w/ EIS. Keeping the keys3 points

-

Bendix King was just about to start production and they realized all 10 purchase orders were from Peter.3 points

-

Hi my name is Charles and I can't stop buying new avionics for my Mooney2 points

-

Why not put in 64 gallon bladders and fuel to 64 gal? Why limit it to 55 gal? This doesn't make sense. At the beginning of a flight, I fill mine to the top; when refueling after a flight, I leave 1/2" to 1" of space for the fuel to heat up and expand without overflowing. But leaving out 4-1/2 gallons per side? I'm confused . . . . .2 points

-

You would have a very difficult time convincing me that. Medicine and dentistry are two entirely different disciplines and a person who worked their entire academic life towards medical school is not going to say "hey, this Obamacare thing is crap, and instead of clearing arteries I'm going to clean teeth". That's akin to a flight instructor working towards building his time and saying "hey, I don't like having to deal with TSA at the airport, instead of working my way towards flying 787's, I'm going to set my sights on flying freight in a Cessna Caravan as my life's goal".2 points

-

Oh, I'll endorse AGL, their oil screen videos were great Frankly, I would love to see a feature length film of an E getting an annual...plane porn video.2 points

-

But ya gotta look at the long term picture... Increasing the comfort in the plane equates to a pleasurable experience. An increased pleasurable experience means when you say "Hon, I sure wish I had this gizmo in my plane, it would make the flight more pleasurable and safe" you'll get that approval for that overpriced gizmo. Worked for me. My wife is the one that suggested I get the ADS-B stuff done early and with TAS included. She is also the one that keeps asking for more trips. The short seat bottom is an issue. Not difficult to correct with an extension of the memory foam. I never knew how bad my seats were until I had them redone. The memory foam makes a world of difference over that stuff they used in the 1970s.2 points

-

I use a clevis pin and clip. Surely more elegant that a cotter pin. https://www.zoro.com/zoro-select-clevis-pin-std-zinc-0187x1-l-pk10-p11-011z/i/G3371137/feature-product?gclid=EAIaIQobChMI--6-6ZDE2wIVlTqBCh09vgL3EAQYBCABEgIVzPD_BwE2 points

-

Their pictures look great https://propellerheadaviation.com/aircraftservices/mooney-fuel-tank-reseal/2 points

-

We have scoops on both sides. Of course we still don't have the plane they're attached to... but I hope to pick it up next week.2 points

-

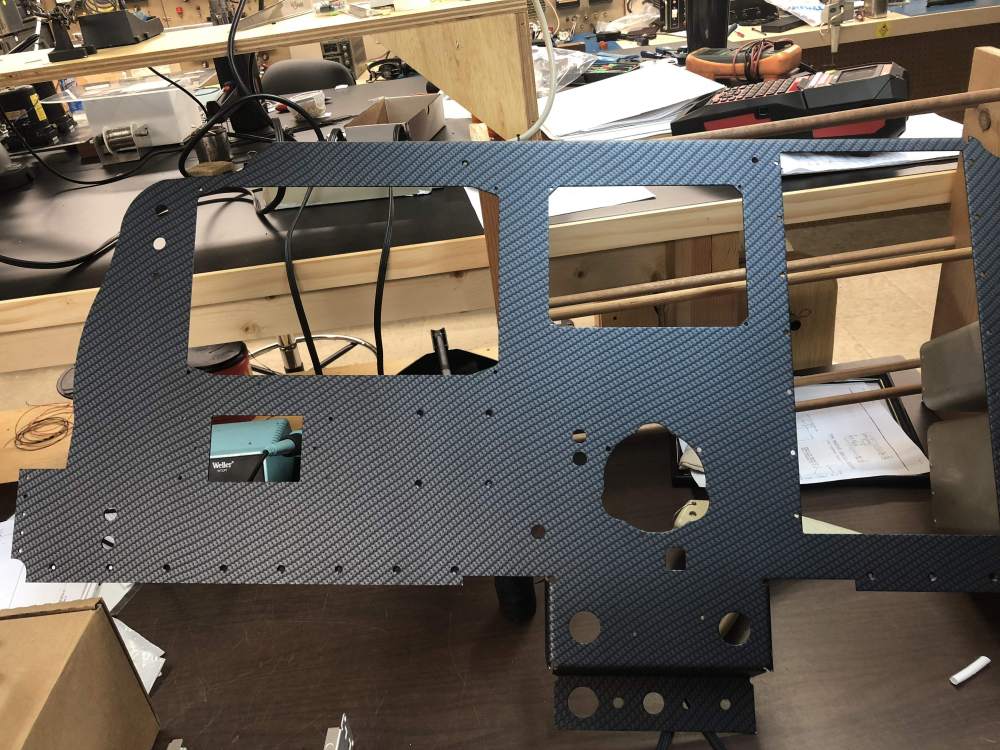

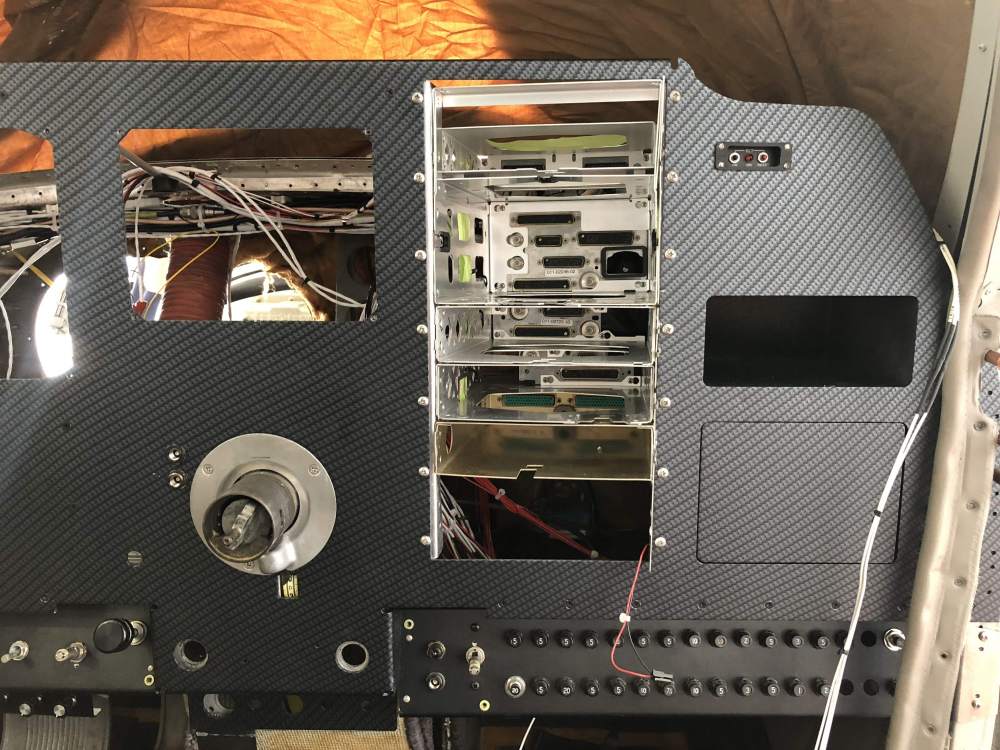

Sorry, here's a copy/paste: We have been working on our company demo aircraft, a highly modified N35, for a bit now. I thought it was about time to post some photos documenting the build. The pre-existing avionics that are staying:Garmin GMA35c Audio PanelGarmin GTN 750 GPS/Nav/ComGarmin GNC255A Nav/ComGarmin GTX345 ADS-B TransponderS-tec 55X AutopilotEverything else is coming out and being replaced by:Garmin G500 Txi 10.6" PFD w/ Synthetic VisionGarmin EIS Txi Dedicated 7" Landscape EIS DisplayMidContinent MD302 SAM for backup instrumentationAll of this is going in a trick new custom instrument panel. The panel started life as a blank from DeShannon Aviation. It was designed and cut in house on our Panel Pro 5925 CNC router built by Buller Enterprises. It is finished in a carbon fiber hydrographic and coated in clear CeraKote ceramic for durability. New reverse engraved circuit breaker and switch panel overlays, as well as placards were also manufactured in house utilizing the Panel Pro 5925.And now for the photos....2 points

-

The picture of the pile of wires doesn’t do it justice.... Sent from my iPhone using Tapatalk2 points

-

Scott, post some pics, but don’t change your avatar... The avatar is like your soul. Best regards, -a-2 points

-

topped off today. CEIS and JPI 900 fuel gauges said I should get 32 gallons to be topped off. Took 32.12 points

-

I have dual G5’s on my F and I just configured my Brittain autopilot to gpss and heading bug off the G5. I am only using the TC100EVT turn coordinator connected directly to the GAD29b. Pin 8 on gad to pin E on TC100EVT and pin 14 to pin F. Pin E and F are on the plug that went to the Brittain controll head and is now disconnected in my case. Pin F is the orange wire, pin E blue. I have not test flown yet. I will in the morning but ground check shows it working. On the G5 I have third party autopilot set to Cessna DC scale 1:1. Pin E and F control the torquer motor on the back of the TC100EVT. 0 volts is centered. +10volts is one direction and -10volts the other. With the engine 4.5 in-hg when I turn the heading bug on the G5 the yokes fallow. I don’t think it will fly a true coupled approach but it should hold the straight line. I will post the test flight results tomorrow. 82337924-6D6F-40CA-9594-F16F234797FA.MOV2 points

-

2 points

-

1 point

-

You guys are funny. Thank you for your responses. Firstly, I am considering a Mirage (turbo), not a Meridian (turbine). BradB, since I cant swing it, I will be sure not to fly in someones Meridian or TBM. But if I do close on the deal, will be sure to let all of you know my views on Mooney vs Mirage. Carusoam: 25 years of Mooney, I dont plan to get off this space. Flew in a friends Mirage last week. Really cool. Lots of room. In the back, you dont need headsets. I didnt check the db level but my doctor friend had a baby he was flying without headsets (and a couple of dogs) and a toddler - and the plane is quiet, the A/C is cool and the plane gets going nicely at flight levels. Someone did mention that getting into the plane is really easy but getting to the pilot and co-pilots seats is certainly a pain. Its a tight squeeze. But just like the Mooney, once you get the hang of the technique, I found it to be easy. Thanks for all the advice folks...1 point

-

OSH as an aviation enthusiast is worth the price of admission. Magazine and online advertising will probably reach more people per dollar however there is a lot to be said about pressing the flesh and getting your story out face to face as well.1 point

-

We should be getting close. Barry emailed me back today and said we are close to the 15 and he would have a full count on Monday.1 point

-

1 point

-

The OP also asked about this company on FB-Mooney Pilots as well as here. I am surprised, and concerned, that as of yet no one has stepped up to say they know the company let alone that they have experience with their fuel tank sealing expertise.1 point

-

I thought you had to be an A&P to R&R the spinner. When I used to have the ECI done I would fly over to Ellington Field (KEFD) and the tech would wheel his tester out on the tarmac, pull the spinner, poke around the hub, sign off and I would be on my way. He was at least an A&P. Before that, the Legend of Longview suggested I have it done at Meacham (KFTW) and they did it the same way. Fly in, test, sign-off, hand a check and fly out. BTW, Jordan Propeller rebuilt my prop a few years ago and did a mod on the hub that eliminates the need for the AD.1 point

-

@Bartman you couldn't have made this post like a week earlier?? I just replaced mine the other week and your write-up would have definitely helped. A few things I think we did different. I removed only the front headliner in my F, and not the rear. I didnt have to drill any rivets or even remove the plenum. I simply removed the metal screws that hold the control mechanism to the metal plate that attached to the plenum and was able give myself enough room to run the new wire, attach it, and reinstall it without removing the plenum. I probably did around 4 wraps on the vent door side and then compressed them with a pair of pliers to make a nice symmetrical stack, like a bunch of dimes on top of each other. Interesting that my control mechanism didnt have the spring attached to it like yours. It looked like the cable had been replaced in the past (and stranded safety wire used and installed....) so perhaps it was lost then. Thanks for the writeup.1 point

-

I don’t think Andrew is thinking about Kelly. [emoji4] Sent from my iPhone using Tapatalk Pro1 point

-

On my '67F, cotter pin hole is some 2" aft of the last seat pin hole on the rail. I'm 6'4" and comfortably use the last hole for take off/landing but often slide to the stop (cotterpin) on long flights when I don't need rudder. it gives me more room from the panel/yoke and better instrument scan.1 point

-

In nearly 50 years of flying Mooneys I had never had the exact knowledge of fuel on board that I now have with the CiES and the JPI 930.1 point

-

When I bought the 252, I knew the first thing I'd be doing is installing the EDM-900. But I'm very glad I decided to pull the trigger and get the CiES senders at the same time. There's nothing quite like knowing exactly how much fuel and where it is... at all times.1 point

-

@LANCECASPER Warm is one way to put it, fuel just went up last week but still a good price. If T65 is a common stop, give me a heads up and I'll buy your lunch.1 point

-

Yes, you can do it under owner maintenance. I think the hours you were quoted are a little high. I didn't keep up with the hours, but if I had stayed after it diligently, I think I could have done all 4 in two days. It sounds like yours are exactly like my K model in fasteners and double copilot window. Yes, the gray looks nice, especially with the gray windshield. I have no opinion on the darker ones for the rear. It will take some cutting and fitting. It will really help to have a band saw (A cheap one from Harbor Freight works fine). If you have specific questions feel free to PM or call me. 214 207-6744.1 point

-

Yes they do (http://www.electroair.net/switchPanel.html)1 point

-

Yes, it's STC'd for conventional mags as well. I was going to do this as part of my panel upgrade and was about to place the order. But I'm glad I checked the size as I just didn't have room in my panel for that Electroair switch. It's just too big.1 point

-

They trap moisture...or they did in this case. The bladders sit in between those frames.1 point

-

Phil, sounds like a very useful project. @AGL Aviation should take note.1 point

-

1 point

-

I think its too soon for that, maybe in #3? But then again I'm not normally a betting man... because I usually lose when I do. Cheers, Rick1 point

-

How much weight does your long range tank mod add, Jose? I mean several cans of sealer, buna-N topcoat. Additional fuel caps and accces panels and doublers. i actually am of the idea that sealed integral wing tanks are the way to go, but in this specific application I’m not impressed. Most of the fleet has some leak somewhere. Ten grand for a whole strip and reseal yet even those leak after a few years, requiring a 1,000$ trip to the installing shop for warranty work . At some point we should admit that it’s not a “once and done” sure fire fix for chronic Mooney tank leaks. Despite having now the third engine booties onto my plane, I’m very specific to fix something once and forever. Our plane came with 20+ year old bladders because the previous owner spent several grand and 3 attempts to patch the left tank. Everyone here is quick to add the smooth belly mod which adds no performance at all and loses 29lbs, or keep their old KX-170B com2 when they Install whole new IFR GPS kit, but when bladders are involved, oh the humanity over 29lbs. Unacceptable.1 point

-

Wasn't me. I don't seem to fly my Mooney, just pay for it to be in the shop.1 point

-

1 point

-

You'll get the same answers. You need to remember most of us are crotchety old men who are set in our ways. Give any of us a beautiful blonde and some would complain she wasn't a red head. Both fuel tank approaches are fine. I love the comments about the weight penalty. 29 pounds of extra weight is nothing when you realize some Mooney pilots are 50 pounds overweight. I do agree with the comment about getting the 64 gallons version of the bladders if you plan on flying long legs. You will love the CiES senders. When these senders were introduced by Scott and the CiES folk, I was one of their toughest critics. Not that the technology didn't make sense, rather Scott, while a great engineer, is a lousy sales guy. And after working through some intercompany technical issues, I was able to get them calibrated in frequency mode. Since I installed them, they have spot on. And I mean literally within a few tenths of a gallon on fill-ups. Never have I flown my plane with that level of confidence in the fuel gauges.1 point

-

1 point

-

Well I wasn't hot after that but I flew on another hour and began sweating again when pulling up in front of the owner's hangar...1 point

.thumb.png.7c67574d7b28f67b0b4a17760919b1ac.png)