Leaderboard

Popular Content

Showing content with the highest reputation on 04/28/2018 in all areas

-

On April 26th my wife and I were traveling to Nassau for a long weekend in the Bahamas. We planned a stop in Daytona Beach for fuel. When we departed Huntsville, AL there was a low pressure to the west pushing a cold front to the east so we had to pass through about 90 miles of light to moderate rain. When we arrived at Daytona Beach the controler took us several miles off shore to enter a right base for 25R. To make sure we had our best glide in case of an engine problem I left the gear up until we started our descent on final. As we started to descend on final I put the gear switch down and started my gear checks. Switch down, manual gear indicator in the floor in the green and and gear down light on is my normal procedure. When I looked at the floor indicator I remarked to my wife that the light must have burned out as it was hard to see the green indicator but it was there and I could see it. When I looked at the annunicator gear light it was off. At this point I knew something was wrong but I didn't know what. I am still at a couple thousand feet so I had time to cycle the gear up and back down and had the same indications. I checked the manual gear cover to be sure it was latched and I pulled the manual gear handle to confirm the gear was down. It is now time for a different plan as I knew I wasn't landing without a gear light since I didn't trust that the gear was locked down even though I was confident the gear was down. I thought I probably had a stuck or broken gear down switch. I have always felt and I teach my complex students that the worse place to diagnose a problem is in the pattern. Close to the ground is no place to deal with the distractions of a gear problem. My call to tower was "Daytona tower, Mooney 49Q has a gear problem and needs to depart the pattern to troubleshoot the issue". He immediately offered an orbit over the speedway and a climb to 1500 feet which I took. In hindsight, maybe not the best spot since I had to stay away from the runways which was a lot more complicated because the autopilot was randomly disconnecting. Lots of distractions during the entire event including the tower asking fuel and souls on board. The tower was great during the entire event but I did have to ask him to standby once since I was feeling overloaded. Flying, troubleshooting and talking was one too many things to do. Things got really quiet after that. After arriving at the speedway and getting the altitude back where it belonged I started troubleshooting the gear issue. At this point I planned to manually put the gear down since I had tried all the electric troubleshooting I could. When I reached to the circuit breaker panel to pull the electric gear breaker I noticed the gear indicator breaker was popped which explained the lack of lights. I pressed the gear indicator breaker back in and put the gear down which promptly tripped the breaker again. Not good. Next plan is to pull the breaker and manually extend the gear. That worked but I still didn't have a gear light. I reset the gear light breaker and the lights came on. I told the tower that I had a gear down indication and I was ready to land. He sent me on a fairly long downwind since he had two jets to land. I didn't realize until later but the controllers were holding the other planes on the ground to give us the runway. During the downwind leg I heard someone asking about the alert aircraft and realized they were talking about us. That was a bit sobering. When we turned final we had two fire trucks and an ambulance on our left. They had four trucks at various places on the right of the runway. Lots of airplanes holding on the parallel taxiway since Emery Riddle does a lot of training here. Ok, this is for real. I made a nice slow descent and as gentle touchdown as I could. The gear stayed locked down and after I made the right turnoff on the taxiway I felt fairly confident that the gear wasn't going to collopse. We had one of the alert trucks and a fire truck follow us for a while. The alert truck followed us to the ramp and the airport authority guy took our statement. End of the incident but I still have a broken airplane and reservations in Nassau. First step is to call Joey Cole and get some advice. He is at lunch and will have to call me back. Daytona Aircraft Services is on the field and were kind enough to put the plane on jacks to check the gear. We performed several gear cycles and no issues were seen. We pulled the gear indicator and confirmed that the gear would lock down even if the gear down indicators wouldn't light. The guys at Daytona Aircraft Services were confident that there were no issues with the gear and that I just had a problem with the gear indicator system. When I spoke with Joey and told him the problem his first question was did I fly through a lot of rain. I said that I had flown through about 45 minutes of moderate rain that morning. Joey said that water can cause issues with the gear indicators and that was probably what happened. At this point I felt comfortable that the gear would come down even if the indicators failed to work. We fueled and loaded up to depart for Nassau. When we arrived in Nassau the gear extended and the lights lit with no issues. When we get home I plan to pull the wiring diagram and check for anything that could cause the breaker to trip. What I did right: 1) Left the pattern to diagnose the problem 2) Managed the flight and got all the help I needed 3) Didn't do anything to make it worse. I was really tempted to cycle the gear instead of getting it on jacks. How much worse would it have been if I had the gear down, put it up and then it wouldn't come down. 4) Landed at a field that had a Mooney service center on the field. What I did wrong: 1) I should have gotten out the checklist instead of doing everything by memory. I would have caught the popped breaker sooner. 2) I should have cancelled my IFR clearance sooner. I didn't need it and it made the controller's and my job harder. I definitely busted my assigned altitude due to distraction. I didn't declare an emergency but I am sure the tower controller did it for me. It will be interesting to see if I hear anything from the FAA about the event.12 points

-

I’d recommend mounting the guns in the wings, just outboard of the fuel tanks. Any closer and you’d have to start thinking about a synchronism mechanism. Load the belts through the inspection doors. Convergence should be set to about 350 yards. Then an it’s just a mafter of finding a bonanza or Cessna to roll in on. oh...... you meant in the cabin....6 points

-

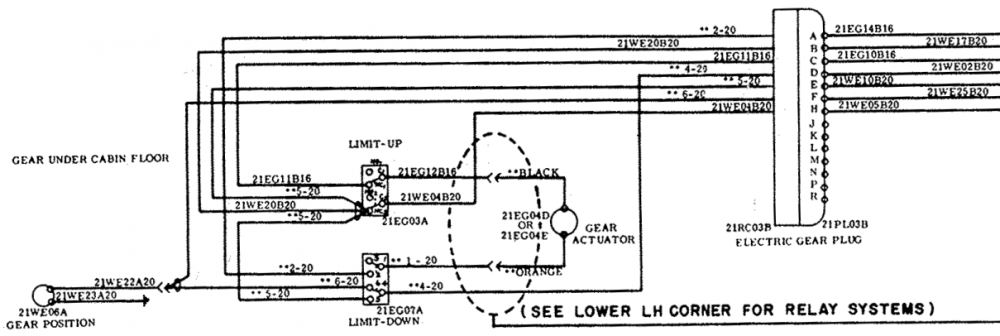

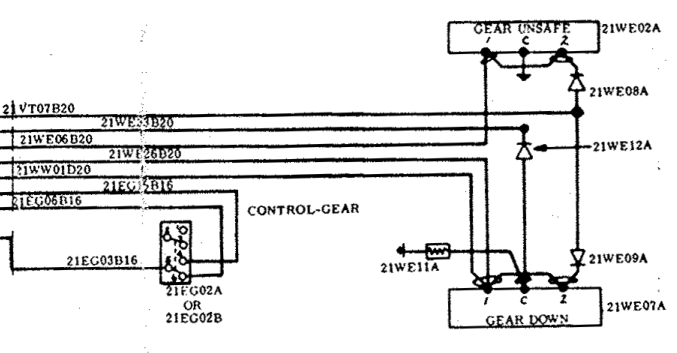

I don't have the schematics for an M20J handy, but I have late-model M20F schematics which I'm betting are similar. Here's the portion of the schematic showing the gear motor, the limit switches in the belly, and the light that controls the floor indicator lamp. Note that one side of the limit-down DPDT switch controls the relays that shut off the gear motor, the other side goes to the floor lamp. The schematic happens to show the switches in the gear-down position, i.e. power applied to the lamp and power removed from the gear motor. That ring terminal splicing off the floor lamp indicator goes to the annunciator light on the instrument panel. In other words, the same connection powers both the "Gear Position" floor lamp and the "Gear Down" instrument panel light. If you trace that wire in the schematic, it leads to the panel annunciator lights themselves: Notice the annunciator lights have one common (ground) terminal, but two terminals for power (applying voltage to either one will light the lamp). The "2" terminals on the right side connect to the push-to-test switch. The "1" terminals on the left side connect to the limit switches in the belly... and also the floor lamp indicator in the case of the gear down indicator, as explained above. In particular, when the down-limit switch moves to the "Gear Down" position, power is applied to the "1" terminal of the Gear Down indicator above. So, couple of things to understand about failure modes. First, if the gear indicator breaker trips, it affects both the panel annunciator and the floor lamp. These two gear down lights are not on independent circuits, they're only "redundant" in the case of a burned out bulb. The good news is, the mechanical lubber line on the floor indicator is still a good indication of gear down regardless of any lights. Second, the terminals on the instrument panel indicators have to be physically close together since there are three of them - maybe 1/4" to 1/8" apart. If you get a drop of moisture on the back of the indicator - perhaps streaming in through imperfectly sealed access panels just outside the windshield when flying in rain - it can form a short between the terminals. If moisture forms a short between terminal "1" and terminal "C" of the gear down indicator, this can create an electrical short between power and ground - but not until the gear reaches the down position and the limit switch in the belly closes to apply power to terminal "1". If you put the gear back up, power is not applied to terminal "1" and the breaker can be reset. If you put the gear back down, the breaker will pop again when the down limit switch in the belly closes. Sounds like this may be what happened to you. Hope that helps.3 points

-

I am a dealer for this product and could probably get decent pricing if there are five or so who want one. PM me if you're interested. -dan3 points

-

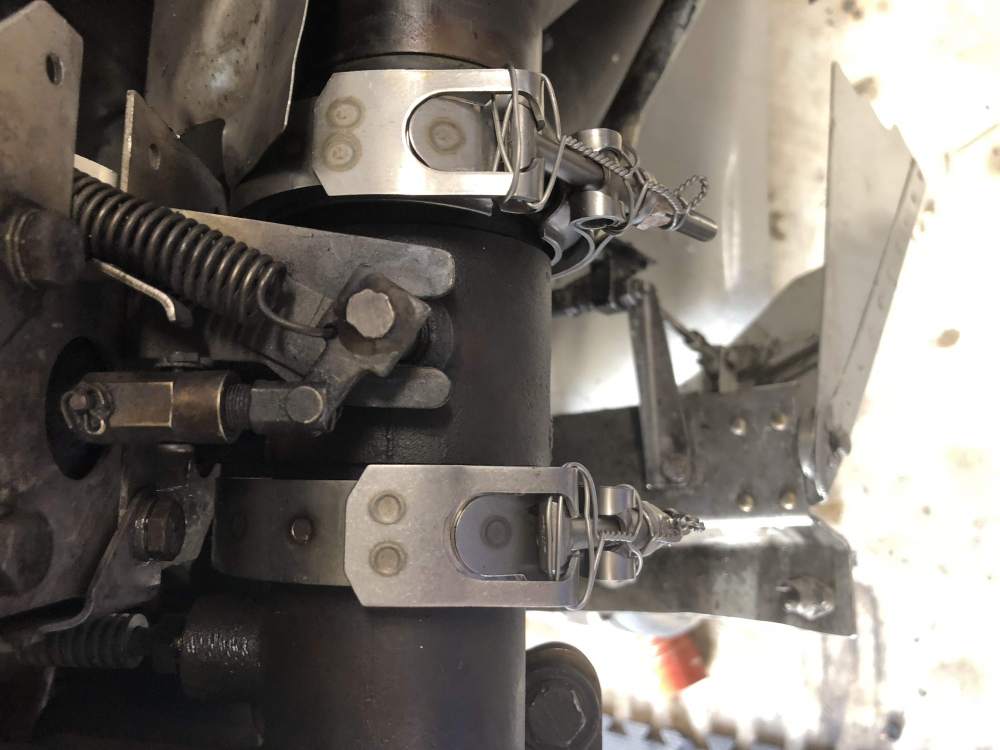

It looks like tomorrow we should be able to start it up and look for leaks. It is amazing how fast it is to take it apart and how long it takes to put it together. The clutch driven back-up vacuum pump has been removed and has freed up some space on the backside of the engine. As soon as an Aspen is installed the other vacuum pump is going away. I already have an electric Mid Continent Lifesaver as backup so I'm legal to go all electric. The V-bands that connect the wastegate got torqued and safety wired today. The prop was installed. The ignition was timed. A few little odds and ends to do in the morning. Hopefully by 2 pm it will be running.3 points

-

Still need to worry about synchronization when firing forward and low. And requires a second person to ride in the back seat, not as spacious in my plane as in yours.2 points

-

There are some fairly stiff and repeated warnings in the 231 POH about applying full power in a situation where the engine has cooled below specified levels. Warnings as in THE ENGINE WILL QUIT. This is a little bit of a problem with the power off 180, but a bigger problem with steep spirals if you go to idle, which you must, and then do three spirals down. It wasn’t a big problem in the summer months, but I would up doing my CPL in November, and it was a problem as day temps cooled off. What concerned me the most was the classic combination maneuver where the DPE might ask you to spiral down and then do a power off 180. If you hit it, fine, but if there was a problem in the last phase of the 180 you would be in a regime of flight where the POH definitely warned against sudden application of full power for a go around. I showed all this to my DPE (the warnings in the POH), and told her I just wouldn’t do the combined maneuver. Its not called for in the PTS. I didn’t mind doing the steep spirals to an altitude where I could power up slowly per the manual, but being the guy who gets to pay if the engine is fried, I was not going to do them where an immediate application of power for a go around might be necessary.2 points

-

I hesitate to tell my power off 180º story, but It might benefit someone. Two months ago I was performing my check ride for a CPL. I chose to use my Acclaim for the flight test. All the reference maneuvers, steep turns, short/soft field techniques and 3 Precision power landings were spot on. I wish I could have stopped there. The last maneuver was the power off 180º Precision spot landing. Flight conditions-clear skies, wind 20-25 kts with rather freq gusts to 35kts down the runway. Our normal. At 1000 ft (pattern alt), 90 kts and abeam touch down point, throttle pulled full aft. started turn to base-then gear down. Making the runway was not an issue, hitting the exact point was. The head wind with gusts became a real unrecognized danger. As we all know, Moonies like to float (1 kt extra = 100 ft). That extra 100 ft on a CPL test is a bust. I was right where I needed to be maybe 5 feet above ground at 67 kts (per FFA examiner). Then the unthinkable.....I instantly lost a good 15 kt head wind. With an unexpected sudden 52 kt air speed, I experienced an immediate stall and my plane literally fell out of the sky just before the touch down site-all in about 2 milliseconds. I landed VERY firm of the main gear. At the time I did not notice any significant bounce, just a "were did that come from" feel. We returned to the hanger having completed the exam, engine running fine, no vibration. Upon shut down, I immediately became nauseous at what I saw. You guest it, I had a prop strike. Seeing the bend tips of your prop can bring a grown man to tears. After a full inspection I had also literally blown out all of the rubber gear biscuits, TKS sling ring had chewed up the lower cowl by 1 inch, engine mount bent down 1/4 inch and the lower front edges of the main gear doors bent up. I still get sick thinking about it. Items to consider: -I'm not sure the power off, precision 180 (in the pattern) is realistic and necessary. Possible just a high risk/benefit maneuver. Yes, I completed many successful power off landings, but the risk was still present. -Landing with no power (it's really like negative thrust) is a very different circumstance when compared to a std low power landing. Beware! -Stalling a few feet off the ground is not recoverable. The entire experience was instantaneous. -A prop strike may not be immediately noticed. A hard landing means taxi back, shut down and look. -Even with insurance, a prop strike is expensive. -Completing a CPL in a Mooney is very doable. It is also very difficult, thus making you a better pilot. Keeping speeds under control is a real challenge. There is nothing lazy about "lazy 8's". The whole point of a CPL is to perfect our piloting skills. No regret from this pilot. In thinking this event over-a million times, I really don't know how I could have prevented this from happening, given the circumstances and requirement. Chose a different day? It's always windy at our airport. This was a typical day. Had the wind been consistent I would have had no problem. Plus, you don't get to choose when an engine will fail. Carry more speed? Then you bust your distant, particularly if you get a nice gust. Under a real engine failure, I don't think anyone cares if you were >100 ft from a "your" landing spot. Keep the speed and force the plane to the ground? Not happening.Typically, very little power under similar circumstances makes a big difference. This was not an option. These are just my thoughts. After 25 years and 5000+ hrs of PIC I still have more to learn! Wondering if I passed the CPL check ride? Well the answer is yes...and no. I passed initially. On the taxi ride back the examiner provided his assessment, all very complimentary. At one point he suggested my instruments were rigged. After recognizing the prop strike, he changed his mind and failed me. I get my plane back on Monday and have the pleasure of performing one more power off, precision 180º landing. Ya, I can't wait. haha2 points

-

Nice work Jim! I’d still fill out a NASA report just for the record. Thanks for your thoughts! Enjoy your trip!! -Matt2 points

-

Likewise next door in Alabama I think more people are carrying than not. Our permits are good for up to 5 years and with very few exceptions let’s you carry anywhere, even in private business and at your employment provided you leave it in the car. I was renewing my permit a few months ago and asked the sheriff how many permits he had out. He said there was currently 9000 issued for our county. A quick check of the census shows that our county has 24,000 residents with 1/3 of them under the age of 18 which is min min age to get a permit. That leaves 9000 residents with ccw permit out of 16000 who are eligible to have one, about 56%. That doesn’t include the thugs or others who are carrying illegally.2 points

-

This maybe a little prejudiced since I have my J for sale and the engine is technically over TBO but this is why I'd consider buying an aircraft with a high time engine. How was the engine treated and what has been done to it over the last few hundred hours? ie: Has it been dependable and needed little work? - If the plane you're looking at hasn't had any major work done to it, has had regular oil changes, has good compressions and they can prove it's a good engine through frequent oil analysis and maybe a savvy analysis that it's been dependable you'll most likely get a few more years/hundreds of hours of trouble free flying for very little cost. Are the avionics up to date (maybe some bells and whistles included) and will you have to do any upgrades in the near future. (more money you'll save because you won't have to do updates) How much work will you have to do for the rest plane such as the interior or brakes or tires? Mine had a complete IRAN done on the cases 970 hours ago by PenYan including bearings, cam, lifters, pistons and rod bolts. As for the cylinders they were rebuilt 660 hours ago. I'd keep mine but I want to go turbo!2 points

-

Gun regulation is a matter of state law, meaning it is going to be different in every state you land in. Some states are more hostile to guns than others. As far as transporting the firearm across state lines is concerned, there fortunately is a Federal law, called the Firearms Owners Protection Act. It provides: Notwithstanding any other provision of any law or any rule or regulation of a State or any political subdivision thereof, any person who is not otherwise prohibited by this chapter from transporting, shipping, or receiving a firearm shall be entitled to transport a firearm for any lawful purpose from any place where he may lawfully possess and carry such firearm to any other place where he may lawfully possess and carry such firearm if, during such transportation the firearm is unloaded, and neither the firearm nor any ammunition being transported is readily accessible or is directly accessible from the passenger compartment of such transporting vehicle: Provided, That in the case of a vehicle without a compartment separate from the driver’s compartment the firearm or ammunition shall be contained in a locked container other than the glove compartment or console. (Added Pub. L. 99–360, § 1(a), July 8, 1986, 100 Stat. 766.) A few years ago I had occasion to do some legal research on the law and the issue of transportation, and the cases were somewhat hair raising. Hostile states, and I remember NJ in particular, were using every excuse they could to get around the law. A basic premise of the law as you can see in the language, is that is allows transportation from one place where you are lawfully allowed to possess and carry the firearm, to another where you are allowed to lawfully possess and carry it. Once you get to your destination, local law applies. There literally are cases where people were arrested and prosecuted because they had arrived at their destination and then drove around for a day or two with the gun in their car before unpacking, or just forgetting it was there. There are also cases where someone, say, living in NJ and lawfully possessing a gun there, drove to NY for an errand, and were arrested, and it was asserted they were not transporting from destination to destination, so the law did not apply. Remember that in East Coast states and in CA in particular, if you are arrested, you will face a local judge who may not be a fan of guns. Generally speaking - and this is truly a generalization, you need to carefully check both local and state law at your destination - long guns are not a problem if they are carried either broken down, or in a locked case or in a locked and inaccessible location such as the trunk of a car, and so long as the ammunition is separate. You must assume that handguns will always be a problem unless you have a conceal and carry permit that covers you for the state and the locality. We have flown from Minneapolis out to the Dakotas many times (we being my hunting partner and I) and never had a problem. I have also traveled with shotguns to competitions on the East Coast, to Europe, and into Canada. Each and every time I would research the laws and follow them scrupulously. I have never had a problem. But a couple of decades ago I went to Spain for a shoot. I knew, from my research, that I had to get a permit from the Spanish Guardia Civil on arriving at the airport. Well, that part of the airport was under construction and I had a devil of a time finding it, but I got my permit. I was at a World Championship with several hundred other shooters from many countries. On the way back out, a Brit had not registered his gun on the way in, finding no place to do it. I had to intervene on his behalf and, in very broken Spanish, I explained what happened. The Colonel who was in charge was incensed with the situation, and my friend was very nearly arrested and his gun confiscated. The fact that there were several of us there, all having come from the same fairly prestigious Championship, probably was what saved the guy. Always do your research, never assume.2 points

-

Hi Everyone, thank you for the comments. For those of you who don't know me, I am the proud new owner of several of the RAJAY STCs. I don't own the airframe STCs for the Mooneys, but I do own the engine STCs... I want to help out and offer new products to the existing RAJAY aircraft owners. If I understand the comments, the answer is yes, RAJAY owners have run into problems in the past when trying to upgrade to new prop designs. The good news is that I own the engine STCs and the prop is specified at the engine level! I *believe* there could be a market for new props that are customized with RAJAY altitudes in mind to get even better performance. RAJAY owners have not been supported with regards to enhancements for a long time and I want to change that.1 point

-

1 point

-

Yes, it is from experience with conscious attention placed on the proper slope recognition. No, not by a small attitude indicator that has nowhere near satisfactory resolution. By the time a transitioning student is ready to be signed off by me they recognized the nominal 3° slope that will lead to perfect landings every time when combined with the proper speed. It is so important that I spend probably more time on slope management than on speed control. Unfortunately, I haven't met ANY instructor who has recognized the issue, so they miss a more effective way to teach good landing technique.1 point

-

Thanks for the recommendation. The good man at Zeftronics talked to the good man at KBJJ, and it was decided that there was likely nothing wrong with the voltage regulator. Thus we are richer by two 24-volt batteries and one alternator and accessories, and poorer by a couple of AMUs, but the trip home went well, and the new purchases behaved themselves.1 point

-

Ha. Good point. The water around your knees would be a dead giveaway somethings not right.1 point

-

Except the jbar gear warning system is nothing more than a reed switch in the socket. If my gear warning malfunctions, it's a simple matter of confirming that the jbar is locked in the gear down position. If it malfunctions due to rain, I have bigger issues.1 point

-

Well - its only that cold now and then. No. I'm not flying when its that cold. But sometimes I will go to the hangar in the evening to plug everything in for heating in case I might want to fly the next day when it might warm up to 0. We are talking a cold snap - not average - weather. PS - I cope much better with cold weather than hot weather. Atlanta?!!! I would just melt. Come up and visit the Adirondacks in the summer... but the winters are glorious too.1 point

-

1 point

-

Thanks for all the kind comments. I had not thought about the NASA form. I'll get that taken care of. The thing I found most confusing about the incident was that it was a failure in the gear warning system (which you jbar guys also have) not the gear motor system. When i take my annual flight review we always manually extend the gear by pulling the gear motor breaker. I manually extend the gear and the lights come on. In this case the gear extended like it should but I didn't get the lights. That senario isn't something I had practiced. It will be in the future. My wife was great during the entire event. She helped when she could and stayed quiet when I needed her to. She watched the manual gear indicator as I cranked the gear down. I could have given her the checklist to read to me but I didn't think of that. I will show her how to do that so she will be ready if needed.1 point

-

depend if you are good with lectricity or good with valves and fluids. both have their merits/drawbacks and some are good with both. One your hands stay cleaner working with.1 point

-

The “m” is added for a mobile version of the website (on your phone or tablet) automatically.1 point

-

1 point

-

Why not a small glass dome above the back seats roof so the gunner can the pivot his mounted gun and shot at will in all directions?1 point

-

+1 sell as is... the customer buying this plane is pretty knowledgeable, will most likely have preferences of what OH he will prefer to go with... +1 consulting AAA to see if they have something you are interested in trading for. AAA can shorten your time between planes or time having two planes... Consider the down-time as well... A factory reman can be delivered in two weeks. Overall the logistics required for the R&R takes a month... If getting a new prop with that... the prop takes six weeks to show up... Engine, prop, R&R, Break-in flights, You are in for a couple of months and 60amu of costs... to raise the price of the plane 60amu... The advantage of asking this question.... we get to see what is coming up for sale! Best regards, -a-1 point

-

Isn't that the whole idea? Most commercials are done in a Cutlass or Arrow. The power off 180 in the Arrow is often described in part as including: 3. Throw brick out window. 4. Follow brick down.1 point

-

Tech at Command Aviation in Bellingham, WA found no power to intercom. He ran a new wire from circuit breaker to plug and got it working again. Two hours labor1 point

-

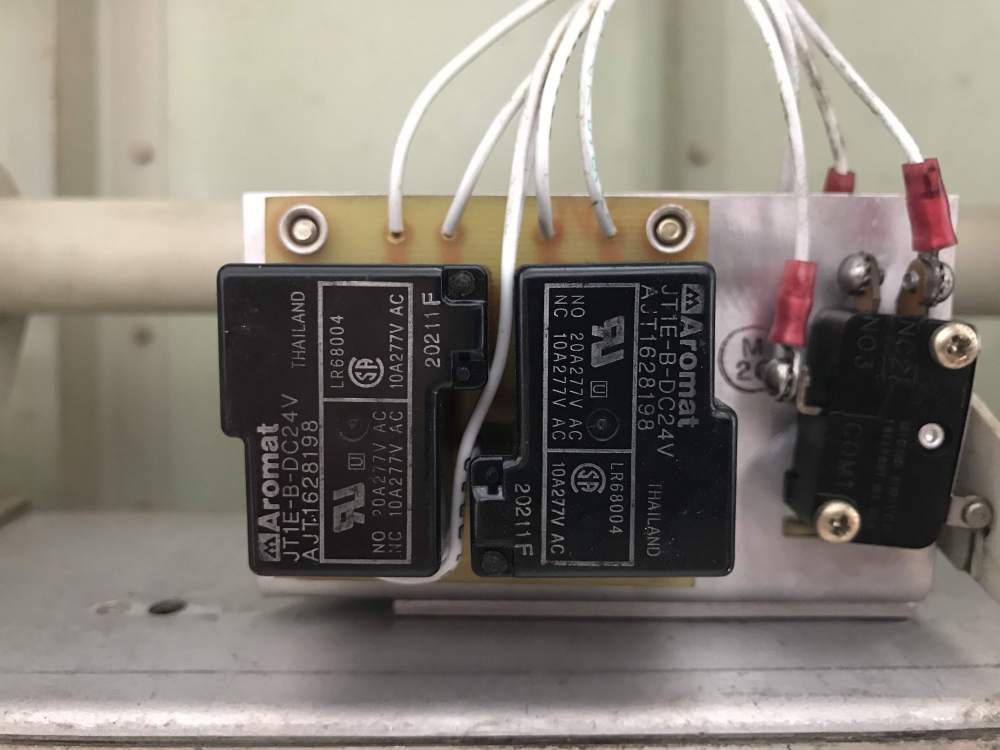

If you call Mooney like I did when I had trouble with flap retraction on my 1996 M20R they may try to sell you a new board with new relays. Said they didn't sell the relays separately and they had a new p/n for the board with relays. The cost? A bit over 1600$ !1 point

-

I pull the throttle all the way out. The prop is set for cruise and the mixture is set for cruise. Get closer to the runway to deal with the sink rate. I need to wear the other camera on my head and get shots of the distance from the runway.1 point

-

Check with Aerodon on what he has. I purchased a pre-owned WX-500 from him and am very pleased with it.1 point

-

1 point

-

Number 1: You had Jake and the rest of the guys at Daytona Aircraft Service look at your plane. I just had a total panel redone there and you may have seen my C on the ramp, I am in the process of writing up a review on them for all here to read. Oh and I never have these issues with my J bar.....1 point

-

Hi Speedy..nice looking Ovation...when you get serious about selling in order to upgrade to Turbo...consider a trade...assuming you want to keep total investment about the same ,maybe there is a Bravo owner out East that doesn't need the high teen low twenties performance...You are already dealing with terrain issues right where you are so you have a good idea of performance needed while fully loaded and dealing with downdrafts.I agree with others,the Turbo is the big thing...of course you can nurse a 300 hp ovation up to the teens...but once your there than what?I concurr with selling / trading as is .As far as pricing...pretend you are actually in the market for a late model Ovation similarly equipped just like yours.Not that many are there?1 point

-

Great report Jim. We can all learn something from this. You could not have picked much better of a place to test yourself in. The Daytona approach controllers are amazing considering all the training traffic they deal with along with the big iron. Jakes' crew at Daytona Aircraft services are top drawer wrenches. Glad you worked the problem and saved a prop. Think NASA form since you busted altitude, probably no big deal since your sure the tower declared an emergency, but it doesnt hurt to do this. After all, the whole purpose is to learn and prevent of the NASA system.1 point

-

Hi Bob, Quite similar, but plan to have it removable with camlocs like the cowling. I think too much air is lost through the seals and it makes the cowling more difficult to install. The plenum will not let much air leak out. I need to have something standard on all the airplanes as I can't chase one that has higher CHT's and others that don't. The plenum will be attached to the inlet air rings for a controlled airflow. I suspect Mooney continues to use baffles with seals because thats what their TCDS says they must use. David1 point

-

1 point

-

Here goes: Testing is going good finally. Like Marauder said, we made progress on the CHT’s. Right now, 4 airplanes have been modded. Nothing specific yet on the oil cooler relocation. Baffling will be changing to a plenum instead of baffle seals. Matt’s and mine will get a plenum in the next month or so. If it works like I think it will, I’ll mod the other 2 airplanes baffling. We’re thinking of closing the sides of the cowl flaps like on the later Mooney’s. I have a good number of customers who would like it done but are also waiting for the final solution so there’s not any more modifications needed later. We plan to install cheek vents similar to Ray-Jay and LoPresti cowlings on Matt's next to increase the air exit flow. Pricing is in the $5-6 k range including installation and spinner if necessary. Thanks, David1 point

-

I just read the couple of posts on concealed carry. Fine if you get away with it. There are a number of states with reciprocity laws that recognize a conceal carry permit from specific other jurisdictions, but never assume. Your conceal carry permit from Minnesota won't keep you out of jail in NY. If you want to conceal carry, check where you have reciprocity, if you don't have reciprocity, unload and case the gun in a lockable case. Try here: https://www.usacarry.com/concealed_carry_permit_reciprocity_maps.html I am sure there are guys who fly around thinking its ok that their aircraft is "just a little" out of annual, or its ok if they are not IFR current, they can accept a clearance anyway. Don't do that.1 point

-

I carry a pistol on me all the time but it’s concealed. Last hunting season I flew into two fbo’s and had long riffles with me. They were signature fbo’s. With my other gear and the riffles no one really paid much attention. Depending on the case some people might not have a clue what it is, and those that do hopefully they will have the understanding it’s a nonissue. And the ga fbo’s that I’ve been to there are not a lot of people let alone a fence so I think you’ll be fine.1 point

-

1 point

-

1 point

-

In your case isnt it, "once you go turbine"?1 point

-

As they say, "Once you go turbo..."1 point

-

See below. It is not attached to the flap motor. The relays are on a circuit board. They are sealed relays....electronic cleaner will do you no good on this...... A relay contact can hang up/stick after so many cycles. This is an interment problem. Don is a fair guy. I'm sure he would be reasonable, to remove and replace the relays. You first need to run a continuity test on each switch and make sure it is activated at each travel limit. If you see continuity on each switch at the travel stop position it can only be the relays. The panel switch is very robust... not saying it cannot go bad but I see it as unlikely.1 point

-

My EDM 700 and factory gauge have the same relationship. That poor engine would not last long using the factory CHT and TIT gauges for monitoring! iain1 point

-

It’s pretty easy,... the bottom basement 201 is around 65,000$ and top of the line is around 120k. It takes about 90!grand to make the airplane tiptop from bottom of the barrel. Pick an entry point.1 point

-

Sounds like an electrical connection issue...I'd start with the grounding jumper behind the panel for the cluster gauge. You might pop the glareshield off, remove the wire terminal, scotch brite the terminal and the panel and then reassemble. Sent from my LG-US996 using Tapatalk1 point

-

1 point

-

I'll be glad when we're through screwing around with all these Fs so that we can move on to important models.1 point