Leaderboard

Popular Content

Showing content with the highest reputation on 05/12/2018 in all areas

-

Much less of a gray area than making the part a two piece assembly with screws. My part is identical except for the knurling. I don't believe I'd have a problem presenting my part to the FAA as owner produced.4 points

-

Today the first hour was in rain with a slight north tail wind. Then I crossed a weak frontal line. I was showing about 1:00 ETE at 140 knots. For the next 20 minutes my ETE sat at about 1:00 as my ground speed slowly dropped to as low as 99 knots. When the trucks on I-15 start passing you, you know the head wind is getting bad . I deviated around a mountain ridge and picked up twenty knots from the ridge lift. Was glad to finally see the ETE start going down again.3 points

-

2 points

-

One can't blame wear on the starter adaptor do to Camguard. But its certainly a fact that as the starter adaptor wears out, that since it works off of friction, that anything you do to reduce the oil viscosity (the fluids resistance to flow) is going to allow the starter adaptor to slip earlier. A few ounces of Camguard though has a much smaller effect though than going from a single weight oil to a multi-weight oil since the multi-weight oil is going to thicken significantly less at ambient cold start temperatures than its single weight version. So although its true that a Continental should be able to get a few more hours out of its starter adaptor by using a straight weight oil without any thinning agents I personally think it matters little in the big picture where its more important to optimize our oil formula to the true needs of the engine as whole. Thus I would put much greater priority in reducing chance of internal corrosion as the engine sits between flights, which Camguard is designed to do, and oil that reduced high wear at startup which could mean a multi-weight if conditions warranted or changing single weight oils between summer and winter, and avoiding the popular synthetic blend Aeroshell 10-40 because of it high 50% synthetic PAO content which has been shown to add to starter adaptor slipping, as well as have poor anti-corrosion protection, with increased oil leakage as well as result in high copper in oil analysis. When you do need a multi-weight oil Phillips XC multi-weight which is 100% mineral oil (0% PAO) is preferred but its best to combine it with Camguard since the Phillips XC oil alone doesn't offer much in its additive package. But another compromise is Exxon Elite which is only 25% PAO or 75% mineral and has an excellent additive package. RAM has additionally reported that in their experience they see engines that are frequently run do best on the pure 100% multi-weight mineral oil and the engines that are not frequently run do better on a straight weight 100% mineral oil.2 points

-

Some one of these days I'll have to post pictures of my bird when I bought it. It sat in a dry hangar in Dallas from 1982 - 2003 when I bought it. It was mostly apart at that point. Had no damage or corrosion history with 1975 hours TT on airframe and 1358 on engine. Then I started my rebuild. It was first ferried in 2009 with the rebuilt mostly completed by 2015. It was stripped to the bare airframe and everything now is either new or rebuilt. John Breda2 points

-

I suppose they could, but that assumes you know what my customer and I are doing to satisfy the owner produced parts requirements.2 points

-

2 points

-

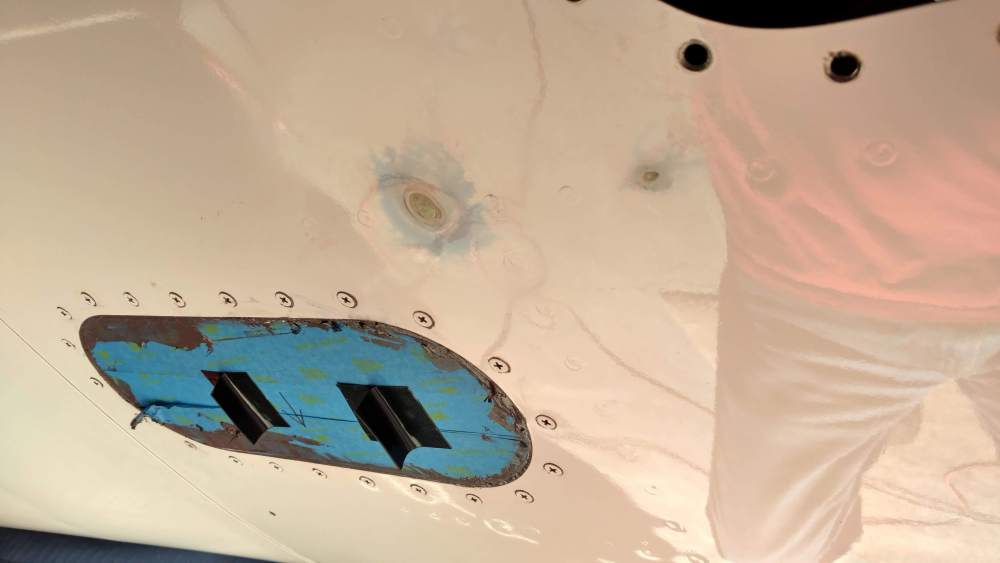

I removed all my access panels, it's easier to scrape and apply Poly Gone. You will need 2 very thin scrapers to remove the access panels. Just work it around the panels many times and they will release. I first used a vacuum with dish soap to find the leaks (there's a thread on this on MS). Used clear plastic over the panels to see the leaks. Used Poly Gone to strip. Give it time to work, It comes off like snot. When it dries reapply. I had to scrape and apply a few times. It is difficult to remove and takes a long time. You will need plastic scrapers and plastic brushes. Used aluminum tape under the wing around the access panel to direct the washed out Poly Gone into the cement trays to catch the water. Also used a mirror on the bottom to look at the top of the tank inside with a led light inside the tank to apply the Poly Gone and Flamemaster sealant. I used Flamemaster CS 3204 CLASS B-2 Black for the tank and Flamemaster CS 3330 Class B-2 for the panels. Going into it knowing it's going to take a long time helps, take your time and do a good job, in the end after doing it I would do it again if needed, it's not hard. Did this myself, an A&P signed off after I was done. That's my 2 cents.2 points

-

CO2 is a liquid in the cartridges. It is about 800 PSI. the 10 or so PSIA difference between sea leavel and the flight levels will make little difference to the cartradge .2 points

-

2 points

-

I’m planing on flying in with the Caravan and camping with the plane. This will be my first time in the north 40. I always camped in vintage with my C. Should be a good time! Cheers, Dan2 points

-

Trying to do the caravan and bring my 5 yo daughter for a couple of days. Got the time for the formation training weekend - just have to be able to juggle dates with a cross state move and a newborn. But that’s life I guess.2 points

-

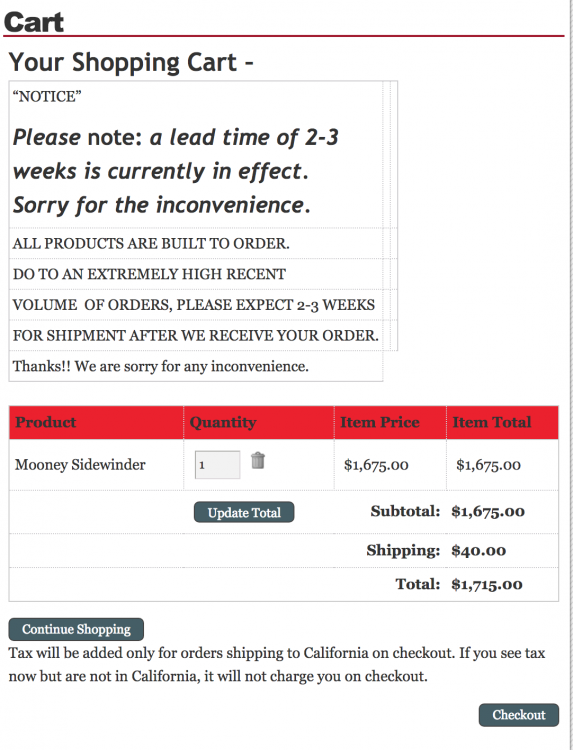

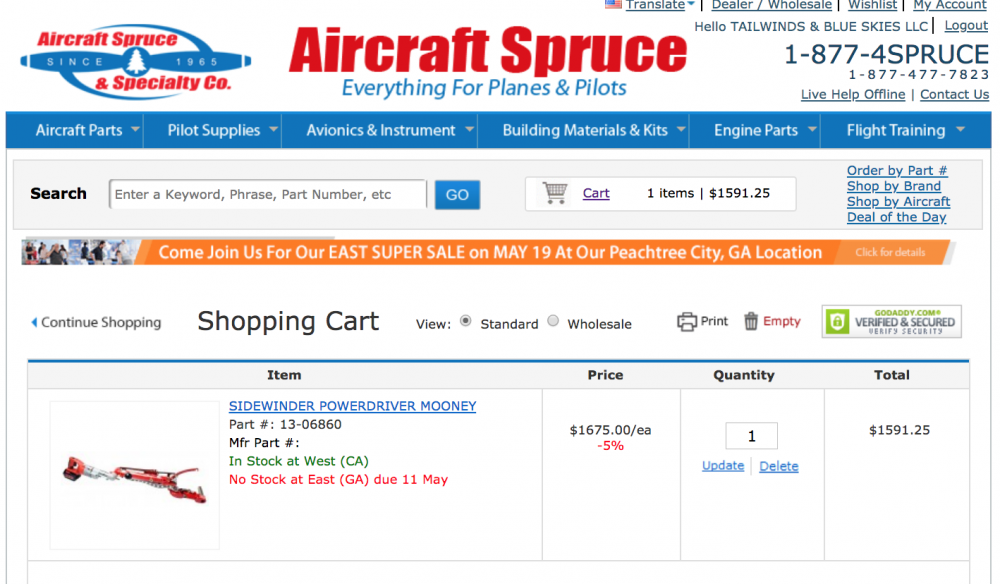

The manufacturer will discount the $1675 list price to $1525 plus shipping if I can get five ordered. He also told me they are putting up a new website with online ordering, and there will be a price increase in the next few weeks. -de2 points

-

2 points

-

2 points

-

I’ve been considering owning a Mooney for a while and now this Rocket has come back on sale here in the UK, I was gutted when it went under offer the first time, now it’s back on I don’t want to missing out again. Can anyone out these give me a good reason not to sign the dotted line?! I’m hours away from buying this 252 with the Rocket conversion. Last minute advice would be appreciated. Mission: 10-15 Uk-Central Europe PA + Local flights. Mainly tarmac with ocational grass including Lessay & Caen-Falaise in Normandy, France. Experience: PPL + 50 hours. KMA 242 X GNS 430KFC 150GTX 330KR 87KN 62AGarmin G500s Video:1 point

-

1 point

-

That skin wedge is about the most useful tool in my hangar period. Doesn’t damage anything.1 point

-

No diagnosis has been made yet but I’m looking ahead at options/remedies. My oil temp runs about 10-15 F high for a J even though my CHTs are excellent (CHTs in the lower 10th percentile according to Savvy’s data analysis). Being based in hot/humid Texas doesn’t help either. Resolving the discrepancy is on my to-do list though not urgent. It’s likely either a restricted cooler or a leaky vernatherm. The cooler is old but has been thoroughly pressure flushed twice, flows well and exhibits no cool spots. The fins aren’t in great shape which could be a factor. It has not been ultrasonically cleaned but the flushing was done back and forth several times over a few hours time at 75 psi. Several people have reported no improvement following service such as provided by Pacific Oil Cooler, and one close friend had his cooler overhauled at great expense without authorization (though he’d have purchased a new one instead if the vendor had been straight with him). So until I’m certain the cooler is at fault I won’t send it across the country for service, and even then I’ll likely just pay the $700 for a new one. At oil change (this week) we plan to check the vernatherm for proper seating and functionality. If it shows signs of irregular seating I plan to replace it and resurface the contact area as per Lycoming SI-1316A. I’m hoping that there’s simply some binding or lack of full extension as that would be the easiest and least expensive repair. If you (or anybody) has input I’d welcome the thoughts. Thanks! Sent from my iPad using Tapatalk1 point

-

Makes sense ^^^. Simplification: Straight weight for infrequently run engines with more anti corrosion properties sticking to a cam. Frequently used engines probably don’t have to worry about oil running off the cam but do have to worry about wear during startup and their valve stem librication. Pick your poison I suppose.1 point

-

If a guy ramp checks me and notices my seat back cams are not original and seizes my plane. He had not gotten laid EVER so he was going to find something to ruin my day anyways. Sent from my iPhone using Tapatalk1 point

-

When trying to reduce my GAMI spread in my J I went as far as to put a bead of RTV around each one and it helped!1 point

-

Expect that the Mooney factory/MSC can make a recomendation for this switch. Their latest birds come with two alternators... Send a request over to Dan at Lasar, He might even have the parts in stock.... The latest birds have really nicely updated buss bar layouts for primary vs. Emergency operations... The maintenance manual /parts manual might be good at defining some good ideas.... PP thoughts only. Going all electric has options that are different/better in a few ways.... Best regards, -a-1 point

-

1 point

-

1 point

-

So I stumbled across this thread about a month ago. I had a leak in a servo and Brittain has no closed its doors. I carefully measured and did some research on the Bellowfram website. I found the 3-350-212-DCJ to be the best match for the Mooney servo. I got the lady to send me a free sample. But she said that they are about $30 per normally. After winding it with about 3 layers of electrical tape, (which is what Jerry at Brittain did), its going to work great! So if you get a tear, order one of these and you'll be good! This is for a aileron or rudder servo. The step servo is a different part, but I'd be willing to bet that they have one that works. The ones in their catalog with an asterisks next to them are standard stock items. Others are custom order.. Brad1 point

-

I have posted this before, but this is the best tool for removing the panels: https://aircraft-tool.com/shop/detail.aspx?PRODUCT_ID=SWG71 point

-

1 point

-

"I'll be at Oshkosh 2018" no "Transportation" no... This field is required. "Lodging" no... This field is required. Can't submit a vote. Sounds like a pretty rigged election where the only valid choice is to go to Oshkosh.1 point

-

This will be my first time to Oshkosh and I cant wait !! I would have REALLY liked to join the Caravan but am unable to attend a formation training clinic in time. Although not a snotty person and would be happy to park next to anyone, I would prefer to park/camp next to my fellow Mooney brothers/sisters.... Hope that does not make me a bad person. I was originally going to arrive Sunday AM but had no idea if I would even be offered a place on the North 40. No idea how fast the area fills up. I thought I would arrive at noon Saturday, 21 July and fly the Fisk arrival. Perhaps if I arrive behind the Caravan (time wise) I will be directed to park in the same area???? I'm not sure if my logic is sound.1 point

-

1 point

-

1 point

-

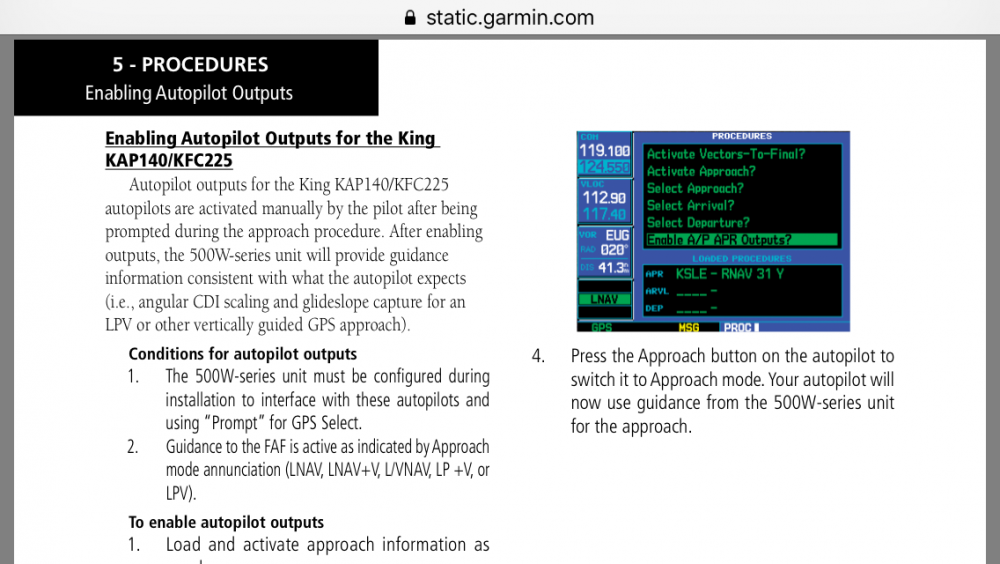

The KFC225 is different, so much so that the Garmin manuals devote special sections to its use. The GNS530 Pilot’s Guide describes the specific steps and specific sequence to couple the autopilot for GPS RNAV approaches. If you don’t do it this way and in this order you won’t get approach guidance from the 530 to the 225.1 point

-

If you're plane has the doghouse, I don't think the CHT's will show much difference at all.1 point

-

Stop a minute and think: when the prop goes round and round, the plane goes forward because the prop pushes a lot of air backwards. A lot of air, very quickly. What would happen in your hangar if you pointed God's own leaf blower in the door? Anything laying around? Papers, maps, boxes, rags, funnels on a shelf, small containers, a hat or two, cups, water bottles . . . . You get the idea. To say nothing of the noise the engine reverbrating inside a large metal box would make. Hope your hangar neighbors aren't there when you do this . . .1 point

-

That's what Joe keeps telling me... "we want to get you the paint job you deserve..." But I'm confident the job will be done right. Apparently there were plenty of dings and dents from 52 years of wear and tear. Joe removes all the old "bondo" before priming. The fresh filler goes on top of the epoxy primer.1 point

-

Looking to get in touch with Alan Fox the Grim Reaper as I am in need of quite a few M20C parts. Rob 512-986-32681 point

-

@Dream to flyUnfortunately my book was "borrowed" and I may never see it again. It is incredibly hard to find such simple information on the internet but here is a quick reference and education. Here is what I was able to find. Option 1 - the way too complicated engineer route. My weakness. 1. To anneal, you need to hold at 775 F for 2-3 hours, then cool slowly (ideally 50F/hour to 500F, then air cooled). This is for ideal -O condition. For your purposes, cool as slowly as reasonable. 2. To heat treat (here is where I gave incomplete guidance). To get back to a heat treated state, you need to solution anneal the material (heat to 975 F for approx. 1 hour and water quench). Then age at 350 for 8 hours and air cool. Attached is the official data sheet to achieve a true -T6 heat treat. Be careful at the higher temperatures. 6061 starts to melt at 1080F. This might be a little difficult to do effectively without a heat treat furnace and good temperature control. Option 2 - way more practical. I talked to the guys in the shop and they said if you were to heat to approx. 500F you could likely bend it relatively easily and cool without impacting the heat treat significantly (might want to try this with a test part first). Just don't overheat it and don't spend too much time at temperature. Good luck.1 point

-

I try to skip belief and trust in science For the Ovation (per the AFM) MANEUVERING SPEED -- The maximum speed at which application of full available aerodynamic control will not overstress the airplane. Maneuvering Speed at: lbs. /Kg. 2232/1012 . . . . . . . . . 104/103 2430/1102 . . . . . . . . . 109/108 3300/1497 . . . . . . . . . 127/126 3368/1528 . . . . . . . . . 128/1271 point

-

Congratulations on your A model purchase. I own N8335E '59 model. I have nothing but good words to say about Al Mooney's final AC design! Looks like you also have the dual pipe exhaust - THE ONLY way to go on the 180 hp mooneys! Best wishes! Joe Philips1 point

-

1 point

-

Thanks, Dave! That is a powerful panel. I must have got side tracked after I saw the Charlie Dugosh signed Certificate of Airworthiness... before the FAA even existed... Quite the Modern Museum piece. @Bill Pugh, do you have the first log book for your plane? The first page or two will probably have some interesting test flights recorded in it by some interesting pilots... Thanks for sharing the details! Best regards, -a-1 point

-

He's got what he needs. He has fuel flow and a JPI 700. While no longer state of the art, it does give him all the info he needs to manage that engine.1 point

-

Just to give you an update. The shop that installed my Garmin GPSs (they are out of business) used the wrong splitter and incorrectly wired the COM. Smart Avionics (Ben) at N71 was able to squeeze me in today and solved the issue. He installed a new Garmin Splitter and rewired COM 2. Everything is working fine.1 point

-

I had some similar behavior for a while, and it may have been multiple issues. I did find a USB power adapter that was going a little crazy once in a while, so replacing that helped. I also swapped out my ancient KMA20 audio panel for one I got on ebay for cheap, and that helped, too. I think replacing the 40-year-old KMA20 with another forty-year-old KMA20 was a partial fix, because although things did get better, it didn't completely solve the problem. I nursed things along long enough that it lasted until the airplane went in for new avionics. In my case I suspect the second audio panel was better, but still had it's own issues. YMMV.1 point

-

Chris, We will have are standard hot dogs hamburgers ect... any sides or specialty food you would like to bring would be great.1 point

-

Best to check with your IA and ask him to show you how to do it. Some IAs prefer to do that themselves during your Annual Inspection and don’t want us hamfisted Pilots fooling around with our airplanes.1 point

-

The only thing I can think of more dangerous than an engine out emergency in a single is eating Sushi in rural Pennsylvania.1 point

-

1 point

-

I’d be willing to sell them in pairs, enough for one seat. David1 point

.thumb.jpg.946e4e6d8f519a448f1237dff52b2821.jpg)